BS EN 445-1997

-

Upload

wahyuniarsih -

Category

Documents

-

view

1.614 -

download

357

description

Transcript of BS EN 445-1997

-

5/19/2018 BS EN 445-1997

1/17

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

British Standard

A single copy of this British Standard is licensed to

man-mcgibew2 man-mcgibew2

06 January 2005

This is an uncontrolled copy. Ensure use of the mostcurrent version of this document by searching British

Standards Online at bsonline.techindex.co.uk

-

5/19/2018 BS EN 445-1997

2/17

||||||||||||||||||||||||||||||||||||||||||||

|||||||||||||||||||||||||

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BRITISH STANDARD BS EN445 : 1997

IncorporatingAmendment No. 1

The European Standard EN 445 : 1996 has the status of aBritish Standard

ICS 91.100.10 ; 91.100.30

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

Grout for prestressingtendons

Test methods

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

3/17

BS EN 445 : 1997 Issue 2, December 1997

This British Standard, havingbeen prepared under thedirection of the Sector Board forBuilding and Civil Engineering,

was published under theauthority of the Standards Boardand comes into effect on15 November 1997

BSI 1997

The following BSI referencesrelate to the work on this

standard:Committee reference B/525/2Draft for comment 91/10645 DC

ISBN 0 580 28311 9

Amendments issued since publication

Amd. No. Date Text affected

9876 December 1997

Indicated by a sideline in the margin

Committees responsible for thisBritish Standard

The preparation of this British Standard was entrusted by Technical CommitteeB/525, Building and civil engineering structures, to Subcommittee B/525/2, Structural

use of concrete, upon which the following bodies were represented:

Association of Consulting Engineers

British Cement Association

British Precast Concrete Federation Ltd.

Concrete Society

Department of the Environment (Building Research Establishment)

Department of the Environment (Construction Sponsorship Directorate)

Department of Transport (Highways Agency)

Institution of Civil Engineers

Institution of Structural Engineers

Steel Reinforcement Commission

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

4/17

BSI 1997 i

Issue 2, December 1997 BS EN 445 : 1997

||

National foreword

This British Standard has been prepared by Subcommittee B/525/2 and is the English

language version of EN 445 : 1996 Grout for prestressing tendons Test methodspublished by the European Committee for Standardization (CEN).

EN 445 was produced as a result of European discussions in which the UK took anactive part. The UK voted against this standard at the CEN Formal Vote stage becauseUK industry considered the standard to be insufficient in providing suitablespecification requirements for grouting materials and procedures, particularly forhighway bridges.

The UK conducted significant development work and subsequently published ConcreteSociety Technical Report No. 47 Durable Bonded Post Tensioned Concrete Bridges,prepared by a Concrete Society Working Party in collaboration with the ConcreteBridge Development Group (September 1996), to which reference may be made.

At the CEN Formal Vote stage, however, the analysis of voting resulted in a positivevote and in accordance with CEN/CENELEC Internal Regulations Part 2 :Commonrules for standards workEN 445 was accepted as a European Standard.

Cross-reference

Publication referred to Corresponding British Standard

EN 196-1 : 1994 BS EN 196-1 : 1995Determination of strength

Textual error

The textual error set out below was discovered when adopting the text of theEuropean Standard. It has been reported to CEN in a proposal to amend the text of theEuropean Standard.

Figure 2 in the published EN version is not correct. In the national annex NA

(informative) of this BS EN an updated version of the figure is given until such time asthe EN is amended.

Compliance with a British Standard does not of itself confer immunityfrom legal obligations.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

5/17

ii blankLicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

6/17

CENEuropean Committee for Standardization

Comite Europeen de Normalisation

Europaisches Komitee fur Normung

Central Secretariat: rue de Stassart 36, B-1050 Brussels

1996 Copyright reserved to CEN members.Ref. No. EN 445 : 1996 E

EUROPEAN STANDARD EN 445

NORME EUROPEENNE

EUROPAISCHE NORM March 1996

ICS 91.100.30

Descriptors: Cables, ropes, prestressed concrete, grouting, viscosity, tests

English version

Grout for prestressing tendons Test methods

Coulis pour cable de precontrainte Methode

d'essais

Einpremortel fur Spannglieder Prufverfahren

This European Standard was approved by CEN on 1994-10-28. CEN members arebound to comply with the CEN/CENELEC Internal Regulations which stipulate theconditions for giving this European Standard the status of a national standardwithout any alteration.

