Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

-

Upload

tabita-jane-siburian -

Category

Documents

-

view

239 -

download

1

Transcript of Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

1/13

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 1 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

Wafer, Semi-Lug, Lug

and Double Flanged Type

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

2/13

The centric replaceable liner butterfly valve is capable of bi-directionalflow and bubble tight shut-off at full rated pressure.

AVAILABLE SERIES

STANDARD COMPLIANCE

PRODUCTION RANGE

APPLICABLE FLANGE

Series 210 Tripple Eccentric Wafer Type Metal Seated Butterfly Valve

Series 220 Tripple Eccentric Lug Type Metal Seated Butterfly Valve

Series 240 Tripple Eccentric Double Flanged Type Metal Seated Butterfly Valve

Product Group 200 butterfly valves comply in general ith the following standards; ISO 5752,

API 609, BS 5155, JIS F7480, JIS B2032, JIS B2064, KSV 7490

Size range DN 50 (2") ~ DN 2000 (80")

Working Temperature range -20C to ~ +200C

Working Pressure up to 16 barg

ASME B16.1 Class 125#ASME B16.5 Class 150#

Description Product Group 200 Butterfly Valves

Wafer Type Lug Type Double Flanged Type

Series 210 Series 240 Series 250

Series 250 Tripple Eccentric Double Flanged Type Metal Seated Butterfly Valve

EN 1092 / DIN 2501, PN 6, PN 10, PN 16

BS 4504 PN 6, PN 10

ISO 2084 PN 6, PN 10

KS / JIS, 5K, 10K, 16K

Semi Lug Type

Series 220

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 2 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

3/13

The Concentric Design Principle

Center of the shaft in Center of the Disc and Valve Seat.

Applicable for Butterffly Valves with elastomer lining.

Classification by Connection

Symmetric disc design ensures favorable flow characteristics and low

pressure drop.

Concentric shaft ensures low operating torque.

Lining gives a good protection to valve body, and acts as flange gasket.

Shaft penetrates the valve seat.

Wide choice of elastomer seating materials.

Suitable for installation in Low Pressure Systems

Type General Characteristics

Series 210

WAFER Type

General ApplicationsShipbuilding, water works, heating and ventilation, power plants,

oil refinery Chemical plants etc.

Valve to be installed between flanges using long bolts.

Valve body with centering lugs for easy installation.

Easy handling and light weight.

Easy installation, less bolt quantity and low cost.

Series 220

SEMI-LUG Type

General ApplicationsShipbuilding, water works, heating and ventilation, power plants,oil refinery Chemical plants etc.

Valve to be installed between flanges, valve body with two pair of threadedlug bolt holes (Top and bottom).

Easy handling and light weight, easy installation.

Suitable for "End of Line" Service.

Series 240

FULL-LUG Type

General Applications

Available in different flange standards.

Series 250

DOUBLE

General ApplicationsShipside valves, ballast valves, water works, power plants, etc all piping system.

Valve body both ends with complete flanges suitable to connect with pipe flanges.

Suitable for shipside valve.

Bi-Directional bubble tight shut off.

Unique replaceable seat design, comparable with bonded liner seats.

FLANGED Type

Appearance

Suitable for "End of Line" Service.

General piping system pump outlets, tank drains, shipbuilding, ship sides etc.

To be installed between flanges, valve body with full pattern threaded lug boltholes.

Available in different flange standards.Suitable for shipside valve.Suitable for "End of Line" Service.

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 3 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

4/13

Major Properties

The valve is, closed by a 90 turn clockwise, non jamming and has aresilient elastomer seat for bi-directional zero leakage service.

The valve is torque seated and the unique replaceable seat is designed

in such a way that it cannot move while opera ing the valve or duringoperation (comparable with a bonded liner seat).

In general the following operation possibilities are available.

Manual operation, handlever or gearbox.

Hydraulic actuators.

Pneumatic actuators.Electric actuators.

Operations

PG 200 butterfly valves have the following approvals, certification.

CE / PED.ABS certificate of design assesment.BV, DNV, LRS and KRS type approvals.

Approvals, Certification

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 4 www.globalvalvecenter.com 2011

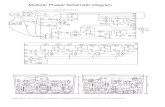

Centric Replaceable Liner

Product Group 200

813

7

1

3

2

9

11

6

9

4

5

10

12

MATERIAL

CAST IRON / DUCTILE IRONSTAINLESS STEEL / CARBON STEELALUMINUM BRONZE

STAINLESS STEEL / ALLOY STEELALUMINUM BRONZE

NBR / EPDM / SILICON / VITONSTAINLESS STEEL(SS304, 316, 410,

420, 17-4PH)

STAINLESS STEEL

RUBBER SAME AS SEAT MATERIAL

BRONZE

STAINLESS STEEL

PTFE + pb

RUBBER SAME AS SEAT MATERIAL

CARBON STEEL / STAINLESS STEEL /

AL-BRONZE / MILD STEEL

STEEL / STAINLESS STEEL

CARBON STEEL, if necessary

PART NAMEP.NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

BODY

DISC

SEATSTEM

DISC PIN

O-RING

PACKING GLAND

GLAND BOLT

BEARING

O-RING

BOTTOM COVER

BOLT & WASHER

KEY

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

5/13

Dimensions Series 210 Wafer

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 5 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

unit : mm

mminch

SIZE

L H H1 H2 H3SQ TYPE N M N- Z

WEIGHT

(APPROX.)

