Builder 3&2 VOL 02 -14044

-

Upload

chad-vanwinkle -

Category

Documents

-

view

225 -

download

0

Transcript of Builder 3&2 VOL 02 -14044

-

8/8/2019 Builder 3&2 VOL 02 -14044

1/353

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

NONRESIDENTTRAINING

COURSEMarch 1994

Builder 3 & 2, Volume 2NAVEDTRA 14044

-

8/8/2019 Builder 3&2 VOL 02 -14044

2/353

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

Although the words he, him, andhis are used sparingly in this course toenhance communication, they are notintended to be gender driven or to affront ordiscriminate against anyone.

-

8/8/2019 Builder 3&2 VOL 02 -14044

3/353

COMMANDING OFFICERNETPDTC

6490 SAUFLEY FIELD RDPENSACOLA, FL 32509-5237

ERRATA #l 16 Aug 1999

Specific Instructions and Errata forNonresident Training Course

BUILDER 3 & 2, VOLUME 2

1. This errata supersedes all previous erratas. No attempt has been made toissue corrections for errors in typing, punctuation, etc., that do not affectyour ability to answer the question or questions.

2. To receive credit for deleted questions, show this errata to your localcourse administrator (ESO/scorer). The local course administrator isdirected to correct the course and the answer key by indicating the questionsdeleted.

3. Assignment Booklet

Delete the following questions, and leave the corresponding spaces blankon the answer sheets:

Questions

2-432-74

3-704-404-444-654-665-155-25

-

8/8/2019 Builder 3&2 VOL 02 -14044

4/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

5/353

i

PREFACE

By enrolling in this self-study course, you have demonstrated a desire to improve yourself and the Navy.Remember, however, this self-study course is only one part of the total Navy training program. Practicalexperience, schools, selected reading, and your desire to succeed are also necessary to successfully round

out a fully meaningful training program.THE COURSE : This self-study course is organized into subject matter areas, each containing learningobjectives to help you determine what you should learn along with text and illustrations to help youunderstand the information. The subject matter reflects day-to-day requirements and experiences of personnel in the rating or skill area. It also reflects guidance provided by Enlisted Community Managers(ECMs) and other senior personnel, technical references, instructions, etc., and either the occupational ornaval standards, which are listed in the Manual of Navy Enlisted Manpower Personnel Classificationsand Occupational Standards , NAVPERS 18068.

THE QUESTIONS : The questions that appear in this course are designed to help you understand thematerial in the text.

VALUE : In completing this course, you will improve your military and professional knowledge.Importantly, it can also help you study for the Navy-wide advancement in rate examination. If you arestudying and discover a reference in the text to another publication for further information, look it up.

1994 Edition Prepared by BUCS(SCW) John Buza

Published byNAVAL EDUCATION AND TRAINING

PROFESSIONAL DEVELOPMENTAND TECHNOLOGY CENTER

NAVSUP Logistics Tracking Number0504-LP-026-7190

-

8/8/2019 Builder 3&2 VOL 02 -14044

6/353

ii

Sailors Creed

I am a United States Sailor.

I will support and defend theConstitution of the United States of

America and I will obey the ordersof those appointed over me.

I represent the fighting spirit of theNavy and those who have gonebefore me to defend freedom anddemocracy around the world.

I proudly serve my countrys Navycombat team with honor, courageand commitment.

I am committed to excellence andthe fair treatment of all.

-

8/8/2019 Builder 3&2 VOL 02 -14044

7/353

C O N T E N T S

CHAPTER Page

1. Light Floor and Wall Framing . . . . . . . . . . . . . . . . . .1-1

2. Roof Framing . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

3. Roof Construction and Trim Carpentry . . . . . . . . . . . . . . . .3-1

4. Exterior Finish of Walls . . . . . . . . . . . . . . . . . . . . . .4-1

5. Interior Finish of Walls and Ceilings . . . . . . . . . . . . . . . . .5-1

6. Interior Finish of Floors, Stairs, Doors, and Trim . . . . . . . . . .6-1

7. Plastering, Stuccoing, and Ceramic Tile . . . . . . . . . . . . . . .7-1

8. Structural Coatings and Preservatives . . . . . . . . . . . . . . . . 8-1

9. Advanced Base Field Structures and Embarkation . . . . . . . . . .9-1

10. Heavy Construction . . . . . . . . . . . . . . . . . . . . . . .10-1

APPENDIX

I. Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AI-1II. References Used to Develop the TRAMAN . . . . . . . . . . . AII-1

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INDEX-1

i i i

-

8/8/2019 Builder 3&2 VOL 02 -14044

8/353

SU MMARY OF THERATE TRAINING

BU ILDER 3&2MANUALS

VOLUME 1

Builder 3&2, Volume 1, NAVEDTRA 14043, is a basic book that should bemastered by those seeking advancement to Builder Third Class and Builder SecondClass. The major topics addressed in this book include construction administrationand safety; drawings and specifications; woodworking tools, materials and methodsof woodworking; fiber line, wire rope, and scaffolding; leveling and grading;concrete; placing concrete; ma sonry; and plannin g, estimat ing, and scheduling.

VOLUME 2

Builder 3&2, Volume 2, NAVEDTRA 14044, continues wher e Volume 1 ends.The topics covered in this volume include floor and wall construction; roof framing;exterior and interior finishing; plastering, stuccoing, and ceramic tile; paints andpreservatives; advanced base field structures; and heavy construction.

iv

-

8/8/2019 Builder 3&2 VOL 02 -14044

9/353

v

INSTRUCTIONS FOR TAKING THE COURSE

ASSIGNMENTS

The text pages that you are to study are listed atthe beginning of each assignment. Study thesepages carefully before attempting to answer thequestions. Pay close attention to tables andillustrations and read the learning objectives.The learning objectives state what you should beable to do after studying the material. Answeringthe questions correctly helps you accomplish theobjectives.

SELECTING YOUR ANSWERS

Read each question carefully, then select theBEST answer. You may refer freely to the text.The answers must be the result of your ownwork and decisions. You are prohibited fromreferring to or copying the answers of others andfrom giving answers to anyone else taking thecourse.

SUBMITTING YOUR ASSIGNMENTS

To have your assignments graded, you must beenrolled in the course with the NonresidentTraining Course Administration Branch at theNaval Education and Training ProfessionalDevelopment and Technology Center(NETPDTC). Following enrollment, there aretwo ways of having your assignments graded:(1) use the Internet to submit your assignmentsas you complete them, or (2) send all theassignments at one time by mail to NETPDTC.

Grading on the Internet: Advantages toInternet grading are:

you may submit your answers as soon asyou complete an assignment, and

you get your results faster; usually by thenext working day (approximately 24 hours).

In addition to receiving grade results for eachassignment, you will receive course completionconfirmation once you have completed all the

assignments. To submit your assignmentanswers via the Internet, go to:

http s ://courses.cnet.navy.mil

Grading by Mail: When you submit answersheets by mail, send all of your assignments atone time. Do NOT submit individual answersheets for grading. Mail all of your assignmentsin an envelope, which you either provideyourself or obtain from your nearest EducationalServices Officer (ESO). Submit answer sheetsto:

COMMANDING OFFICERNETPDTC N3316490 SAUFLEY FIELD ROADPENSACOLA FL 32559-5000

Answer Sheets: All courses include onescannable answer sheet for each assignment.These answer sheets are preprinted with yourSSN, name, assignment number, and coursenumber. Explanations for completing the answersheets are on the answer sheet.

Do not use answer sheet reproductions: Useonly the original answer sheets that weprovidereproductions will not work with ourscanning equipment and cannot be processed.

Follow the instructions for marking youranswers on the answer sheet. Be sure that blocks1, 2, and 3 are filled in correctly. Thisinformation is necessary for your course to beproperly processed and for you to receive creditfor your work.

COMPLETION TIME

Courses must be completed within 12 monthsfrom the date of enrollment. This includes timerequired to resubmit failed assignments.

-

8/8/2019 Builder 3&2 VOL 02 -14044

10/353

vi

PASS/FAIL ASSIGNMENT PROCEDURES

If your overall course score is 3.2 or higher, youwill pass the course and will not be required toresubmit assignments. Once your assignmentshave been graded you will receive coursecompletion confirmation.

If you receive less than a 3.2 on any assignmentand your overall course score is below 3.2, youwill be given the opportunity to resubmit failedassignments. You may resubmit failedassignments only once. Internet students willreceive notification when they have failed anassignment--they may then resubmit failedassignments on the web site. Internet studentsmay view and print results for failedassignments from the web site. Students who

submit by mail will receive a failing result letterand a new answer sheet for resubmission of eachfailed assignment.

COMPLETION CONFIRMATION

After successfully completing this course, youwill receive a letter of completion.

