C llllllll Ill lllll Ill11 lllll lllll Ill11 11111 of Acquisition NASA Washington, D. C llllllll Ill...

Transcript of C llllllll Ill lllll Ill11 lllll lllll Ill11 11111 of Acquisition NASA Washington, D. C llllllll Ill...

Source of Acquisition NASA Washington, D. C

llllllll Ill lllll Ill11 lllll lllll Ill11 11111 US007038358B

(12) United States Patent (io) Patent No.: us Bryant et al. (45) Date of Patent: May 2,2006

ELECTRO-ACTIVE TRANSDUCER USING fWDL4.L ELECTRIC FIELD TO PRODUCE/

MOTION SENSE OUT-OF-PLANE TRANSDUCER

Inventors:

A4ssignee:

Notice:

Robert G. Bryant, Lighifoot, V4 (US); Robert L. Fox, Hayes, V4 (US)

The United States of America as represented by the Administrator of the National Aeronautics and Space Administration, Washington, DC (US)

Subject to any disclaimer, the tern of this patent is extended or adjusted under 35 U.S.C. 154(b) by 312 days.

Appl. No.: 101347,563

Filed Jan. 16, 2003

Prior Publication Data

US 2003/0173872 A1 Sep. 18. 2003

Related U.S. Application Data Provisional application No. 601364,652, filed on Mar. 15, 2002.

Int. c1. HOIL 41/047 (2006.01)

US. C1. ....................... 3101365; 3101334; 3101368: 3101369

Field of Classi6cation Search ................. 3101320, 3101324,333,344.348,365,368,369

See application file for complete search history.

References Cited

US. P-4TENT DOCUMENTS

2,540,187 A 2/1951 Cherry, Jr. 2,540,194 A 21951 Ellett 2,836.737 A 5/1958 Crownover

2,836,738 A 5/1958 Crownover ................. 310/331 2,967,956 A 1/1961 Dranetz et al. ............. 3101330 3,114,849 A 121963 Poschenrieder

3,510,698 A 5/1970 Massa ._.._. 3,457.543 A 711969 Akervold et al. ........... 3671155

(Continued)

FOREIGN PATENT DOCUMENTS

DE 1165667 B 311964 EP 0534389 A 311993 JP 54-138392 * 10f1979 P 02-174499 * 711990

OTHER PUBLICATIONS

Hari Singh Nalwa, “Ferroelectric Polymers; Chemistry. Physics. and ,4pplications,” Marcel Dekker, Inc.. p. 710-711,.

(Contillued)

Pr i7~7y E.raminer-Thomas M. Dougherty (74) Attorney, Agent, or Firm-Helen M. Galus

(57) ABSTRCT ’

An electro-active transducer includes a ferroelectric material sandwiched by first and second electrode patterns. When the device is used as an actuator, the first and second electrode patterns are configured to introduce an electric field into the ferroelectric material when voltage is applied to the elec- trode patterns. When the device is used as a sensor. the first and second electrode patterns are configured to introduce an electric field into the ferroelectric material when the fem- electric material experiences deflection in a direction sub- stantially perpendicular thereto. In each case, the electrode patterns are designed to cause the electric field to: i) orid- nate at a region ofthe ferroelectric platerial between the first and second electrode patterns. and ii) extend radially od- ward from the region of the fehoelectric material (at which the electric field originates) and substantially parallel to the ferroelectric material’s plane.

34 Claims, 7 Drawing Sheets

t2B I uw

https://ntrs.nasa.gov/search.jsp?R=20060017039 2018-05-27T17:08:53+00:00Z

US 7,038,358 B2 Page 2

US. PATENT DOCUMENTS

4,051,455 A 911977 Fowler ....................... 310037 4,2S4,921 A %I981 Lemonon et al. ........... 310;322 4,401,911 A a1953 Ravinet et al. ............. 380/190 4,409,631 A 10/1983 White ........................ 3671166 4.439,706 A * 311984 Matsuoka et al. .......... 3101353 4.452,0S4 A 611984 Taenzer ....................... 301334

5,122,993 A 6/1992 Hikita et al. ................ 3671155 4,581,556 A 4i1986 Yamatnoto 5,081.995 A 1/1992 Lu et al. ..................... 600/459

5,262,696 A * 11/1993 Culp .......................... 3101325 5,291,090 A 311994 Dias ........... 101334 5,327,041 A 711994 Culp 5.503,034 A 411996 Amno et al. ......... 731862.473 5,552,655 A * 911996 Stokes et al. ............... 3101330 5,592.042 A 111997 Takuchi et al.

5,862,275 A 111999 Takeuchi et d. 6,072,267 A 612000 Atsuta

5,663,505 h 911997 Nakamwa ................... 73/702

6,091,152 A 7/2000 Talceuchi et ai. ............ 3101330 6,323,550 B1 11/2001 Bemstein 6,351,196 B1 a2002 Nakamura et al. .......... 3331195 6,297,578 €31 10/2001 Takeuchi et al. ............ 310/330

OTHER PUBLICATIONS

Sbinichi Sakai et al, Presented at the 78th Convention of the h d i o Engineering Society, “Digitalto-analog Conversion by Piezoelectric Headphone,”-GS, p. 1-18, (May 3,1985). R. G. Bryant et al, Proceedings, Actuator 2002, Paper AI .3, “Radial Field Piezoelectric Diaphragms,” 6 pages, ( J u . 10,

R. G. Bryant et al, Presented at the First World Congress on Biolnimetics and -4rtificial Muscles, Albuquerque, NM, “The Effect of Radial Electric Fields on Piezoceramics and the Application of these Devices,” 6 pages, (Dec. 9, 2002).

2002).