(kg)

STEM TOP FLANGE

VALVE DIMENSIONS

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

6/13

Dimensions Series 220 Semi-Lug

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 6 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

unit : mm

KEY

SIZED

H4H2H1HLmminch

SIZE

TYPE

WEIGHT

(APPROX.)

(kg)N M N- ZSQUARE

STEM TOP FLANGE

SQ H3

VALVE DIMENSIONS

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

7/13

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 7 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

unit : mm

KEY

SIZED

H4H2H1HLmminch

SIZE

TYPE

WEIGHT

(APPROX.)

(kg)N M N- ZSQUARE

STEM TOP FLANGE

SQ H3

VALVE DIMENSIONS

Dimensions Series 240 Lug

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

8/13

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 8 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

unit : mm

KEY

SIZED

H4H2H1HLmminch

SIZE

TYPE

WEIGHT

(APPROX.)

(kg)N M N- ZSQUARE

STEM TOP FLANGE

SQ H3

Dimensions Series 250 Double Flanged

VALVE DIMENSIONS

C i R l bl Li

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

9/13

General

Characteristic

Features

Handlever with intermediate position lock plate

Suitable for nominal sizes up to and including DN 150

For quarter turn valves, spring loaded lever with 10 positions interval lock plate

Handle indicates valve position

Model No.

L-1 50.65.80 9 30 265

L-2 100~150 12 30 265

Valve size A B L

1

2

3

4

5

6

Handle

Lever

Pin

Spring

Screws

Indicator

Mild Steel

Mild Steel

Mild Steel

SS Steel

Mild Steel

Mild Steel

STANDARD MATERIALS

Use

Options

General purpose manual operator for

on / off or throtting duties.

Heavy duty, weather proof type

Limit switch, Chainwheel,

Locking device

Features

1

2

3

4

5

6

7

8

9

10

HousingWorm wheel

Worm

Cover

Bush

Adjust bolt

Oil seal

Worm shaft

Indicator

Handle

Cast IronSS. Steel

Cast Iron

Cast Iron

Bronze

SS. Steel

Rubber

SS. Steel

Mild steel

Cast Iron

Item No. Part name Material

145

315

400

400

45

65

80

120

120

102

138

208

244

244

155

235

280

340

370

59

71

91

126

126

123

167

220

305

305

F07

F10

F14

F16

F16

70

102

140

165

165

E G B F LAMODEL

NO.

ApplicationSIZE

RATOTYPE PCD N-M

ISO 5211

24:1

32:1

42:1

53:1

212:1

4-MB

4-M10

4-M16

4-M20

4-M20

WG-01

WG-02

WG-03

WG-04

WG-05

50A~150A

200A~350A

400A~450A

500A~650A

700A~850A

195

250

Lever Operators

Gear Operators

Handwheel extension shafts

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 9 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

Centric Replaceable Liner

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

10/13

CV values Product Group 200 Butterfly Valves

Rated flow coefficient (Cv) is a number which represents a valve's ability to pass flow.

The bigger the Cv, the more flow can pass through the valve at a given pressure drop. The Cv value means the volume of water in

US gallons per minute that passes through a given valve opening with a pressure drop of 1 pound square inch (Water at 60F)

A Cv of 1900 means a valve will pass 1900 US gpm water of 60F at a Dp of 1 PSI.

The relation between Cv and Kv, expressed in the above mentioned unit of measure are as follows

Cv=1.16kv

Formula 1

FLOW RATE LBS/HR(Steam or Water)

Where :

dp = pressure drop in PSIF = flow rate in lbs /hr.

= square root of specific volume ft.(downstream of valve)

63,5 CvF

dp= ( )2

or Cv =dp

V

63,5

F V

Formula 2

FLOW RATE GPM(Water or Other Liquids)

Where :

dp = pressure drop in PSISg = specific gravity

Q = Flow rate in GPM

CvQ

dp= ( )2

or Cv =

v

dpSg

Cv

20 30VALVE SIZE

40 50 60 70 80 90

inch mm

DISC OPENNG

Basic Formulas Cv-Value

V3

/lb.

