Building An Electronics Bay In The Cosmodrome Aerobee-Hi kit · Building An Electronics Bay In The...

Transcript of Building An Electronics Bay In The Cosmodrome Aerobee-Hi kit · Building An Electronics Bay In The...

Building An Electronics Bay In The Cosmodrome Aerobee-Hi kit

By Tim Van Milligan

Parts RequiredPerfectFlite Mini-Timer9Volt NiCad Battery9V battery connector and wireMounting board (1 inch X 4 inch long)

(2) BT-80 Tube couplers(1) 29mm heavy-wall Engine Mount tube (Apo-

gee P/N 31170 - please call to order)(1) Paper Straw (used as a wire conduit)(1) Cardstock to make centering rings (Apogee

P/N 44002)(4) Round Head, Slotted Machine Screws and

nuts. Size #4-40 X 1/4”

MaterialsFix-It Epoxy Clay3M Spray Mount adhesive1/4” drill bit and electric hand drillwood clamp

IntroductionThe purpose of this document is to fill in some

of the missing holes in the kit instructions that come with the Cosmodrome Aerobee-Hi rocket kit. Those instructions begin with the note about using a elec-tronic stager, but they do not tell you how you’ll need to modify the kit to accept the electronic stag-ing device.

These instructions will cover the installation of the PerfectFlite Mini-Timer (available from Apogee Components). If you are using other electronics, you may need to modify the size of the electronics bay length to accomodate the different length device.

I’m sorry if these instructions are not totally perfect and complete. I am writting them up quickly to get something available in the shortest amount of time. It is something that wish I had more time to de-vote to making them much better. But it is certainly better than what came with the kit.

Suggestions and Modifications To The Aerobee Hi kit

I like the engine retention method in the kit. But I don’t like using regular epoxy glue. It is too messy. I recommend using the Fix-it epoxy clay to hold down the metal threaded rods.

11.5

”8-5/8” Long straw for wires.

Electronic Payload4 inches long

Cut-out Reinforce-ment. Glued to inside of tube around panel opening.

Existing Plywood Centering Ring

New - Cardstock Centering Ring from pattern sheet

Existing Plywood Centering Ring

Outside body tube. Supplies with kit.

New - Cardstock Centering Ring from pattern sheet

29mm Heavy Wall Engine Tube(Apogee P/N 31170) 5.0 inches long

29mm Heavy Wall Engine Tube(Apogee P/N 31170) Cut ends using cutting pattern sheet.

29mm Engine Tube. Supplied with the kit.

I found the tube couplers on the kit to be very tight. I peeled off several layers of paper to get them to fit into the tube. After that, the wall was too thin. So I recommend taking the Apogee Components BT-80 tube coupler and using it to reinforce the inside of the tube coupler before you peel off the outside lay-ers. You’ll have to trim its length, and also remove a section so that it fits inside the coupler.

Building the New Engine Mount It would have been easy to put the electronics

in a bay between the centering rings of the engine mount tube. But unfortunately, we cannot do that because the PerfectFlite Staging Electronics and the baattery will not fit between the engine mount tube and the inside wall of the sustainer body tube. That means we have to put it ahead of the engine mount tube.

Putting it ahead of the engine tube would expose the delicate electronics to the heat of the ejection charge. So we need to protect it from that by ducting the ejection charge around the compartment holding the electronics. This is not the easiest thing to do, but it can be done if you have a little patience and follow my instructions.

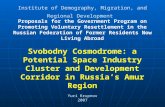

Figure 1 shows a drawing of the layout of the electronics bay and how the exhaust gases will be ducted around the compartment.

Figure 1: This is a drawing of how the en-gine mount tube will be constucted so that it ducts the exhaust gases around the com-partment holding the staging electronics.

The straw will allow wires to pass down through the rocket from the electronics bay to the base of the sustainer stage.