* cited by examiner

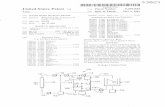

US. Patent May 2,2006 Sheet 1 of 7 US 7,038,358 B2

UPPER ELECTRODE PATTERN 1 I I

FERROELECTRIC MATERIAL

16

LOWER ELECTRODE PATTERN

FIG. 1

Y

FIG. 2

1 t I 12E -/ 128

FIG. 3

.lo

I

126J

FIG. 4

U S . Patent May 2,2006 Sheet 2 of 7 US 7,038,358 B2

E E E

1 22 I22 122

E E E

E E FIG. 5. FIG. 6

14

FIG. 8A

d-

16A

E FIG. 7

FIG. 80

E

1

16

168’

FIG. 8C

US. Patent May 2,2006 Sheet 3 of 7 US 7,038,358 B2

1 4 ~ ~ 1 4A

16B - 148

+ FIG. 9A FIG. 9 B \ t ,

E I

r 16

- - FIG. 1OA FIG. 105

E

18

FIG. 1OC

US. Patent May 2,2006 Sheet 4 of 7 US 7,038,358 B2

1 4A +’ FIG. 11A

J- 14

1 6A + ’ - FIG. I l B

E

(J7-F f - + - u/u/u + - ”\‘ +

14 7 7

l8-J l8 - I

FIG. 12A FIG. 129

1 1 2 8

16’ 18 16

16’ 18 16

FIG. 12C

U.S. Patent May 2,2006 Sheet 5 of 7 US 7,038,358 B2

16

+ FIG, 13A

r14 P4

FIG. 138

1 8 1 187

E E

FIG. 13C

14c

16

-15

FIG. 14A FIG. 148

E

FIG. 14C

U.S. Patent May 2,2006 Sheet 6 of 7 US 7,038,358 B2

14 -

1

16

FIG. 15A FIG. 158

+E

FIG. 156

24

FIG. 16

U.S. Patent May 2,2006 Sheet 7 of 7 US 7,038,358 B2

r 1 4

FIG. 17

I4-l 7

b

-10

1

f loo

e

16-N L- 12

FIG. 18

US 7,038,358 B2 1

ELECTRO-ACTIVE TRANSDUCER USING RADIAL ELECTRIC FIELD TO PRODUCE/

MOTION

ORIGIN OF THE INWNTION

The invention described herein was made by employees of the United States Govement and may be manufactured and used by or for the Government for governmental pur- poses without the payment of any royalties thereon or therefor. Pursuant to 35 U.S.C. 5 119, the benefit of priority from provisional application No. 60/364,652, with a filing date of Mar. 15, 2002. is claimed for this non-provisional application.

SENSE OUT-OF-PLANE TRANSDUCER

BACKGROUND OF THE INVENTION

1. Field of the Invention This invention relates to electro-active transducers. More

specifically, the invention is an electro-active transducer that generates out-of-plane motion wheu a radial electric field is induced in the plane of the transducer, or that converts applied out-of-plane motion into a radial electric field in the plane of the transducer.

2. Description of the Related Art Solid-state transducers generally make use of electro-

active materials. In the case of an actuator, the electro-active material generates physical displacement in response to an applied voltage. In one embodiment, these actuators are planar and have one or inore pieces of ferroelectric material (e.g., piezoelectric, piezostrictive, pyroelectric. etc.) with one or more electrodes coupled thereto. The plane of the achmtor is typically referenced as the “X-r’ plane with the “Z” direction being perpendicular thereto. In terms of an actuator, with the electrodes lying in the X - Y plane, the electric field (induced when voltage is applied to the electrodes) will also lie in the X - Y plane. Displacement of such actuators will also occur in the X - Y plane. Thus. in terms of the device’s piezoelectric charge constant, these devices are said to be “d,,”, “dll”, or ‘‘d2;) where the first subscript refers to the direction of applied field strength and the second subscript refers to the direction of measured induced strain. The numbers 1,2, and 3 correspond to the X . Y, and 2 directions, respectively. To summrize. the induced electric field and corresponding displacement are essentially co-planar for such solid-state planar-types of actuators. The opposite would be true in terms of planar-types of sensors. That is, in-plane displacement would generate an in-plane electric field indicative of the force creating the in-plane displacement.

Transducers may also function in a situation where out- of-plane displacement &e., in the Z direction) is caused by the application of an electric field in the X - Y plane. In such situations, the transducer behaves as a ‘‘d,,” or ‘‘4; device.

SUhtIVLmY OF THE INVENTION

In accordance with the present invention, an electro- active transducer includes at least one piece of ferroelectric material defining a first surface and a second surface oppos- ing the first surface. The first and second surfaces lie in substantially parallel planes. A first electrode pattern is coupled to the first surface and a second electrode pattern is coupled to the second surface. When nsed as an actuator, the first and second electrode patterns are consgured to intro- duce an electric field into the ferroelectric material when voltage is applied to the electrode patterns. The electrode

5

10

15

20

25

30

35

40

45

50

55

60

65

2 patterns are designed to cause the electric field to: i) origi- nate at a region of the ferroelectric material between the first and second electrode patterns! and ii) extend radially out- ward from the region of the ferroelectric material (at which the electric field originates) and substantially parallel to the parallel planes defined by the ferroelectric material. As a result, the ferroelectric material deflects symmetrically about the region of the ferroelectric material at which the electric field originates. In other words, the ferroelectric material deflects in a radially symmetric fashion and in a direction that is substantially perpendicular to the electric field.

