BS 3958 part6

Transcript of BS 3958 part6

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

B S I BS*3754 P A R T * b 72 W L b 2 q b b 9 0 0 3 7 0 0 9 7 W

SPECIFICATION FOR

THERMAL INSULATING MATERIALS

Part 6. Finishing materials; hard setting composition,

self-setting cement and gypsum plaster

BS 3958 : Part 6 : 1972

BRITISH STANDARDS INSTITUTION Incorporated by Royal Charter

. 2 PARK STREET, LONDON W1A 2BS Telex: 266933 Telephone: 01-629 goo0

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

-I__-- - ---__IpI__

ES1 B S * 3 9 5 ô P A R T * b i 2 L b 2 4 6 6 9 00370LO 3 W

BS 3958 : Part 6 : 1972

THIS BRITISH STANDARD, having been approved by the Refrigeration, Heating and Air Conditioning Industry Standards Committee, was published under the authority of the Executive Board on 7 April, 1972.

OBritish Standards Institution, 1972.

SBN : 580 97121 9

The Institution desires to call attention to the fact that this British Standard does not purport to include all the necessary provisions of a contract.

In order to keep abreast of progress in the industries concerned, British Standards are subject to periodical review. Suggestions for improvements will be recorded and in due course brought to the notice of the committees charged with the revision of the standards to which they refer.

A complete list of British Standards, numbering over 5000, fully indexed and with a note of the contents of each, will be found in the British Standards Yearbook, which may be purchased from BSI Sales Department, It may also be consulted in many public libraries and similar institutions.

This standard makes reference to the following British Standards and Code of Practice:

BS 874. Methods of determining thermal properties, with definitions of thermal insulating terms.

BS 2972, Methods of test for thermal insulating materials. BS 3533. Glossary of terms relating to thermal insulation. BS 3958. Thermal insulating materials. CP 3005. Thermal insulation of pípework and equipment.

British Standards are revised, when necessary, by the issue either of amendment slips or of revisededitions. It is important that users of British Standards should ascertain that they are in possession of the latest amendments or editions.

The following BSI references relate to the work on this standard: Committee reference RHE/9 and RHE/9/4 Draft for comment 70/20324

~~

Printed in England ;The Baynard Press. London, ECIR OJU (2500)

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

BSI BS*3358 P A R T * b 7’2 1b24hb7 0037011 5 W

BS 3958 : Part 6 : 1972

CONTENTS Page

Foreword 5 Co-operating organizations 4

SPECIFICATION

2. Definitions 5

4. Classification 6 5. Bulk density 6 6. Wet covering capacity 6

1. Scope 5

3. Sampling and testing 5

7. Thermal conductivity 7 8. Storage requirements 7 9. Additional requirements 7

by the manufacturer 9 11. Packaging 9 12. Marking 10 13. Identification of asbestos-free material

10. Information to be given by the purchaser and

10

APPENDICES A. Consistency test 11 B. Conditioning of test specimens 11 C. Test for determination of wet covering capacity 12 D. Heat resistance test 13 E. Resistance to impact test for self-setting cement 14

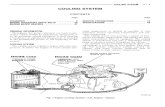

FIGURE 1, Apparatus for comparison of consistency 15

3

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

~~

B S I B S X 3 9 5 B P A R T * b 72 3 6 2 4 b b ï 0 0 3 7 0 3 2 7

BS 3958 : Part 6 : 1972

CO-OPERATING ORGANIZATIONS The Refrigeration, Heating and Air Conditioning Industry Standards Committee, under whose supervision this British Standard was prepared, consists of representatives from the following Government departments and scientific and industrial organizations : Association of Consulting Engineers Association of Manufacturers of Domestic Electrical Appliances Boiler and Radiator Manufacturers’ Association

British Oil and Gas Firing Equipment Manufactureys’ Association

Department of Health and Social Secuyity Electricity Council, The Central Electricity Generating Board

and the Area Boards in England and Wales Engineering Equipment Users’ Association

Heating and Ventilating Contractors’ Association Heating and Ventilating Research Association HEVAC Association Institute of Fuel Institute of Refrigeration Institution of Electrical Engineers

*Institution of Gas Engineers *Institution of Heating and Ventilating Engineers Lloyds Register of Shipping Ministry of Defence (Navy) National Coal Board Water-tube Boilermakers’ Association

a British Mechanical Engineering Confederation *British Refrigeration and Air Conditioning Association *Department of the Environment

