C 936 – 01 ;QZKZNG__

-

Upload

aubrey-norman -

Category

Documents

-

view

213 -

download

1

description

Transcript of C 936 – 01 ;QZKZNG__

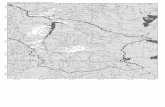

Designation: C 936 01Standard Specication forSolid Concrete Interlocking Paving Units1ThisstandardisissuedunderthexeddesignationC 936;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. Asuperscript epsilon (e) indicates an editorial change since the last revision or reapproval.1. Scope1.1This specication covers the requirements for interlock-ing concrete pavers manufactured for the construction of pavedsurfaces.1.2Whenparticular features aredesired, suchas weightclassication, higher compressivestrength, surfacetextures,nish, color, or other special features, such properties shouldbe specied by the purchaser. Local sellers, however, should beconsulted as to availability of units having the desired features.1.3The values stated in SI units are to be regarded as thestandard. The values given in parentheses are for informationonly.2. Referenced Documents2.1ASTM Standards:C 33Specication for Concrete Aggregates2C 67Test Methods for SamplingandTestingBrickandStructural Clay Tile3C 140Test Methods for SamplingandTestingConcreteMasonry Units and Related Units3C 150Specication for Portland Cement4C 207Specicationfor HydratedLimefor MasonryPur-poses4C 260Specication for Air-Entraining Admixtures for Con-crete2C 331Specicationfor Lightweight Aggregates for Con-crete Masonry Units2C 418Test Method for Abrasion Resistance of Concrete bySandblasting2C 494/C 494MSpecicationforChemical AdmixturesforConcrete2C 595Specication for Blended Hydraulic Cements4C 618Specication for Coal Fly Ash and Raw or CalcinedNatural Pozzolan for Use as a Mineral Admixture inConcrete2C 979Specication for Pigments of Integrally ColoredConcrete2C 989Specicationfor GroundGranulatedBlast-FurnaceSlag for Use in Concrete and Mortars2C 1240Specication for Use of Silica Fume as a MineralAdmixture in Hydraulic-Cement Concrete, Mortar, andGrout23. Terminology3.1Denitions:3.1.1architectural nishessurface modied by mechani-calmeanssuchasblasting, hammering, polishing, tumbling,washing, or other methods.4. Materials4.1Cementitious Materials shall conform to the followingapplicable ASTM specications:4.1.1Portland CementsSpecication C 150.4.1.2BlendedCementsSpecicationC 595, TypesISorIP.4.1.3Hydrated Lime, Type SSpecication C 207.4.1.4Fly AshSpecication C 618.4.1.5Ground SlagSpecication C 989.4.1.6Silica FumeSpecication C 1240.4.2Aggregates shall conformto the following ASTMspecications, except that grading requirements shall notnecessarily apply:4.2.1Normal WeightSpecication C 33.4.2.2LightweightSpecication C 331.4.3Chemical Admixtures shall conformtothefollowingapplicable ASTM specications:4.3.1Air-entraining AdmixturesSpecication C 260.4.3.2 Water-reducing, Retarding, and AcceleratingAdmixturesSpecication C 494/C 494M.4.3.3 Pigments for Integrally Colored ConcreteSpecication C 979.4.4Other ConstituentsIntegral water repellents, and othermaterials for which no ASTM standards exist, shall be previ-ouslyestablishedassuitableforuseinconcreteorshall beshown by test or experience not to be detrimental to theconcrete.5. Physical Requirements5.1Units shall have an exposed face area#0.065 m2(101in.2), and their overall length divided by thickness shall be #4.The minimum thickness shall be 60 mm (2.36 in.). See Fig. 1.5.2Concrete units coveredbythis specicationmaybe1This specication is under the jurisdiction of ASTM Committee C27 on PrecastConcreteProducts andis thedirect responsibilityof SubcommitteeC27.20onArchitectural and Structural Products.Current editionapprovedNov. 