British Ae rospace Hawk Mk. 51 - Velocity RCBAe Hawk Mk. 51 : 70mm Sport Jet Construction Guide v1.3...

Transcript of British Ae rospace Hawk Mk. 51 - Velocity RCBAe Hawk Mk. 51 : 70mm Sport Jet Construction Guide v1.3...

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 1 of 47

British Aerospace Hawk

Mk. 51

70mm class

Electric Ducted Fan

Sport Jet

Designed By

Al Sprosta

Construction Guide

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 2 of 47

Thank You and Introduction:

Thank you for your purchase of the ‘Mr. Boogie’ designed British Aerospace Hawk Sport Jet.

This model of the Hawk was born out of a desire to have a large size BAe Hawk that was reasonably scale, and

fit comfortably in the 70mm electric ducted fan class.

Sophisticated CAD tools were employed in the development of this model. This allowed for the optimization of

‘model sized’ flight characteristics, as well as preserving the lines that make the Hawk such a beautiful subject.

This model utilizes fiberglass composite molding technology, greatly reducing the time required by the builder

to get the aircraft ready for flight.

I hope that you enjoy this Hawk model, as much as I enjoyed designing it.

Many Happy Landings,

Al ‘Mr. Boogie’ Sprosta

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 3 of 47

Disclaimer:

BY ASSEMBLING AND OPERATING THIS MODEL YOU ASSUME FULL RESPONSIBILITY FOR

YOUR ACTIONS

This aircraft is not a toy. This is a high performance radio controlled jet aircraft model that if not operated

responsibly could result in serious injury to you and others. The designer, manufacturer and distributors cannot

control how you assemble this model, what equipment you choose to outfit it with, or how you choose to pilot it

and can assume no liability whatsoever for any damages that may occur when you fly your aircraft.

By assembling this model, you are agreeing to indemnify and hold blameless the manufacturer and/or his agents

from any and all torts and liability associated with the use of this product. For your safety and the safety of

others, please operate your model according to the laws and regulations governing model flying in the country

of use.

Precautions:

This plane is capable of high speeds. If you are unsure of your ability or have never flown a radio controlled

aircraft before, please seek the help of an expert. It is highly recommended that you be a member of the AMA

(Academy of Model Aerodynamics), BMFA (British Model Flying Association) or similar organization

depending on your country of use.

Notes:

A web discussion related to the development of this aircraft can be viewed at the following address:

http://www.rcgroups.com/forums/showthread.php?t=595117

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 4 of 47

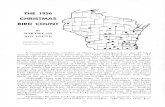

Taken from Wikipedia, the free encyclopedia

The BAE Systems Hawk is a British single engine, advanced jet trainer aircraft. It first flew in 1974 as the

Hawker Siddeley Hawk. The Hawk is used by the Royal Air Force, and other air forces, as either a trainer or a

low-cost combat aircraft. The Hawk is still in production with over 900 Hawks sold to 18 customers around the

world.

The Hawk 50 was the original export trainer version, and offered a limited attack capability. Finland, Indonesia

and Kenya ordered 89 of this variant.

Hawk 51 - Export version for the Finnish Air Force.

Hawks 51A - Seven Hawks were sold to Finland as part of a follow-on order.

Hawk 52 - Export version for the Kenyan Air Force.

Hawk 53 - Export version for the Indonesian Air Force.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 5 of 47

MODEL SPECIFICATIONS: Scale: approx 1/10 full scale

Length: 46in (1168mm)

Span: 37in (940mm)

Minimum Power requirements*: 800 Watts

Weight w/battery*: up to 75oz (2126g)

*Prototype Setup (as initially flown):

Controls: Aileron, Elevator, Rudder, Steering, Retracts and Flaps.