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 10 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

Cv Cv Cv Cv Cv Cv Cv

Centric Replaceable Liner

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

11/13

kg-m Nm Nm

CONCENTRIC TYPE

3bar 5bar mm

SIZE

inch

TORQUE TABLE

Nm Nm Nm

10bar 13bar 16bar

kg-m kg-m kg-m kg-m

Torque figures as mentioned in the torque table below are;

Initial break away values in Nm (Newton Meters) Excluding any safety factor For valves that are operated at least once per month

Temperature 0 to 50 degr. C

Safety factor (sf)

For sizing and safe operation purposes the specified torque values needto be multiplied with the following minimum safety factors;

For liquid and lubricant media sf = 1.25 For powdery (non-lubricant) media sf = 2.00

For dry gasses and high viscous media sf = 2.00

For assistance in sizing and dimensioning actuator-valve combinations please contact our Engineers.We have wide experience in sizing Pneumatic, Electric and Hydraulic actuators.

Service

Torque figures

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 11 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

Centric Replaceable Liner

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

12/13

The following chart should be used as a general guide.Application suggested derives from recommendation given by elastomer manufacturer.

The resistance can be affected by type of fluid, concentration, temperature, pressure, flow rate or evaporation of the

medium.

The final choice is to be taken by the customer, based on characteristics and specific application.

MATERIAL

Fresh Water

Sea Water

Brine

Esters

Alkalis

Ozone

Alcohols

Brake Fluid

Treated Water With Caustic Soda

Fresh Water

Sea Water

Treated Water With Caustic Soda

Hydrocabons

Natural GasOil and Fat

Air

Gasoline

Acids and Alkalis

Acids, Oils

Hydrocarbon

Solvents

Corrosive Products

Ketones

Acid, Ozone, Oils

Fats

Greases

Solvents

Food

Beverage

GENERAL APPLICATION SERVICE TEMPERATURE NOT RECOMMENDED FOR

Hydrocarbons

Oils

Fats

Greases

EPDM

NBR

SBR

VITON

S LICONE

TEFLON

NEOPRENE

-15C to +120C(for intermittent opration)

(Allowable temperature

in continuous use)

(Allowable temperaturein continuous use)

Solvents

BenzeneXylol

Steam, Ester

Freon22, Alkalis

Solvents, Ketones

Steam

Solvents

Hydrocarbons

Fluid Containing Powders

Alkaline

Gaseous Fluorine

Ketones, Thinners

Concentrated Acids

General Guid Elastomers

0C ~ 100C

-10C to +80C

0C ~ 70C(L-NBR -50C to +70C)

-20C to +140C

-20C to +80C

-18C to +90C

-10C to +230C

-50C to +230C(PTFE -196C to +230C)

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 12 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

D t PG200Centric Replaceable Liner

-

7/26/2019 Buterfly Valve Wafer Type Jis 10K DN 20 - DN 1000

13/13

Global Valve Center B.V.Boelewerf 142987 VD RidderkerkThe Netherlands

Tel 1 +31 (0) 180 39 89 38Tel 2 +31 (0) 180 39 88 69

Fax +31 (0) 84 22 98 163

Product Group 100

Bonded Rubber Liner Butterfly Valves

Product Group 200Replaceable Rubber Liner Butterfly Valves

Product Group 300

Cassette Type Rubber Liner Butterfly Valves

Product Group 400

Double Eccentric Replaceable Seat RingType Butterfly Valves

Product Group 500

High Performance Butterfly Valves

Product Group 600

Tripple Eccentric Metal Seated Butterfly Valves

Product Group 700

Disc Seated Butterfly Valves

Product Group 800

Cryogenic Butterfly Valves (LPG, LNG)

Product Group 900

Damper Butterfly Valves

Document

Revision

Year

: PG200

: 1

: 2011

Butterfly Valves

Page 13 www.globalvalvecenter.com 2011

Centric Replaceable Liner

Product Group 200

Global Valve Center B.V.Boelewerf 142987 VD RidderkerkThe Netherlands

Tel 1 +31 (0) 180 39 89 38Tel 2 +31 (0) 180 39 88 69

Fax +31 (0) 84 22 98 163

Product Group 100

Bonded Rubber Liner Butterfly Valves

Product Group 200Replaceable Rubber Liner Butterfly Valves

Product Group 300

Cassette Type Rubber Liner Butterfly Valves

Product Group 400

Double Eccentric Replaceable Seat RingType Butterfly Valves

Product Group 500

High Performance Butterfly Valves

Product Group 600

Tripple Eccentric Metal Seated Butterfly Valves

Product Group 700

Disc Seated Butterfly Valves

Product Group 800

Cryogenic Butterfly Valves (LPG, LNG)

Product Group 900

Damper Butterfly Valves