ERRATA

Errata are used to correct minor errors or delete

obsolete information in a course. Errata mayalso be used to provide instructions to thestudent. If a course has an errata, it will beincluded as the first page(s) after the front cover.Errata for all courses can be accessed andviewed/downloaded at:

ht tp s : / /www. advancement .cnet .navy.mi l

STUDENT FEEDBACK QUESTIONS

We value your suggestions, questions, and

criticisms on our courses. If you would like tocommunicate with us regarding this course, weencourage you, if possible, to use e-mail. If youwrite or fax, please use a copy of the StudentComment form that follows this page.

For subject matter questions:

E-mail: [email protected]: Comm: (850) 452-1001, Ext. 1826

DSN: 922-1001, Ext. 1826FAX: (850) 452-1370(Do not fax answer sheets.)

Address: COMMANDING OFFICERNETPDTC (CODE N314)6490 SAUFLEY FIELD ROADPENSACOLA FL 32509-5237

For enrollment, shipping, grading, orcompletion letter questions

E-mail: [email protected]: Toll Free: 877-264-8583

Comm: (850) 452-1511/1181/1859

DSN: 922-1511/1181/1859FAX: (850) 452-1370(Do not fax answer sheets.)

Address: COMMANDING OFFICERNETPDTC (CODE N331)6490 SAUFLEY FIELD ROADPENSACOLA FL 32559-5000

NAVAL RESERVE RETIREMENT CREDIT

If you are a member of the Naval Reserve, youwill receive retirement points if you are

authorized to receive them under currentdirectives governing retirement of NavalReserve personnel. For Naval Reserveretirement, this course is evaluated at 9 points.(Refer to Administrative Procedures for Naval

Reservists on Inactive Duty, BUPERSINST1001.39, for more information about retirementpoints.)

COURSE OBJECTIVES

In completing this nonresident trainingcourse, you will demonstrate a knowledge of the subject matter by correctly answeringquestions on the following: floor and wallconstruction; roof framing; exterior andinterior finishing; plastering, stuccoing, andceramic tile; paints and preservatives;advanced base field structures; and heavyconstruction.

-

8/8/2019 Builder 3&2 VOL 02 -14044

11/353

vii

Student Comments

Course Title: Builder 3 & 2, Volume 2

NAVEDTRA: 14044 Date :

We need some information about you :

Rate/Rank and Name: SSN: Command/Unit

Street Address: City: State/FPO: Zip

Your comments, suggestions, etc .:

Privacy Act Statement: Under authority of Title 5, USC 301, information regarding your military status isrequested in processing your comments and in preparing a reply. This information will not be divulged withoutwritten authorization to anyone other than those within DOD for official use in determining performance.

NETPDTC 1550/41 (Rev 4-00)

-

8/8/2019 Builder 3&2 VOL 02 -14044

12/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

13/353

CHAPTER 1

LIGHT FLOOR AND WALL FRAMING

In the n ormal sequen ce of constru ction events, th efloor and wall activities follow the completedfoun dat ion work. In th is chapt er, well exam ineestablished methods of frame construction and discussin general how floor and wall framing members areassembled. An explanation of subflooring installation,exterior sheathing, interior partitions, and roughopenings for doors and windows is also given.

WOOD S ILL FRAMING

LEARNING OBJECTIVE: Upon completingthis section, you should be able to describe silllayout and installation.

Fr am ing of the str uctur e begins a fter completion of the foundation. The lowest member of the framestru cture rest ing on the foundation is th e sill plate, oftencalled the mud sill. This sill provides a roiling base for

joists or studs resting directly over the foundation. Work

in this area is critical as it is the real point of departurefor actual building activities.

LAYOUT

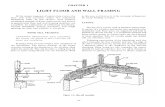

The box sill is usually used in platform construction.It consists of a sill plate and header joist an chored to th efoundation wall. Floor joists are supported and held inposition by the box sill (fig. 1-1). Insulation material andmeta l termit e shields are placed under t he sill if desiredor when specified. Sills are usually single, but doublesills are sometimes used.

Following construction of the foundation wall, thesill is normally the first member laid out. The edge of the sill is setback from the outside face of the foundationa distance equal to the thickness of the exteriorsheathing. When laying out sills, remember the comersshould be halved together, but are often butted ormitered. If splicing is necessary to obtain required

Figure 1-1.Box-sill assembly.

1-1

-

8/8/2019 Builder 3&2 VOL 02 -14044

14/353

Figure 1-2.Anchor bolt layout.

length, you should halve the splice joint at least 2 feetand bolt together.

Once the required length has been determined, thenext step is to lay out the locations of the anchor boltholes.

1.

2.

3.

4.

5.

Use the following steps:

Establish the building line points at each of thecorner s of the foun dation.

Pull a chalk line at these established points andsnap a line for the location of the sill.

Square the ends of the sill stock, (Stock receivedat jobsites is not necessarily squared at bothends.)

Place the sill on edge and mark the locations of the anchor bolts.

Extend these mar ks with a squa re across thewidth of the sill. The dista nce X in figure 1-2

shows how far from the edge of the sill to bore

Figure 1-4.Installing termite shields.

the holes; that is,X equals the thickness of thexterior sheathing.

After all the holes are marked, bore the holes. Ea

should be about 1/4 inch larger than the diameter of bolts to allow some adjustment for slight inaccuracin th e layout. As each section is bored, position th atsection over the bolts.

When all sill sections are fitted, remove them froth e an chor bolts. Insta ll sill sealer (insulat ion) as shoin figure 1-3. The insulation compresses, filling theirregularities in the foundation. It also stops drafts areduces heat loss. Also install a termite shield (fig. 1-if specified. A termite shield should be at least 26-gaualuminum, copper, or galvanized sheet metal. The out

edges should be slightly bent down. Replace the sills a

Figure 1-3.Installing sill sealer.

1-2

-

8/8/2019 Builder 3&2 VOL 02 -14044

15/353

Figure 1-5.Methods of sill fastening to foundations.

Figure 1-6.Spacing of anchor bolts.

install the washers and nut s. As the nu ts ar e t ightened,ma ke sur e th e sills are pr operly aligned. Also, check th edistance from the edge of the foundation wall. The sillmust be level and straight. Low spots can be shimmied

with wooden wedges, but it is better to use grout ormortar.

FASTENIN G TO FOUND ATION WALLS

Wood sills are fastened to masonry walls by1/2-inch anchor bolts. These bolts, also known as j-boltsbecause of their shape, should be embedded 15 inchesor more into the wall in unreinforced concrete (fig. 1-5,

view A) and a minimum of 7 inches into reinforced

concrete (view B). The length of the anchor bolt is foundin t he sp ecifications; the sp acing an d locat ion of the

bolts are shown on the drawings. If this information isnot available, anchor bolt spacing should not exceed 6feet on center (OC). Also, a bolt must be placed within1 foot of the ends of each piece (as shown in fig. 1-6).

There are alternative ways to fasten sill plates tofoundations. Location and building codes will dictatewhich to use. Always consult the job specifications

before proceeding with construction.

1-3

-

8/8/2019 Builder 3&2 VOL 02 -14044

16/353

Figure 1-7.Basic components of floor framing.

Figure 1-8.Floor framing on sill plates with intermediate posts and built-up girders.

FLOOR FR AMING Floor framing consists specifically of the posts,girders, joists, and subfloor. When these are assemble

LEARNING OBJECTIVE: Upon completing as in figure 1-7, they form a level anchored platform fthe rest of the construction.this section, you should be able to identify

members used in floor construction, and the POSTS

construction m ethods u sed with subfloor and Wood or steel posts and girders support floor joisbridging. an d th e subfloor. Sizes depend on th e loads carr ied. T

1-4

-

8/8/2019 Builder 3&2 VOL 02 -14044

17/353

Figure 1-9.Post fastened using dow el method.

Figure 1-10.Metal base plates for wood posts.

dimensions and locations are shown on the foundationplan. When required, posts give central support to thelong span of girders. Also, girders can be used to supportother girders. There should be at least 18 inchescleara nce between th e bottoms of the floor joists a nd t heground and at least 12 inches between the bottom of thegirder and the ground (fig. 1-8).

Wood

Wood posts are placed directly below wood girders.As a genera l rule, the width of the wood post sh ould beequal to the width of the girder it supports. For example,a 4-inch-wide girder requires a 4- by 4- or 4- by 6-inchpost.

A wood post can be secured to a concrete pillar inseveral ways. The post can be nailed to a pier block secured t o the t op of a concrete pier; it can be placedover a previously inserted 1/2-inch steel dowel in theconcrete; or, it can be placed into a metal base set intothe concrete pier at the time of the pour. When usingthe dowel method, make sure the dowel extends at least3 inches into the concrete and the post, as shown infigure 1-9. A metal base embedded in the concrete(fig. 1-10) is the preferred method since nothing else isneeded to secure the base.

