Business Plan Template - Tehnomont · TEHNOMONT SHIPYARD PULA Ltd is a company that has tradition...

Transcript of Business Plan Template - Tehnomont · TEHNOMONT SHIPYARD PULA Ltd is a company that has tradition...

Company Profile

of

Main company contact: Tel.: +385 52 386 011; +385 52 386 943 Fax: +385 52 386 328 e-mail: [email protected] Website: www.tehnomont.hr

Business, Administrative & Contact Information Business name: Tehnomont Shipyard Pula Ltd Business type: Private company, member of Tehnomont Group Company registration number: 3674240 Tax reference number: 36173983291 VAT number: 36173983291 Fax: +385 52 386 328 E-mail: [email protected] Physical address: Fizela 6, HR-52100 Pula, Croatia Postal Address: p.o. box 111, HR-52100 Pula, Croatia Introduction Company History TEHNOMONT SHIPYARD PULA Ltd is a company that has tradition in shipbuiding and shiprepairing industry, since 1905. Shipbuilding and metal industry in general is basis of our business reaching high technology level confirmed by generations of our skilled workers over the long period, and building of the ships and various kind of top quality vessels. That conduced to valuable references and reputation which we are constantly increasing. What the company does Core business of the company is shipbuilding and ship repairing of the vessels up to 80 m, as well as building of various metal constructions mainly affiliated with shipbuilding. Leading part of our production is concerning shipbuilding of different types of working ships, and shipbuilding of sophisticated special purpose vessels made of aluminium and steel, of the top quality and low exploitation costs and long product life, all customized to a client requirements. Strategy Vision statement TEHNOMONT SHIPYARD PULA d.o.o. is creating the aded value recognizing the new business opportunities and seting up the market trends, as well as recognizing and development of human resources. Mission statement Our company is listed as a leading Croatian medium sized shipyard, with note that in Croatian frame we are the leading builder of aluminium vessels. For the high competition reasons from Far East in shipbuilding of steel vessels, our choice for development in direction to the sophisticated aluminium vessels, has revealed as right and in due time decision, and our goal is to go further with development in this trend. All our future investments in material and human resources are following development of this concept aiming to accessing this market segment which involves shipbuilding of aluminium working vessels up to 80 m in length.

3 Business Profile of Tehnomont Shipyard Pula ltd

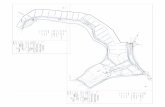

Business goals & objectives In strategy achievment the following default tasks are defined, in order to considerate present, and define future: - product quality improval as a postulate of client satisfaction, in a way that the services are conducted according to latest technology and aplying latest actual knowledge. - creation of modern organisation simultaneously with strenghtening of team work creating stimulative working enviroment. - promotion of single creativity as a basis of business improvement - promotion of the passion for success in all business aspects - with quality, keeping deadlines and prices furthermore increase the company reputation Business strategy Business strategy is pointed to development of shipbuilding of various kinds (as much as possible) of special purpose vessels, in particular of aluminium but from steel as well, with accent to offshore, patrol, fishing and other special purpose vessels. The main objective is company development fitting in environment preservation as much as possible. Profit is our main goal but care of employee’s satisfaction and working conditions must be constantly improved. Economic intent Basic economic intent of our company is making profit by mindful investments which leads to increasing of competitiveness on target market. Beside this, we are taking care of good working environment. Our goal for next ten years is to approximate to worldwide leader shipyards of our size. Business concept Technical capacity & competence Shipyard disposes of an area of 40.000 m2 . For the launching of the ships from 50 to 80 m we use double crane technology, and for the small and medium size vessels there are two slipways with capacity of slipping up and lounching the vessels up to 50 m, in lenght 18 m in beam and up to 600 t of weight. Slipway area is covered with all necessary infrastructure including the cranes. Covered area, workshops, covers about 3990 m2 providing cranes, machinery and all energetic infrastructure. Uncovered working areas are settled among the coastal quay which is 200 m in lenght,and the sea depth beside is 4.5m. You can observe the layout of the shipyard on the following graphics:

Photo has been taken before building of the new production segmental workshop

5 Business Profile of Tehnomont Shipyard Pula ltd

Profesional improvement of the emloyes in our company is constant process, that gives us oportunity to accept designing and performing of most complicated projects. CERTIFICATES Production facilities, processes and employes are certificated: According to ISO 9001-2000 from BVQI For welding processes in shipbuilding, from CRS (Croatian Registry of Shipping) For shipbuilding in aluminium and steel according to BV (Bureau Veritas) rules For manufacturing of steel constructions according to norm DIN 18800 from SLV München Mr.Milan Bičić in accordance to International Institute of Welding for International Welding Engineer Mr.Pliško Davor in accordance to International Institute of Welding for International Welding Engineer