*Gas Council

*Royal Institute of British Architects

The Government department and scientific ani industrial organizations marked with an asterisk in the above L t , together with the following, were directly represented on the committee entrusted with the preparation of this British Standard: Asbestos Cement Manufacturers’ Association British Chemical Plant Manufacturers’ Association Combustion Engineering Association Council of British Manufacturers of Petroleum Equipment Department of the Environment (Building Research Station) Electrical Research Association Fibre Building Board Development Organization Eurosil-UK Association of Manufacturers of Mineral Fibre

Gypsum Plasterboard Development Association Ministry of Defence (Combined) Structural insulation Association Thermal Insulation Contractors’ Association

Insulation

4

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

B S I BSm3958 PARTmh 7 2 = 3b24bb7 0 0 3 7 0 3 3 9 ~ ~ ~~

BS 3958 t Part 6 : 1972

BRITISH STANDARD SPECIFICATlON FOR

THERMAL INSULATING MATERIALS Part 6. Finishing materials ; hard setting composition,

t self-setting cement and gypsum plaster

FOREWORD This Part of this British Standard gives requirements for certain finishing materials that are used in conjunction with the thermal insulating materials specified in other Parts of the Standard.

A complementary series of British Standards* relating to the use of thermal insulation materials for temperatures above ambient and up to 650 "Chas been established to give guidance on the thickness of insulation to be used.

SPECIFICATION 1. SCOPE

This British Standard specifies requirements for finishing materials, prepared for use by mixing with water, for application to insulating materials after they have been applied a t site to the plant or piping systems.

Some of these hishing materials are used for services at temperatures below ambient, in which case a vapour barrier is required (see CP 3005). NOTE. The titles of British Standards referred to in this standard are listed on page 2.

2. DEFINITIONS For the purposes of this British Standard, the definitions given in BS 874, BS 3533 and BS 3958 apply.

3. SAMPLING AND TESTING Sampling and testing shall be in accordance with the appropriate clauses of BS 2972, supplemented where necessary, or where demanded by the user, by additional tests, details of which are given in appendices to this standard.

For the purposes of the tests in this standard, the water to weight ratio shall be such as to give a consistency of between 5 and 20 revolutions as given by the results of the consistency test described in Appendix A.

*BS 1334, 'The use of thermal insulating materials for central heating and hot and cold water supply installations'. BS 1588, 'The use of thermal insulating materiais in the temperature range 95 O C to 230 OC'. BS 3708, 'The use of thermal insulating materials between 230 OC and 650 OC'.

5

For conditioning prior to test, see Appendix B.

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

,--- -- /4.1 Finishing materials are generally supplied as dry powders which, when‘,

mixed with water in suitable proportions, are applied in plastic form and dried or set in place to form a hard, smooth surface.

4.2 Finishing materials may be classified in three main types, as follows: (i) Hard setting composition, which sets by removal of water on heating,

is a mixture of inorganic fillers and well distributed reinforcing fibres with a I

clay bonding agent, (2) Sevsetfittg cement, which sets without the application of heat, consists

of well distributed reinforcing fibres with a hydraulic cement as binder, with or without a plasticizing agent or fillers.

( 3 ) Gypsum plaster composition, which sets without the application of heat, consists of calcium sulphate hemihydrate, with the addition of well distributed reinforcing fibres, usually to a lower percentage by weight than fxsglf-set t k c m e n t . NOTE. Materials (1) and (3) above are adversely affected by water. Material (2) is “07% adversely affected but may absorb and transmit water if it is allowed to lie for long i

periods. 1 Materiais (1) and (3) should not be used out of doors unless protected, and care should be taken in using material (2) out of doors (see CP 3005).

The bulk density shall be determined in accordance with BS 2972.

5.1 Hard setting composition. The density of the coating, applied and dried, shall be not greater than 1500 kg/m*. 5.2 Self-setting cement. The density of the coating, applied and dried, shall be not greater than 1800 kg/m3.

5.3 Gypsum piaster composition. The density of the coating, applied and dried, shall be not greater than 1600 kg/ms.

5.4 Limits. For any particular product the variation from the manufacturer’s quoted value for bulk density shall not exceed f 15 %.

~ - -- ---- 4 . - € I X % n O N BS 3958 : Part 6 : 1972 I

I

5. BULK DENSITY

6, WJ3T COVERING CAPACïïY The wet covering capacity shall be determined in accordance with Appendix C.