As with t he bottom of the post, th e top must also besecured to the girder. This can be done using angle ironbrackets or metal plates. Figure 1-11 shows two metalpost caps used with posts and girders, either nailed orbolted to the girders.

Figure 1-11.Metal post caps.

1-5

-

8/8/2019 Builder 3&2 VOL 02 -14044

18/353

Figure 1-12.Bolting of steel column.

Steel

Steel pipe column s ar e often used in wood-frameconstruction, with both wood and steel girders. When

using wood girders, secure the post to the girder withlag bolts. For steel girders, machine bolts are required.

The base of the steel post is bolted to the top of the pas shown in figure 1-12. The post can also be boltedanchor bolts inserted in the slab prior to pouring.

GIRDERS

Girders are classified as bearing and nonbeariaccording to the amount and type of load supported.

Bearing girders m ust support a wall fram ed directlyabove, as well as the live load and dead load of the floNonbearing girders support just the dead and live loaof the floor system directly above. The dead load is tweight of the mat erial used for the floor u nit it self. Tlive load is the weight created by people, furniture,appliances, and so forth.

Wood

Wood girders may be a single piece of timber, orthey may be laminated (that is, built up) of more thone plank. The built-up girder in figure 1-13, forexample, consist s of th ree 2- by 12-inch plan ks. The

Figure 1-13.Built-up girder.

1-6

-

8/8/2019 Builder 3&2 VOL 02 -14044

19/353

Figure 1-14.Spaced wood girders.

joints between the planks are staggered. In framing, abuilt-up girder is placed so that the joints on the outsideof the girder fall directly over a post. Three 16-penny(16d) nails ar e driven at t he ends of the plan ks, and othernails are staggered 32 inches OC. As shown in figure1-13, the top of the girder is flush with the top sill plate.

When space is required for heat ducts in a partition

supported on a girder, a spa ced wood girder, such as th atshown in figure 1-14, is sometimes necessar y. Solidblocking is used at intervals between the two members.A single-post support for a spaced girder usuallyrequires a bolster, preferably metal, with a sufficientspan to support the two members.

The ends of a girder often rest in pockets preparedin a concrete wall (fig. 1-13). Here, the girder ends mustbear at least 4 inches on the wall, and the pocket shouldbe large enough to provide a 1/2-inch air space aroundthe sides and end of the girder. To protect against

termites, treat the ends of the girder with a preservative.As a further precaution, line the pockets with metal.

Steel

S-beams (standard) or W-beams (wide flange), bothshown in figure 1-15, are most often used as girders inwood-framed construction. Whether the beam is wood

or steel, make sure it aligns from end to end and side toside. Also mak e sure the length of th e bearing post un derthe girder is correct t o ensure t he girder is pr operlysupported.

PLACING P OSTS AND GIRDERS

Posts must be cut to length and set up before thegirders can be installed. The upper surface of the girdermay be in line with th e founda tion plate sill, or t he girderends may rest on top of the walls. Long girders must be

Figure 1-15Types of steel be ams.

1-7

-

8/8/2019 Builder 3&2 VOL 02 -14044

20/353

Figure 1-16.Header joist.

placed in sections. Solid girders must be measured andcut so tha t t he ends fall over th e center of a post. Built-upgirders should be placed so their outside joints fall overthe posts (fig. 1-13).

FLOOR JOISTS

In platform framing, one end of the floor joistres ts di rect ly on the s i l l p la te of the exter iorfoun dation wall or on th e top plate of a framed out sidewall. The bearing should be at least 1 1/2 inches. Theopposite end of the joist laps over or butts into an

interior girder or wall. The size of joist material (2 by6, 2 by 10, 2 by 12, and so forth) must be chosen withconsiderat ion for t he span an d th e amount of load t obe car ried. The founda tion plan u sua lly specifies th e

joist size, the spacing between joists, and whatdirection the joists should travel.

The u sua l spa cing of floor joists is 16 inches OC.Floor joists are supported and held in position overexterior walls by header joists or by solid blockingbetween th e joists. The hea der-joist system is used m ostoften.

Header

Header joists ru n a long th e outside walls. Three 16dnails are driven through the header joists into the endsof the common joists, as shown in figure 1-16. Theheader and joists ar e toenailed to the sill with 16d na ils.The header joists prevent the common joists from

Figure 1-17.Lapped joists.

rolling or tipping. They also help support the wall abovan d fill in t he spa ces between the common joists.

Lapped

Joists are often lapped over a girder running dowthe center of a building. The lapped ends of the joismay also be supported by an interior foundation orframed wall. It is stan dard procedure t o lap joists th e fuwidth of the girder or wall. The minimum lap should b4 inches. Figure 1-17 shows lapped joists resting on steel girder. A 2- by 4-inch plate has been bolted to thtop of a steel beam. The joists are toenailed into the pSolid blocking may be inst alled between t he lapped end

after all the joists have been nailed down. Anothersystem is to put in the blocks at the time the joists arplaced.

Double

Joists should be doubled under pa rtit ions ru nning ithe same direction as the joists. Some walls have watepipes, vent stacks, or heating ducts coming up from thbasem ent or th e floor below. Place bridging bet weendouble joists to allow space for these purposes(fig. 1-18).

Cantilevered

Cant ilevered joists a re u sed when a floor or ba lconof a building projects past the wall below, as shown ifigure 1-19. A head er piece is nailed to th e ends of th

1-8

-

8/8/2019 Builder 3&2 VOL 02 -14044

21/353

Figure 1-18.Double joists.

Figure 1-19.Cantilevered joists.

1-9

-

8/8/2019 Builder 3&2 VOL 02 -14044

22/353

Figure 1-20.Framing for cantilevered joists.

joists. When regular floor joists run parallel to theintended overhang, the inside ends of the cantilevered

joists are fastened to a pair of double joists (fig. 1-20).Nailing should be through the first regular joist into theends of the cantilevered joists. Framing anchors arestrongly recommended and often required by the

specifications. A header piece is also nailed to theoutside ends of the cantilevered joists.

Butted over a Girder

J oist ends can a lso be butted (rather th an lappedover a girder. The joists should then be cleated togethewith a metal plate or wooden cleat, as shown in

Figure 1-21.Butting joists over a girder. Figure 1-22.Butting Joists against a girder.

1-10

-

8/8/2019 Builder 3&2 VOL 02 -14044

23/353

Figure 1-23.Joists supported by steel beams.

figure 1-21. These can be left out if th e line of panelsfrom the plywood subfloor str addles th e but t joints.

Butted against a Girder

Butting joists against (rath er t han over) a girderallows more headroom below the girder. When it isnecessary for the underside of the girder to beflush with the joists to provide an unbroken ceilingsurface, the joists should be supported with joisthangers (fig. 1-22).

Blocking be tween Jo is t s

Another system of providing exterior support to joists is to place solid blocking between the outside endsof the joists. In this way, the ends of the joists have morebearing on the outside walls.

Interior Support

Floor joists u sua lly ru n a cross t he full width of thebuilding. However, extremely long joists are expensive

Figure 1-24.Joists supported on steel plates.

and difficult to handle. Therefore, two or more shorter joists are usually used. The ends of these joists aresupported by lapping or butting them over a girder,butting them against a girder, or lapping them over awall.

Suppor ted by a Stee l Beam

Wood joists ar e often support ed by a st eel beamrather than a wood girder. The joists may rest ontop of the steel beam (fig. 1-23, view A), or theymay be butted (and notched to fit) against the sidesof the beam (view B). If the joists rest on top of a

steel beam, a plate is fastened to the beam and the joists are toenailed into the plate. When joists arenotched to f i t against the s ides of the beam,allowance must be made for joist shrinkage whilethe steel beams remain the same size. For averagework with a 2- by 10-inch joist, an allowance of 3/8inch above the t op flange of th e steel girder or beamis usually sufficient.

Another method of attaching butted joists to asteel girder is shown in figure 1-24. A 3/8-inchspace i s shown above the beam to a l low fo rshrinkage. Notching the joists so they rest on thelower flange of an S-beam is not recommended; theflange surface does not provide sufficient bearingsurface. A wide plate may be bolted or welded tothe bo t tom of the S -beams to p rov ide be t t e rsupport . Wooden blocks may be placed a t thebottoms of the joists to help keep them in position.Wi d e - f l a n g e d b e a m s , h o w e v e r , d o p r o v i d esuff i c i en t suppor t su r face fo r th i s me thod o f

1-11

-

8/8/2019 Builder 3&2 VOL 02 -14044

24/353

Figure 1-25.Joists supported by S-beam using wooden blocks.

construction. Figure 1-25 shows the lapped (view A) andbutt (view B) methods of framing over girders.

