Brochure Inside Pages 21...

Transcript of Brochure Inside Pages 21...

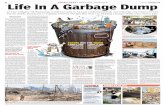

A br ie f ing paper based on an exp lora tory s tudy

Resource Initiative

23 May 2013, New Delhi

Leveraging efficiency to meet India's needs

Co

nte

nts

Resource Efficiency – Key for Sustainable Development

Concept of Life Cycle Thinking to Analyse Resource Efficiency

Case Study: Automotive Sector

Case Study: Housing Sector

Initiatives and Policies from Across the World

Key Messages and the Way Forward

1

6

7

11

14

16

Jointly prepared by:The Energy and Resources Institute (TERI)Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH Institut für Energie- und Umweltforschung (IFEU)

Financial support provided by: German Ministry of Economic Cooperation and Development (BMZ)

Design and PrintingM/s Rouge Communications, S-185, Greater Kailash Part 2, New Delhi

DISCLAIMER:“All results and key messages in this brochure are taken from the scoping study: “India's Future Needs for Resources - Dimensions, Challenges and Possible Solutions". Since the project is still in at a premature stage, all data and results should be used carefully and considered in its context. It is the objective of this project to further enhance the database and the assumptions of the developed models and support a larger debate on resource security and efficiency in India and globally."

Resource Efficiency –Key for Sustainable Development

Natural resources are essential for our quality of life and health. We depend on

resources like biogenic or mineral raw materials, energy resources like fuels, sun

and water as well as biodiversity and ecosystem services, land area and clean air

for our survival, and they all constitute vital inputs that keep our economy

functioning. Consequently, the importance of devoting attention to resource use,

with rising wants and needs but finite resources, is ever becoming more important.

It is obvious that the availability of natural resources is limited on a finite planet. But

resource demands are ever increasing. Industrialized countries already have a

high level of resource use while developing countries need resources to arrive at

an appropriate living standard for their population. Coordinated and

collaborative efforts are required to ensure both availability and conservation of

natural resources. Industrialized countries have to demonstrate how they can

maintain their living standard with a considerable lower use of resources and

developing countries need to reflect on how they can enhance their necessary

growth with the most efficient use of scarce natural resources.

Co

nte

nts

Resource Efficiency – Key for Sustainable Development

Concept of Life Cycle Thinking to Analyse Resource Efficiency

Case Study: Automotive Sector

Case Study: Housing Sector

Initiatives and Policies from Across the World

Key Messages and the Way Forward

1

6

7

11

14

16

Jointly prepared by:The Energy and Resources Institute (TERI)Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH Institut für Energie- und Umweltforschung (IFEU)

Financial support provided by: German Ministry of Economic Cooperation and Development (BMZ)

Design and PrintingM/s Rouge Communications, S-185, Greater Kailash Part 2, New Delhi

DISCLAIMER:“All results and key messages in this brochure are taken from the scoping study: “India's Future Needs for Resources - Dimensions, Challenges and Possible Solutions". Since the project is still in at a premature stage, all data and results should be used carefully and considered in its context. It is the objective of this project to further enhance the database and the assumptions of the developed models and support a larger debate on resource security and efficiency in India and globally."

Resource Efficiency –Key for Sustainable Development

Natural resources are essential for our quality of life and health. We depend on

resources like biogenic or mineral raw materials, energy resources like fuels, sun

and water as well as biodiversity and ecosystem services, land area and clean air

for our survival, and they all constitute vital inputs that keep our economy

functioning. Consequently, the importance of devoting attention to resource use,

with rising wants and needs but finite resources, is ever becoming more important.

It is obvious that the availability of natural resources is limited on a finite planet. But

resource demands are ever increasing. Industrialized countries already have a

high level of resource use while developing countries need resources to arrive at

an appropriate living standard for their population. Coordinated and

collaborative efforts are required to ensure both availability and conservation of

natural resources. Industrialized countries have to demonstrate how they can

maintain their living standard with a considerable lower use of resources and

developing countries need to reflect on how they can enhance their necessary

growth with the most efficient use of scarce natural resources.

India's material demand

To eradicate poverty and meet India’s human development needs, the Planning

Commission of India estimates that India needs to grow at a rate of 8% annually

until 2031/32 compared to the base year 2003/04. Concomitant with this growth is

the need for increased energy, minerals and metals, water and food. Per-capita

consumption of materials in India is still low compared to the rest of the world: with

3.8 tonnes per capita, India ranks at the 161st position in the world out of 191

countries (Dittrich et al., 2012). However, considering the future economic growth

rate and the growing population, it is obvious that in absolute terms the material

consumption will rise significantly.

During the past twenty years, India doubled the amount of materials used for

food, housing, infrastructure and energy supply as well as for consumption. Based 1on a Material Flow Analysis , in 2008, India consumed around 1.9 billion tonnes of

biomass (including all food, feed, animal and forestry products as well as products

made of biomass such as paper), more than 2.5 billion tonnes of non-renewable

materials, of which more than 1.8 billion tonnes are minerals (including metals,

industrial and construction minerals and products made out of minerals and

metals such as machines or glass) and around 700 million tonnes are fossil fuels

1 The Material Flow Analysis introduced by OECD (2007) is a widely-used concept internationally and aims at quantifying the material basis of the

economy in a comprehensive manner which is harmonized with economic accounting; integrating materials which enter further processing and are moved during economic activities. 2 The scenarios are based on the following main observations of global, regional and national material consumption in a historic and/or cross-

country comparison perspective: While the dynamic of biomass consumption is mainly linked to population size, the dynamic of minerals (including metal) and fossil fuels consumption is predominantly linked to economic growth. Further major influencing factors are for example production and consumption pattern (e.g. diet) and the energy mix.

Resource Initiative – Leveraging Efficiency to meet India's needs

2Figure1: India's past material demand and future projections until 2050

1980 2000 2010 2020 2030 2040 2050

30

25

20

15

10

5

0

billio

n t

on

nes

growth of economy as expected by government (around 8% p.a. until 2030) and between 6 and 7% p.a. thereafter as expected by TERIhigh growth in economy (higher than 10% p.a.); scenario until 2030low growth in economy (7% p.a. until 2015, decreasing 0.5% each 5 years thereafter)past material consumption

3

Where will the materials come from?