As a general guide, it will be found that the covering capacities will lie between the following ranges:

(1) Hard setting composition. 105-50 ma/lOOO kg at 13 mm thickness. (2) Self-setting cement, 95-40 ma/lOOO kg at 13 mm thickness. (3) Gypsumplaster composition. 60-45 ma/lOOO kg at 13 mm thickness.

NOTE. The wet covering capacity of the self-setting cements cannot be directly related fo the applied and dried density as some of the water used for mixing combines chemically with hydraulic cement, The self-setting cements, of course, vary with the manufacturer and the water of hydration will vary from material to material.

I

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

BS 3958 : Part 6 : 1972

The covering capacity over insulation may differ from figures obtained by the method described in Appendix C, which refers to a non-absorbent substrate.

7. THE- CONDUCïMTY Finishing compositions are not specifically manufactured as thermal insulants,

system. Where it is necessary to take this into account in calculations, a thermal conductivity of 0.2 W/m K may be assumed.

4 but they do make some contribution to the thermal resistance of the insulation

9. ADDITIONAL REQUIREMENTS‘ 9.1 Homogeneity. The materials shaü be thoroughly premixed and substan- tially free from unopened or badly distributed fibre or coarse constituents.

9.2 Inertness. The material shall not include substances that will promote corrosive attack on the surfaces with which it is in contact (e.g. wire netting used as reinforcement).

Attentionlis drawn to the effects of chlorides on austenitic steels (see CP 3005).

9.3 Heat resistance. The material as applied shall not deteriorate at the maximum temperature of use.

Finishing compositions and self-setting cements are normally not applied to surfaces that will be above 65 OC, but íhey may come into contact with hot surfaces where the insulation is penetrated by supports or valves or terminates at boiler or furnace casings,

In some applications the insulated equipment may be entirely enclosed in spaces where the ambient temperature is relatively high, with a correspondingly elevated temperature of the finishing composition.

A method of test for stability at elevated temperatures is given in Appendix D. NOTE. Normally, hard setting composition is not recommended for use above 150 OC, or gypsum plaster above 50 OC.

9.4 Setting time. The conditions of setting should be stated by the manu- facturer. NOTE 1. Hard setting compositions do not contain hydraulic setting agents and setting time will depend upon the rate at which the mixing water is either absorbed into the underlying insulation or evaporated from the surface, or both.

I

8. STORAGE REQUEUMENT S For hard setting compositions, the maximum free moisture content shall be not greater than 5%. Self-setting compositions and gypsum plaster will be supplied dry and it is essential that they are maintained dry during storage.

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

BSI ~ s * 3 7 5 8 PART*6 7 2 lib2Llbb7 0 0 3 7 0 3 6 q rn ~

BS 3958 : Part6 : 1972

Application is facilitated and setting time reduced when the equipment to be insulated is gently heated, Then the hard setting composition wiii be reasonably set in 5 hours to 6 hours, although complete drying may take much longer. NOTE 2. Self-setting cements are hydraulic setting and only as much as can be used within 1 hour should be mixed at one time.

The time for the cement to take an initiai set depends upon the absorbency of the under- lying insulating material. On absorbent material the cement takes its initial set and can be compacted and &ally trowelled in 2 hours to 3 hours.

On non-absorbent or only slightly absorbent materials the initial set may take up to 24 hours.

Final drying out wul depend on the ambient temperature. NOTE 3. Gypsum plaster compositions set much more rapidly and only as much as can be used within 30 minutes shouíd be mixed at one time.

These compositions will set hard over absorbent or non-absorbent insulation materials within 1 hour. 9.5 Resistance to compression. The characteristics of the insulating materials to which the finishing materials are applied vary widely both in respect of mechanical strength and adhesion between the insulation and covering.

Commonly used reinforcing materials, such as wire netting, also affect the mechanical strength of the complete installation,

The test specified in 7.2 of BS 2972 : 1961 may be used to determine the resistance to compression of finishing materials except that the sample size shall be 75 mm x 75 mm x 25 mm.

For 10 % deformation the resistance to compression shall be not less than the following values :

Hard setting composition lo00 kN/ma Self-setting cement 1700 kN/ma Gypsum plaster 800 kN/m8

The density of the specimen tested shall be stated. 9.6 Flexural strength. When coating compositions are applied over resilient or easily compressed insulating materials, any loading such as may arise, for example, from a ladder placed against the surface, may cause damage by flexing the covering rather than by direct compression.