Bridging be tween Jo is t s

Floor plans or specifications usually call forbridging between joists. Bridging holds the joists in lineand helps distribute t he load carried by the floor unit. It

is usually required when the joist spans are more than 8feet. J oists spa nning between 8 a nd 15 feet need one rowof bridging at the center of the span. For longer spans,two rows of bridging spaced 6 feet ap art are required.

C R O S S B R I D G I N G . A l s o k n o w n a sherringbone bridging, cross bridging usually consists of 1- by 3-inch or 2- by 3-inch wood. It is installed asshown in figure 1-26. Cross bridging is toenailed at each

Figure 1-26.Wood cross bridging.

end with 6d or 8d nails. Pieces are usually precut on aradial-arm saw. Nails are started at each end before thecross bridging is placed between the joists. The usualprocedure is to fasten only the top end of the crossbridging. The na ils at th e bottom en d are n ot driven inuntil the subfloor has been placed. Otherwise the joistcould be pu shed out of line when t he bridging is na iledin .

An efficient method for initial placement of crossbridging is shown in figure 1-26. In st ep 1, snap a cha lkline where th e bridging is to be nailed between the joists.In step 2, moving in one direction, stagger and nail the

1-12

-

8/8/2019 Builder 3&2 VOL 02 -14044

25/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

26/353

Figure 1-29.Floor joists layout.

Figure 1-30.Comp1ete layout for floor joists.

Joists should be laid out so that the edges of edge of the building. From then on, the layout is 16standard-size subfloor panels break over the centers of inches OC. A layout for th e ent ire floor is sh own inthe joists (see insert, fig. 1-29). This layout eliminates figure 1-30.additional cutting of panels when they are being fitted Most of the framing members should be precutand nailed into place. One method of laying out joists before construction begins. The joists should all bethis way is t o mark the first joists 15 1/4 inches from t he trimmed to their pr oper lengths. Cross bridging and

1-14

-

8/8/2019 Builder 3&2 VOL 02 -14044

27/353

Figure 1-31.Steps in framing a floor opening.

solid blocks should be cut to fit between the joists having of stren gth in th e area of the opening. You need to frame

a common spacing. The distance between joists is the opening in a way that restores this strength. Theusu ally 14 1/2 inches for joists spaced 16 inches OC. procedure is shown in figure 1-31. Refer to the figure asBlocking for t he odd spa ces is cut afterwar ds. you study the following steps:

Framing Floor Openings 1. Measure and mark the positions of the trimmers

Floor openings, where st airs rise to th e floor or large on the outside wall and interior wall or girder.

duct work passes through, require special framing. 2. Position and fasten the inside trimmers and mark

When t he joists a re cut for su ch openings, ther e is a loss the position of the double headers.

1-15

-

8/8/2019 Builder 3&2 VOL 02 -14044

28/353

3.

4.

5.

6.

Figure 1-32.Types of framing anchors.

Place the outside pieces between the insidetrimmers. Drive three 16d nails through thetrimm ers into the hea ders. Mark th e position of

the tail joists on the headers (the tail joists shouldfollow t he regular joist layout).

Fasten the tail joists to the outside headers withthr ee 16d nails driven th rough the headers int othe ends of the tail joists.

Double the hea der. Drive three 16d nails th roughthe trimmer joists into the ends of the doubledheader pieces. Nail the doubled header pieces toeach other with 16d nails staggered 16 inchesOC .

Double the trimmer joists and fasten themtogether with 16d nails staggered 16 inches OC.

A pair of joists, called trimmers, is placed at eachside of the opening. These trimm ers support t he hea ders.The headers should be doubled if the span is more than4 feet. Nails supporting the ends of the headers aredriven through the trimmer joists into the ends of theheader pieces. Tail joists (cripple joists) run from theheader to a supporting wall or girder. Nails are driventhr ough t he hea der into th e ends of the ta il joist. Variousmetal anchors, such as those shown in figure 1-32, arealso used to strengthen framed floor openings.

Crowns

Most joists have a crown (a bow shape) on one side.Each joist should be sighted before being nailed in placeto make certain the crown is turned up. The joist willlater settle from the weight of the floor and straightenout. Caution should be exercised when sighting the

board for the crown. Some crowns a re t oo large an dcannot be turn ed up for u se as a joist.

SUBFLOOR

The subfloor, also known as rough flooring, isnailed to the top of the floor frame. It strengthens theentire floor unit and serves as a base for the finish floor.The walls of the building are laid out, framed, and raisedinto place on top of the subfloor.

Panel products, such as plywood, are used forsubflooring. Plywood is less labor in ten sive tha n boar dlumber.

Plywood is the oldest type of panel product. It is st ill

the most widely used subfloor mat erial in r esidential a ndother light-framed construction. Other types of materialavailable for use as subflooring include nonveneered(reconstituted wood) panels, such as structuralparticleboard, waferboard, oriented strandboard, andcompositeboard.

Plywood is available in many grades to meet abroadrange of end uses. All interior grades are also availablewith fully waterproof adhesive identical with that usedin exterior plywood. This type is useful where prolongedmoisture is a hazard. Examples are un derlayments,

subfloors adjacent to plumbing fixtures, and roof sheathing that may be exposed for long periods duringconstruction. Under normal conditions and forsheathing used on walls, standard sheathing grades aresatisfactory.

Plywood suitable for the subfloor, such as standardsheathing, structural I and II, and C-C exterior grades,has a panel identification index marking on each sheet.

1-16

-

8/8/2019 Builder 3&2 VOL 02 -14044

29/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

30/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

31/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

32/353

Figure 1-36.Types of bracing.

nailed between the sill and soleplate. Additional cripple requirement is an outside wall covered with structuralstuds may be placed under each end of the sill.

sheathing nailed according to building specifications.

BracingThis t ype of wall does not requ ire bra cing.

Diagonal bracing is most effective when installed a ta 45 to 60 an gle. You can do this a fter th e wall has

Diagonal bracing is necessary for the lateral been squared and still lying on the subfloor. The moststren gth of a wall. In all exterior walls and ma in inter ior widely used bra cing system is the 1 by 4 let-in t ype, aspartitions, bracing should be placed at both ends (where shown in figure 1-36. The studs are notched so that thepossible) and at 25-foot intervals. An exception to this 1 by 4 piece is flush with the surface of the studs.

1-20

-

8/8/2019 Builder 3&2 VOL 02 -14044

33/353

Figure 1-37.Fire blocking.

Cut-in bracing (fig. 1-36) is another type of diagonalbracing. It us ually consists of 2 by 4s cut a t a n a ngle andtoenailed between st uds a t a diagonal from t he top of acorner post down to the soleplate.

Diagonal sheathing (fg. 1-36) is the strongest typeof diagonal br acing. Ea ch boar d acts as a brace for t hewall. When plywood or other panel sheathing is used,other methods of bracing maybe omitted.

Fire stops

Most local building codes require fire stops (alsoknown as fire blocks) in walls over 8 foot 1 inch high.Fire stops slow down fire travel inside walls. They canbe nailed between the studs before or after the wall israised. Fire stops can be nailed in a straight line orstaggered for easier nailing. Figure 1-37 shows a sectionof a framed wa ll with fire st ops.

It is not necessary to nail fire stops at the midpointof the wall. They can be positioned to provide additionalbacking for nailing the edges of drywall or plywood.

CONSTRUCTION

All major components of a wall should be cut beforeassembly. By reading the blueprints, you can determinethe number of pieces and lengths of all components. Thedifferent part s of the wall are t hen a ssembled. Any hard,level surface can be used for assembly. After completingnailing, raise the walls in place for securing.

Two layout procedures are used in wall layout:horizontal plate and vertical layout. In horizontal platelayout, the location of the wall is determined from thedimensions found in the floor plan of the blueprints. Forvertical layout, the dimension can be found in thesectional views of the buildings blueprints.

1-21

-

8/8/2019 Builder 3&2 VOL 02 -14044

34/353

Figure 1-38.Layout and cutting of plates.

Figure 1-39.Marking inside and outside corners.

1-22

-

8/8/2019 Builder 3&2 VOL 02 -14044

35/353

Figure 1-40.First exterior wall stud layout.

Figure 1-41.Second exterior wall stud layout.

Horizonta l P la te Layout

After all the lines are snapped, the wall plates are

cut and tacked next to the lines (fig. 1-38). The platesare then marked off for corner posts and regular studs,

as well as for the studs, trimmers, and cripples for therough openings. All framing members must be clearlymarked on the plates. This allows for efficient and

error-free framing. Figure 1-37 shows a wall with

framin g members na iled in pla ce according t o layout

markings.