Dia

gona

l Tub

e C

uttin

g P

atte

rn

Cardstock Bulkheads

1.00

inch

es Step 1: From the 29mm heavy-wall Engine Mount tube (Apogee P/N 31170) cut the two new pieces. One will be 5.0 inches long. The other piece is the diagonal tube. Wrap the diagonal tube cutting guide around the tube and cut the tube on both ends.

5” Tube

Existing Engine Mount Tube

Diagonal Piece

Step 2: Coat the inside of the diagonal piece with Fix-it Epoxy clay to protect it from the heat of the ejection charge. Make the epoxy as thin as you possible can. OK, make it even thinner than that. It is important to make it very very thin so it doesn’t restrict the flow of the gases passing through it. Now go back and make it thinner yet.

Step 3: Tack glue the 5” tube to the diagonal piece using thick CA glue. Then mix up a small glob of Fix-It Epoxy and overlap the tubes on the in-side of the dog leg. Don’t go all the way around the outside of the tube, or it won’t rest tightly up against the inside of the big body tube in the kit.

Step 4: Transfer the bulkheads from the pattern sheet to a cardstock sheet, and cut them out with a sharp hobby knife.

Step 5: This is a critical step, because we need per-fect alignment on the tubes.

Temporarily put the two plywood rings from the kit on the engine mount tube (also from the kit). DO NOT GLUE.

Stand the sustainer tube upright on the floor, and slide the engine mount tube into the sustainer body tube from kit. Push it down deep into the tube so you can also position the dog-leg section from step three on top of it. MAKE SURE THE 5” SECTION OF TUBE RESTS STRAIGHT ALONG THE INSIDE EDGE OF THE TUBE. Then using thick-viscosity CA glue, tack the diagonal piece to the top end of the engine mount tube. Allow the glue to harden, and CAREFULLY pull it out of the sus-tainer body tube, and then remove the plywood rings. Reinforce the joint with more CA glue so it can’t break free.

Step 6: Mix up another small glob of Fix-It Epoxy Clay and reinforce the joint where the engine mount tube meets the diagonal tube.

Step 7: Stack the bulkhead disk with the small hole on top with the two plywood rings from the kit. Align the little notch on the cardstock ring with the notch on the one plywood ring. Clamp all the rings together, and drill a 1/4” hole through both of the plywood rings as shown below.

Step 8: The purpose of this step is to correctly posi-tion and glue the lower bulkhead onto the dog-leg engine mount assembly. DO NOT GLUE anything in this step until directed.

Temporarily slide the upper Plywood centering ring with the metal shock cord onto the engine mount tube that came with the kit. Then slide the lower plywood ring onto the tube too.

Slide the cardstock disk with the 1/4” hole onto the 5 inch portion of the engine mount tube. Remem-ber to thread the steel shock cord wire through the small hole as you slip it onto the tube. You can coil the excess shock cord wire up to keep it from getting in the way in this next part.

Stand the big sustainer body tube up on the floor. Slide the engine mount assembly into the tube. As you slide it down, rotate the cardstock bulk-head so that it aligns properly onto the tube.

At the same time, carefully slide the cardstock ring down the 5” portion of the engine tube so that it just touches the epoxy ring you put on the tube joint. You want this ring down as low as pos-sible on the engine tube.

When the bulkhead disk is properly positioned, tack glue the disk only to the engine mount tube using thick CA glue. Then carefully remove everything from the big sustainter tube.

Step 9: Remove the lower plywood centering ring from the assembly. Insert the paper straw through the top plywood centering ring. Rotate the plywood centering around until the straw is perfectly parallel with the engine tube. Tack glue the straw and the plywood ring into place using thick CA glue.

Step 10: Reinstall the bottom plywood centering ring onto the engine mount tube. Rotate the ring so the straw passes through the small hole on the ring. Slide the ring into the position on the tube as shown in the Cosmodrome kit instructions. Tack glue into place using thick CA glue.

Step 11: Using the same technique to align the bulkhead disk as done in step 8, go ahead and position and tack glue the forward bulkhead to the top of the 5 inch long engine mount tube. After removing it from the sustainer tube, you can apply a fillet of wood glue around the two cardstock bulkhead disks where they touch the engine mount tube.