The method of test of flexural strength shall be as given in BS 2972, except that the specimen size shall be 300 mmx75 mmx 13 mm and that the test shall be carried out on 250 mm centres.

The flexural strength of self-setting cement shall benot less than 2000 kN/ma. Figures for hard setting compositions and gypsum plaster vary consider-

ably from one manufacturer to another and manufacturers’ recommendations should be sought.

The density of the specimens shalI be stated in the test report. 9.7 Resistance to impact. The test for resistance to impact is only intended for self-setting cement and the method of test is given in Appendix E.

The average diameter of five indentations shall not exceed 30 mm. Any cracking of the specimen that is observed shall be reported.

8

r’

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

BSI BSm3’758 PART*b 7 2 M 1 b 2 4 b b ï 0037037 b m BS 3958 : Part 6 : 1972

9.8 Consistency of wet-mixed finishing materiais. The consistency of the wet material, as prepared in accordance with the manufacturer’s recommendations for application, affects such properties as ease of trowelling, wet adhesion, drying, shrinkage and density.

A method of test for consistency is given in Appendix A. For the purposes of the tests in this standard, the water to weight ratio

shaU be such as fo give a consistency of between 5 and 20 revolutions (as given by the results of the consistency test described in Appendix A).

10. INFORMATION TO BE GIVEN BY THE PURCHASER AND BY THEMANUFACTURER

10.1 The following information shall be given by the purchaser. (1) Type of finishing material required, i.e. hard setting composition or

(2) Whether or not the finishing material is to be asbestos-free. (3) Nature of insulation material to which ñnishing material is to be

(4) Whether heat is expected to be available at the time of application. (5 ) Any special features of storage conditions so that appropriate packing

may be arranged, e.g. where the material may be kept in very humid conditions.

(0 Any special or unusual conditions of service anticipated, e.g. high ambient temperatures.

self-setting cement or gypsum plaster.

applied.

10.2 The following information shall be given by the manufacturer. (1) Limiting temperature of the applied and dried coating. (2) Recommendations for mixing and application. (3) Recommended thickness of use. (4) Setting times, initial and ñnal. (5) Shelf life and recommended storage conditions. (0 Covering capacity. (7) Recommendations on additional treatment (see Note),

NOTE. Suitable anti-alkali or insulating primers may be nececsary for a satisfactory paint application and the advice of the manufacturer of the finishing material should be sought.

11. PACñAGING The material shall be supplied in 12.5,25 or 50 kg multiwall bags incorporating a waterproof membrane, or in waterproof plastics containers.

Packages of other weights may be supplied subject to agreement between the purchaser and the supplier.

To minimize dust problems, the bags may be supplied large enough to allow for the mixing water to be added to the material in the bag.

9

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

BS 3958 : Part 6 : 1972

12. MARKING Material purporting to comply with this standard shall be supplied in sealed containers with the following markings:

(i) Manufacturer's name, designation or trade mark; if the material con- tains asbestos, this shall be clearly indicated.

(21 Classification of material (see 4). (3) The number of this British Standard, Le. BS 3958/6.

NOTE; Attention is drawn to the certification facilities offered by BSI; see back cover of this standard.

13. IDENTIFICATION OF ASBWTOS-F€U3E MA"J2RTAL 13.1 Government Regulations* concerning asbestos-containing insulation materials require that special precautions be observed in order to safeguard the health of individuals who are handling these materials, or who are working in the vicinity.

13.2 In order to identify those materials that will not involve regulation control, asbestos-free finishing materials manufactured in accordance with Part 6 of this standard, shall be distinctively coloured red/brown. The colouring matter shall remain sufficiently stable and permanent under service conditions to permit the ready identification of the outer surface of the insulation.

13.3 Materials that contain asbestos fibre shall not be other than self-coloured.

*Statutory Instruments 1969, No. 690, Factories, 'The Asbestos]Regulations~l969'.

10

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

~~ ~~

BSI BSm3958 PART*b 7 2 L b 2 q b b ï 00370119 T ~~-

BS 3958 : Part 6 : 1972

APPENDIX A

CONSISTENCY TEST

A.l Apparatus. The sample of wet-mixed material is contained in a metal beaker. The beaker is carried in a vertically sliding cage that is lifted in guides by means of a pair of cams shaped so that, at the top of the stroke, the cage and beaker are allowed to drop freely. The camshaft may be manually or power driven. A counter is fitted to count thenumber of drops (see Fig. 1).