When nsed as a sensor, the first and second electrode patterns are configured to produce an induced electric field in the ferroelectric material when the ferroelectric material experiences deflection in a direction substantially perpen- dicular to the first and second surfaces. The induced electric field originates at the region of the ferroelectric inaterial between the first and second electrode patterns, and extends radially outward from the region substantially parallel to the first and second surfaces. As a result, a current is induced in each of the first and second electrode patterns with the current being indicative of the deflection. ‘

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a schematic view of an electro-active transducer according to the present invention:

FIG. 2 is a side, schematic view of the elecwo-active transducer shown in FIG. 1 illustrating the radial electric field and out-of-plane displacement generated thereby;

FIG. 3 is a side view of a layered construction of the transducer’s ferroelectric material;

FIG. 4 is a side view of a piece-wise construction of the transducer’s ferroelectric material:

FIG. 5 is a diagrammatic view of a radial electric field originating koni a point in the X - Y plane of the transducer’s ferroelectric material;

FIG. 6 is a diagrammatic view of a radial electric field originating from the peripliery*of a circle in the X - Y plane of the transducer’s ferroelectric material:

FIG. 7 is a diagrammatic view of a radial electric field originating kom the periphery of a square in the X - Y plane of the transducer’s ferroelectric material;

FIG. 8A is an isolated view of au upper electrode pattern using circular intercirculating electrodes;

FIG. 8B is an isolated view of a lower electrode pattern using circular intercirculating electrodes:

FIG. 8C is a cross-sectional view of a portion of the electro-active transducer having the upper and lower elec- trode patterns depicted in FIGS. 8A and 8B:

FIG. 9.4 is an isolated view of an upper electrode pattern using square intercirculating electrodes;

FIG. 9B is an isolated view of a lower electrode pattern using square intercirculating electrodes;

FIG. 9C is a cross-sectional view of a portion of the electro-active transducer having the upper and lower elec- trode patterns depicted in FIGS. 9.4 and 9B;

FIG. 10.4 is an isolated view of an upper electrode pattern using circular interdigitated riug electrodes;

FIG. 10B is an isolated view of an lower electrode pattern using circular interdigitated ring electrodes;

FIG. 1OC is a cross-sectional view of a portion of the electro-active transducer having the upper and lower elec- trode patterns depicted in FIGS. 1OA and 10B;

US 7,038,358 B2 3 4

FIG. lL4 is an isolated view of an upper electrode pattern

FIG. 11B is an isolated view of a lower electrode pattern

FIG. 11c is a cross-sectiona~ view of a podon of the 5 is not a limitation of the present invention.

of a variety of well known ways. For example. electrode using square interdigitated ring electrodes; patterns 14 and 16 could be applied directly to opposing

Surfaces of ferrOelectric material 12 bY meam of Vapor using square interdigitated ring electrodes: deposition, printing. plating, or gluing. the choice of which

electro-active transducer having the upper and lower elm- Ferroelectric material 12 is any piezoelectric, trode patterns depicted in FIGS. 1lA and 11B; piemrestrictive. electrostrictive (such as lead magnesium

pattern lliobate lead titallate pm-pT)), pyroelectric, etc-. Illateria1

using a spiraling electrode; stnicture tbat deforms when exposed to an electrical field (or 10 generates an electrical field in response to deformation as in

tric materials that has performed well in tests of the present using a spiraling electrode;

invention is a ce&c piezoelectric material known as lead electro-active transducer having tlie upper and lower elec- zirconate which has stiffness that trode patterns depicted in FIGS. 12.4 and 12B: 15 transducer 10 maintains a symmetric, out-of-plane displace-

FIG. 13A is an isolated view of an upper electrode pattern ment as will be described further below. using concentric ring electrodes; Ferroelectric material 12 is typically a composite material

FIG. 13B is an isolated view of a lower electrode pattern where the term “composite” as used herein can mean one or using concentric ring electrodes; more materials mixed together (with at least one of the

FIG. 13c is a cross-sectio~l view of a of the 20 materials being ferroelectric) and formed as a single sheet or electro-active transducer having the upper and lower el=- monolithic slab with major opposing surfaces 12A and 12B trode patterns depicted in FIGS. 13A and 13B; lying in substantially parallel planes as best illustrated in the

FIG. 14A is an isolated view of anodler upper electrode side view- shown in FIG. 2. However, the term“‘composite” as used herein is also indicative of: i) a ferroelectric laminate pattern based on intercirculating electrodes; ’’ made of multiple ferroelectric material layers such as layers

FIG. 14B is an isolated view of another lower electrode 12c, 12D, 12E (FIG. 3) or ii) mllltiple pieces bonded together such as pieces 12F, 12G, 12H (FIG. 4). pattern based on intercirculating electrodes:

FIG. 14c is a cross-sectional view Of a portion Of the Note that in each case, major opposing si&aces 12A and electro-active transducer having the upper and lower elec- 1 2 ~

In general, upper electrode pattern 14 is aligned with trode patterns depicted in FIGS. 14-4 ,and 14B: FIG. 15Ais an isolatedview of another embodiment of an lower electrode padern 16 such that, when voltages are

electrode pattern based on intercirculating electrodes; applied thereto, a radial electric field E is generated in FIG. 15B is an isolated view of another embodiment of an ferroelectric material 12 in a plane that is substantially

electrode pattern based on intercirculating electrodes; 35 parallel to the parallel planes defined by surfaces 12A and FIG. 1~ is a cross~sectiona~ view of a of the 12B, is.. in tlie X-Y plane. More specifically, electrode

eledro-active transducer having the upper and lower elec- patterns 14 and 16 are aligned O n either side of ferroelectric trode patterns depicted in FIGS. 15A and 15B: material 12 such that the electric field E originates and

FIG. 16 is an exploded view of an electro-active tram- extends radially outward in the x-Y plane from a region 122 ducer of the present invention encased in a diel&ric mate- 3o of ferroelectric material 12. The size and shape of region

122 is determined by electrodepafterns 14 and 16, a variety rial package; of which will be described fiuther below.