A procedure for marking outside and inside comersfor stud-and-block corner post construction is shown infigure 1-39. For laying out stu ds for t he first ext eriorwall, see figure 1-40. In figure 1-40, the plates aremarked for the first stud from a corner to be placed 151/4 inches from the end of the turner. Studs after the firststud follow 16 inches OC layout. This ensures the edgesof standard-size panels used for sheathing or wallboardfall on the centers of the studs. Cripples are laid out tofollow the layout of the studs.

A procedure for laying out studs for the secondexterior wall is shown in figure 1-41. The plat es ar e

1-23

-

8/8/2019 Builder 3&2 VOL 02 -14044

36/353

Figure 1-42.Starting measurement for interior wall.

marked for the first stud to be placed 15 1/4 inches fromthe outside edge of the panel thickness on the first wall.This layout allows the corner of the first panel on thesecond wall to lineup with the edge of the first panel onthe second wall. Also, the opposite edge of the panel onth e second wa ll will break on th e cent er of a st ud.

A procedure for laying out studs for interior walls(partitions) is shown in figure 1-42. If panels are placedon the exterior wall first, the wall plates for the interiorwall are ma rked for t he first stu d to be placed 15 1/4inches from the edge of the panel thickness on the

exterior wall. If panels are to be placed on the interiorwall, the wall plates of th e inter ior wa ll are ma rked forthe first stud to be placed 15 1/4 inches from theunpaneled exterior wall.

If drywall or other interior finish panels are to benailed to an adjoining wall (fig. 1-42, view A), you mustmeasur e 15 1/4 inches plus t he th ickness of the m aterial.When panels are to be nailed on a wall first (view B),measure and mark the 15 1/4 inches from the frontsurface of the bottom plate. These procedures ensurestud alignment remains accurate throughout the nailing

process.

Rough openings for doors and windows must alsobe marked on the wall plates. The rough openingdimensions for a window (fig, 1-43, view A) or wooddoor (view B) are calculated based on the window ordoor width, the thickness of the finish frame, and1/2-inch clearance for shim materials at the sides of the

frame. Some blueprint door and window schedules givethe rough opening dimensions, simplifying the layout.

A rough opening for a metal window often requiresa 1/2-inch clearance around the entire frame. When themeasurements are not given in the window schedule,ta ke them from the ma nufacturer s installat ioninstructions supplied with the windows.

A completely laid out bottom plate includesmarkings for corner posts, rough openings, studs, andcripples. The corner posts are laid out first. Next, the16-inch marks for the studs and cripples are marked, and

then the marks for the rough openings are made.Some Builders prefer to layout the rough openings

before the studs and cripples are marked. There is,however, an advan ta ge to laying out t he 16-inch OCmarks first . Studs and trimmers framing a door a ndwindow often fall very close to a 16-inch OC stu d m ar kSlight ly shifting t he position of th e rough opening ma yeliminate an unnecessary stud from the wall frame.

Vertical Layout

Vertical layout is the procedure for calculating thelengths of the different vertical members of awood-framed wall. This makes it possible to precut allstuds, trimmers, and cripples required for a building.

Some blueprints contain section views giving theexact rough heights of walls. The rough height is thedistance from the subfloor to the bottom of the ceiling

1-24

-

8/8/2019 Builder 3&2 VOL 02 -14044

37/353

Figure 1-43.Measurements for windows and doors.

joists. The rough height to the top of the door (the The distance from the bottom to the top of a roughdistance from the subfloor to the bottom of the door window opening can be found by m easur ing down fromhea der) may also be noted on th e section dra wing. In the bottom of the window header using dimensionsaddition, it may be given in the column for rough provided in th e rough openin g colum n of the windowopening measurements on the door schedule. The roughheight to th e top of the door esta blishes th e measu rement

schedule.

for the rough height to the top of the window, as window Many Builders prefer to frame t he door a nd window

headers are usually in line with door headers. openings before assembling the wall. View A of

1-25

-

8/8/2019 Builder 3&2 VOL 02 -14044

38/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

39/353

Figure 1-45.Assembly of wall components.

Figure 1-46.Double top plate.

1-27

-

8/8/2019 Builder 3&2 VOL 02 -14044

40/353

Figure 1-47.Squaring a w all.

been raised. The topmost plates are nailed so that theyoverlap the plates below at all corners. This helps to tie

the walls together. All ends are fastened with two 16dnails. Between the ends, 16d nails are staggered 16inches OC. The butt joints between the topmost platesshould be at least 4 feet from any butt joint between theplates below them.

Squaring Walls and Placing Braces

A completely framed wall is often squared while itis still lying on the subfloor. In this way, bracing,plywood, or other exterior wall covering can be nailedbefore the wall is raised. When diagonal measurements

are equal, the wall is square. Figure 1-47 showsexamples of unsquared and squared walls.A let-in diagonal brace maybe placed while the wall

is still on the subfloor. Lay out and snap a line on thestuds to show the location of the brace (fig. 1-48). Thestuds are then notched for the brace. Tack the brace toth e stu ds while th e wall is still lying on the subfloor.Tacking instead of nailing allows for some adjust mentafter the wall is raised. After any necessary adjustmentis made, the nails can be securely driven in.

Raising

Most wa lls can be raised by ha nd if enough h elp isavailable. It is advisable to have one person for every 10feet of wall for the lifting operation.

The order in which walls are framed and raised mayvary from job to job. Generally, the longer exterior wallsare raised first. The shorter exterior walls are then raised,and the comers ar e nailed together. The order of framinginterior partitions depends on the floor layout.

Figure 1-48.Let-in diagional brace.

After a wall has been raised, its bottom plates mustbe nailed securely to the floor. Where the wall rests ona wood subfloor and joists, 16d nails should be driventhrough the bottom plate and into the floor joists belowthe wall.

Plumbing and Aligning

Accurate plumbing of the comers is possible onlyafter all the walls are u p. Most framing ma terials ar e notperfectly str aight; walls should never be plum bed byapplying a hand level directly to an end stud. Alwaysuse a st ra ightedge along with t he level, as shown infigure 1-49, view A. The straightedge can be a pieceripped out of plywood or a straight piece of 2 by 4lumber. Blocks 3/4 inch thick are nailed to each end. Theblocks mak e it possible to accur at ely plum b th e wallfrom t he bottom plate to the top plate.

Plumbing corners requires two persons workingtogether -one working th e bottom a rea of the brace andthe other watching the level. The bottom en d of the braceis rena iled when the level shows a plumb wa ll.

The tops of the walls (fig. 1-49, view B) arestraightened (aligned or lined up) after all the cornershave been plumbed. Prior to nailing the floor or ceiling

joists to the tops of the walls, make sure the walls arealigned. Heres how: Fa sten a string from th e top plateatone corner of the wall to the t op plate at a nother cornerof the wall. You then cut three small blocks from 1 by 2lumber, Place one block under each end of the string sotha t t he line is clear of the wall.

The th ird block is used as a gauge to check the wa llat 6- or 8-foot intervals. At each checkpoint, a temporarybrace is fastened to a wall stud.

When fastening the t emporar y brace to the wallstud, adjust t he wall so tha t th e string is barely touchingthe gau ge block. Nail the other end of the brace to a sh ort2 by 4 block fastened t o the su bfloor. These t emporar y

1-28

-

8/8/2019 Builder 3&2 VOL 02 -14044

41/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

42/353

Figure 1-50.-Plywood sheathing.

walls range in size from 4 by 8 feet to 4 by 12 feet withth icknesses from 5/16 inch to 3/4 inch. The pan els ma ybe placed with the grain running ver t ical ly orhorizontally (fig. 1-50). Specifications may requireblocking along the long edges of horizontally placedpanels.

Typical nailing specifications require 6d nails withpanels 1/2 inch or less in thickness and 8d nails forpan els more than 1/2 inch t hick. The na ils should bespaced 6 inches apart along the edges of the panels and12 inches apart at the intermediate studs.

When nailing the panels, leave a 1/8-inch gapbetween the horizontal edges of the panels and a1/16-inch gap between the vertical edges. These gapsallow for expan sion caused by moistur e an d preventpanels from buckling.

In larger wood-framed buildings, plywood is oftennailed to some of the ma in inter ior pa rtitions. The resultis called a shear wall and adds considerable strength tothe entire building.

Plywood sheathing can be applied when the squaredwall is still lying on t he su bfloor. However, problemscan occur after the wall is raised if the floor is notperfectly straight and level. For this reason,Builders pr efer t o place the p lywood after th ebuilding has been framed.

Nonveneered Panels

someentire

Although plywood is the most commonly usedma teria l for wa ll sheat hing, specs sometim es call for

Figure 1-51.Typical metal stud construction.

nonveneered (reconstituted wood) panels. Panels madeof waferboard, oriented strandboard, and composite-board have been approved by most local building codesfor use as wall sheathing. Like plywood, these panelsresist racking, so no comer bracing is necessary innormal construction. However, where maximum shearstr ength is requir ed, conventional veneered plywoodpanels are still recommended.

