By: Raymond Tyler Dalke Dr. Jan Brink Mr. Mark Weller.

-

Upload

laurel-dott -

Category

Documents

-

view

219 -

download

2

Transcript of By: Raymond Tyler Dalke Dr. Jan Brink Mr. Mark Weller.

STEEL IDENTIFICATIONTHROUGH

SPARK OBSERVATIONBy:

Raymond Tyler DalkeDr. Jan Brink

Mr. Mark Weller

Introduction

• Steel Manufacturing• Open Hearth Furnace• Basic Oxygen Furnace• Electric Arc Furnace

• Steel Categories• Killed• Semi-Killed• Rimmed• Capped

• History of Spark Testing• 1909-1970’s

Why Spark Testing?

• Cost• Availability• Ease of Use

Spectrometer

198.78922 278.76615 352.74466 435.06593 528.47135 614.89235 695.24498 766.10953 857.512410

50

100

150

200

250

1018 Plain Carbon Steel

1018

Wavelength (nm)

Counts

589.07 C

259.79 Fe

Methods of Spark Testing

• Grinding Wheel• Prototypes

• Compressed Air

1015 Plain Carbon Steel

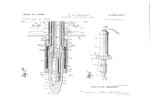

Apparatus

• Baldor 8 inch Bench Grinder• ¾ Hsp• 3600 RPM• 2.4 Amp• Serial# G8-165-11• Coarse grit Al2 O3

grinding wheel• Medium grit Al2 O3

grinding wheel

Medium Grit Abandoned

• 1015 plain carbon steel

1 2 3

Apparatus

• Mounting Arm• 2”x 2” box tubing• One- 5/16”-18 x 1 ¼” machine screw• One- 5/16”-18 x 2” bolt

Apparatus

• Current Backboard• 2 – black poster boards• Inch scale

• Future Backboard• 2”x 2” pine studs (frame)• 40”x 45” black background ¼” paneling• Inch scale

Mounting Apparatus

• Remove eye shields, tool rest, and guards• Utilized the existing bolt holes• Loctite®!!!

Specimens Tested

• Plain Carbon Steel• 1015• 1018• 1045• 1075• 1095

• Alloy Steels• 1215• 4140• 4340

• Tool Steel• O1• D2

• Stainless Steels• 17-4• 303• 316

• Others• Gray Cast Iron

Procedure

• Observe Safety!• Mount Specimen• Turn on grinder• Prepare camera and turn off lights• Swing mounting arm into grinding position• Stand back roughly 4 foot and take six pictures• Return mounting arm to non-grinding position• Turn light on and align pattern density card• Take two readings, a 10 second and 30 second blast on

separate cards• Turn grinder off• Measure the force applied to grinding wheel• Record measurements• Upload photos using Image J software and record data

Data Measured

• Rockwell Hardness• Brinell Hardness• Spark Length• Projected Angle• Angle of Extremes

Image J

Spark Length

Angle of Extremes

Projected Angle

Results

• Average Force3.3 Newtons = .74 lbs

• Average projectedangle -58.35° from the positive x-axis

• Measured RPM 3575

Spark Testing

Type of Steel HRC Brinell Spark Length(in.)

Angle of Extremes

(°)

1015 55.67 560 44.82 17.36

1018 50.67 475 35.93 27.08

1045 61.00 670 38.83 34.48

1075 83.00 N/A 30.96 27.62

1095 86.67 N/A 24.73 25.94

1215 57.33 601 40.13 27.86

4140 60.33 653 33.98 27.01

4340 53.33 530 37.41 32.25

O1 61.67 670 28.24 26.12

D2 58.00 620 14.26 16.72

17-4 Stainless 79.33 N/A 22.86 30.32

304 Stainless 75.33 N/A 12.51 25.26

316 Stainless 78.00 N/A 22.13 25.79

Gray Cast Iron 58.67 620 5.24 11.64

Pattern Density Cards

Spark Detail

1015 Plain Carbon Steel

1095 Plain Carbon Steel

Comparison Chart

Further Research

• Lab Experiments• Thermal Imaging• Pneumatic Fixture

References

• American Society of Metals (1978). Metals Handbook: Properties and selection: Irons and Steels. (Ninth Edition).Library of Congress Cataloging in Publication Data. United States of America

• DeGarmo, E. P., Black, J. T., Kohser, R. A., and Klamecki, B. E.(2003). Materials and Processes in Manufacturing. (Ninth Edition) Hamilton Printing. United States of America

• Stookey, D. and Dargan, N.(1967). Spark Testing Training Manual• Tschorn, G.(1963). Spark Atlas of Steels. The Macmillan

Company. New York• Azzouz, S., Brink, J., and Weller, J. M.(2011). Material Science

Lab Manual• www.steel.org• www.matweb.com• asm.matweb.com• www.azom.com

Special Thanks

• Dr. Magaly Rincón-Zachary• Dr. Jan Brink• Mr. Mark Weller• Dr. Jonathan Price• Dr. Rebecca Dodge• UGROW

Questions?