FIG. 17 is a side view of the electro-active transducer of FIG. 16 after constnlct~on bwn completed; and The symmetric, radially-distributed electric field E

mechanically strains fermelectric material 12 along the FIG. 18 is a schematic view of an electro-active trans- 45 z-axis (perpendictlar to the applied electric field E). This

ducer ‘array according to the present invention. result is surprising and contrary to related art electro-active transducer teachings and devices. That is, it has been well- accepted in the transducer art that out-of-plane (Le.. Z-axis) displacement required an asymmetric electric field through

Referring now to the drawings. and more particularly to 50 the thickness of the active material. The asymuletric electric FIG. 1, a top-level schematic drawing of the electro-active field introduces a global asymmetrical strain gradient in the transducer of the present invention is shown-and referenced material that, upon electrode polarity reversal, counters the generally by numeral 10. By way of illustrative example, inherent induced polarity thou& only part of the active transducer 10 will be described for its use as an actuator. material to create an in-situ bimorph. This result had been However, it is to be understood that transducer 10 can be 55 achieved by having electrodes on one side of the ferroelec- operated as an actuator (Le., voltage applied to generate an tric material. However, tests of the present invention have electric field that results in Z-axis displacement) or a sensor shown that displacement is substantially increased by using (Le., environmentcaused Z-axis displacement generating an electrode patterns 14 and 16 that are aligned on both sides electric field that is indicative of a voltage). of ferroelectric material 12 such that the symmetric electric

The essential elements of transducer 10 are a ferroelectric 60 field E Onghates and extends both radially outward frorn material 12 sandwiched between an upper electrode pattern regon 122 and kn!&ut the thickness of the ferroelectric 14 and a lower electrode pattern 16. More specifically, material. electrode patterns 14 and 16 are coupled to ferroelectric Electrode patterns 14 and 16 can define a variety of shapes material 12 such that voltage applied to the electrode pat- ’ (is., viewed across the X-Y plane) of region 122 without terns is coupled to ferroelectric material 12 to genemte an 65 departing fiom the scope of the present invention. For electric field as will be explained fiufher below. Such example, as shown in FIG. 5, region 122 could be a point coupling to ferroelectric material 12 can be achieved in any with radial electric field E extending radially outward there-

FIG. 124is an isolatdView ofan upper

FIG. 12’ is an isolated view of’ lower electrode pattern the case of an electro-active semor). one class of ferroelK-

FIG. 12C is a cross-sectional View of a Portion of the

defined for ferroelectric material 12. 30

DETAILED DESCRIPTION OF THE INVENTION

US 7,038,358 B2 5

from. The periphery of region 122 could also be a circle (FIG. 6) or a square (FIG. 7) with radial electric field E extending radially outward therefrom. Other X-Y plane shapes (e.g., triangles, pentagons, hexagons. etc.) of region 122 could also be defined without departing from the scope of the present invention.

In accordance with the present invention, radially- extending electric field E lies in the X-Y plane while displacement D occurs in the 2 direction substantially perpendicular to surfaces 12-4 and 12B. Depending on how electric field E is applied, displacement D can be up or down along either the positive or negative Z-axis. but does not typically cross the X-Y plane for a given electric field. The amount of displacement D is greatest at the periphery of region 122 where radial electric field E originates. The amount of displacement D decreases with radial distance from region 122 with deflection of ferroelectric material 12 being symmetric about region 122. That is, ferroelectric material 12 deflects in a radially symmetric fashion and in a direction that is substantially perpendicular to surfaces 12A and 12B.

As mentioned above, a variety of electrode patterns can be used to achieve the out-of-plane or Z-axis displacement in the present invention. A variety of non-limiting electrode patterns and resulting local electric fields generated thereby will now be described with the aid of FIGS. 8-15 where the “A” figure depicts an upper electrode pattern 14 as viewed from above same. the “ B figure depicts the corresponding lower electrode pattern as viewed from below same, and the “C” figure is a cross-sectional view of the ferroelectric material with the upper and lower electrode patterns coupled thereto and further depicts the resulting local electric fields generated by application of a voltage to the particular electrode patterns.

In FIGS. SA-SC, tipper electrode pattern 14 and lower electrode pattern 16 comprise intercirculating electrodes with electrodes 14A and 16A conuected to one polarity and electrodes 14B and 16B conuected to an opposing polarity. For illustrative purposes. electrodes 14A and 16.4 have a positive polarity applied thereto and electrodes 14B and 16B have a negative polarity applied thereto.

Patterns 14 and 16 are positioned such that they are a mirror image of one another as illustrated in FIG. 8C. The resulting local electric field lines are indicated by shaped lines 18. In this example, the radial electric field E originates from a very small diameter region 122 which is similar to the electric field illustrated in FIG. 5.

The spiraling intercirculating electrode pattern need not be based on a circle. For example, the intercirculating electrodes could be based on a square as illustrated on FIGS. 9.4-9C. Other geometric intercirculating shapes ( e g . triangles, rectangles, pentagons, etc.) could also be used without departing from the scope of the present invention.

The electrode patterns may also be fabricated as inter- digitated rings. For example, FIGS. 10A-10C depict circular-based interdigitated ring electrode patterns where upper and lower electrode patterns 14 and 16 are positioned to be aligned with one another in the Z-axis so that their polarities are aligned as shown in FIG. 1OC. Once again, the interdigitated ring electrode pattern could be based on geometric shapes other than a circle. Accordingly, FIGS. 11A-11C depict square-based interdigitated ring electrode patterns as an example of another suitable geometric shape.