The application of nonveneered wall sheathing issimilar to that for plywood. Nailing schedules usuallycall for 6d common nails spaced 6 inches OC above the

pan el edges, and 12 inches OC when na iled int o th eintermediate stu ds. Nonveneered panels are u suallyapplied with t he long edge of the pan el in a verticalposition.

METAL FRAMING

Metal is an alternative to wood framing. Manybuildings are framed entirely of metal, whereas some

1-30

-

8/8/2019 Builder 3&2 VOL 02 -14044

43/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

44/353

Figure 1-53.Wood blocking for celling or wall-mounted fixtures.

Figure 1-54.Standard corner bead.

Figure 1-55.Multiflex ta pe bead.

Figure 1-56.Casing and trim beads.

hinges, locks, rubber stops, and weather stripping. Thewindows are also integral to the system, prefabricatedand painted. These units may include interior andexterior trim designed to accept 1/2-inch wallboard and1/2-inch sheathing plus siding on the outside.

Plumbing is installed in prepunched stud webs.Wiring is passed through insulated grommets insertedin the pr epunched webs of the st uds an d plates. Wall andceiling fixtures are mounted by attaching wood blockingspaced between the flanges of the wall studs or trusses

1-32

-

8/8/2019 Builder 3&2 VOL 02 -14044

45/353

Figure 1-57.Expans ion joint.

(fig. 1-53). Friction-tight insulation is installed byplacing the batts (bundles of insulating material)between the st uds on the exterior walls. Studs a re spaced12, 16, or 24 inches OC as specified in t he bluepr ints.

Corner and Casing Beads

Standard wallboard corner bead is manufacturedfrom galvanized steel with perforated flanges, as shownin figure 1-54. It pr ovides a protective reinforcement

of straight corners. The corner bead is made with l-inchby 1- inch f langes for 3/8- or 1/2- jnch s ingle-layer wallboard; 1 inch by 1 1/4 inches for 1/2-inch

or 5/8-inch single-layer wallboard; 1 1/4 inches by1 1/4 inches for two-layer wallboard application. It isavailable in 10-foot lengths.

Multiflex tape bead consists of two continuousmetal strips on the undersurface of 2 1/8-inch-widereinforcing tape (fig. 1-55). This protects cornersformed at any angle. Multiflex tape bead comes in100-foot rolls.

Casing and trim beads (examples are shown in fig.1-56) are used as edge protection and trim aroundwindow and door openings and as moldings at ceilingangles. They are made from galvanized steel in threestyles to fit 3/8-inch, 1/2-inch, and 5/8-inch wallboardand come in 10-foot lengths.

Expansion Jo in ts

Expansion joints are vinyl extrusions used ascontrol joints in drywall partitions and ceilings. A typicalform is shown in figure 1-57.

Figure 1-58 shows a typical metal frame layout anduse of corner a nd casin g beads for corners, pa rt itionintersections, and partition ends. It also shows a typical

Figure 1-58.Metal frame layout with various beads and joints.

1-33

-

8/8/2019 Builder 3&2 VOL 02 -14044

46/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

47/353

Figure 1-60.Ceiling frame tying exterior walls together.

JOISTS

J oists are t he most importan t framing members of the ceiling. Their size, spacing, and direction of travelare given on the floor plan. As mentioned earlier, thespacing between ceiling joists is usually 16 inches OC,although 24-inch spacing is also used. The size of aceiling joist is determined by the weight it carries andthe span it covers from wall to wall. Refer to theblueprints and specifications for size and OC spacing.Alth ough it is m ore convenient t o have all th e joistsrun ning in th e sam e direction, plans sometimes call fordifferent sets of joists running at right angles to eachother.

Interior Support

One end of a ceiling joist rests on an outside wall.The other end often overlaps an interior bearing par titionor girder. The overlap should be at least 4 inches. Ceiling

joists are sometimes butted over the partition or girder.In this case, the joists must be cleated with a3/4-inch-thick plywood board, 24 inches long, or an18-gauge metal strap, 18 inches long.

Ceiling joists may also butt against the girder,supported by joist ha ngers in th e same m an ner a s floor

joists.

Roof Rafters

Whenever possible, the ceiling joists should run inthe sa me direction a s th e roof rafters. Nailing the outsideend of each ceiling joist to the heel of the rafter as wellas to the wall plates (fig. 1-61) strengthens the tiebetween the outside walls of the building.

A building maybe designed so that the ceiling joistsdo not run parallel to the roof rafters. The rafters are

therefore pushing out on walls not tied together byceiling joists. In this case, 2 by 4 pieces are added to run

Figure 1-61.Nailing of ceiling joists.

1-35

-

8/8/2019 Builder 3&2 VOL 02 -14044

48/353

Figure 1-62.2 by 4 ties.

Figure 1-63.Stub joists.

1-36

-

8/8/2019 Builder 3&2 VOL 02 -14044

49/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

50/353

Figure 1-66.Ceiling joist spacing.

Figure 1-67.Constructing a typical ceiling frame.

1-38

-

8/8/2019 Builder 3&2 VOL 02 -14044

51/353

Layout

Figure 1-68.Backing for nailing joists to ceiling frame.

Ceiling joists should be placed directly above thestuds when t he spacing between th e joists is the sam e asbetween the stu ds. This arra ngement makes it easier toinstall pipes, flues, or du cts run ning up the wall andthrough the roof. However, for buildings with wallsha ving double top plates, most bu ilding codes do notrequire ceiling joists to line up with the studs below.

If the joists are being placed directly above thestuds, they follow the same layout as the studs below(fig. 1-66, view A). If the joist layout is different fromthat of the studs below (for example, if joists are laid out24 inches OC over a 16 inch OC stu d layout), ma rk t hefirst joist at 23 1/4 inches and then at every 24 inchesOC (fig. 1-66, view B).

It is a good practice to mark the positions of the roof rafters at the time the ceiling joists are being laid out. If the spacing between the ceiling joists is the same asbetween the roof railers, there will be a rafter next toevery joist. Often, the joists are laid out 16 inches OC

an d th e roof rafters 24 inches OC. Therefore, every otherrafter can be placed next to a ceiling joist.

FRAME

All the joists for the ceiling frame should be cut tolength before t hey a re pla ced on t op of the walls. Onstructures with pitched-roofs,

joists should a lso be tr immedthe out side ends of thefor the roof slope. This

angle must be cut on the crown (top) side of the joist.The prepared joists can then be handed up to theBuilders working on top of the walls. The joists arespread in a flat position along the wa lls, close to wher ethe y will be nailed. Figure 1-67 shows one procedurefor const ructing t he ceiling frame. In this exam ple, the

joists lap over an interior par tition. Refer t o the figureas you

1.

2.

3.

4.

5.

6.

7 .

study the following steps:

Measure and mark for the ceiling joists.

Install the ceiling joists on one side of thebuilding.

Install the ceiling joists on the opposite side of the building.

Place backing on walls running parallel to the joists.

Install 2 by 4 blocks flat between joists whereneeded to fasten th e tops of inside walls runn ingpara llel to the joists.

Cut an d frame the a ttic scuttle.

Place strongbacks at the center of the spans.

Fastening Walls

The tops of walls running in the same direction asthe ceiling joists must be securely fastened to the ceilingframe. The method most often used is shown in figure1-68. Blocks, 2 inches by 4 inches, spaced 32 inches OC,ar e laid flat over t he t op of the pa rtit ion. The ends of

1-39

-

8/8/2019 Builder 3&2 VOL 02 -14044

52/353

Figure 1-69.Backing for interior wall plates.

each block are fastened to the joists with two 16d nails.Two 16d nails are also driven through each block intothe top of the wall.

Applying Backing

Walls running in the same direction as the ceiling

joists require backing. Figure 1-68 (insert) shows howbacking is nailed to the top plates to provide a nailingsurface for the edges of the finish ceiling material.Lumber u sed for backing usua lly ha s 2-inch nominalthickness, although l-inch boards are sometimes used.

Figure 1-68 shows backing placed on top of walls.The 2 by 4 pieces nailed to th e exterior wall pr ojectsfrom one side of the wall. The interior wall requires a 2by 6 or 2 by 8 piece extendin g from both sides of thewall. Backing is fasten ed to the top plates with 16d n ailsspaced 16 inches OC. Backing is also used wh ere joistsrun at right angles to the partition (fig. 1-69).

Attic Scutt le

The scuttle is an opening framed in the ceiling toprovide an entrance into the attic area. The size of theopening is decided by specification requirements andshould be indicated in the blueprints. It must be largeenough for a person t o climb thr ough easily.