Up-to-date lists and bibliographical references concerning such national standardsmay be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German).A version in any other language made by translation under the responsibility of aCEN member into its own language and notified to the Central Secretariat has thesame status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Denmark,Finland, France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Netherlands,Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

7/17

Page 2

EN 445 : 1996

BSI 1997

Foreword

This European Standard has been prepared byTechnical Committee CEN/TC 104, Concrete Performance, production, placing and compliancecriteria, the Secretariat of which is held by DIN.

This European Standard shall be given the status of anational standard, either by publication of an identicaltext or by endorsement, at the latest bySeptember 1996, and conflicting national standardsshall be withdrawn at the latest by September 1996.

According to the CEN/CENELEC Internal Regulations,the following countries are bound to implement thisEuropean Standard: Austria, Belgium, Denmark,

Finland, France, Germany, Greece, Iceland, Ireland,Italy, Luxembourg, Netherlands, Norway, Portugal,Spain, Sweden, Switzerland and the United Kingdom.

Contents

Page

Foreword 2

0 Introduction 31 Scope 3

2 Normative references 3

3 Testing of grout 3

3.1 General conditions 3

3.2 Fluidity test 3

3.2.1 Immersion method 3

3.2.1.1 Principle of test 3

3.2.1.2 Apparatus 3

3.2.1.3 Calibration procedure 3

3.2.1.4 Test procedure 33.2.1.5 Reporting the results 5

3.2.2 Cone method 5

3.2.2.1 Principle of test 5

3.2.2.2 Apparatus 5

3.2.2.3 Test procedure 5

3.2.2.4 Reporting of results 5

3.3 Bleeding test 5

3.3.1 Principle of test 5

3.3.2 Apparatus 5

3.3.3 Procedure 5

3.3.4 Reporting of results 6

Page

3.4 Volume change test 6

3.4.1 Principle of test 6

3.4.2 Cylinder method 6

3.4.2.1 Apparatus 6

3.4.2.2 Procedure 6

3.4.2.3 Reporting of results 6

3.4.3 Can method 6

3.4.3.1 Apparatus 6

3.4.3.2 Procedure 6

3.4.3.3 Reporting of results 6

3.5 Compression strength test 6

3.5.1 Prisms 6

3.5.1.1 Principle of the test 6

3.5.1.2 Apparatus 7

3.5.1.3 Procedure 7

3.5.1.3.1 Moulding of the test specimens 7

3.5.1.3.2 Curing of test specimens 8

3.5.1.3.3 Compression test 8

3.5.1.4 Reporting of results 8

3.5.2 Cylinders 83.5.2.1 Principle 8

3.5.2.2 Apparatus 8

3.5.2.3 Procedure 8

3.5.2.4 Reporting of results 8

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

8/17

Page 3EN 445 : 1996

BSI 1997

0 Introduction

In post-tensioned prestressed concrete construction,

the grouting of tendons is an important operation. ThisEuropean Standard provides methods of test for groutspecified in EN 447. Some tests given herein arealternatives and it will be necessary to relate thechosen test method to the specified requirements.

1 Scope

This European Standard describes the methods of testfor grout specified in EN 447.

2 Normative references

This European Standard incorporates by dated orundated reference, provisions from other publications.These normative references are cited at theappropriate places in the text and the publications arelisted hereafter. For dated references, subsequentamendments to or revisions of any of thesepublications apply to this European Standard onlywhen incorporated in it by amendment or revision. Forundated references the latest edition of the publicationreferred to applies.