In the light of increase material consumption, a key question of where to source

the materials arises. Materials come either from domestic resources or can be

imported as raw materials or finished goods. Both sources have advantages as

well as limitations as described below.

Domestic extraction of materials

India is rich in primary raw materials. Currently, around 97 % of all materials,

including all biotic and non-renewable materials, consumed in India are extracted

within India. However, meeting a tripling demand of domestic raw materials would

mean that extraction has to increase from currently around 4.5 billion tonnes up to

more than 13 billion tonnes in the year 2030. To achieve this will require a

concentrated effort, financial outlays and social acceptability. For example,

some constraints to increased domestic mineral availability are the following:

¤ Insufficient exploration activity and lack of information: According to the

Ministry of Mines, India's mining sector has one of the lowest exploration

spends worldwide. The reserves for iron ore and bauxite in Australia grew 150

to 200% between 1985 and 2005. In contrast, in India they increased by only

15-20% as result of low exploration activity. Large investments in exploration

and generation of good quality geological data are required.

¤ Technological constraints: The lack of cost-effective technology for viable

extraction hampers the effort to increase the domestic supply. For instance,

suitable underground mining technology could increase the chromium ore

supply by 33%. Molybdenum could be obtained as a by-product of copper in

the presence of suitable technology for by-product production.

¤ Overlap with social/ecological sensitive regions: As some mineral reserves are

located within environmentally sensitive region, access to these materials is

difficult. Material extraction is linked to environmental, social and health

impacts.

¤ Policy/ regulatory deficits: There are problems in terms of unclear jurisdictions;

non action or delays in clearances; inefficient administration, a set of issues

that is currently receiving policy attention through the MMDR Bill.

(including coal, oil, gas and products made from fossil fuels such as plastics). As

shown in figure 1, if India continues to grow at the projected 8 % p.a. until 2030

and follows typical patterns of material use during development process, the

country would more than triple its material requirements and further increase its

material demand up to nearly 24 billion tonnes in 2050. In a lower estimation of

economic growth in India, material demand would increase up to more than 10

billion tonnes in 2030 and around 20 billion tonnes in 2050.

India's material demand

To eradicate poverty and meet India’s human development needs, the Planning

Commission of India estimates that India needs to grow at a rate of 8% annually

until 2031/32 compared to the base year 2003/04. Concomitant with this growth is

the need for increased energy, minerals and metals, water and food. Per-capita

consumption of materials in India is still low compared to the rest of the world: with

3.8 tonnes per capita, India ranks at the 161st position in the world out of 191

countries (Dittrich et al., 2012). However, considering the future economic growth

rate and the growing population, it is obvious that in absolute terms the material

consumption will rise significantly.

During the past twenty years, India doubled the amount of materials used for

food, housing, infrastructure and energy supply as well as for consumption. Based 1on a Material Flow Analysis , in 2008, India consumed around 1.9 billion tonnes of

biomass (including all food, feed, animal and forestry products as well as products

made of biomass such as paper), more than 2.5 billion tonnes of non-renewable

materials, of which more than 1.8 billion tonnes are minerals (including metals,

industrial and construction minerals and products made out of minerals and

metals such as machines or glass) and around 700 million tonnes are fossil fuels

1 The Material Flow Analysis introduced by OECD (2007) is a widely-used concept internationally and aims at quantifying the material basis of the

economy in a comprehensive manner which is harmonized with economic accounting; integrating materials which enter further processing and are moved during economic activities. 2 The scenarios are based on the following main observations of global, regional and national material consumption in a historic and/or cross-

country comparison perspective: While the dynamic of biomass consumption is mainly linked to population size, the dynamic of minerals (including metal) and fossil fuels consumption is predominantly linked to economic growth. Further major influencing factors are for example production and consumption pattern (e.g. diet) and the energy mix.

Resource Initiative – Leveraging Efficiency to meet India's needs

2Figure1: India's past material demand and future projections until 2050

1980 2000 2010 2020 2030 2040 2050

30

25

20

15

10

5

0

billio

n t

on

nes

growth of economy as expected by government (around 8% p.a. until 2030) and between 6 and 7% p.a. thereafter as expected by TERIhigh growth in economy (higher than 10% p.a.); scenario until 2030low growth in economy (7% p.a. until 2015, decreasing 0.5% each 5 years thereafter)past material consumption

3

Where will the materials come from?

In the light of increase material consumption, a key question of where to source

the materials arises. Materials come either from domestic resources or can be

imported as raw materials or finished goods. Both sources have advantages as

well as limitations as described below.

Domestic extraction of materials

India is rich in primary raw materials. Currently, around 97 % of all materials,

including all biotic and non-renewable materials, consumed in India are extracted

within India. However, meeting a tripling demand of domestic raw materials would

mean that extraction has to increase from currently around 4.5 billion tonnes up to

more than 13 billion tonnes in the year 2030. To achieve this will require a

concentrated effort, financial outlays and social acceptability. For example,

some constraints to increased domestic mineral availability are the following:

¤ Insufficient exploration activity and lack of information: According to the

Ministry of Mines, India's mining sector has one of the lowest exploration

spends worldwide. The reserves for iron ore and bauxite in Australia grew 150

to 200% between 1985 and 2005. In contrast, in India they increased by only

15-20% as result of low exploration activity. Large investments in exploration

and generation of good quality geological data are required.

¤ Technological constraints: The lack of cost-effective technology for viable

extraction hampers the effort to increase the domestic supply. For instance,

suitable underground mining technology could increase the chromium ore

supply by 33%. Molybdenum could be obtained as a by-product of copper in

the presence of suitable technology for by-product production.

¤ Overlap with social/ecological sensitive regions: As some mineral reserves are

located within environmentally sensitive region, access to these materials is

difficult. Material extraction is linked to environmental, social and health

impacts.

¤ Policy/ regulatory deficits: There are problems in terms of unclear jurisdictions;

non action or delays in clearances; inefficient administration, a set of issues

that is currently receiving policy attention through the MMDR Bill.