A corrosion-resistant steel ball, weighing 225 g and of diameter 40 mm, is required.

Speed of camshaft Approximately 1 rev/s

Size of beaker 500 ml (approximately 75 mm diameter x 130 mm height).

Drop height 20 mm

A.2 Method. The ambient temperature, the temperature of the water and of the dry mixture at the time of test is to be 16 f 2 OC. Thoroughly mix a represen- tative quantity of dry material and take a 500 g sample. Gauge the sample with the recommended quantity of water and mix by trowel to give a uniform paste. Place the mixture in the metal beaker in four approximately equal layers. Unless the manufacturer's instructions state otherwise, the time taken from gauging the mix to filling the beaker is to be not less than 3 minutes or more than 5 minutes, Place the beaker in the cage in which it should rest freely and then rotate the cam 20 times in order to remove entrained air and compact the mixture. With the cage in the highest position place the steel ball on top and in the centre of the mixture, Turn the counter to zero and rotate the cam at a constant rate (about one revolution per second) until the ball just disappears below the surface of the material. Note the number of revolutions and use as a measure of the consistency.

APPENDIX B

CONDITIONING OF TEST SPECIMENS

B.1 Hard setting compositions. Condition specimens in accordance with 9 of BS 2972 : 1961.

B.2 Seif-setthg cements. Condition the specimens after mixing and moulding in impervious moulds by the following procedure.

Cover the material with polyethylene or other suitable plastics film and leave in the mould for two days to set. Remove the specimen from the mould

11

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

-Ip--- -.-.I- ---- I BSI 'BS*3958 P A R T * b 7 2 - Lb24bb9 0037020 b a BS 3958 : Part 6 : 1972

and allow to cure on wire mesh trays with free circulation of air in normal laboratory conditions (approximately 20"C, 64 r,hJ for 11 days.

Dry the specimen to constant weight at 105OC. Total curing time, 14 days.

B.3 Gypsum plaster compositions. After moulding cover the specimen with polyethylene or other suitable plastics film and leave in the mould for two days.

After removal from the mould dry the specimen to constant weight in a weil-ventilated oven maintained at a temperature of between 35 "C and 40 OC.

APPENDIX C

TEST FOR DETERMINATION OF WET COVERING CAPACITY

C.1 General. The test for covering capacity involves the application of the finishing material in a metal or other non-absorbent mould.

(2.2 Mould. The mould shall be rigid and have internal dimensions 450 mm x 300 mm x 25 mm deep.

The base of the mould may be of metal plate or other non-absorbent smooth flat material. The walls may be of angle section or of wood firmly secured to the baseplate by tap bolts or screws. NOTE. The provision of wing nuts for securing the walls to the baseplate is of assistance for easy removal of the specimen.

C.3 Preparation. Treat the mould with a release agent to prevent sticking of the material. Alternatively, thin polyethylene sheet may be used to line the mould.

C.4 Method. Mix in a bowl a known weight of the composition or cement with water to the appropriate ratio (see 3). Note the weight of mixing water.

Fill sufficient of the wet mix into the mould, taking care to avoid undue pressure, and work by trowel or float to a compacted level surface flush with the sides.

Weigh the unused material and obtain the amount used to ñíl the mould by difference, To obtain the weight of dry material used (W, see C.6), a correction must be made for the water used in mixing.

C.5 Drying. Drying is not essential to the test, but the specimen may be left to air dry if so recommended by the manufacturer or may be heated over a hot plate.

After drying, the hishing material should be examined for cracking or shrinkage from the sides of the mould.

12

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

B S I BS*375B P A R T * b 7 2 Z b 2 4 b b ï 0037023 B ~~

BS 3958 : Part 6 : 1972

C.6 Expression of results. The covering capacity is expressed as follows: bl c=-

1000 w where C = covering capacity at 25 mm thickness (rn*/lOûO kg),

b = breadth of mould (mm), I = length of mould (mm), W = weight of dry material used in mould (kg).