EN 196-1 : 1987 Methods of testing cement Determination of strength

EN 447 Grout for prestressing tendons

Specification for common grout

ISO 4012 Concrete Determination ofcompressive strength of testspecimens

3 Testing of grout

3.1 General conditions

The grouts shall be tested by competent personnelexperienced in the subject. The normal conditions oftemperature and relative humidity at test shall be asfollows:

temperature (20

2) C; relative humidity > 65 %.

These conditions are for the specification of the grout.Variations in temperature and humidity on site maycause variations in the test results and shall bereported.

The grout for the tests shall be made from materialsspecified in clause 4of EN 447 and mixed inaccordance with clause6 of EN 447. The temperatureof the freshly mixed grout is to be given in all testreports.

3.2 Fluidity test

3.2.1Immersion method3.2.1.1 Principle of test

The test consists of measuring the time a plungerneeds to drop through a defined amount of grout in atube.

3.2.1.2Apparatus

a)Calibrated immersion equipment, according to

figure 1.b)A 0,5 m spacer rod, according to figure 1.

c)A stopwatch.

3.2.1.3Calibration procedure

Calibrate the immersion equipment with glycerol(analytical grade) having a density of 1,226 g/cm3 at(200,5) C. The temperature of the room, immersionequipment and glycerol shall be (20 0,5) C during thecalibration.

Fill the cylinder with about 1,9 l glycerol up toapproximately 260 mm below the rim. After filling theimmersion equipment the glycerol shall be allowed torest for about 1 h. Then immerse the plunger to expelthe air bubbles from the glycerol, which may havebeen introduced into the glycerol during the filling ofthe cylinder.

After at least 1 h position the plunger so that its stopon the tail rod lies on the spacer placed at the top ofthe tube. Then pull the spacer away to allow theplunger to sink to the stop of the tube. Record thistime to the nearest second.

Repeat the calibration at least three times.

The mean value of all measured immersion times shallbe (341) s. If the test result deviates from this valuethe weight of the plunger shall be increased wheret > 35 s or reduced where t < 33 s. This is done byvarying the quantity of the lead pellets in the plunger.Delay repeating the calibration procedure for atleast 30 min to ensure that no air bubbles are in theglycerol resulting from the preceding calibrationprocedure.

3.2.1.4 Test procedure

Preparation

The adjustment of the immersion equipment shall betested before it is used. Adjustment of the immersionequipment shall be tested subsequently once a yearand/or after any damage.

Directly before the test place the equipment verticallyand dampen the inside of the tube and the plunger sothat the surface is moist but without free water.

Procedure

Fill the cylinder with approximately 1,9 l grout up toapproximately 260 mm below the rim, so that theplunger is fully immersed on introduction if its stop onthe tail rod lies on the spacer placed at the top of thetube. Then pull the spacer away; the plunger sinks tothe stop in the tube. Then raise the plunger back to itsinitial position, insert the spacer, pull it away again andmeasure the time until the stop lies on the tube.Measure the immersion times of the grout immediatelyafter the mixing process and after 30 min.

For the test after 30 min, grout from the same mix asthat used for the immersion test immediately after themixing process shall be used; the grout is to be kept inmotion with the stirrer until the carrying out of the testafter 30 min. Each test is carried out three times insuccession with the same filling.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

9/17

Page 4

EN 445 : 1996

BSI 1997

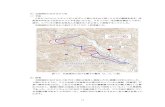

1 Stop2 Guide rod3 Wooden rod (as spacer)4 Cu-Zn tube5 Final position of the plunger6 Level7 Wooden rod (as measuring rod)8 White dye

9 Guide cam10 Grout level in the starting position of the plunger11 Grout level without plunger ( 1,9 l)

Figure 1. Immersion equipment for determining the immersion time

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

10/17

Page 5EN 445 : 1996

BSI 1997

3.2.1.5Reporting of results

Report the result as the average of the immersion

times to the nearest second of the second and thirdimmersion, ignoring the first immersion time.

3.2.2Cone method

3.2.2.1 Principle of test

The fluidity of grout, expressed in seconds, measuredby the time necessary for a stated quantity of grout topass through the orifice of the cone, under statedconditions.