(including coal, oil, gas and products made from fossil fuels such as plastics). As

shown in figure 1, if India continues to grow at the projected 8 % p.a. until 2030

and follows typical patterns of material use during development process, the

country would more than triple its material requirements and further increase its

material demand up to nearly 24 billion tonnes in 2050. In a lower estimation of

economic growth in India, material demand would increase up to more than 10

billion tonnes in 2030 and around 20 billion tonnes in 2050.

In sum, India's growth, independent of any given GDP rate, will involve the need

for more materials. Socio-economic and environmental concerns may limit

domestic access and availability. The alternative, to increase imports, has its own

concerns, connected with market dependencies, as argued above. Hence, it is

important to leverage efficiency in resource use early on and along the entire life-

cycle of a product. The efficient use of energy is already recognised as being

important, but a case needs to be made for other materials as a key resource

policy option for India's growth story and development needs.

Resource Initiative – Leveraging Efficiency to meet India's needs

Materials imports

Currently, India net imports are approximately 3% of all materials consumed. India

has dependencies related to some raw materials as illustrated in the figure 2

which can raise a number of issues.

Fig 2: Import dependencies for selected raw materials

5

Resource efficiency can be understood as all kinds of activities which aim at

improving the input-output-relation of material and energy consuming or

transforming processes while contributing to the mitigation of impacts on the

environment caused by these products (GIZ 2012). A key element of

implementing resource efficiency measures is to promote the substitution of

primary raw materials by secondary materials through eco-design, waste

minimization and recycling. This will lead not only to a reduction in environmental/

climate burden but also a reduction in social conflicts. Further, economizing on

resources triggers cost reductions and promotes innovation processes. Economies

and companies that succeed in improving their energy and resource use

optimization are likely to develop a structural cost advantage, improve their ability

to capture new growth and job opportunities and reduce their exposure both to

energy, resource and environment-related interruptions to their business and to

resource price risk. Moreover, enhancing resource efficiency would also imply a

reduction in import dependencies and fluctuation in world market prices. A major

consequence of implementing a resource efficiency strategy is on the recycling

activities and market of secondary materials. The goal in these sectors should be

to focus on material flow management within closed cycles keeping in mind that

today's products are tomorrow's resources.

In particular, higher market dependencies along with rising and volatile prices for

raw materials endanger affordability and increase the economic burden for India.

Internationally, the global competition has led to strategic concerns due to raw

material nationalism and vulnerability of supply. Hence, import dependency may

imply a higher exposure to consequences of geopolitical conflicts and trade

distorting measures (e.g. export bans, taxes). The aforementioned risks are beyond

the influence of a single country and as the dependency grows, these risks will

jeopardize the secure material supply.

Source: IBM,2011

90% of phosphate

87% of fluorite

100% of molybdenum

95% of copper

74% of lead

100% of magnesite

100% of antimony

100% of nickel

100% of cobalt

70% of oil

INDIA

Pakistan

Tect

SriLanka

Andaman & Nicobar Islands(INDIA)

Lakshadweep(INDIA)

In sum, India's growth, independent of any given GDP rate, will involve the need

for more materials. Socio-economic and environmental concerns may limit

domestic access and availability. The alternative, to increase imports, has its own

concerns, connected with market dependencies, as argued above. Hence, it is

important to leverage efficiency in resource use early on and along the entire life-

cycle of a product. The efficient use of energy is already recognised as being

important, but a case needs to be made for other materials as a key resource

policy option for India's growth story and development needs.

Resource Initiative – Leveraging Efficiency to meet India's needs

Materials imports

Currently, India net imports are approximately 3% of all materials consumed. India

has dependencies related to some raw materials as illustrated in the figure 2

which can raise a number of issues.

Fig 2: Import dependencies for selected raw materials

5

Resource efficiency can be understood as all kinds of activities which aim at

improving the input-output-relation of material and energy consuming or

transforming processes while contributing to the mitigation of impacts on the

environment caused by these products (GIZ 2012). A key element of

implementing resource efficiency measures is to promote the substitution of

primary raw materials by secondary materials through eco-design, waste

minimization and recycling. This will lead not only to a reduction in environmental/

climate burden but also a reduction in social conflicts. Further, economizing on

resources triggers cost reductions and promotes innovation processes. Economies

and companies that succeed in improving their energy and resource use

optimization are likely to develop a structural cost advantage, improve their ability

to capture new growth and job opportunities and reduce their exposure both to

energy, resource and environment-related interruptions to their business and to

resource price risk. Moreover, enhancing resource efficiency would also imply a

reduction in import dependencies and fluctuation in world market prices. A major

consequence of implementing a resource efficiency strategy is on the recycling

activities and market of secondary materials. The goal in these sectors should be

to focus on material flow management within closed cycles keeping in mind that

today's products are tomorrow's resources.

In particular, higher market dependencies along with rising and volatile prices for

raw materials endanger affordability and increase the economic burden for India.

Internationally, the global competition has led to strategic concerns due to raw

material nationalism and vulnerability of supply. Hence, import dependency may

imply a higher exposure to consequences of geopolitical conflicts and trade

distorting measures (e.g. export bans, taxes). The aforementioned risks are beyond

the influence of a single country and as the dependency grows, these risks will

jeopardize the secure material supply.

Source: IBM,2011

90% of phosphate

87% of fluorite

100% of molybdenum

95% of copper

74% of lead

100% of magnesite

100% of antimony

100% of nickel

100% of cobalt

70% of oil

INDIA

Pakistan

Tect

SriLanka

Andaman & Nicobar Islands(INDIA)

Lakshadweep(INDIA)

Resource Initiative – Leveraging Efficiency to meet India's needs 7

Case Study: Automotive Sector

Economic growth and development is coupled with an increasing mobility which

often comes along with negative impacts such as pollution, collisions and

congestion. In India, mobility relies heavily on rail and road infrastructure. The

major modes of transport are two-wheelers, three-wheelers (auto-rickshaws), cars,

buses and railways. Nowadays the majority of trips in large Indian cities are made

by non-motorized or public transport. In 2003, 32% of all commuter trips in Delhi

were by foot, whereas motorized trips amounted up to 42%, with a large share of

bus trips. During the 1990's the share of personal transit modes (cars, two-wheelers,

auto-rickshaws) increased from 16.2% to 21.2%. Conventional public transportation

experienced an increase in absolute numbers but could not keep up with the

dynamic development of individual personal mobility. The highest increases in

vehicle numbers can be observed for two-wheelers and auto-rickshaws. But it is

expected that the ownership of cars will increase rapidly in the future due to rising

incomes in India. Figure 4 demonstrates the correlation between a rising GDP and

car ownership. The car ownership rate of India is still low, but as the trend indicates

this may change. The immense growth potential calls for a sustainable model of

transportation; given the “low car density path” with a broad use of bicycles and

public transit (e.g. NLD, SWE, CHE) in contrast to the “high car density path” with a

strong car dependent mobility (e.g. GER, USA).