Battery: 4S 3700mah Lipo weighing 13.5oz (383g)

RADIO/ELECTRONIC REQUIREMENTS: Minimum: 4 channel radio (see minimum control setups)

Preferred: 6+ channel radio

CONTROL SETUPS: Minimum Bungee:

Throttle, Aileron, Elevator

Minimum Rise off Ground:

Throttle, Aileron, Elevator, Steering

Mr. Boogie Preferred (Full House):

Throttle, Aileron, Elevator, Steering, Rudder, Flaps, Retracts

Minimum Servo Requirements**: Control function qty Servo description

Aileron: 2 Hitec HS-65MG (Y connected)

Elevator: 1 Hitec HS-82MG

Nose Steering: 1 Hitec HS-55

Rudder: 1 Hitec HS-55

Flaps: 2 Hitec HS-55 (Y connected)

Retract valve: 1 Hitec HS-55

**Substitutes are fine as long as servo torque and weight is comparable**

CONTROL THROWS: Aileron: +/- 0.40in (+/- 10mm); expo 35%

Elevator: +/- 0.40in (+/- 10mm) measured at the Root (on the Fuselage) Leading Edge; expo 30%

Nose Steering: +/- 15 degrees

Rudder: +/- 0.6in (+/- 15mm); measured at rudder base/bottom

Flaps: As much downward deflection as you can get, not exceeding 55 degrees.

Center of Gravity: Measured rearwards, from the front center of the wing (see page 42)

4.2in - 4.4in

(107mm – 112mm)

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 6 of 47

What’s in the box?

Qty Description

1 Fiberglass composite fuselage

1 Fiberglass composite rear hatch

1 Fiberglass composite vertical tail

2 Fiberglass composite horizontal stabs

1 Fiberglass composite wing belly pan

1 Set Fiberglass ducting (1 left, 1 right)

1 Sheeted and covered right wing half, with freed aileron

1 Sheeted and covered left wing half, with freed aileron

1 WM400 70mm edf unit

1 In-runner motor (rated to 800 Watts)

Vacuum formed parts 1 Canopy bubble

1 Cockpit tub

1 Front instrument shroud

1 Rear instrument shroud

2 Instrument panels

2 Ejection seat backs

2 Sets ejection seat sides

Wood parts

1 Set Nose gear formers

1 Set Main gear mounting plates

1 Set Fan mount formers

1 Set Elevator servo mount formers

1 Vertical fin spar

1 Vertical fin root

1 Forward wing saddle former

1 Wing joiner

1 Wood dowel (builder cuts into smaller pieces)

1 Front canopy former

1 Rear canopy former

2 Cockpit tub stringers

1 Cockpit tub front former

2 Cockpit tub wood angle supports

2 Ventral fins

2 Wing fences

2 Horizontal stab spacers

Misc parts 1 Pre-bent Steel Elevator pivot rod (1/8in diameter)

2 Aileron control arms and screws (4)

2 Wing mounting bolts/captive nuts

2 Aileron wire push rods and EZ-connectors

8 CA hinges

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 7 of 47

What’s in the box? Cont’d

Wood parts visual guide

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 8 of 47

Required to Complete*

*See RADIO/ELECTRONIC REQUIREMENTS for servo recommendations

Bungee Launch/Belly Lander:

Qty Item

1 ESC (80Amps+)

1 4S Lipo 3300+ (for included motor)

____________________________________

1 Radio receiver (min 4 channels)

1 Servo control arm, for use as an elevator control arm. I used a surplus arm from my HS82MG package

1 4-40 or 2-56 threaded pushrod and clevis connector, for elevator

2 12in (305mm) servo extensions, for ailerons

1 Servo Y- connector, for ailerons

1 Thrust/efflux tube (Mylar or overhead transparency film)

1 Bungee hook

1 Bungee setup

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 9 of 47

Required to Complete*

*See RADIO/ELECTRONIC REQUIREMENTS for servo recommendations

Retractable Landing Gear:

Qty Item

1 ESC (80Amps+)

1 BEC or separate receiver battery pack

1 4S Lipo 3300+ (for included motor)