The scutt le is fra med in t he sa me way as a flooropening. If the opening is no more th an 3 feet squar e,is not necessary to double the joists and headers. Scumust be placed away from the lower areas of a slopinroof. The opening may be covered by a piece of plyworesting on stops. The scuttle opening can be cut out aftall the regular ceiling joists have been nailed in place

RECOMMENDED READING LIST

NOTE

Although the following referenceswere current when this TRAMAN waspublished, their continued currencycannot be assured. You therefore needto ensure that you are studying thelatest revisions.

Carpent ry, Leonard Keel, American TechnicalPublishers, Alsip, Ill., 1985.

Design of Wood Frame Structures for Permanence,National Forest Products Association, WashingtonD.C., 1988.

Exterior and Interior Trim, John E. Ball, DelmarPu blishers, In c., Albany, N.Y, 1975.

1-40

-

8/8/2019 Builder 3&2 VOL 02 -14044

53/353

CHAPTER 2

ROOF FRAMING

In this chapter, we will introduce you to thefundamentals of roof design and construction. But,

before discussing roof framing, we will first reviewsome basic terms and def ini t ions used in roof construction; we will then discuss the framing squareand learn how its used to solve some basic constructionproblems. Next, well examine various types of roofsand rafters, and techniques for laying out, cutting, anderecting rafters. We conclude the chapter with adiscussion of the types an d par ts of roof trus ses.

TERMINOLOGY

LEARNING OBJECTIVE: Upon completingthis section, you sh ould be able to ident ify thetypes of roofs and define common roof framingterms.

The primary object of a roof in any climate isprotection from the elements. Roof slope and rigidnessare for shedding water and bearing any extra additionalweight. Roofs must also be strong enough to withstandhigh winds. In this section, well cover the mostcommon types of roofs and basic framing terms.

TYPE S OF ROOFS

The most commonly used types of pitched roof construction are the gable, the hip, the intersecting, andth e sh ed (or lea n-to). An example of each is shown infigure 2-1.

Gable

A gable roof has a ridge at the center an d slopes intwo directions. It is t he form most commonly used bythe Navy. It is simple in design, economical to construct,

and can be used on any type of structure.

Hip

The h ip roof has four sloping sides. It is t he st rongesttype of roof because it is braced by four hip rafters.These hip rafters run at a 45 angle from each corner of the building to the ridge. A disadvantage of the hip roof is that it is more difficult to construct than a gable roof.

Intersecting

The intersecting roof consists of a gable and valley,or hip and valley. The valley is formed where the twodifferent s ections of th e roof meet, genera lly at a 90an gle. This type of roof is more complicated t ha n t he

Figure 2-1.Most common types of pitched roofs.

2-1

-

8/8/2019 Builder 3&2 VOL 02 -14044

54/353

other types and requires more time and labor toconstruct.

Shed

The shed roof, or lean-to, is a roof having only oneslope, or pitch. It is used where large buildings areframed under one roof, where hasty or temporary

constr uction is needed, and wher e sheds or additions areerected. The roof is held up by walls or posts where onewall or the posts on one side are at a higher level thanthose on the opposite side.

FRAMING TERMS

Knowing the basic vocabulary is a necessary part of your work as a Builder. In the following section, wellcover some of the more common roof and rafter termsyoull need. Roof framing terms are related to the partsof a t riangle.

Roof

Features associated with basic roof framing termsare shown in figure 2-2. Refer to the figure as you studythe terms discussed in the next paragraphs.

Span is the h orizontal distan ce between th e outsidetop plates, or t he base of two abutt ing right t riangles.

Uni t o f run is a fixed unit of measure, always 12inches for the common r after. Any measur ement in ahorizontal direction is expressed as run and is always

measured on a level plane. Unit of span is also fixed,twice th e un it of ru n, or 24 inches. Unit of rise is th edistance the rafter rises per foot of run (unit of run).

Total run is equal to half the span, or the base of one of the right triangles. Total rise is the verticaldistance from t he t op plate to th e top of the ridge, or thealtitude of the tria ngle.

Pi tch is the r atio of unit of rise to the u nit of span.It describes the slope of a roof. Pitch is expressed as afraction, such as 1/4 or 1/2 pitch. The term pitch isgradually being replaced by the term cut. Cut is the

angle tha t t he roof surface makes with a h orizonta lplane. This angle is usually expressed as a fraction inwhich th e numera tor equals the unit of rise and th edenominator equals the unit of run (12 inches), such as6/1 2 or 8/12. This can also be expressed in inches perfoot; for example, a 6- or 8-inch cut per foot. Here, theunit of run (12 inches) is understood. Pitch can beconverted to cut by using the following formula:unit of span (24 in.) x pitch = unit of rise. For example,

Figure 2-2.Roof framing terms.

1/8 pitch is given, so 24 x 1/8 equa ls 3, or u nit of risein inches. If the unit of rise in inches is 3, then t he cut is

the u nit of rise and t he un it of run (12 inches), or 3/12.

Line length is the hyptenuse of the triangle whosebase equals the total run and whose altitude equals thetotal rise. The distance is measured a long the r after fromthe outside edge of the top plate to the centerline of theridge. Bridge measure is the hypotenuse of the trianglewith the unit of run for the base and unit of rise for thealti tude.

2-2

-

8/8/2019 Builder 3&2 VOL 02 -14044

55/353

Figure 2-3.-Rafter terms.

Rafter

The members making up the main body of theframework of all roofs are called rafters. They do for theroof what the joists do for the floor and what the studsdo for the wa ll. Rafters a re inclined member s spacedfrom 16 t o 48 inches a part . They vary in size, dependingon their lengt h a nd spa cing. The tops of the inclinedrafters are fastened in one of several ways determinedby the type of roof. The bottoms of the r after s rest onthe plate member, providing a connecting link betweenthe wall and the roof. The rafters are really functionalparts of both the walls and the roof.

The structural relationship between th e rafters andthe wa ll is the sam e in all types of roofs. The ra fters arenot framed into the plate, but are simply nailed to it.Some are cut to fit t he plate, whereas others, in h astyconstruction, are merely laid on top of the plate andnailed in place. Rafters usually extend a short distancebeyond the wall to form the eaves (overhang) andprotect th e sides of th e building. Fea tu res as sociatedwith various rafter types and terminology are shown infigure 2-3.

Common rafters extend from the plate to theridgeboard at right angles to both. Hip rafters extenddiagonal ly f rom the outs ide corner formed byperpendicular plates to the ridgeboard. Valley raftersextend from the plates to the ridgeboard along the lineswhere two roofs intersect. Jack rafters never extend the

Figure 2-4.Rafter layout.

full distance from plate to ridgeboard. Jack rafters aresubdivided into the hip, valley, and cripple jacks.

In a hip jack, the lower ends rest on t he plate an d theupper ends a gainst the h ip rafter. In a valley jack th elower ends rest against the valley rafters and the upperends a gainst th e ridgeboar d. A cripple jack is na iledbetween hip and valley rafters.

Rafters are cut in three basic ways (shown infig. 2-4, view A). The t op cut , also called the plum b cut,is made at the end of the rafter to be placed against theridgeboard or, if the ridgeboard is omitted, against the

opposite rafters. A seat, bottom, or heel cut is made atthe end of the rafter that is to rest on the plate. A side cut(not shown in fig. 2-4), also called a cheek cut, is a bevelcut on the side of a rafter to make it fit against anotherframe member.

Rafter length is the shortest distan ce between t heouter edge of the top plate and the center of the ridgeline. The cave, tail, or overha ng is th e portion of th e

2-3

-

8/8/2019 Builder 3&2 VOL 02 -14044

56/353

rafter extending beyond the outer edge of the plate. Ameasure line (fig. 2-4, view B) is an imaginary referenceline laid out down the middle of the face of a rafter. If aportion of a roof is represented by a right triangle, themeasure line corresponds to the hypotenuse; the rise tothe altitu de; and, the run to the base.

A plumb lin e (fig. 2-4, view C) is an y line th at isvertical (plumb) when the rafter is in its proper position.

A level line (fig. 2-4, view C) is a ny line t ha t is horizont al(level) when the rafter is in its proper position.

FRAMING SQUARE

LEARNING OBJECTIVE: Upon completingthis section, you should be able to describe and solve roof framing problems using the framingsquare.

The framing squa re is one of the most frequentlyused Bu ilder tools. The problems it can solve ar e so

many and varied that books have been written on thesqua re a lone. Only a few of th e more comm on uses of the square can be presented here. For a more detaileddiscussion of the various uses of the fram ing squar e insolving construction problems, you are encouraged toobtain and study one of the many excellent books on thesquare.