Concept of Life Cycle Thinking to Analyse Resource Efficiency

Comprehensive environmental assessments must consider all stages of the life

cycle of a product. By looking at all stages in a product's life from material

extraction, processing, transport and manufacturing to the use/operation phase

and the disposal or recycling (end-of-life) phase we can help detect, assess and

identify processes and activities that are prone to high resource consumption.

Mostly, the attention of resource consumption is associated with material input in

the production process. However, the material consumption at the extraction

phase (e.g. energy and water to extract metals from its ore) or the operation in

the consumption phase (e.g. fuel, energy) can be considerably high, too. Further,

the LCA helps to assess the potential of reuse and recycling options at the end-of-

life phases (e.g. secondary metals from the car or secondary concrete from

demolished buildings) and fosters a circular economy. There is potential to

improve resource efficiency at every stage of the life cycle.

Figure 3: Life cycle in the case of a car

Source: World Bank 2013, World Development Indicators

Figure 4: Cars per 1,000 population: Growth potential and saturation level (2010)

GDP per capita, PPP (constant 2005 international $)C

ars

per

1,0

00 p

op

ula

tio

n

Growth potential

Saturation

USA

CYP

ITA

GRCSVN

ESP FRA

FINAUS

BEL

JPN GBRSWE NLD

CHE

UKR

ROMMEX

BRATURZAF

THACHN

INDBGD

700

600

500

400

300

200

100

00 5000 10000 15000 20000 25000 30000 35000 40000 45000

USA

NZL

ESTCZE

SVK

ITA

GRC

SVN

ESP FRA

FINAUS

DEU

BELJPN

GBR

SWE NLD

CHE

UKR

ROMMEX

BRA

TURZAF

THA

CHN

INDBGD

HUNKOR

Resource Initiative – Leveraging Efficiency to meet India's needs 7

Case Study: Automotive Sector

Economic growth and development is coupled with an increasing mobility which

often comes along with negative impacts such as pollution, collisions and

congestion. In India, mobility relies heavily on rail and road infrastructure. The

major modes of transport are two-wheelers, three-wheelers (auto-rickshaws), cars,

buses and railways. Nowadays the majority of trips in large Indian cities are made

by non-motorized or public transport. In 2003, 32% of all commuter trips in Delhi

were by foot, whereas motorized trips amounted up to 42%, with a large share of

bus trips. During the 1990's the share of personal transit modes (cars, two-wheelers,

auto-rickshaws) increased from 16.2% to 21.2%. Conventional public transportation

experienced an increase in absolute numbers but could not keep up with the

dynamic development of individual personal mobility. The highest increases in

vehicle numbers can be observed for two-wheelers and auto-rickshaws. But it is

expected that the ownership of cars will increase rapidly in the future due to rising

incomes in India. Figure 4 demonstrates the correlation between a rising GDP and

car ownership. The car ownership rate of India is still low, but as the trend indicates

this may change. The immense growth potential calls for a sustainable model of

transportation; given the “low car density path” with a broad use of bicycles and

public transit (e.g. NLD, SWE, CHE) in contrast to the “high car density path” with a

strong car dependent mobility (e.g. GER, USA).

Concept of Life Cycle Thinking to Analyse Resource Efficiency

Comprehensive environmental assessments must consider all stages of the life

cycle of a product. By looking at all stages in a product's life from material

extraction, processing, transport and manufacturing to the use/operation phase

and the disposal or recycling (end-of-life) phase we can help detect, assess and

identify processes and activities that are prone to high resource consumption.

Mostly, the attention of resource consumption is associated with material input in

the production process. However, the material consumption at the extraction

phase (e.g. energy and water to extract metals from its ore) or the operation in

the consumption phase (e.g. fuel, energy) can be considerably high, too. Further,

the LCA helps to assess the potential of reuse and recycling options at the end-of-

life phases (e.g. secondary metals from the car or secondary concrete from

demolished buildings) and fosters a circular economy. There is potential to

improve resource efficiency at every stage of the life cycle.

Figure 3: Life cycle in the case of a car

Source: World Bank 2013, World Development Indicators

Figure 4: Cars per 1,000 population: Growth potential and saturation level (2010)

GDP per capita, PPP (constant 2005 international $)

Car

s p

er 1

,000

po

pu

lati

on

Growth potential

Saturation

USA

CYP

ITA

GRCSVN

ESP FRA

FINAUS

BEL

JPN GBRSWE NLD

CHE

UKR

ROMMEX

BRATURZAF

THACHN

INDBGD

700

600

500

400

300

200

100

00 5000 10000 15000 20000 25000 30000 35000 40000 45000

USA

NZL

ESTCZE

SVK

ITA

GRC

SVN

ESP FRA

FINAUS

DEU

BELJPN

GBR

SWE NLD

CHE

UKR

ROMMEX

BRA

TURZAF

THA

CHN

INDBGD

HUNKOR

Resource Initiative – Leveraging Efficiency to meet India's needs

Source: Ministry of Road Transport & Highways 2012

Figure 5: Development of total registered cars in India*

* Taxis and jeeps not included; projected annual rate of 10.8% (2011-2030)

2001

2000

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2027

2028

2029

2030

Veh

icle

s

120,000,000

100,000,000

80,000,000

60,000,000

40,000,000

20,000,000

0

It is assumed that the personal mobility in India will further rise in the future. The

choice of means of transportation determines the demand for raw materials

which in turn creates environmental impacts. Indiviual transport with different

kinds of two- and three-wheelers as well as cars have a different demand for

natural resources than, for instance, public transport.