3.2.2.2Apparatus

The following apparatus is required for the test.

a)Cone, a cone of the dimensions given in figure 2.

It shall be robust and manufactured from materialsnot reactive with any materials specified in clause 4of EN 447. The volume of the cone (excluding thecylindrical portions at top and bottom) shallbe 1,7 l 10 %.

b) Sieving medium, the sieving medium apertureshall be 1,5 mm and the sieving medium shall befitted as shown in figure 2, and be removable.

c)Stopwatch.

d) Container,of 1 l capacity.

3.2.2.3 Test procedure

Preparation

Mount the cone with its axis vertical and its largestdiameter uppermost. Fix the sieving medium at theposition indicated in figure 2. During the test preventthe cone from vibrating. Place the container under thecone outlet. All surfaces of the cone shall be clean andshall be dampened so that the surfaces are moist butwithout free water. Close the lower cone orifice.

Procedure

Pour the grout through the sieving medium to fill theconical section of the cone. Pour the grout sufficientlyslowly to prevent the build-up of air in the grout in thecone. Open the lower cone orifice and at the same

time, start the stopwatch. Measure the time taken tothe nearest 0,5 s to fill the container. The presence oflumps on the sieving medium shall be reported. Threetests shall be carried out, the first immediately afterthe grout is mixed and the remaining two tests 30 minafter mixing or injection. While testing is in progressthe grout shall be kept agitated.

3.2.2.4Reporting of results

Report the time taken to the nearest 0,5 s. Report alsothe presence of lumps.

Report the result as the average of the timesdetermined to the nearest 0,5 s of the second and thirdtests, ignoring the results of the first test.

Dimensions in mm

Figure 2. Cone for fluidity test

3.3 Bleeding test

3.3.1Principle of test

The test consists of measuring the quantity of waterremaining on the surface of the grout which has beenallowed to stand protected from evaporation.

3.3.2Apparatus

A transparent 100 ml cylinder 25 mm in diameterand 250 mm in height graduated in ml. Alternatively, atransparent cylinder 50 mm in diameter and 200 mm inheight graduated in mm.

3.3.3Procedure

Preparation

Place the cylinder on a surface free from shocks orvibration. The grout used should be from the samebatch as that used for the fluidity test.

Procedure for 25 mm diameter cylinder

Pour 95 to 100 ml of grout into the cylinder. Note the

level of the grout (v) ignoring the meniscus. After 3 h,measure the quantity of water on top of the grout (v1),taking appropriate measures to prevent evaporation.The test is carried out on one sample of grout.

Procedure for 50 mm diameter cylinder

Pour grout into the cylinder to a height ofapproximately 150 mm. Note the height to the top ofthe grout (h) ignoring the meniscus. After 3 h, measurethe height of water on top of the grout (h1) takingappropriate measures to prevent evaporation. The testis carried out on one sample of grout.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

11/17

Page 6

EN 445 : 1996

BSI 1997

3.3.4Reporting of results

Bleeding at the end of 3 h is given by

3 100 % for 25 mm diameter cylinderv1v

and

3 100 % for 50 mm diameter cylinderh1h

where:

v1 is the volume of water in ml on the surface ofthe grout after 3 h

v is the initial volume in ml of grout

h1 is the height in mm of water on the surface ofthe grout after 3 h

h is the initial height in mm of grout.

The report shall state the temperature at the time oftest.

3.4 Volume change test

3.4.1Principle of test

The volume change is measured as a percentage of thevolume of grout between the start and the end of thetest. The test measures mainly the volume changecaused by segregation or expansion.

The grout used in this test may have been used for thebleeding test (see 3.3).

3.4.2Cylinder method

3.4.2.1Apparatus

A transparent cylinder, 50 mm in diameter and 200 mmin height.

3.4.2.2Procedure

Place the cylinder on a surface free from shocks orvibration. Fill it with the grout to a height h.24 h afterfilling the cylinder measure the height (h2) of the groutin the cylinder.