DESCRIPTION

The framing square (fig. 2-5, view A) consists of awide, long member called the blade and a nar row, short

member called th e tongue. The blade and tongue forma right angle. The face of the square is the side one seeswhen the square is held with the blade in the left hand,the tongue in the right hand, and the heel pointed awayfrom t he body. The man ufacturer s na me is usu allystam ped on the face. The blade is 24 inches long an d 2inches wide. The tongue varies from 14 to 18 inches longand is 1 1/2 inches wide, measured from the outer corner,where th e blade and th e tongue meet. This corner iscalled the heel of the square.

The outer and inner edges of the tongue and t heblade, on both face and back, are graduated in inches.Note how inches are subdivided in the scale on the backof the square. In the scales on the face, the inch issubdivided in the regular units of carpenter s measure(1/8 or 1/16 inch). On the back of the square, the outeredge of the blade and tongue is graduat ed in inches andtwelfths of inches. The inner edge of the tongue isgraduat ed in inches and t enths of inches. The inner edgeof the blade is graduated in inches and thirty-seconds of

Figure 2-5.Framing square: A. Nomenclature; B. Problemsolving.

inches on most squares. Common uses of the twelfthsscale on the back of the framing square will be describedlater. The tenths scale is not normally used in roof framing.

SOLVING BASIC PROB LEMS WITH THEFRAMING SQUARE

The framing square is used most frequently to findth e length of th e hypotenu se (longest side) of a r ighttriangle when the lengths of the other two sides areknown. This is the basic problem involved in

determ ining the length of a roof rafter, a bra ce, or a nyother member that forms the hypotenuse of an actual orimaginary right triangle.

Figure 2-5, view B, shows you how the framingsquare is u sed to determine the length of the h ypotenuseof a right triangle with the other sides each 12 incheslong. Place a true straightedge on a board and set thesquar e on th e board so as to bring the 12-inch mar k on

2-4

-

8/8/2019 Builder 3&2 VOL 02 -14044

57/353

Figu re 2-6."Stepping off"with a framing square.

the t ongue an d the blade even with t he edge of the board.Draw the pencil marks as shown. The distance betweenthese marks, measured along the edge of the board, isthe length of the hypotenuse of a right triangle with theother sides each 12 inches long. You will find that thedistance, called the bridge measure, measur es just under17 inches16.97 inches, as shown in the figure. Formost practical Builder purposes, though, round 16.97

inches to 17 inches.

Solving for Unit and Total Run and Rise

In figure 2-5, the problem could be solved by asingle set (called a cut) of the framing square. This wasdue to the dimensions of the triangle in question lyingwithin the dimensions of the square. Suppose, though,you a re t rying to find th e length of the hypotenuse of aright triangle with the two known sides each being 48inches long. Assume th e mem ber whose length you a retrying to determ ine is t he bra ce shown in figure 2-6. Thetotal ru n of this brace is 48 inches, and th e total rise isalso 48 inches.

To figure the length of the brace, you first reducethe tr iangle in question to a similar tr iangle within th edimensions of th e fra ming squa re. The length of thevertical side of this triangle is called unit of rise, and thelength of the horizontal side is called the unit of run. By

Figure 2-7."Stepping off"w ith a square w hen the unit of runand unit of rise are different.

a general custom of the t rade, unit of run is always takenas 12 inches and measured on the tongue of the framingsquare.

Now, if the total ru n is 48 inches, the t otal r ise is 48inches, and the unit of run is 12 inches, what is the unitof rise? Well, since the sides of similar triangles areproportional, the u nit of rise must be the value of x inthe proportional equation 48:48::12:x. In this case, theunit of rise is obviously 12 inches.

To get t he length of the brace, set t he framing squar eto the unit of run (12 inches) on the tongue and to theunit of rise (also 12 inches) on the blade, as shown infigure 2-6. Then, step off this cut as many times as theunit of run goes into the total run. In this case, 48/12, or4 times, as sh own in the figure.

In th is problem, the total ru n an d total rise were thesame, from which it followed that the unit of run andunit of rise were also the same. Suppose now that youwant to know the length of a bra ce with a total run of 60inches an d a t otal rise of 72 inches, as in figure 2-7. Sincethe unit of run is 12 inches, the unit of rise must be thevalue of x in the proportional equation60:72::12.x. Thatis, the proportion 60:72 is the same as the proportion12:x. Working this out, you find the unit of rise is

2-5

-

8/8/2019 Builder 3&2 VOL 02 -14044

58/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

59/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

60/353

Figure 2-11.-Brace table.

brace ta ble, located on the back of the tongue; and t heEssex board measure table, located on the back of theblade. Before you can use the unit length rafter table,you m ust be fam iliar with t he different types of ra ftersand with the methods of framing them. The use of theunit length r after ta ble is described later in this chapter.The other two tables are discussed below.

Brace

The brace table sets forth a series of equal runs andrises for every three-units interval from 24/24 to 60/60,

together with the brace length, or length of thehypotenuse, for each given r un and rise. The ta ble canbe used to determine, by inspection, the length of thehypotenuse of a right triangle with the equal shortersides of any length given in th e ta ble. For example, inthe segment of the brace table shown in figure 2-11, youcan see that the length of the hypotenuse of a righttriangle with two sides 24 units long is 33.94 units; with

two sides 27 units long, 38.18 units; two sides 30 unitslong, 42.43 units; and so on.

By applying simple arithmetic, you can use thebrace table to determine the hypotenuse of a righttriangle with equal sides of practically any even-unitlength. Suppose you wan t t o know the length of th ehypotenuse of a right triangle with two sides 8 incheslong. The brace table shows tha t a right tr iangle with twsides 24 inches long has a hypotenuse of 33.94 inches.Since 8 amounts to 24/3, a right triangle with two shortsides each 8 inches long must have a hypotenuse of

33.94 3, or approximately 11.31 inches.

Suppose you want to find the length of thehypotenu se of a right t riangle with t wo sides 40 incheseach. The sides of similar trian gles a re pr oportional, an dany right triangle with two equal sides is similar to anyother right t riangle with two equal sides. The brace tableshows that a right triangle with the two shorter sides

2-8

-

8/8/2019 Builder 3&2 VOL 02 -14044

61/353

Figure 2-12.-Segmen t of Essex board me asure table.

being 30 inches long has a hypotenuse of 42.43 inches.The length of the h ypotenuse of a r ight tr iangle with thetwo shorter sides being 40 inches long must be the valueof x in the proportional equation 30.42.43::40:x, orabout 56.57 inches.

Notice that the last item in the brace table (the onefarthest to the right in fig. 2-11) gives you thehypotenu se of a r ight tr iangle with th e other proportions

18:24:30. These proportions are those of the mostcommon type of unequal-sided right triangle, with sidesin the proportions of 3:4:5.

Essex Board

The primary use of the Essex board measure tableis for estimating the board feet in lumber of known

dimensions. The inch graduations (fig. 2-12, view A)above the table (1, 2, 3, 4, and so on) represent the widthin inches of the piece to be measured. The figures underthe 12-inch graduation (8, 9, 10, 11, 13, 14, and 15,arranged in columns) represent lengths in feet. Thefigure 12 itself represents a 12-foot length. The columnheaded by the figure 12 is the starting point for allcalculations.

To use the table, scan down the figure 12 column tothe figure that represents the length of the piece of lumber in feet. Then go horizontally to the figure

directly below the inch ma rk t ha t corr esponds to thewidth of th e stock in inches. The figure you find will bethe number of board feet and twelfths of board feet in a1-inch-thick board.

2-9

-

8/8/2019 Builder 3&2 VOL 02 -14044

62/353

-

8/8/2019 Builder 3&2 VOL 02 -14044

63/353

Figure 2-15.A birds-mouth is formed by the heel plumbline and seat line.

various calculations, layouts, cutting procedures, andassembly requirements required for efficient con-struction.

GABLE

Next to the shed roof, which has only one slope, thegable r oof is th e simples t t ype of sloping roof to buildbecause it slopes in only two directions. The basicstructural members of the gable roof are the ridgeboard,the common rafters, and the gable-end studs. Theframework is shown in figure 2-13.

The ridgeboard is placed at the peak of the roof. Itprovides a nailing surface for the top ends of thecommon rafters. The common rafters extend from thetop wall plat es to the ridge. The gable-end stu ds ar eupright framing members that provide a nailing surfacefor siding an d shea thing a t t he gable ends of the roof.

Common Raf ters

All common ra fters for a gable roof are t he sa melength. They can be precut before the roof is assembled.Today, most common rafters include an overhang. Theoverha ng (an example is shown in fig. 2-14) is th e par tof the rafter that extends past the building line. The runof the overhang, called the projection, is the horizontaldistan ce from t he building line to the t ail cut on t he