Brochure Shading Tension System 440 Horiso 2012

-

Upload

logeswaran-raji -

Category

Documents

-

view

214 -

download

0

description

Transcript of Brochure Shading Tension System 440 Horiso 2012

-

Applications

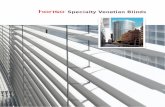

STS 440 is primarily designed for commercialbuildings such as offices, shops, hotels and airports as well as glazed structures such as conservatories, winter gardens and restaurants.

The STS 440 is suitable for rectangular fabric shades installed externally in front of or above horizontal and vertical glazing, including drawing vertically bottom to top.

A stainless steel wire acts as both a guide and restraint for the hembar and eliminates the need for relieving rollers or other forms of intermediate fabric support.

Design Specifications

A single 85 mm galvanized steel roller

incorporating both the drive motor and the spring compensation cassette with integral tension adjustment gear.

Extruded aluminium hem bar supporting the free end of the fabric.

Extruded aluminium headbox.

Shading Tension System 440 External wire guided tension system

Two 5 mm diameter stainless steel cables.

A continuous nylon coated tension to deploy and retract the blind.

Two 6.5 m capacity cable drums, one on either end of the fabric roller.

Design Options

Relieving roller for intermediate fabric support.

Finishes

Aluminium components - polyester powder finish, 30% gloss.

Steel - galvanised against corrosion.

Installation Option

Available with either with back fix or bottom fix headbox and return pulleys.

Maximum width: 4 mMaximum draw: 6.5 mMaximum fabric area: 16 m2Maximum fabric weight: 450 g/m2

1 / 4

-

STS 440 Components

7 Hem bar end cap

1 Head box back fix 2 Head box bottom fix 3 Return pulley back fix

5 Fabric roller 6 Motor with cable spool without mounting plate

4 Return pulley bottom fix

8 Hem bar

4

71

5

1

8

3

6

2 / 4

-

Tess 440 Technical specifications

System dimensions

Maximum width (m) 4

Maximum draw (m) 6.5

Maximum fabric area (m2) 16

Motor

Torque (Nm) 15

Current 0.65 amps

Supply 230 V AC single phase

Other voltages and frequencies available on request

System weights and structural loading

Base weight for a 1m wide system - 18 kg, additional metre width - 8 kg

Load created by fabric tension & guide wire - 100 kg per anchor point

Wind speed 11 metres / sec max.

Max. draw with Back fix return pulleys 5.0m

Max. draw with Bottom fix return pulleys 6.5m

Maximum draw (screen)

Maximum fabric area 16 m2

Maximum fabric weight 450 g/m2

Minimum width Std motor 1080 mm

Minimum width Radio motor 1230 mm

Maximum widthMinimum width

1.1 1.5 2 2.5 3 4

6.5

6

5

4

3

2

1

0

System width (m)

Sys

tem

dra

w (

m)

3 / 4

-

211

221

System width

79

79CRS

12 12

12

7525

53

25 A

25

180M

IN

Syst

em D

raw

- b

ack

fix

10

16020 21 30

10C

RS

55

78 67

140

MIN

191

Syst

em D

raw

- b

otto

m f

ix

25

25

142

10

156

5575

CRS

10CRS

30

220

10CRS

155

5015

Tess 440 Installation

All measurements in mm.

Horiso 2012 horiso.com 4 / 4