APPENDIX D HEAT RESISTANCE TEST

D.l Heat resistance test. This test is designed to determine changes in weight, dimensions and resistance to compression following the heating of test speci- mens for 24 hours at the desired service temperature. D.2 Preparation of test specimens. Mix a sample of the material with clean water to the ratio as determined according to the method shown in Appendix A (see 3) and trowel to uniform thickness in a mould as specified in Appendix C (13 mm thickness) or as specified in 9 of BS 2972 : 1961.

Allow the sample to air dry or set. From the dry sample cut to the requisite degr& of accuracy specimens of dimensions governed by subsequent test sample measurements.

D.3 Procedure D.3.1 Initial drying and weighing. Dry the specimens in a well-ventilated oven, at 105 "C to 110 "Cy to constant weight, For gypsum plaster, the oven temper- ature is between 35 "C and 40 O C .

Determine and note the weight and resistance to compression (see 7 of BS 2972 : 1961). D.3.2 Heating. Heat the samples continuously for 24 hours in an oven at the desired temperature.

D.3.3 Examination after heating. Remove the specimens from the desiccator and carry out the tests without delay in the following order:

At the end of the heating allow the specimens to cool in a desiccator.

(1) Weighed. (2) Measured. (3) Subjected to a resistance to compression test.

D.4 Reporting. In addition to reporting changes noted in accordance with D.3, note any cracking that occurred during heating.

13

I COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

B S I BSm3958 P A R T * b 7 2 W Lb2Vbb9 0 0 3 7 0 2 2 T W

BS 3958 : Part 6 : 1972

APPENDIX E

RESISTANCE TO IMPACT TEST FOR SELF-SETTING CEMENT

Cut specimens from samples modded in accordance with the method specaed for the determination of covering capacity in accordance with Appendix C. A convenient size of specimen is 250 mm x 250 mm and the thickness is nominally 25 mm.

Place the specimen on a flat, smooth concrete floor or steel plate. Drop a steel ball of mass 1 kg and 62.5 mm diameter from a height of

1.5 ni on to the surface of the specimen, at least 50 mm from the nearest edge and from the location of a previous indentation.

Measure the diamefer of the impression made by the ball. Repeat the test at least five times and report the average diameter of five

Report any cracking of the specimen that is observed. indentations.

14

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

B S I BS*3958 PART*b 72 m Lb2qbb9 0037023 m ~

BS 3958 : Part 6 : 1972

Counter *Counter

+ Fig. 1. Apparatus for comparison of consistency

15

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

B S I BSm3958 PART*b 7 2 m l b 2 4 6 6 9 0037024 3 m

BRITISH STANDARDS INSTITUTION The British Standards Institution was founded in 1901 and incorporated by Royal Charter in 1929,

The principal objects of the Institution as set out in the charter are to co-ordinate the efforts of producers and users for the improvement, standardization and simplification of engineering and industrial materials ; to simplify production and distribution; to eliminate the waste of time and material involved in the pro- duction of an unnecessary variety of patterns and sizes of articles for one and the same purpose; to set up standards of quality and dimensions, and to promote the general adoption of British Standards.

In carrying out its work the Institution endeavours to ensure adequate representation of all viewpoints. Before embarking on any project it must be satisfied that there is a strong body of opinion in favour of proceeding and that there is arecognized need to be met.

The Institution is a non-profit-making concern, It is financed by subscriptions from members-indi- viduals, companies, technical and trade associations, and other bodies interested in its work, by a Govern- ment grant and by the sale of its publications. Membership of the Institution confers a number of specific rights and privileges. The demands on the services of the Institution are steadily increasing and can only be met if continuing and increasing support is provided by those who use British Standards,

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

'BSI B S * 3 7 5 B - P A R T * b 72 1 b 2 4 b b î 0037025 5 - ~- __ ~-

AMD 3287

Amendment Slip No. 1 published and effective from 30 May 1980

to BS 3958 : Part 6 : 1972

Thermal insulating materials Part 6. Finishing materials; hard setting composition,

self-setting cement and gypsum plaster

Revised text Clause 4.2. Delete the existing note and substitute the following:

'NOTE. Materials (i) and (3) above are adversely affected by water. Material (2) is not adversely affected but may absorb and transmit water if it is allowed to lie for long periods. Materials (1) and (3) should not be used out of doors unley protected, and care should be taken in using material (2) out of doors (see CP 3005).

8005-2.4k-8 Gr O COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services

COPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling ServicesCOPYRIGHT British Standards Institution on ERC Specs and StandardsLicensed by Information Handling Services