Budour Integrated Project · Dehydration Package Heater Sweet Gas Recovery Comp. Booster Comp. Stg1...

Transcript of Budour Integrated Project · Dehydration Package Heater Sweet Gas Recovery Comp. Booster Comp. Stg1...

Budour Integrated Project

Health Management Plan for Execute Phase

BUD-00-000000-HX-5880-00002-0000

Revision Record

02 15/01/2015 approved Jose

Petrizzo MCOH1

Elshan

Samadov

CBE51

Salim Sawai MCOH

01 03/03/2013 Issued for

Approval

Jose Petrizzo MCOH1

Elshan

Samadov

CBE51

Salim Sawai MCOH

Rev. Date Reason for

Issue

Originator Checker Approver

“Electronic Documents once printed are Non-Controlled and may become Outdated”

This document is the property of Petroleum Development Oman, LLC. Neither the whole nor any part of this document may be

disclosed to others or reproduced, stored in a retrieval system, or transmitted in any form by any means (electronic, mechanical,

reprographic recording or otherwise) without prior written consent of the owner.

Responsible RTA’s distribution list:

Consulted/Informed Distribution List:

As per PCAP (included in doc. no BUD-00-000000-AA-6003-00001-0000 Opportunity Assurance Plan) - Only for DCAF documents

Hold Record

Specify any outstanding issues in the document

Hold

No.

Section Description of Hold

Revision Tracking Specify significant changes from previous revisions of the document (sorted by date)

Rev. Date Description of Revision

02 15/01/2015 Issued for Execute Phase

Name Function Signature

TABLE OF CONTENTS

1. INTRODUCTION ............................................ 4

2. PROJECT DESCRIPTION ..................................... 5

Location ................................................... 5

Site Selection and Field Lay-out .................................. 6

Budour Processing Facility ..................................... 6

3. HEALTH SECTION ........................................... 8

3.1 Health resources scoping and deliverables ...................... 8

4. ANNEXES ................................................ 11

Health Priorities ............................................ 11

DCAF EXECUTION PHASE Overview ............................ 11

5. REFERENCES ............................................. 12

1. INTRODUCTION

A Health Plan brings together all essential health information that must be

produced for each project phase from Identify to Operate. The Health Plan must

be re-developed in the EXECUTION PHASE, because is especially important in

areas with challenges medical care, where there will be a focus on Medical

Emergency Response and individual fitness.

A competent Health professional must sign off all health reports and plans. The

Health Plan will identify activities and control measures for the Health aspects of

the HSE CMF and where these are integrated into the project, in order to comply

with it and with Project Standards.

This Health Plan summarizes the Health elements that are required for the

Boduor Integrated Project during EXECUTION PHASE. These Health elements

will be developed, updated and delivered according to the HSSE&SD Plans for

Construction and Installation Sites (updated).

. The plan pursues two main objectives:

Ensure that Health requirements and specifications are comprehensively implemented during construction.

Complete specific Health assessments mandated by the HSE CMP, Discipline Controls and Assurance Framework (DCAF), local legislation and rules on the project.

2. PROJECT DESCRIPTION

Location

The Budour (BUD), Birba North (BBN), Budour NE (BUDNE) and Budour SE (BUDSE) fields are situated in South Oman in the Greater Birba area. The Budour and Birba North gas field falls under the Government Gas Directorate; the Budour NE and Budour SE oil fields are governed by PDO’s Oil South Directorate. The Budour NE field is located approximately 16 km north east of the Birba Gathering Station and approximately 32 km north of the Marmul Main Production Station.

Figure 1: Budour Location in South Oman

The fluids in Greater Birba range from highly under-saturated to near critical mixtures, with API gravities 30°to 39° (light oil) and 40°+ for the gas condensate. The fields are all sour, with H2S contents ranging from 0.2 mol% to 10 mol% ( gas phase ) , and CO2 ranging from 0.5 mol% to 4 mol%.

There are two separate producing carbonate oil reservoirs in the Budour NE-SE field: the Basal Ara Carbonate, more commonly referred to as the A1C (“Ara 1 Carbonate”), and the “Ara 4 Carbonate” (A4C). The field was discovered in 2005, to date seventeen wells have being drilled – eleven boreholes penetrating the A4C and eight boreholes in the deeper A1C reservoir. The A4C has produced through Birba since 2007 and the A1C has been in production through Al Noor and Birba since 2009.

The Budour gas field is located approximately 10 km north of the Birba Gathering Station. There are four exploration/appraisal wells in the Budour field, two of which have been tested.

The Budour integrated project provides an opportunity to develop an incremental recovery undiscounted/discounted (above NFA) of 15.0 /12.0 MMm3 oil and 2.2/1.8 Bm3 associated gas from the Budour NE field, through water flood of the Budour NE/SE A4C A1C oil reservoirs. Also to be developed are 8.3 Bm3 of non-associated gas and 1.7 MMm3 of condensate from the Budour gas field

Site Selection and Field Lay-out

A site selection exercise for the Budour Processing Facility (BPF) was carried out during the SELECT phase by a joint Budour /SGS team. The exact site location further optimized within the local area by the Budour team.

The construction camp proposed location was to be adjacent to the production site for the duration of the construction as this option resulted in lower risk; in particular from road transport, which is assessed as the highest single risk exposure for staff.