If the growth rate of car registration follows a similar pattern to the previous ten

years, the total amount of registered cars will rise by up to 100 million vehicles in

2030. The number for two-wheelers would be even higher.

2001

2000

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2027

2028

2029

2030

Source: Ministry of Road Transport & Highways 2012; World Steel Association 2011

Figure 6: Projected annual steel demand for cars

A ssumption: every car would be a compact car weighting 1.2 t

t/a

12,000,000

10,000,000

8,000,000

6,000,000

4,000,000

2,000,000

0

10% of steel production in India (2010)

9

Resource efficiency comes with the choice of mobility

There are a number of different measures to increase resource efficiency within

the automotive sector. One of the most effective measures is the car type, as it

has a significant influence on resource consumption. Figure 7 presents the

cumulative raw material demand by different classes of cars.

¤ Compact Car: an average car (weight 1.2 t)

¤ City Car: a light car (weight 850 kg)

¤ SUV: Sports Utility Vehicle or Jeep (weight 1.8 t)

The figure 7 shows the amount of extracted primary raw materials, e.g. iron ore,

bauxite, crude oil etc. which are required along the life-cycle. Another option is

the lightweight compact car that substitutes steel components for aluminium. The

weight will be reduced by 165 kg, which directly decreases the fuel consumption.

The production of the vehicle consumes mostly metals and energy resources,

Source: IFEU 2013

Figure 7: Cumulative raw material demand

Stages of life cycle

end-of-life treatment

maintenance

production vehicle

energy supply and use

Cumulative raw material demand: Amount of extracted primary raw materials

35,000

30,000

25,000

20,000

15,000

10,000

5,000

0

Compact Car Compact Car(Light weight)

City Car SUV

3 The cumulative raw material demand is defined as all raw materials consumed along the life cycle of a vehicle. It takes the ore into account rather

than just the refined metal.

Consequently, the annual steel demand for cars in 2025 would, at a rough

estimation, account for 10 % of the total Indian steel production of today (base

year 2010). Indeed, not only steel but also other metals such as copper and

aluminium will rise accordingly.

kg p

er v

ehic

le

Resource Initiative – Leveraging Efficiency to meet India's needs

Source: Ministry of Road Transport & Highways 2012

Figure 5: Development of total registered cars in India*

* Taxis and jeeps not included; projected annual rate of 10.8% (2011-2030)

2001

2000

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2027

2028

2029

2030

Veh

icle

s

120,000,000

100,000,000

80,000,000

60,000,000

40,000,000

20,000,000

0

It is assumed that the personal mobility in India will further rise in the future. The

choice of means of transportation determines the demand for raw materials

which in turn creates environmental impacts. Indiviual transport with different

kinds of two- and three-wheelers as well as cars have a different demand for

natural resources than, for instance, public transport.

If the growth rate of car registration follows a similar pattern to the previous ten

years, the total amount of registered cars will rise by up to 100 million vehicles in

2030. The number for two-wheelers would be even higher.

2001

2000

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

2025

2026

2027

2028

2029

2030

Source: Ministry of Road Transport & Highways 2012; World Steel Association 2011

Figure 6: Projected annual steel demand for cars

A ssumption: every car would be a compact car weighting 1.2 t

t/a

12,000,000

10,000,000

8,000,000

6,000,000

4,000,000

2,000,000

0

10% of steel production in India (2010)

9

Resource efficiency comes with the choice of mobility

There are a number of different measures to increase resource efficiency within

the automotive sector. One of the most effective measures is the car type, as it

has a significant influence on resource consumption. Figure 7 presents the

cumulative raw material demand by different classes of cars.

¤ Compact Car: an average car (weight 1.2 t)

¤ City Car: a light car (weight 850 kg)

¤ SUV: Sports Utility Vehicle or Jeep (weight 1.8 t)

The figure 7 shows the amount of extracted primary raw materials, e.g. iron ore,

bauxite, crude oil etc. which are required along the life-cycle. Another option is

the lightweight compact car that substitutes steel components for aluminium. The

weight will be reduced by 165 kg, which directly decreases the fuel consumption.

The production of the vehicle consumes mostly metals and energy resources,

Source: IFEU 2013

Figure 7: Cumulative raw material demand

Stages of life cycle

end-of-life treatment

maintenance

production vehicle

energy supply and use

Cumulative raw material demand: Amount of extracted primary raw materials

35,000

30,000

25,000

20,000

15,000

10,000

5,000

0

Compact Car Compact Car(Light weight)

City Car SUV

3 The cumulative raw material demand is defined as all raw materials consumed along the life cycle of a vehicle. It takes the ore into account rather

than just the refined metal.

Consequently, the annual steel demand for cars in 2025 would, at a rough

estimation, account for 10 % of the total Indian steel production of today (base

year 2010). Indeed, not only steel but also other metals such as copper and

aluminium will rise accordingly.

kg p

er v

ehic

le

Resource Initiative – Leveraging Efficiency to meet India's needs

Figure 9: Consumption of fresh water by different modes of transport

whereas fossil fuels are consumed during the use phase. The graph clearly shows

that the choice of car has a high impact on raw material demand.

Taking into account the public mobility options, the material saving potentials are

even higher. Public transport is by factor 5 more efficient than a conventional car.

Figure 8 compares private mobility options with public options such as regional

trains, suburban trains, trams and buses on the basis of one kilometre travelled by

a person, taking into account how many people will use the related

transportation. If we look at “fresh water” demand, along its life, a bus saves up to

three quarters of fresh water resources as compared to a car. The rail based

options show even higher saving potentials.

Figure 8: Consumption of raw materials* by different modes of transport

Compact Car Two-wheeler Regional Train Suburban Train Tram Bus

Private Mobility Public MobilityInfrastructure is not included in this comparison.

*The cumulative primary raw materials consumed along the life cycle.

Gra

ms

per

pas

sen

ger

km

80

70

60

50

40

30

20

10

0

Stages of life cycle

end-of-life treatmentmaintenanceenergy supply and use

production vehicle

Stages of life cycle

end-of-life treatmentmaintenanceenergy supply and use

production vehicle

Compact Car Two-wheeler Regional Train Suburban Train Tram Bus

Private Mobility Public Mobility

ml p

er p

asse

ng

er k

m

20

0

40

60

80

100

120

140

160

180

Infrastructure is not included in this comparison.The indicator "fresh water" does not include water for cooling.