The upper and lower electrode patterns are not limited to mirror image or other aligned patterns. For example, FIGS. 12.4-12C depict the use of spiraling electrodes in which

6 upper and lower electrode patterns are staggered with respect to one another when viewed in the cross-section shown in FIG. 12C. Each electrode pattern is defined by a single polarity electrode pattern so that local electric field 18

5 extends between surfaces 12.4 and 12B of ferroelectric material 12. Note that the resulting stagered or cross pattern could be achieved by other electrode patterns such as the ring-based electrode patterns illustrated in FIGS. 13A-13C.

For applications requiring greater amounts of out-of- plane displacement D, the electrode patterns can be designed such that the induced radial electric field E enbances the localized strain field of the transducer. In general, this is accomplished by providing an electrode pittern that comple- ments the mechanical strain field of the transducer. One way

15 of accomplishing this result is to provide a shaped piece of electrode material at the central portion of each upper and lower electrode pattern with the shaped pieces of electrode materials having opposite polarity voltages applied thereto. The local electric field between the sliaped electrode male- *,, rials is perpendicular to the surfaces of the ferroelectric material, while the remainder of the upper and lower elec- trode patterns are designed so that the radial electric field originates from the aligned edges of the opp+ng-polarity shaped electrode materials.

For example, FIGS. 14-4-14C depict spiral-based inter- circulating electrode patterns in which a shaped negative electrode 14C is aligned over a shaped positive electrode 16C at the center portions of upper electrode pattern 14 and lower electrode pattern 16. Under this embodiment. a cir-

3o cularly shaped region 122 (aligned with the perimeters of electrodes 14C and l6C) is defined in ferroelectric miterial 12 with the radial electric field E extending radially outward therefrom. Note that such strain field enhancement is not limited to circularly-shaped electrodes 14C and 16C, as

35 these shapes could be triangular. square, hexagonal. etc. Further, the remaining portions of the electrode patterns could be based on the above-described interdigitated ring or cross-pattern (staggered) electrode patterns.

Enhancement of the transducer’s local strain field could 40 also be achieved by providing an electrode void or “hole” at

the center portion of the electrbde pattern so that the radial electric field essentially starts from a periphery defined by the start of the local electric fields. For example, FIGS. 15A-15C depict spiral-based intercirculating electrode pat-

45 terns that define centrally-positioned upper and lower areas 14D and 16D, respectively, that are void of any electrodes. As a result, the induced radial electric field E originates at the points at which local electric field 18 begins, Le.. about the perimeter of aligned areas 14D and 16D. Once again, the

50 central electrode void areas 14D and 16D are not l i i t e d to circular shapes, and the electrode patterns could be based on the above-described interdigitated ring or crosspattern elec- trode patterns. Further, ferroelectric miterial 12 could be eliminated or “punched our where it is aligned with areas

55 14D and 16D thereby providing a hole through the trans- ducer assembly 10.

Regardless of the type of electrode pattern, construction of the electro-active transducer can be accomplished in a variety of ways. For example, the electrode patterns could be

60 applied directly onto the ferroelectric material. Further, the transducer could be encased in a dielectric material to waterproof or otherwise protect the transducer from envi- ronmental effects. By way of non-limiting example, one simple and inexpensive construction is shown in an

65 exploded view in FIG. 16. Upper electrode pattern 14 is etched, printed, plated, or otherwise attached to a film 20 of a dielectric material. Lower electrode pattern 16 is similarly

2s

FIG. 16 is pressed together, an environmentally protected electro-active transducer assembly 10 is fonned as illus- trated in FIG. 17 where the non-conductive adhesive is omitted for clarity of illustration.

The present invention is not limited to a single electm- active transducer as has been described tlius far. More specifically, the teachings of the present invention can be extended to provide an electro-active transducer assembly ‘array, an example of which is illustrated schematically in FIG. 18 and is referenced generally by numeral 100. Trans- ducer assembly array 100 includes ferroelectric material 12 with a plurality of electrode pattern pairs 14-1/16-1. . . . , 14-N/16-N. Each electrode pattern pair functions as the previously-described electrode pattern pairs defined-by upper electrode pattern 14 and lower electrode pattern 16. Each electrode pattern pair used in transducer assembly array 100 can be the same or could be different. The options for each electrode pattern pair include all of those previously described herein for a single electro-active transducer in accordance with the present invention. Further, as was the case with a single electro-active transducer, the transducer array defined by ferroelectric material 12 and electrode pattern pairs 14-1116-1, . . . , 14-N/16-N can be encased in a protective dielectric material 30.

The present invention allows individual transducer parameters and functions to be tailored for specific applica- tions. For example, electrode patterns ‘and spacing between electrodes can be varied to adjust electric field intensity. strain vectors, and displacement vectors. Ferroelectric mate- rial composition and/or geometry can be varied to adjust electrical and mechauical behavior of the device, The per- formance parameters of the dielectric encasement and adhe- sive will affect processing, operational, and durability parameters of the constructed device. The power and fre- quency of the applied voltages will affect strain. displacement, and power consumption parameters.

The electro-active transducer can be used to generate Z-axis out-of-plane displacement from an X-Y plane induced electric field. The out-of-plane movement is con- centric with respect to the radial electric field’s point or area of origination. The out-of-plane movement is effected with- out ,my mechanical linkage thereby reducing the size and weight of the device. Because the present invention lends itself to thin film fabrication, devices made in accordance with the teachings of the present invention can be incorpo- rated into a wide variety of micro-electronics applications where size is of consideiable concern.