Figure 2: Budour Integrated Development – Area Layout Overview

Budour Processing Facility

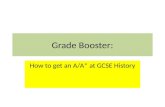

The project scope for the Budour Integrated project is illustrated in Figure 3.The process fluids will be routed to a nearby new production station. The oil and condensate will be exported stabilized and sweet to the MOL. The gas will be dehydrated and exported sour to the RHIP future gas sweetening plant. The priority is placed on the associated gas with non-associated Budour gas providing the “swing” to fill the pipeline ullage.

Water for injection and artificial lift will be sourced from Marmul Production Station and the produced water will be reused for water injection and any surplus for disposal to the Haima formation following treatment. Fuel gas supply will be sourced from the South Oman Gas Line (SOGL) to provide energy for the process crude heater and H2S stripping (40,000 Sm3/d).

Figure 3 – Budour Integrated Project Development Overview

The new facilities include gathering systems consisting of wellhead piping, flowlines, extension of existing remote manifold station (RMS) and single trunkline to transfer the multiphase flow from the RGM to the new production station which will be located between the oil and gas fields. Budour non associated gas wells will be routed individually to the new station. The production station includes facilities to dehydrate the sour gas for export to RHIP. The crude oil and condensate will be exported to the MOL via existing 18” Harweel oil export line. Water supply will be sourced from Marmul produced water for treatment at Budour production station, then it will be distributed to the field for injection and artificial lifting via 200 barg transfer line, distribution manifold and individual flowlines.

The selected concept that meets the above parameters is a 4000 Sm3/d oil rate, 0.6mln sm3/d associated gas rate and supplemental make up gas from Budour non associated gas to export total of 1.5 mln Sm3/d to RHIP.

Figure 4: Process Flow Scheme for Budour Concept Facilities

3

5 4

1

62

Oil Inlet Sep.

Gas Inlet Sep. Gas 2nd Sep.

FWKO

Dehyd.Storage

Gas Dehydration

Package

HeaterSweet Gas

Recovery Comp.

Booster Comp. Stg1

Booster Comp. Stg2

Export to Raba

Export to Birba as Back-up

Flare

Export to MOL

to WL

BudNE A1C + A4C

Bud Gas SkimTank

mixer IGF NSF

to WI

Marmul

Water Supply

Self-cleaning

Filter

StorageTank

GuardFilters

Booster Pumps

Injection Pumps

IGF Feed Pumps

3. HEALTH SECTION

The Health elements of the plan for the EXECUTION PHASE are related to the following components:

a) HSSE&SD Plans for Construction and Installation Sites (uptaded) b) PDO Health hazard Inventory

3.1 Health resources scoping and deliverables

The following table summarizes the Health requirements and resources for compliance with local legislation and PDO CMF. It also allows the appropriate action tracking for the Plan.

Deliverable Comments Schedule

Health Management Plan

The PDO Health ATA2, José Petrizzo as Health Project Owner, will provide Health deliverables required for Boduor Integrated Project and associated activities in the EXECUTION PHASE.

01/2015

Human Factor Engineering (HFE) Elements*

HFE and Ergonomic aspects will be captured as part of The Health Risk Assessment. HSE team will be available for any further review during the construction.

Starting engagements with HSE Team in Q2 2015

Health Risk Assessment (HRA)

Contractors will deliver an HRA during construction. PDO Occupational Health will provide a completed Generic HRA for it.

The HPO will review / validate the HRA(s).

05/2015

Deliverable Comments Schedule

MER Plan

The assigned HPO will provide input into MER Plan as part of the Emergency Response Plans developed for contractors during EXECUTION PHASE. Main Contractors Involved within the Project during EXECUTION PHASE and PDO visiting employees will be covered by site(s) MER Plan(s). Aspects that link the PDO-Contractors interface should be defined in the applicable “Construction Contractors HSSE management Plan”.

Q2 2015

Deliverable Comments Schedule

CMF Health Specifications

The assigned HPO will engage with project HSE for supporting the implementation of CMF Health specifications along EXECUTION PHASE regarding following Specifications:

Fitness to Work (SP-1230 – Medical Examination, Treatment and Facilities)

Health Risk Assessment (SP-1231 – Occupational Health)

Public Health (SP-1232 – Public Health)

Human Factors Engineering (SP-1231 – Occupational Health)

Medical Emergency Response (PR-1243 – Medical Emergency Response Manual)

Reporting and investigation of HSE incidents (PR 1418 – Incident Notification, Reporting and Follow-up Procedure Part 1)

Chemicals Management and SHOC (SP1231- Occupational Health)

Exposure Monitoring (SP 1231- Occupational Health)

Smoking, alcohol and drug policy (SP 1233 – Smoking, Drugs and alcohol)

Continuous support

5. REFERENCES

Discipline Controls and Assurance Framework (DCAF) Tool

HFE Shell DEPs

Fitness to Work (SP-1230 – Medical Examination, Treatment and Facilities)

Health Risk Assessment (SP-1231 – Occupational Health)

Public Health (SP-1232 – Public Health)

Smoking, alcohol and drug policy (SP 1233 – Smoking, Drugs and alcohol)

Medical Emergency Response (PR-1243 – Medical Emergency Response

Manual)

Reporting and investigation of HSE incidents (PR 1418 – Incident Notification, Reporting and Follow-up Procedure Part 1)

Boduor Integrated Project Health Management Plan 2013.