____________________________________

1 Radio receiver (min 6 channels)

1 Servo control arm, for use as an elevator control arm. I used a surplus arm from my HS82MG package

1 4-40 or 2-56 threaded pushrod and clevis connector, for elevator

2 12in (305mm) servo extensions, for ailerons

1 Servo Y- connectors, for ailerons

1 Thrust/efflux tube (Mylar or overhead transparency film)

4 12in (305mm) servo extensions for retract valve servo and steering

Gear specific 1 Set Lightweight pneumatic retracts rated to 4-5 lbs (2 main units and 1 steerable nose unit)

1 Set Retract accessories (Small air tank, tubing, tee’s, control valve, fill valve)

2 Lightweight wheels 2in (51mm) diameter; mains

1 Lightweight wheel 1.25in (32mm) diameter; nose

3 Wheel collars

4 2in (51mm) squares of lightweight fiberglass cloth (for main gear mount area reinforcement in wing)

1 0.25in x 0.5in (6mm x 13mm) cross-section, 6-7inch (152-178mm) length of hardwood stick

This will be used to raise the main gear mounting plates

Optional 2 12in (305mm) servo extensions, for flaps

1 Servo Y- connectors, for flaps

2 Control horns for flaps

2 Push rods and connectors for flaps

1 Control horn for rudder

1 Push rods and connectors for rudder

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 10 of 47

Construction aids:

Glues/Adhesives:

5 and 30 minute epoxy

CA thin to medium

Polyurethane glue (Gorilla glue/Probond)

White glue (Elmers)

Canopy glue

Rubber Cement

Sandpaper 200 – 600 grit assortments

Sanding block

Painter’s masking tape (low tack)

Rotary tool (Dremel)

Straight edge

Assorted Drill bits

Extra long 1/8” drill bit (10 inches minimum)

Hobby knife with #11 blades

Felt tip/fine line marker (Sharpie)

Cling wrap

Alcohol or Acetone (for cleanup)

For Fiber glassing:

Laminating epoxy

Microballons

Epoxy brushes

Mixing cups

Mixing (Popsicle) sticks

Scissors

Rubber gloves

Paper towels

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 11 of 47

Vertical Fin Attachment:

1 Start by sanding the vertical fin root outline on the fuse. To protect the surrounding areas, mask them

off with low tack painters tape.

*Focus your sanding on the side walls of the root outline

2 Glue the ply fin root outline to the fuselage.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 12 of 47

3 Open the root to allow the vertical fin spar to pass through. The spar opening should be inline with the back of the smaller square panel line.

*The second hole is for access to a rudder servo wire.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 13 of 47

4 Sand the inside lower edges of the vertical fin and glue it on with slow cure epoxy and filler. Apply epoxy to the root outline on the fuse (including the sidewalls of the ply former) and the sides of the spar.

5 Clean up excess epoxy. 6 Align vertically and tape in place as shown. Let fully cure.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 14 of 47

Wing Preparation: Servo boxes and wire tunnel (Before gluing the wing halves)

As a general rule lay down a layer of masking tape for marking cut lines, locations, etc. This will keep

your surfaces cleaner.

1 On the bottom (flat side) of the wing mark the shown dimensions.

167mm (6.57in) is the length measured along the trailing edge of the aileron for cutting.

10mm (0.39in) back from the aileron cut line is the location for the center of the control horn.

65mm (2.56in) is the distance measured perpendicular from the hinge line to the center of the servo arm.

*The little squares mean 90 degrees or a perpendicular line

2 Draw your servo box. Box dimensions are 40mm x 40mm. Place your servo on the wing with the servo arm closest to the hinge line and the arm center located at the 65mm mark. The servo body should be

point toward the center of the wing. Then draw a box around the servo.

3 Cut out the box with a sharp #11 blade. 4 Route out a servo wire tunnel, using a long drill bit or a long (brass) tube. Tunnel dimensions are not

critical as long as they intersect your servo box.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 15 of 47

5 On the top side of your wing half, cut a small hole (shown right) above your servo wire tunnel. This will allow you pull the servo wires once the wing halves are glued. The hole on the left is for my retract air

lines.

6 Using fishing line or your choice of strong thread, run a long length through the servo tunnel. It should come through the hole on the top of the wing and out the servo box. Tape it down to make sure it

doesn’t move. We’ll use it later to pull the servo leads through the tunnel.