The electro-active transducer of the present invention can also be configured to convert Z-axis out-of-plane displace- ment into an X-Y plane-induced electric field. More specifically, any Z-axis displacement of the ferroelectric material induces/produces a radial electric field therein that, in turn, generates a potential in the upper and lower elec- trode patterns. The resulting current (or voltage) in the electrode patterns can be measured and is indicative of the mount of Z-axis displacement which, in turn, is indicative of the Z-axis component of the force causing such displace- ment.

Although only a few exemplary embodiments of ‘Jiis invention have been described in detail above, those skilled

US 7,038,358 B2 7 8

attached to a fih 22 of the dielectric material. F i b 20 and 22 with their respective electrode patterns are coupled to ferroelectric material 12 using a non-conductive adhesive referenced by dashed lines 24. Each of films 20 and 22 should be larger thau ferroelectric material 12 so that film portions 20A and 22.4 that extend beyond the perimeter of ferroelectric material 12 can be joined together using non- conductive adhesive 24. When the structure illustrated in

in the art will readily appreciate that m y modifications are possible in the exemplary embodiments without materially departing fiom the novel teachings and advantages of this invention. AccordingJy, all such modifications are intended to be included within the scope of this invention as defined in the following claims. In the claims, means-plus-function and step-plus-function clauses are intended to cover the stnictures or acts described herein as performing the recited function and not only stnictural equivalents, but also equiva- lent structures. Thus, although a nail and a screw m y not be

lo structural equivalents in that a nail employs a cylindrical surface to secure wooden parts together. whereas a screw employs a helical surface, in the environment of fastening wooden parts. a nail and a screw may be equivalent struc- tures.

What is claimed as new and desired to be secured by Letters Patent of the United States is:

1. An electro-active transducer, comprising: a ferroelectric material defining a first stuface and a

second surface opposing said first surface, wherein said first surface and said second surface lie in substantially parallel planes;

l5

20

a first electrode pattern coupled to said firs! surface; a second electrode pattern coupled to said second surface, wherein said first electrode pattern and said second elec-

trode pattern are codgured to introduce an electric field into said ferroelectric material when said first electrode pattern and said second electrode pattern have voltage applied thereto. said electric field originating at a region of said ferroelectric material between said first electrode pattern and said second electrode pattern said electric field extending radially outward from said region of said ferroelectric material and substantially parallel to said lirst surface and said second surface, whereby said ferroelectric material correspondingly deflects symmetrically about said region in a direction substantially perpendicular to said electric field. and

wherein said first electrode pattern and said second elec- trode pattern are conf?gured to produce an induced electric field in said ferroelectric material when said ferroelectric material exp&riences deflection in a direc- tion substantially perpendicular to said first surface and said second surface, said induced electric field origi- nating at said region of said ferroelectric material between said first electrode pattern and said second electrode pattern, said induced electric field extending radially outward from said region of said ferroelectric material and substantially parallel to said first surface and said second surface, whereby a current induced in each of said first electrode pattern and said second electrode pattern is indicative of said deflection; ‘and.

a shaped electrode pair. the first piece of said shaped electrode pair being electrically coupled to a center portion of said first electrode pattern, the second piece of said shaped electrode our being electrically coupled to a center portion of said second electrode pattern, wherein each said center portion is aligned with one another to define a common perimeter, wherein voltage applied to said first piece of said shaped electrode pair is an opposite polarity with respect to voltage applied to said second piece of said shaped electrode pair, and wherein said ferroelectric material aligned with said common perimeter defines said region of said ferro- electric material at which said electric field originates.

2. ,4n electro-active transducer as in claim 1 wherein said first electrode pattern and said second electrode pattern are mirror images of one another.

25

3o

35

411

45

jo

55

60

6s

US 7,038,358 B2 9

3. An electro-active transducer as in claim 2 wherein each of said first electrode pattern and said second electrode pattern comprises at least two independat electrodes having opposite polarity and arranged in an altematiug sequence as they extend radially outward from said region of said ferroelectric material, said alternating sequence beiug defined with respect to a cross-sectional view of said electro- active transducer. 4. An electro-active transducer as in claim 1 fiuther

comprising a dielectric material encasiug said ferroelectric material with said first electrode pattern and said second electrode pattern coupled thereto.

5. An electro-active transducer as in claim 1 wherein said ferroelectric material comprises a single sheet of ferroelec- tric material, and wherein each of said first surf-ace and said second surface is a major surface of said single sheet.

6. An electro-active transducer as in claim 1 fiirther comprising:

a first piece of dielectric material with said first electrode pattern coupled thereto:

a second piece of dielectric material with said secoud electrode pattern coupled thereto; and

said first piece of dielectric material joined to said second piece of dielectric material beyond the perimeter defined by said ferroelectric material.

7. Au electro-active tr‘ausducer as in claim 1 wherein said ferroelectric material comprises a ceramic piezoelectric material.

8. An electro-active transducer, comprising: a composite ferroelectric material d e h i i g a first surface

and a second surface opposing said first surface, wherein said first surface and said second surface lie in substantially parallel planes;

a first electrode pattern coupled to said first surface; a second electrode pattern coupled to said second surface;

and a dielectric material encasing said ferroelectric material

with said first electrode patteru and said secoud elec- trode pattern coupled thereto,

whereiu said first electrode patteru ‘aud said second elec- trode pattern are configured to introduce an electric field into said ferroelectric material when said first electrode pattern and said second electrode pattern have voltage applied thereto, said electric field orighting at a region of said ferroelectric material between said first electrode pattern and said second electrode pattern. said electric field extending radially outward from said region of said ferroelectric material and substantially parallel to said first surface and said second surface. whereby said ferroelectric material correspondingly deflects symmetrically about said region in a direction substantially perpendicular to said electric field. and

wherein said first electrode patteni and said second elec- trode pattern are configured to produce an induced electric field in said fernelectric material when said ferroelectric material experiences deflection in a direc- tion substautially perpendicular to said first surface and said second surface, said induced electric field origi- nating at said region of said ferroelectric material between said first electrode pattern and said second electrode pattern, said induced electric field extending radially outward from said region of said ferroelectric material and substantially parallel to said first surface and said second surface, whereby a current induced in each of said first electrode pattern and said second electmde pattern is indicative of said deflection