11

Source: Dittrich, 2012, SERI, 2011, World Bank, 2012

Figure 10: Mineral consumption per capita during build-up and maintenance of infrastructure

of selected countries (2008)

Resource efficiency potentials in the housing sector

As cement is crucial for the housing sector, the cement production holds large

resource efficiency potential. The estimated quantity of cement required to

construct one square meter of a typical one-storey residential unit is about 269 kg.

At present, India still has a low per capita consumption of cement of less than 200

kg per person which is predicted to increase up to 400 - 600 kg per person until

2030. This would equal between 600 to 850 million tonnes of total production. India

Case Study: Housing Sector

Housing forms a major part of the construction sector which is one of the fastest

growing sectors and is the second largest employer in India. In 2011, India's 4housing stock amounted up to more than 330 million housing units . According to

the forecasts available from the US-based Natural Resources Defence Council's

India Initiative, 75% of housing units existing in 2030, still has to be built which is

equivalent to around 950 million housing units. The housing sector requires minerals

such as limestone for cement, sand /gravel, bricks and aggregates as well as

metals for structural elements (such as steel etc.), especially during the build-up

phase and the maintenance. Figure 10 presents the relation between the rising

GDP and mineral consumption per capita. The size of a housing unit determines

material requirements for construction, maintenance and running of the building.

4 A housing unit is a Census house defined 'as a building or part of a building having a separate main entrance from the road or common courtyard

or stair case etc. used or recognised as a separate unit (Government of India).

0

1

2

3

4

5

6

7

8

9

10

BGD

IDN

IND

ZAF

VIE MAR

ALB

MYS RUS

TUR

CHIIRN

CHNCZE

KOR

SAU

ISRITA

FRADEU

CHE

AUS

JPN GBR

build-up of infrastructure

maintenance of infrastructure

0 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000

Min

eral

co

nsu

mp

tio

n in

to

nn

es p

er c

apit

a

GDP per capita (ppp, constant 2005 international $)

EGY

Figure 9: Consumption of fresh water by different modes of transport

Source: IFEU 2013

Resource Initiative – Leveraging Efficiency to meet India's needs

Figure 9: Consumption of fresh water by different modes of transport

whereas fossil fuels are consumed during the use phase. The graph clearly shows

that the choice of car has a high impact on raw material demand.

Taking into account the public mobility options, the material saving potentials are

even higher. Public transport is by factor 5 more efficient than a conventional car.

Figure 8 compares private mobility options with public options such as regional

trains, suburban trains, trams and buses on the basis of one kilometre travelled by

a person, taking into account how many people will use the related

transportation. If we look at “fresh water” demand, along its life, a bus saves up to

three quarters of fresh water resources as compared to a car. The rail based

options show even higher saving potentials.

Figure 8: Consumption of raw materials* by different modes of transport

Compact Car Two-wheeler Regional Train Suburban Train Tram Bus

Private Mobility Public MobilityInfrastructure is not included in this comparison.

*The cumulative primary raw materials consumed along the life cycle.

Gra

ms

per

pas

sen

ger

km

80

70

60

50

40

30

20

10

0

Stages of life cycle

end-of-life treatmentmaintenanceenergy supply and use

production vehicle

Stages of life cycle

end-of-life treatmentmaintenanceenergy supply and use

production vehicle

Compact Car Two-wheeler Regional Train Suburban Train Tram Bus

Private Mobility Public Mobility

ml p

er p

asse

ng

er k

m

20

0

40

60

80

100

120

140

160

180

Infrastructure is not included in this comparison.The indicator "fresh water" does not include water for cooling.

11

Source: Dittrich, 2012, SERI, 2011, World Bank, 2012

Figure 10: Mineral consumption per capita during build-up and maintenance of infrastructure

of selected countries (2008)

Resource efficiency potentials in the housing sector

As cement is crucial for the housing sector, the cement production holds large

resource efficiency potential. The estimated quantity of cement required to

construct one square meter of a typical one-storey residential unit is about 269 kg.

At present, India still has a low per capita consumption of cement of less than 200

kg per person which is predicted to increase up to 400 - 600 kg per person until

2030. This would equal between 600 to 850 million tonnes of total production. India

Case Study: Housing Sector

Housing forms a major part of the construction sector which is one of the fastest

growing sectors and is the second largest employer in India. In 2011, India's 4housing stock amounted up to more than 330 million housing units . According to

the forecasts available from the US-based Natural Resources Defence Council's

India Initiative, 75% of housing units existing in 2030, still has to be built which is

equivalent to around 950 million housing units. The housing sector requires minerals

such as limestone for cement, sand /gravel, bricks and aggregates as well as

metals for structural elements (such as steel etc.), especially during the build-up

phase and the maintenance. Figure 10 presents the relation between the rising

GDP and mineral consumption per capita. The size of a housing unit determines

material requirements for construction, maintenance and running of the building.

4 A housing unit is a Census house defined 'as a building or part of a building having a separate main entrance from the road or common courtyard

or stair case etc. used or recognised as a separate unit (Government of India).

0

1

2

3

4

5

6

7

8

9

10

BGD

IDN

IND

ZAF

VIE MAR

ALB

MYS RUS

TUR

CHIIRN

CHNCZE

KOR

SAU

ISRITA

FRADEU

CHE

AUS

JPN GBR

build-up of infrastructure

maintenance of infrastructure

0 5,000 10,000 15,000 20,000 25,000 30,000 35,000 40,000 45,000

Min

eral

co

nsu

mp

tio

n in

to

nn

es p

er c

apit

a

GDP per capita (ppp, constant 2005 international $)

EGY

Figure 9: Consumption of fresh water by different modes of transport

Source: IFEU 2013

Figure 11: Demand on limestone depending on type of cement in low-demand scenario

Resource Initiative – Leveraging Efficiency to meet India's needs

Figure 12: Limestone reservesis the second largest producer of cement worldwide after China, however, it will

be expected that India will exceed the Chinese production in the next decades.