3.4.2.3Reporting of results

The volume change at the end of 24 h is given by

3 100 %h2 2 h

h

where:

h is the initial height in mm of grout (see 3.4)

h2 is the height of grout in mm after 24 h.

3.4.3Can method

3.4.3.1Apparatus

a)Three metal cans, 120 mm high andapproximately 100 mm in diameter, with lids capableof preventing the loss of moisture.

b)Measuring rod orsliding calipers.c)Plates:

stop plate, for placing on the can with a diameterof 120 mm (see figure 3);

transparent stop plate, for placing on the groutand having a diameter of 98 mm and weight of 10 gapproximately (see figure 4).

d) Filling gauge.

3.4.3.2Procedure

Place the cans on a surface free of vibration and heatradiation and store for 24 h. Immediately after mixing,pour the grout into each can using the filling gauge, toa depth of 100 mm. Carry out a measurement of thedistance from the top of the can to the top of thegrout:

immediately after the containers are filled; and

24 h after the containers are filled;

by one of the following methods.

a) Measurement with the stop plate on the can

Take the first measurement immediately after thecans have been filled with grout, by measuring thedistance between the surface of the grout and thetop edge of the can, with the stop plate on the can,in at least six places with the depth gauge or byother means (first measurement). The marking shallcoincide with the top edge of the can (referencepoint). Then seal the cans by covering the lid with aweight of approximately 300 g until the secondmeasurement. Carry out the secondmeasurement 24 h after the filling of the cans.In the second measurement, measure the distancebetween the firm surface of the grout and the top

edge of the can at the same places with the samemeans as for the first measurement.

b) Measurement with the stop plate on the grout

Immediately after filling the cans, put the stop plate(figure 4) on the fresh grout and measure with thedepth gauge the distance between this plate and thetop edge of the can in at least six places (firstmeasurement). Then seal the cans. Carry out thesecond measurement 24 h after the filling of thecans. In the second measurement, measure thedistance between the stop plate and the top edge ofthe can at the same six places as for the firstmeasurement.

3.4.3.3Reporting of results

The difference of the average values between the firstand second measurement(s) in mm correspondsat 100 mm grout level to the volume change in percentand is reported as the percentage change in volume.

Report the percentage change in volume as the averageof the three containers to the nearest 0,1 %. Reportincrease of volume as (+) and decrease as (2).

3.5 Compression strength test

3.5.1Prisms

3.5.1.1Principle of the test

The compression strength of grout in this test (whichis an adaptation to grouts of the mechanical testsdescribed in EN 196-1) is determined on the brokenhalves of prisms.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

12/17

Page 7EN 445 : 1996

BSI 1997

3.5.1.2Apparatus

a)Mixer for grout, in accordance with the

requirements of EN 447.b) Ventilated drying cupboard, with a temperatureof (20 1) C and a relative humidity of (95 5) %.

c)Test machines, and the devices in accordancewith4.7 and 4.8 of EN 196-1.

d) Metal moulds, in accordance with 4.5 ofEN 196-1.

e)Metal straight edge, in accordance with figure 3 ofEN 196-1.

Dimensions in mm

a) Container

b) Plate

Figure 3. Plate on the can

Dimensions in mm

a) Container

b) Plate

Figure 4. Plate on the grout

3.5.1.3Procedure

3.5.1.3.1Moulding of the test specimens

The moulds and accessories shall be prepared and thespecimens made in accordance with EN 196-1, with theexception noted as follows.

Each mould shall be filled with the prepared grout. Asan exception to the procedure in EN 196-1 (andbecause of the liquidity of grouts) the test specimensshall not be subjected to any vibration or shock.

Immediately strike off the excess grout with the metalstraight edge held almost vertically and moved slowly,with a transverse sawing motion once in eachdirection. Smooth the surface of the specimens usingthe same straight edge held almost flat. Then cover thespecimens with a glass plate.

Label or mark moulds to identify the specimens.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

13/17

Page 8

EN 445 : 1996

BSI 1997

3.5.1.3.2 Curing of test specimens

Cure test specimens in accordance with EN 196-1, untilthey are tested.