7 Repeat steps 1 to 6 for the other wing half.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 16 of 47

Wing Preparation: Joining the halves

1 Aside from your wing halves, locate the ply wing joiner and cut a 25mm length of dowel.

Joiner goes in “holes up”.

Dowel aligns wing at the trailing edge.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 17 of 47

2 Apply slow cure epoxy to the joiner, dowel and wing halves. Press together,clean up excess epoxy and tape in place.

3 Place a layer of cling film on your fuse wing saddle, near the front and rear ends.

4 Attach the wing to the fuse and let the epoxy fully cure.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 18 of 47

Wing Preparation: Servo installation

There a numerous ways to install servo’s into a wing, including glueing them in. What I will show is but one

method that allows for maintenance removal and replacement of the servo. The method below assumes you are

using a new servo with all of its included accessories (screws, etc.)

Building a Horizontal Servo Mount

1 You will need thin ply sheet (1/16in) and some balsa blocks (0.5in X 0.25in) in cross section

The idea is to restrain your servo’s movement with the blocks and hold it down with the ply strip.

2 Before you glue the blocks in place with epoxy, wrap your servo in a layer of cling film. Once cured

your mount should have a nice slop free fit to the servo.

3 Using a strip of thin ply and the screws included in your servo package, create a cap for the servo mount.

Gently install the self tapping screws, remove them and drip CA into the holes to harden the threads.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 19 of 47

5 Glue the servo mount plate into the wing. It helps to have the servo installed into the mount so that you can line up the servo arm center with your previously created marks.

6 Connect your servo extension to your servo.

*I tie my extensions to my servo’s end with fishing line so that they don’t separate easily.

7 Pull your servo line through to the center of the wing, using the previously installed lines.

8 Install your control surface control horns, if you haven’t already done so.

9 Test out your ailerons.

At this point you should have installed Aileron servos and connected control surfaces. The previous steps can

be repeated to install Flaps and their related servos.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 20 of 47

Flap Servo Install

1 Installing the flap servos is similar to the aileron servo procedure. Location should be just below the

landing gear (20mm).

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 21 of 47

Elevator Installation: Servo Installation

*This model uses full flying stabs to control pitch, just like the full scale Hawk. As a result of aerodynamic

loads generated on the stabs, a high torque metal geared servo is recommended for use in this model.

1 Locate the 3 wooden parts that make up the elevator servo mount and dry fit the assembly (as shown below) first to become familiar with how it goes together. Complete assembly using CA or Epoxy.

2 Place your (new) servo into the frame to test the fit. You may need to file the opening a bit to allow the servo wire to clear the opening.

3 Use the screws, rubber bushings and brass parts that came with your servo to screw it to the mount.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 22 of 47

4 The mount is positioned such that the servo arm once installed will be on the centerline of the fuselage.

*With the servo in the mount, the servo hub should be positioned closest to the rear of the mount when

installed. Viewed from the speed brake opening, the assembly should be glued in the middle of the opening.

You want to retain access to the servo screws, but not be so far to the rear that you interfere with the efflux tube.

5 Glue the wooden mount into the fuselage via the speed brake opening, using epoxy and filler.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 23 of 47

Elevator Installation: Stab Installation

1 For installation of the stab you will need the bent steel rod, the stabs and a servo arm from your elevator

servo packaging.

2 Rub down the steel rod with sandpaper to rough it up a bit.

3 Insert the rod into the fuselage, even it out and mark (on the rod) the points where it exits the fuse using a marker.

4 Slide the wooden spacers over the rod ends and tack glue them with CA to the fuselage stab root outlines.

5 Make sure that the rod can still pivot/move freely.

Attaching the First Stab

6 Slide a piece of cling film over the rod up against the wood spacer.

7 Apply 5 min epoxy to the rod end and slide the stab onto the rod. Check to make sure your rod marks are still visible on the other side.

8 Position the stab so that it presses against the spacer, and is lined up with root outline. The rod should self adjust to match your stab positioning.