The cement production is energy-intensive and requires large amounts of raw

materials, in particular limestone. Although India's reserves of limestone are

immense with around 15 billion tonnes; a huge quantity of limestone is available in

social and ecological sensitive areas which may be progressively difficult to

access as seen in Figure 12. The amount of limestone required depends on the

type of cement and thus, leaves room for resource efficiency improvements as

illustrated in figure 11. Alternative binders and composite materials such as fly

ashes, slag or red mud reduce the input of limestone considerably. India is already

promoting “blending of cement” which clearly improves resource efficiency in

cement production. Nevertheless, even if only blended cement with the lowest

shares of limestone are produced, Indian reserves will be exhausted between 2035

and 2040. In sum, alternative and renewable materials as well as resource-efficient

technologies could further save resources and reduce the environmental and

social stress associated with the extraction of materials.

Exhausting known limestone reserves

Demand 100% new technologies of resource efficient cement production, here: celitement

Demand 100% blended cement, lowest share of limestone

Demand 100% ordinary portland cement

Demand, current share of cements (25% OPC, 67% PPC, 8% PSC), lowest and highest possible share of limestone in blended cements

mill

ion

to

nn

es

2015 2020 2030 2040 20500

200

400

600

800

1000

1200

1400

1600

13

Limestone reserves in ,000 tonnes

Figure 11: Demand on limestone depending on type of cement in low-demand scenario

Resource Initiative – Leveraging Efficiency to meet India's needs

Figure 12: Limestone reservesis the second largest producer of cement worldwide after China, however, it will

be expected that India will exceed the Chinese production in the next decades.

The cement production is energy-intensive and requires large amounts of raw

materials, in particular limestone. Although India's reserves of limestone are

immense with around 15 billion tonnes; a huge quantity of limestone is available in

social and ecological sensitive areas which may be progressively difficult to

access as seen in Figure 12. The amount of limestone required depends on the

type of cement and thus, leaves room for resource efficiency improvements as

illustrated in figure 11. Alternative binders and composite materials such as fly

ashes, slag or red mud reduce the input of limestone considerably. India is already

promoting “blending of cement” which clearly improves resource efficiency in

cement production. Nevertheless, even if only blended cement with the lowest

shares of limestone are produced, Indian reserves will be exhausted between 2035

and 2040. In sum, alternative and renewable materials as well as resource-efficient

technologies could further save resources and reduce the environmental and

social stress associated with the extraction of materials.

Exhausting known limestone reserves

Demand 100% new technologies of resource efficient cement production, here: celitement

Demand 100% blended cement, lowest share of limestone

Demand 100% ordinary portland cement

Demand, current share of cements (25% OPC, 67% PPC, 8% PSC), lowest and highest possible share of limestone in blended cements

mill

ion

to

nn

es

2015 2020 2030 2040 20500

200

400

600

800

1000

1200

1400

1600

13

Limestone reserves in ,000 tonnes

associated environmental impacts. It builds on the guiding principles of global

responsibility and the belief of joining ecological necessities with economic

opportunities. The framework promotes resource efficiency in production and

consumption and strives towards a circular economy and the expansion of a

closed loop management. Thus, a reduced dependency on primary resources

and a sustainable raw material supply can be achieved.

Japan's Resource Agenda

Japan has a long history of pursuing a track towards a so-called 3R society

(reduce, reuse, recycle). Already at the beginning of this millennium the first law

towards a material-cycle society was passed; followed by strategic plans and

declarations and leading to a cabinet's decision to become a leading

environmental nation in the 21st century. This objective shall be achieved taking

the following actions:

¤ Focus on a “Sound Material Cycle Society” (waste and resource efficiency)

and “Low Carbon Society” (climate and energy efficiency)

¤ Enforce “regional” resource circulation: Environmentally sound resource

circulation at appropriate geographic and economic scale

¤ Expanding “Indicators”: elaborating quantitative targets and additional

indicators

¤ Develop an international Sound Material Cycle Society: International

collaboration with East and Southeast Asia and support international research

activities

Initiatives and Policies from Across the World

Resource efficiency is gaining greater importance around the world. Increasingly,

countries – or even complete regions – set up efficiency programmes, strategies or

initiatives in order to steer development into a resource efficient future.

Resource efficiency examples in India

The government of India has already recognized the need and benefits of

adopting efficiency policies to reduce the demand for energy resources and its

impacts on the environment. The focus on energy efficiency is evident from the

setting up of the Bureau of Energy Efficiency and the policy innovations to

promote more efficient use of energy through measures such as Perform, Achieve

& Trade (PAT) Mechanism which is part of the National Mission for Energy Efficiency

approved in June 2010. It cover facilities that account for more than 50% of the

fossil fuel used in India, and is expected to help reduce CO2 emissions by 25 million

tons per year by 2014-15. Facilities which achieve savings in excess of their

mandated reduction would be issued Energy Savings Certificate (ESCerts) for the

savings that are in excess of their mandated target.

The Green Rating for Integrated Habitat Assessment (GRIHA), a five star rating

system, introduced by TERI and endorsed by Ministry of New and Renewable

Energy Technology, rates a building on set criteria which measures the degree of

its greenness by assessing its environmental performance over its entire life cycle.

The rating system consists of 34 criteria categorized under various sections such as:

Site Selection and Site Planning, Conservation and Efficient Utilization of Resources,

Building Operation and Maintenance, and Innovation points.

Germany's Resource Efficiency Programme (ProgRess)

The goal of the German Resource Efficiency Programme is to manage the

extraction and use of natural resources in a sustainable way and to reduce the

associated environmental impacts. It builds on the guiding principles of global

responsibility and the belief of joining ecological necessities with economic

opportunities. The framework promotes resource efficiency in production and

consumption and strives towards a circular economy and the expansion of a

closed loop management. Thus, a reduced dependency on primary resources

and a sustainable raw material supply can be achieved.