10, 2001. PublishedJanuary2002. Originallypublished as C 93682. Last previous edition C 93696.2Annual Book of ASTM Standards, Vol 04.02.3Annual Book of ASTM Standards, Vol 04.05.4Annual Book of ASTM Standards, Vol 04.01.1Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.made from lightweight or normal weight aggregates or mixedlightweight and normal weight aggregates.5.3CompressiveStrengthAt thetimeofdeliverytothework site, the average compressive strength of the test samplesshall be not less than 55 MPa (8000 psi) with no individual unitless than 50 MPa (7200 psi) as required in 6.2.5.4AbsorptionThe average absorption of the test samplesshallnotbegreaterthan5 %withnoindividualunitgreaterthan 7 % as required in 6.2.5.5Resistance toFreezingandThawingThe manufac-turer shall satisfy the purchaser either by proven eld perfor-mance or a laboratory freezing-and-thawing test that the pavingunitshaveadequateresistancetofreezingandthawing. Ifalaboratorytest isused, whentestedinaccordancewithTestMethods C 67, specimens shall have nobreakage andnotgreater than 1.0 % loss in dry mass of any individual unit whensubjected to 50 cycles of freezing and thawing. This testmethod shall be conducted not more than 12 months prior todelivery of units.5.6Abrasion ResistanceWhen tested in accordance withTest Method C 418, specimens shall not have a greater volumeloss than15cm3/50cm2(0.92in.3/7.75in.2). The averagethickness loss shall not exceed 3 mm (0.118 in.).5.7Dimensional ToleranceLength or width of units shallnot differ by more than 61.6 mm (60.063 in.) from approvedsamples. Heights of units shall not differ more than 63.2 mm(60.125 in.) the specied standard dimension. All tests shall beperformedasrequiredin6.2. Unitsshall meet dimensionaltolerances prior to the application of architectural nishes.6. Sampling and Testing6.1The purchaser or his authorized representative shall beaccorded proper facilities to inspect and sample the units at theplace of manufacture from the lots ready for delivery.6.2Sample and test units in accordance with Test MethodsC 140, except as required in 5.5. Units tested in compressionshall be whole. If the testing machine does not have sufficientforce to break a whole unit, then the unit shall be cut in halfalong the shortest axis and one half tested. Units with protrud-ing, smaller ends shall have the ends saw cut and the remaininglarger pieces tested. This specimen shall be symmetrical abouttwo axes.7. Visual Inspection7.1All units shall be sound and free of defects that wouldinterferewiththeproper placingof theunitsor impair thestrength or performance of the construction. Minor cracksincidental to the usual methods of manufacture or minorchippingresultingfromcustomarymethods of handlinginshipment and delivery shall not be deemed grounds forrejection.8. Rejection8.1Incasetheshipmentfailstoconformtothespeciedrequirements, the manufacturer may sort it, and new specimensshall beselectedbythepurchaserfromtheretainedlot andtested at the expense of the manufacturer. In case the second setof specimens fails toconformtothetest requirements, theentire lot shall be rejected.ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentionedin this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the riskof infringement of such rights, are entirely their own responsibility.This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years andif not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standardsand should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of theresponsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you shouldmake your views known to the ASTM Committee on Standards, at the address shown below.This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,UnitedStates. Individual reprints(singleormultiplecopies)of thisstandardmaybeobtainedbycontacting ASTMat theaboveaddress or at 610-832-9585 (phone), 610-832-9555 (fax), or [email protected] (e-mail); or through the ASTMwebsite(www.astm.org).FIG. 1 Length, Width, and Thickness of Concrete Paving UnitsC 9362

![Daedeok-gu, Daejeon 306-230, Republic of Korea Tel : +82-42-936-0133 Fax : +82-42 …[RStech] OptimaPak... · 2019-01-07 · Tel : +82-42-936-0133 Fax : +82-42-936-0134 e-mail : rstech@rstechcorp.com](https://static.fdocuments.in/doc/165x107/5fa634f44c3d6001795812a8/daedeok-gu-daejeon-306-230-republic-of-korea-tel-82-42-936-0133-fax-82-42.jpg)