9 Let fully cure. You can use tape to hold the stab in position.

10 Remove the single stab/rod assembly, clean up any epoxy that may have gotten past the cling film.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 24 of 47

Attaching the Second Stab 11 Cut off one end of the servo arm.

12 Reinsert the stab/rod assembly, this time sliding your servo arm over the rod before it exits on the other

side of the fuse.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 25 of 47

13 Slide some cling wrap over the rod up to the spacer.

14 Apply 5 minute epoxy to the exposed rod end.

15 Slide the second stab onto the rod, press it up against the spacer and line it up against the root outline.

**IMPORTANT** 16 BEFORE the epoxy fully cures, pivot the stabs (together) up and down (about 25mm) each way. Then

re-align the stabs with the root outlines, making sure the trailing edges of the stabs are in line with each

other.

17 Once cured the stabs should pivot (together) up and down freely.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 26 of 47

18 Position your elevator stabs so that they are level with the fuselage. Use tape to hold in place.

19 With the servo arm hanging straight down and centered on the rod. Use a Popsicle stick or similar to apply *slow cure epoxy and filler to the servo arm/rod intersection

only.

*I used JB weld for similar but faster results.

20 Let fully cure.

21 Link up your elevator servo to your stabs and try them out!

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 27 of 47

Fan Mount Installation:

1 Locate your fan mount formers and fan.

2 Assemble a Right and Left set of formers as shown, using CA or epoxy.

Note front formers have the steeper shoulders. It may help to mark the front supports.

3 Attach the formers to the fan flanges. To get an idea of where to place the screw holes, slip the fan into

the fuse mated up against the ducts, place a former under a flange and mark/trace the front edge of the fan

flange onto the support.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 28 of 47

4 Roll a temporary efflux cone and attach it to your fan, it will help with general alignment.

5 Insert the Fan and former assembly into the fuselage, and slide it as far back as it will go.

6 Insert both ducts sliding them forward to mate with their respective inlet covers.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 29 of 47

7 Slide the Fan/former assembly forward to mate with the ducts. Use tape to hold the ducts to the fan opening or a rolled collar similar to the one depicted in the previous pictures.

8 With the fan in position against the ducts. Tack glue the formers in place with CA.

9 Carefully unscrew and remove the fan and ducting, taking care not to knock the formers loose.

10 Reinforce the former/fuse connections with epoxy/filler.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 30 of 47

Cockpit & Canopy assembly:

1 The cockpit frame is built on the fuselage, use cling wrap to protect your fuse from glue and markings.

2 Place the front and rear canopy formers on the fuse and tape them temporarily in place.

3 Drill the front former through to the fuselage, to accept locating dowels. In the case of the rear former I

drilled to accept rare earth magnets.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 31 of 47

4 Glue 2 short lengths of dowel to the front former.

6 With the front and rear former in place on the fuselage, the cockpit frame goes together as shown using 5 minute epoxy.

7 You may want to add small doublers (using scrap wood) to the forward tub former. See completed frame

below.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 32 of 47

8 Before permanently gluing in the cockpit tub, seats, instrument panels and shrouds, you should probably

trim and paint them. Leave a flange on the tub and IP covers for gluing.

9 Once painted the parts drop in as shown.

10 The canopy can be attached with canopy glue.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 33 of 47

Some Cockpit images:

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 34 of 47

Rear Hatch Attachment:

I chose to use strong magnets for the canopy hold downs. I also did the same for the rear hatch.

1 Epoxy pieces of scrap balsa block at the four corners of the rear hatch. Some shaping and fitting will be

required before final gluing.

2 Recess and epoxy a rare earth magnet into each block so that it is flush with the fuselage when the hatch

is attached.

3 Install mating magnets on the fuselage side and reinforce (from the backside) with epoxy/filler to hold

them in place.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 35 of 47

Retractable Landing Gear: Nose Install

1 Cut out the nose door outline at the front (underside) of the fuse. Follow the panel lines plus 15mm at

the rear of the door.