Step 12: Mix up a small amount of Fix-it Epoxy Clay, and create fillets around the front plywood centering ring. This ring, and the area where the metal shock chord attach really take a lot of stress, so it needs to be very strong.

Step 13: You can now add the threaded rod engine retainer per the Cosmodrome instructions. I rec-ommend securing it in place with a little Fix-It Epoxy clay.

Step 14: Add a small amount of Fix-it epoxy clay around the hole on the forward side of the front bulkhead disk to prevent the steel cable from tearing into the cardstock.

Step 15: At this point, you can test fit your electron-ics between the two bulkheads at the top of the engine mount assembly. You can add mounting supports if you wish.

Step 16: Per the Cosmodrome instructions, cut the slots for the fin tabs in the aft end of the sus-tainer body tube.

Lay the competed engine mount assembly next to the outside of the body tube in the correct posi-tion. Mark on the outside of the sustainer tube the location of all the bulkheads and the ply-wood centering rings.

Step 17: Transfer the hatch cutting pattern (on the next page) to the tube. Center it between the two bulkhead disks and evenly between any two of the fin lines. Then carefully cut out the hatch access from the body tube using a sharp hobby knife.

Fin

Lin

e

Fin

Lin

e

Hatch Panelcutting pattern

Center betweenbulkheads

1 inch

Round the cornersfor a more

professional look

Step 18: This is another critcal step. It describes how to glue the engine mount assembly into the sus-tainer tube and get glue on all the rings.

Start by inserting the engine mount assembly into the sustainer body tube. Slide it far enough in so that the forward plywood ring is in the cut-out area of the hatch access.

Using a wood dowel, spread glue inside the tube where the forward plywood centering ring will be located. Use the marks on the outside of the tube (made in step 15) to help you guage the depth needed for insertion.

While the glue is still wet, slide the engine mount back so it is in the correct location. Also adjust the radial location so the volume is maximized for the electronics, and also so the paper straw will not interfere with the fin tab.

Step 20: Working through the hatch access hole, you can apply a fillet of glue to the aft and forward bulkhead disks as show below.

Aft End

Aft End

Step 21: Cut strips of lightweight cardboard about 1/2 inch wide and long enough to just touch both bulkhead disks inside the electronics bay. Glue these on each side of the hatch opening so that the cover will not fall through. Be sure the opening is large enough so you can still get your electronics in and out of the rocket.

Step 22: Go ahead and complete the rest of the as-sembly of the rocket as directed in the Cosmo-drome instructions.

Step 23: When you’re ready to paint, use double-sid-ed tape to temporarily position the hatch cover on the rocket. This can be pryed off later after the paint is dry.

Step 24: Using a small drill, make pilot holes in each corner of the hatch cover and the cardstock rails. Enlarge the holes so the small posts of the machine screws will easily pass through.

Put a machine screw in each corner hole, and hold in place with the nut on the inside of the tube.

Step 25: Using a small amount of Fix-It epoxy clay, attach the nut on the inside of the tube against the inside wall. Make sure not to get any epoxy on the threads of the screw. After the epoxy has hardened, remove the screw.

Epoxy Clay

Step 25: The hatch cover can now be installed and secured in place with the four corner screws. This completes the assembly of the electronics bay of your Aerobee-Hi kit.

This booklet of tips, assembly instructions and scale data is produced as a courtesy for the custom-ers of Apogee Components, Inc. We appreciate your patronage, and we want you to build and fly the best looking model rockets.

Please let us know what you think. Contact us via our web site at:

http://www.ApogeeRockets.com

Apogee Components, Inc.3355 Fillmore Ridge HeightsColorado Springs, CO 80907 USA

Scale DataHere is some pictures of a couple of museum pieces. The top

is at the space museum in Alamogordo, New Mexico. The bottom is at the National Air and Space Museum in Washington DC.