5

10

15

20

15

30

35

40

45

50

55

60

65

10 9. An electro-active transducer as in claim 8 wherein said

first electrode pattern and said second electrode pattern are mirror images of one another. 10. .Au electro-active trausducer as in claim 9 wherein

each of said first electrode pattern and said second electrode pattern comprises at least two independent electrodes having opposite polarity and arranged in an alternating sequence as they extend radially outward from said region of said ferroelectric material, said alternating sequence being defined with respect to a cross-sectional view of said electro- active transducer. 11. An electro-active tr‘ausducer as in claim 8 wherein said

first electrode pattern ‘and said second electrode pattern are staBered with respect to one another along a direction substantially perpendicular to said substantially parallel planes. and wherein said first electrode pattern is energized with a voltage of a first polarity and said second electrode pattern is energized with a voltage of a second polarity that is opposite that of said first polarity. 12. An electro-active transducer as in claim 8 further

comprising a shaped electrode electrically coupled to a center portion each of said first electrode pattern and said second electrode pattern. wherein each said e a t e r portion is aligned with oue another to define a commou perimeter, wherein voltage applied to said center portion of said first electrode pattern is an opposite polarity with respect to voltage applied to said center portion of said second elec- trode pattern, and wherein said fernelectric material aligned with said conmion perimeter defines said region of said ferroelectric material at which said electric field originates. 13. An electro-active transducer as in claim 8 wherein said

ferroelectric material comprises a ceramic piezoelectric material. 14. An electro-active trausducer, comprising: a piece of ferroelectric material defiuing a first surface and

a second surface opposing said first surface, wherein said first surface ‘and said second surface lie in sub- stantially parallel planes;

a first piece of a dielectric material larger than said piece of ferroelectric material; ,

a second piece of a dielectric material larger than said piece of ferroelectric material;

a first electrode pattern coupled to said first piece of dielectric material;

a second electrode pattern coupled to said second piece of dielectric material;

said first piece of dielectric material with said first elec- trode pattern coupled thereto end said second piece of dielectric material with said second electrode pattern coiipled thereto being sandwiched about said piece of ferroelectric material, wherein said first electrode pat- tern is coupled to said first surface and said second electrode pattern is coupled to said second surface: and

said first piece of dielectric material being joined to said second piece of dielectric material beyond the perim- eter of said piece of ferroelectric material,

whereiu said first electrode pattern is aligned with said second electrode pattern to introduce an electric field into said piece of ferroelectric material when said first electrode pattern and said second electrode pattern have voltage applied thereto. said electric field originating at a region of said ferroelectric material between said first electrode pattern and said second electrode pattea said electric field extending radially outward from said region of said ferroelectric material and substantially parallel to said first surface and said second surface,

US 7,038,358 B2 11

whereby said ferroelectric material correspondingly deflects symmetrically about said region in a direction substantially perpendicular to said electric field. and

wherein said first electrode pattern is aligned with said second electrode pattern to produce an induced electric field in said ferroelectric material when said ferroelec- tric material experiences deflection in a direction sub- stantially perpendicular to said first surface and said second surface, said induced electric field originating at said region of said ferroelectric material between said h t electrode pattern and said second electrode pattern, said induced electric field extending radially outward fkom said region of said ferroelectric material and substantially parallel to said first surface and said second surface, whereby a current induced in each of said first electrode pattern and said second electrode pattern is indicative of said deflection.

15. -4n electro-active transducer as in claim 14 wherein said first electrode pattern and said second electrode pattern are mirror images of one another. 16. -4n electro-active transducer as in claim 15 wherein

each of said first electrode pattern and said second electrode pattern comprises at least two independent electrodes having opposite polarity and a m g e d in an alternating sequence as they extend radially outward from said region of said ferroelectric material, said alternating sequence being defined with respect to a cross-sectional view of said electro- active transducer.

17. An electro-active transducer as in claim 14 wherein said first electrode pattern and said second electrode pattern are staggered with respect to one mother along a direction substantially perpendicular to said substantially parallel planes, and wherein said first electrode pattern is energized with a voltage of a first polarity and said second electrode pattern is energized with a voltage of a second polarity that is opposite that of said first polarity.

18. An electro-active transducer as in claim 14 h t h e r comprising a shaped electrode electrically coupled to a center portion each of said first electrode pattern and said second electrode pattern, wherein each said center portion is aligned with one another to define a common perimeter, wherein voltage applied to said center portion of said first electrode pattern is an opposite polarity with respect to voltage applied to said center portion of said second elec- trode pattern, and wherein said ferroelectric material aligned with said common perimeter defines said region of said ferroelectric material at ,which said electric field originates.

19. An electro-active transducer as in claim 14 wherein said ferroelectric material comprises a ceramic piezoelectric material.

20. An electro-active transducer as in claim 14 fiwther comprising an electrically non-conductive adhesive between i) said first piece of dielectric material and said piece of ferroelectric material, ii) said second piece of dielectric material and said piece of ferroelectric material, and iii) portions of said first piece of dielectric material and portions of said second piece of dielectric material that lie beyond the perimeter of said piece of ferroelectric material.