3.5.1.3.3Compression test

The compression test shall be carried out inaccordance with EN 196-1. The compression strengthshall be measured on six test specimens from threeprisms broken in flexure.

3.5.1.4Reporting of results

The report shall provide all the results of thecompression tests, in MPa.

The value obtained for each test shall be the mean ofthe individual results.

3.5.2Cylinders

3.5.2.1 Principle

The compressive strength of grout in this test isdetermined on the three cylinders used in the volumechange test given in 3.4.3.

3.5.2.2Apparatus

a)The cans, as described in 3.4.3.1.

b)A compression test machine, as described inISO 4012.

c)Equipment, for sawing and grinding testspecimens.

3.5.2.3ProcedureAfter measuring the volume change, store the threecylinders in water at (20 1) C until they are to beprepared for test. Immediately prior to test, carefullydemould the specimens.

Prepare each specimen for test by sawing through thecylinder near the upper surface and then grinding bothcircular surfaces of the cylinder until the disc to beloaded in the test has a thickness of 80 mm.

Then test each specimen in accordance withISO 4012 until the maximum load (Fc) is reached.

3.5.2.4Reporting of results

Calculate the compressive strength Rc in N/mm2

from

Rc =FcA

where

Fc is the failure load in N

A is the cross-sectional area in mm2

and shall be measured on three specimens, the meanvalue of which shall be reported as the compressivestrength. The report shall provide all the test results.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

14/17

BSI 1997

Issue 2, December 1997 Page 9

BS EN 445 : 1997

National annex NA (informative)

Cone for fluidity test

|

152 3

10 0,1

280

10

60

3

1

1. Sieving medium

Figure NA1. Cone for fluidity test

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

15/17

10 blankLicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

16/17

BSI 1997

BS EN 445 : 1997

List of references

See national foreword.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I

-

5/19/2018 BS EN 445-1997

17/17

BSI

389 Chiswick High Road

LondonW4 4AL

||||||||||||||||||

|||||||||||||||||||||||||

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

||||||||||

BSI British Standards Institution

BSI is the independent national body responsible for preparing British Standards. Itpresents the UK view on standards in Europe and at the international level. It is

incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of British Standardsshould make sure that they possess the latest amendments or editions.

It is the constant aim of BSI to improve the quality of our products and services. Wewould be grateful if anyone finding an inaccuracy or ambiguity while using thisBritish Standard would inform the Secretary of the technical committee responsible,the identity of which can be found on the inside front cover. Tel: 020 8996 9000.Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which ensures thatsubscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should beaddressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001.

In response to orders for international standards, it is BSI policy to supply the BSIimplementation of those that have been published as British Standards, unlessotherwise requested.

Information on standards

BSI provides a wide range of information on national, European and internationalstandards through its Library and its Technical Help to Exporters Service. VariousBSI electronic information services are also available which give details on all itsproducts and services. Contact the Information Centre. Tel: 020 8996 7111.

Fax: 020 8996 7048.

Subscribing members of BSI are kept up to date with standards developments andreceive substantial discounts on the purchase price of standards. For details ofthese and other benefits contact Membership Administration. Tel: 020 8996 7002.Fax: 020 8996 7001.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, ofthe publications of the international standardization bodies. Except as permittedunder the Copyright, Designs and Patents Act 1988 no extract may be reproduced,stored in a retrieval system or transmitted in any form or by any means electronic,photocopying, recording or otherwise without prior written permission from BSI.

This does not preclude the free use, in the course of implementing the standard, ofnecessary details such as symbols, and size, type or grade designations. If thesedetails are to be used for any other purpose than implementation then the priorwritten permission of BSI must be obtained.

If permission is granted, the terms may include royalty payments or a licensingagreement. Details and advice can be obtained from the Copyright Manager.Tel: 020 8996 7070.

LicensedCopy:

man-mcgibew2man-mcgibew2,UniversityofManchest

er-(JISC),06January2005

,UncontrolledCopy,(c)BS

I