6 Business Profile of Tehnomont Shipyard Pula ltd

Mr. Romeo Cetina in accordance to International Institute of Welding for International Welding Engineer Mr.Živko Šošić in accordance to Europian Welding Federation for European Welding Specialist Mr.Nenad Matana in accordance to International Welding Federation for International Welding Specialist Mr.Zoran Milošević for Visual control in shipbuilding, for Ultrasonic and Penetrants control in shipbuilding from Croatian Society for NDT Quality assurance is supported thru departments of Technical preparation, technology, Quality Control department, and quality Management System. From our equipment providers we demand the same standards, and we are selecting them according to our quality level. Main condition in selection of equipment providers is that they have to be authorized dealer, that can assure worldwide aftersales services. TECHNICAL EXPERTS PERSONELL 1. Alajbeg Bozo Bachelor deg. mech. ing experience in shipbuilding 30 years. 2. Baričev Ognjen Bachelor deg. mech. ing experience in shipbuilding 30 years. 3. Berc Đorđe Master degree mech. ing experience in shipbuilding 36 years. 4. Bičić Milan Master degree mech. ing experience in shipbuilding 15 years. 5. Brnić Miljenko, Master degree mech. ing experience in shipbuilding 37 years. 6. Bakiš Zdenko Master degree mech. ing experience in shipbuilding 14 years 7. Buntić Martina Master degree naval arc. experience in shipbuilding 4 years 8. Cetina Romeo Master degree mech. ing experience in shipbuilding 17 years. 9. Gavranovic Mato Master degree mech. ing experience in shipbuilding 32 years. 10. Ivančić Kristijan Master degree mech. ing experience in shipbuilding 12 years. 11. Kostešić Elvin Bachelor deg. naval ing experience in shipbuilding 14 years. 12. Marjanović Igor Master degree mech. ing experience in shipbuilding 5 years. 13. Matijasic Branko Bachelor deg. mech. ing experience in shipbuilding 25 years 14. Modrušan Dinko Bachelor deg. mech. ing experience in shipbuilding 23 years 15. Pliško Davor Master degree mech. ing experience in shipbuilding 5 years. 16. Velić Mate Bachelor degree mech. ing experience in shipbuilding 35 years WELDING EXPERTS Shipyard disposes with more than 200 certified welders, with certificates that enables most complicated shipbuilding works regarding the welding procedures in aluminium and steel regardless of welding positions or processes. COMPANY TECHNICAL SCHEDULLE SETUP PRODUCTION Shipbuilding and shiprepairing Department includes folowing activities: Production processing dept (servicing other tech dept.) Ship Construction managment Shipbuilding section Shiprepairing section Heavy metal constructions Department includes folowing activities: Aluminium Hull construction Steel hull construction Rudders manufacturing

7 Business Profile of Tehnomont Shipyard Pula ltd

Production of heavy metal constructions Light metal constructions Department includes folowing activities: Cutting of the plates and profiles Manufacturing of ship equipment Manufacturing of light constructions for civil engineering Various plumber, locksmith and pipe works QUALITY CONTROL MANAGEMENT (2 employes) Responsable for quality control under supervision of company management, dealing with activities for the whole company: Implementation of QCS ISO 9001-2000 Implementation of enviromental legal norms Implementation of safety on work legal norms Implementation of fire fighting mesures and protection QUALITY CONTROL DEPARTMENT (3 employes) Responsable to company management, dealing with following activities for entire company: Phase control and end quality control of production In collaboration with certification institutions, operation control of certification procedures Implementation of regular norms related to production procedures LIST OF TECHNICAL FACILITIES Civil engineerings objects Shipbuilding workshop, segmental, on rails movable, of 45 m x 22 m. (under last stage of design, there are the extention segments up to 90 m in total) Shipbuilding workshop with mechanical and machinery workshop -82 m x 25 m Shipbuilding platforms - 4 areas (4.000 + 1.200+3.600+1.600) in total 10.400 m2 Operating coastal quay 200m in lenght, with depth up to 4,5 m Slipway 1: Slipping and launching of the ships up to 50 m in Lenght 18 m in beam and max 600 t of weight Slipway 2: Slipping and launching of the ships up to 32 m in lenght 6m wide and 100 t of weight on carell Cranes Overhead traveling crane 5,0 t 1 pcs Overhead traveling crane 2,0 t 1 pcs Overhead traveling crane 3,2 t 2 pcs Wheel-mounted crane 16,0 t 1 pcs Wheel-mounted crane 22,0 t 1 pcs Wheel-mounted crane 60,0 t 1 pcs Wheel-mounted crane 120 t 1 pcs Hammerhead tower cranes, 6,0 t 2 pcs Hammerhead tower cranes, 8 t 1 pcs Wood processing machines