21. An electro-active transducer array coniprising: a ferroelectric material defining a first surface and a

second surface opposing said first surface, wherein said first surface and said second surface lie in substantially parallel planes;

a plurality of first electrode patterns coupled to said first surface;

a plurality of second electrode patterns coupled to said second surface; and

12 a dielectric material encasing said ferroelectric material

with said plurality of first electrode patterns and said plurality of second electrode patterns coupled thereto:

each of said plurality of first electrode patterns being aligned with a corresponding one of said plurality of second electrode patterns to define an electrode pattern pair,

wherein each said electrode pattern pair introduces an electric field into said ferroelectric material when volt- age is applied thereto, said electric field originating at a region of said ferroelectric material between said electrode pattern pair, said electric field extending radially outward fkom said region of said ferroelectric material and substantially parallel to said first surface and said second surface, whereby said ferroelectric material deflects symetrically about said region in a direction substantially perpendicular to said electric field, and

wherein each said electrode pattern pair produces an induced electric field in said ferroelectric material when said ferroelectric material therebetween experiences deflection in a direction substantially perpendicular to said first siirface and said second surface. said induced electric field originating at said region af said ferro- electric material of a corresponding said electrode pattern pair, said induced electric field extending radi- ally outward from said regjon of said ferroelectric material and substantially parallel to said first surface and said second surface, whereby a current induced in each said electrode pattern pair is indicative of said

22. Au electro-active transducer array as in claim 21 wherein said first electrode pattern and said second electrode pattern associated with at least one said electrode pattern pair are &or images of one another.

23. .4n electro-active tmisducer as in claim 22 wherein each of said first electrode pattern and said second electrode pattern associated with at least one said electrode pattern pair comprises at least two independent electrodes having opposite polarity and arranged in an alternating sequence as

40 they extend radially outward h m said region of said ferroelectric material, said dternating sequence being defined with respect to a cross-sectional view of saidelectro- active transducer.

24. An electro-active transducer as in claim 21 wherein 45 said first electrode pattern and said second electrode pattern

associated with at least one said electrode pattern pair are staggered with respect to one another along a direction substantially perpendicular to said substantially parallel planes, and wherein said first electrode pattern is energized

50 with a voltage of a first polarity and said second electrode pattern is energized with a voltage of a second polarity that is opposite that of said first polarity.

25. -4n electro-active transducer as in claim 21 further coniprising a shaped electrode electrically conpied to a

55 center portion each of said first electrode pattern and said second electrode pattern associated with at least one said electrode pattern pair. wherein each said center portion is aligned with one another to define a c o m o n perimeter, wherein voltage applied to said center portion of said first

60 electrode pattern is an opposite polarity with respect to voltage applied to said center portion of said second elec- trode pattern, and wherein said ferroelectric material aligned with said common perimeter defines said region of said ferroelectric material at which said electric field originates.

26. An electro-active transducer as in claim 21 wherein said ferroelectric material comprises a ceramic piezoelectric material.

5

15

20

25

30 deflection.

35

65

US 7,038,358 B2 13 14

27. .4n electro-active actuator. comprising: a ferroelectric

30. An electro-active actuator as in claim 27 wherein said first electrode pattern and said second electrode pattern are stagered with respect to one another along a direction

5 planes, and wherein said first electrode pattern is energized with a voltage of a first polarity and said second electrode pattern is energized with a voltage of a second polarity that is opposite that of said first polarity.

and 31. An electro-active actuator as in claim 27 further COmPriSk3 a shaped electrode electrically coupled to a

with said first electrode and =id second elec- lo center portion each of said first electrode pattern and said trode pattern coupled thereto, second electrode pattern. wherein each said center portion is

aligned with one another to define a common perimeter, wherein voltage to said center podon of said first

@Ode patten' are electrode pattern is an opposite polarity with respect to field into said ferroelectric material when said first 15 voltage applied to said center portion of said second elec- electro* Pattern andsaidsecod electrode Panern have trode pattern. and wherein said ferroelectric material aligned voltage applied thereto, said electric field originating at with said comnon perimeter de&es said region of said a region of said ferroelectric material between said first ferroelectric material at which said electric field originates. electrode pattern and said second electrode pattern. said 32. h electro-active actuator as in claim 27 wherein said electric field extending radially outward tiom said 20 ferroelectric material comprises a single sheet of ferroelec- region of said ferroelectric material and substantially tric material, and wherein each of said first surface and said parallel to said first surface and =id second surface, second surface is a major surface of said single sheet. whereby said ferroelectric material co~espondillgiy 33. An electro-active actuator ZIS in claim 27rwherein said deflects symmetrically about said region in a direction dielectric material comprises substsantially perpendicular to said electric field. a first piece of dielectric material with said first electrode

28. An electro-active actuator as in claim 27 wherein said pattern cottpled thereto 'and first electrode pattern and said second electrode pattern are a second piece of dielectric material with said second mirror images of one another. electrode pattern coupled thereto,

29. An electro-active actuator as in claim 28 wherein each said first piece of dielectric material being joined to said of said first electrode pattern and said second pattern com- 30 second piece of dielectric material beyond the perim- prises at least two independent electrodes having opposite eter defined by said ferroelectric material. polarity and arranged in an alternating sequence as they 34. An electro-active actuator as in claim 27 wherein said extend radially outward tiom said region of said ferroelec- fermelectric material comprises a ceramic piezoelectric tric material, said alternating sequence being defined with material. respect to a cross-sectional view of said electro-active 35 actuator. * * * * *

defining a first and a second surface opposing said first surface. wherein said

parallel planes; first surface and said second sirface lie in substantially SUbstanhllY perpendicular to said SUbstantiafiY Parallel

a first electrode pattern coupled to said first surface; a second electrode pattern coupled to said second surface:

a dielectric material encasing said ferroelectric material

wherein said first electmde pattern and said second elec- to introduce an

25