Japan's Resource Agenda

Japan has a long history of pursuing a track towards a so-called 3R society

(reduce, reuse, recycle). Already at the beginning of this millennium the first law

towards a material-cycle society was passed; followed by strategic plans and

declarations and leading to a cabinet's decision to become a leading

environmental nation in the 21st century. This objective shall be achieved taking

the following actions:

¤ Focus on a “Sound Material Cycle Society” (waste and resource efficiency)

and “Low Carbon Society” (climate and energy efficiency)

¤ Enforce “regional” resource circulation: Environmentally sound resource

circulation at appropriate geographic and economic scale

¤ Expanding “Indicators”: elaborating quantitative targets and additional

indicators

¤ Develop an international Sound Material Cycle Society: International

collaboration with East and Southeast Asia and support international research

activities

Initiatives and Policies from Across the World

Resource efficiency is gaining greater importance around the world. Increasingly,

countries – or even complete regions – set up efficiency programmes, strategies or

initiatives in order to steer development into a resource efficient future.

Resource efficiency examples in India

The government of India has already recognized the need and benefits of

adopting efficiency policies to reduce the demand for energy resources and its

impacts on the environment. The focus on energy efficiency is evident from the

setting up of the Bureau of Energy Efficiency and the policy innovations to

promote more efficient use of energy through measures such as Perform, Achieve

& Trade (PAT) Mechanism which is part of the National Mission for Energy Efficiency

approved in June 2010. It cover facilities that account for more than 50% of the

fossil fuel used in India, and is expected to help reduce CO2 emissions by 25 million

tons per year by 2014-15. Facilities which achieve savings in excess of their

mandated reduction would be issued Energy Savings Certificate (ESCerts) for the

savings that are in excess of their mandated target.

The Green Rating for Integrated Habitat Assessment (GRIHA), a five star rating

system, introduced by TERI and endorsed by Ministry of New and Renewable

Energy Technology, rates a building on set criteria which measures the degree of

its greenness by assessing its environmental performance over its entire life cycle.

The rating system consists of 34 criteria categorized under various sections such as:

Site Selection and Site Planning, Conservation and Efficient Utilization of Resources,

Building Operation and Maintenance, and Innovation points.

Germany's Resource Efficiency Programme (ProgRess)

The goal of the German Resource Efficiency Programme is to manage the

extraction and use of natural resources in a sustainable way and to reduce the

Key Messages and the Way Forward

1. Resource consumption and resource efficiency are both key for India's

development. However, more basic information and data is needed in order

to predict realistic future scenarios and trends.

2. A sustainable and inclusive growth must achieve a fine balance between

economic growth and environmental protection. The improved, sustainable

and efficient use of resources reduces economic, social and environmental

risks which are linked to the availability, extraction, processing, consumption

and end-of life use of materials. Managing these risks while at the same time

focusing on closed material flow management, a country strives to decouple

economic activities and environmental impacts.

3. India has already recognized and encouraged efficiency in key sectors such

as energy use and buildings. However, greater efforts must be undertaken in

order to adopt resource efficiency as an organizing principle of the Indian

economy to enable sustainable growth. India already has an informal

recycling system. However, there are substantial room for improvements with

regards to recycling efficiency.

4. The pricing of resources must reflect the “true and fair” marginal social cost

keeping in mind that on occasions the environmental and social imperatives

might work against each other. The on-going efforts to promote

environmental fiscal reforms, aimed at aligning the economic and

environmental drivers for arriving at the “fair” marginal social cost, must be

strengthened.

5. Due to its cross-cutting nature, the concept of resource efficiency calls for an

integrated policy approach and a multi-stakeholder involvement.

Stakeholder dialogues and platforms must be promoted to harmonize

interests and constraints of the different groups involved.

6. Various benefits may arise for different sections in society from resource-

efficiency:

¤ Economic: By reducing the market dependencies of materials, resource

security can be increased. Saving primary resources through higher

efficiency, substitutions, reuse and recycle means saving costs and

strengthening the competitiveness at a micro- and macro-level.

¤ Environment: Enhancement of resource efficiency would mean reduction in

the use of primary materials as well as improved production processes that

reduce waste. Both would reduce the burden on the environment.

¤ Social: Reduced demand for primary raw materials reduce the

environmental, social and health impact related to material extraction and

consumption.

7. The automotive and construction sector demonstrate dynamic development

which is interlinked with a high demand of certain key materials such as steel,

limestone, copper, etc. In order to secure material supply and ensure

competitiveness, existing resource efficient approaches with high saving

potentials must be tapped.

Key Messages and the Way Forward

1. Resource consumption and resource efficiency are both key for India's

development. However, more basic information and data is needed in order

to predict realistic future scenarios and trends.

2. A sustainable and inclusive growth must achieve a fine balance between

economic growth and environmental protection. The improved, sustainable

and efficient use of resources reduces economic, social and environmental

risks which are linked to the availability, extraction, processing, consumption

and end-of life use of materials. Managing these risks while at the same time

focusing on closed material flow management, a country strives to decouple

economic activities and environmental impacts.

3. India has already recognized and encouraged efficiency in key sectors such

as energy use and buildings. However, greater efforts must be undertaken in

order to adopt resource efficiency as an organizing principle of the Indian

economy to enable sustainable growth. India already has an informal

recycling system. However, there are substantial room for improvements with

regards to recycling efficiency.

4. The pricing of resources must reflect the “true and fair” marginal social cost

keeping in mind that on occasions the environmental and social imperatives

might work against each other. The on-going efforts to promote

environmental fiscal reforms, aimed at aligning the economic and

environmental drivers for arriving at the “fair” marginal social cost, must be

strengthened.

5. Due to its cross-cutting nature, the concept of resource efficiency calls for an

integrated policy approach and a multi-stakeholder involvement.

Stakeholder dialogues and platforms must be promoted to harmonize

interests and constraints of the different groups involved.

6. Various benefits may arise for different sections in society from resource-

efficiency:

¤ Economic: By reducing the market dependencies of materials, resource

security can be increased. Saving primary resources through higher

efficiency, substitutions, reuse and recycle means saving costs and

strengthening the competitiveness at a micro- and macro-level.

¤ Environment: Enhancement of resource efficiency would mean reduction in

the use of primary materials as well as improved production processes that

reduce waste. Both would reduce the burden on the environment.

¤ Social: Reduced demand for primary raw materials reduce the

environmental, social and health impact related to material extraction and

consumption.

7. The automotive and construction sector demonstrate dynamic development

which is interlinked with a high demand of certain key materials such as steel,

limestone, copper, etc. In order to secure material supply and ensure

competitiveness, existing resource efficient approaches with high saving

potentials must be tapped.