8 Business Profile of Tehnomont Shipyard Pula ltd

Plate processing machinery Metal processing machinery Welding machinery ARC WM 94 pcs MIG/MAG CO2 (ESAB, LINCOLN) 70 pcs EPP (2 x ESAB, 1 x LINCOLN) 3 pcs Ultrasonic inspection equipment Welding quality measuring device and sheet layer tester- Krautkrämer USM 35X S Wall thicknes measuring device OLYMPUS MG2-XT Products Our entire production is based on shipbuilding industry. Long time ago we were among several most respectable shipyard in our region, building only wooden ships. In course of the time due to the development of technology, our shipyard kept the trend, so that in a certain period of time, first steel vessels began to be the most important part of the production. Firstly joined by rivets, and then new technology of arc welding was adopted. Logical further development imposed acquiring of the new skills and appliance of new materials – aluminium. Our experience with aluminium shipbuilding started 15 years ago, in German and Italian shipyards, where our skilled workers were engaged in building of some sophisticated parts of the ships, in aluminium. That was the basis of future development ad implementation of aluminium shipbuilding technology in our Shipyard. Beginning with the year 2008. until this days, we delivered 29 marine vessels in length range from 7 to 43 meters (work boats, patrol boats, ferries, passenger ships etc.).

9 Business Profile of Tehnomont Shipyard Pula ltd

In 2012 we delivered a new passenger catamaran vessel with dimensions of 37 meters in length, 14 meters wide where the superstructure is completely made of aluminium alloy and constructed without supporting pillars between main deck and sun deck.

For this project, we have invested in a new workshop hall that has been built last year, which is movable on rails, and could be extended up to 100 meters .

10 Business Profile of Tehnomont Shipyard Pula ltd

Furthermore, in the last fifteen years, our engineers and headmans have worked on "turn-key" basis, on building and assembling of aluminium blocks sections on different type of ships e.g. cruisers and other types of ships in Italian and German shipyards. At Shipyard „Fincantieri Cantiere Navale di Monfalcone“, from 2004 up to 2010. we were engaged on series of cruiser ships type „Princess“ and „Carnival“ from deck 12 above, with 25 skilled workers and foremans, with the support of our welding engineers. Production volume of each ship was aprox. 40 to 50 tonnes of aluminium block sections. In Germany we have a large experience in aluminium shipbuilding. For the client Shipyard Lurssen – Bremen we have built large part of aluminium superstructure for 165 m Yacht for Oman Kingdom. Furthermore, we took part in building and complete outfitting of aluminium funnels for the cruise ships in „Meyer Werft“ (ships: AIDA, NCE, DIESNEY). The weight of this funnels was from 104 up to 160 tonnes. We have built several signal masts from aluminium for these ships as well. Most of the personnel engaged on this works, today works in our Shipyard in Pula.

11 Business Profile of Tehnomont Shipyard Pula ltd

Our shipyard has been certified and possess workshop welding approvals for different type of ships and shipbuilding structures in steel and aluminium alloy from Croatian Register of Shipping (CRS), Bureau Veritas (BV) and GSI SLV München (certificates attached). In our WELDING DEPARTMENT we have two specialists with degree of International Welding Engineers (IWE/EWE) and two with degree of International Welding Specialist (IWS/EWS). They are responsible for quality of welding works, implementation of new welding technologies and permanent training and control of our welders and their quality. Training for welders is well organized in our Welding skilled professional school (shop). You can find in attachment, the certificates of our IWE engineers and IWS specialist. Services Having our main orientation toward shipbuilding of new vessels, our other services are based on ship repairing division, but that is not significant part of our incomes. Quality policy & objectives Our Management System is certified in accordance with requirements for the management system standard ISO 9001:2008 by Bureau Veritas (BV). Our CONTROL DEPARTMENT is highly skilled and disposes of all necessary equipment for quality control for the structure buildings and welding works (NDT, Ultrasonic and Penetrants). Business model TEHNOMONT SHIPYARD PULA Ltd model is based on functional and geographical organisation model. In the same time on lower organisational level project organisation model appears, especially in partial departments dealing with shipbuilding and ship repairing. Beside this main business, which take place in domestic region, our company have the obligation to support investment projects in foreign countries with reference to Germany through our branch of company. From above information it is traceable that our company is running the business in different locations, and that leads to forming a task team depending on the project needing. That is the reason that workers can be transferred from one company to another company in our group, depending on project conditions. In slightly lighter volume, the same appears in domestic production, with notice that within the company when ever new project (ship) occurs, we establish appropriate team. In charge to realisation of the project. In the case of providing a special services (welders, assemblers etc..) for the customers, similar situation of manpower transfer appears Management Management structure As the main business of our company is shipbuilding and ship repairing, the basing functions are organized accordingly, as divisions, and in the same time the book keeping, book accounting and administrative jobs are entrusted to company Tehnomont j.s.c.

12 Business Profile of Tehnomont Shipyard Pula ltd

Notice: Layout in charge from August 2011. Manager of Branch company in Germany is directly responsable to general manager Directors President of the board-Director: Miljenko Brnić m.d.eng Member of the board-Technical Director: Kristijan Ivančić m.d.eng Professionals & Advisors Incat Crowther Camarc Design SimTec Marine CADCON R-Project Bruce Roberts Europe BV Tomislav Smirčić Milan Koroman Customers & projects A list of customers, projects and contact details for reference separately. available upon request

Thank you for taking the time to go through this business profile. For any questions or comments, please feel free to contact us.