2 Assemble the nose gear mounting formers as shown.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 36 of 47

3 The nose strut should be angled up when viewed from the side.

4 Mount the retract base to the formers before gluing in place in the fuselage.

5 With the strut inserted and the gear in the down position. Position the formers in the fuselage so that the strut just clears the rear edge of the door and make certain that you can access the screws to remove the

retract from the mounting plate.

6 Glue the formers to the fuselage using slow cure epoxy and microballoons.

7 Bend your nose strut so that when your gear is retracted, the nose wheel has 1-2mm clearance with the

front edge of the door opening. This will help maintain a level-to-slightly nose up attitude when the mains are

installed.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 37 of 47

Retractable Landing Gear: Main Gear Install

1 Look at the image below to see where the center of your struts should be with the gear in the down

position.

2 Place a protective layer of masking tape on the underside of the wing in the general locations of the strut

centers.

3 Place the retract bases at the noted locations using the strut centers as your reference point and trace the

outline of the retract bases onto the wing.

4 Align the supplied wheel well template with your previous tracing and trace the well outline onto the

wing.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 38 of 47

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 39 of 47

5 Using a sharp blade carefully cut the outline away. You want to cut through the covering and the top

wood skin.

6 If there is foam from the wing core in your pocket, remove it.

7 Reinforce the area in the wing where the retract bases will go. I used 2 layers of 3oz glass cloth squares.

8 Mounting plates are provided for the retract mains, but you will need to build offset supports before

attaching the mains to the wing.

9 Using some hardwood blocks, I cut off sections to match the retract mains mounting plates. They are

glued to the plate and act as standoff’s for the retract mains.

10 The plate/blocks structure and retract gets glued into the wing. Wrap the retract base in cling film and

secure it to the mount before final gluing into the wing.

TIP: Insert your unbent wire struts before the glue fully sets, retract them and make sure the struts point to

each other.

11 If using wire struts, follow the bend guidelines provided.

WARNING: The strut centers are very close to the CG, so bent leg struts are highly

recommended.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 40 of 47

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 41 of 47

Retractable Landing Gear: Steering Servo Install (pull-pull)

There are numerous ways to install your steering servo. I chose to position my steering servo between the

retracted nose wheel and the front of the retract cylinder, mounted to the top of the fuselage nose.

I fabricated a mount for my servo that allows me to remove the servo for maintenance.

1 Using some scrap balsa blocks, I constructed a mount that holds my servo in a vertical orientation.

2 The mount is then glued with epoxy to the ceiling of the fuselage.

3 With the gear down, pull lines are then attached to the servo arm ends and to the steering arm.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 42 of 47

General Component Placement and Center of Gravity

Note: The CG pictured below is safely forward. You will need some up elevator trim at the specified balance

point. This CG is recommended for your first flights; you can move it back as you become familiar with the

aircraft.

You should balance the ready to fly aircraft upside down at the indicated position. If you have retracts, put them

in the gear down position before balancing.

The attitude of the aircraft should be level to slightly nose down.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 43 of 47

Retract air

tank, valve

and servo in

Without your battery, chances are your build will be tail heavy with everything installed. Your battery (and

battery tray) should be located so that your craft balances at the stated center of gravity.

The images below show where I chose to locate certain components.

ESC mounted up under rear hatch vents.

Receiver at the back of rear hatch opening,

attached to sidewalls with Velcro.

Battery

and tray

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 44 of 47

Test Flight

* Before the first flights input 2 to 3 clicks of up elevator trim.

Runway takeoff roll should be between 150 and 200 feet, depending on the weight of your aircraft and power

system. Takeoffs should be into the wind (if any) at full throttle. Roll on throttle and build up speed after about

150 feet, smoothly apply a small amount of up elevator. Keep your climb out gentle and gain altitude (2 to 3

mistakes high), retract your gear if you wish and trim the aircraft at ¾ throttle.

Make a few gentle circuits to adjust to the models handling, keep your turns large and smooth. At altitude

check the stall of the aircraft, and practice slow flight to become familiar with the aircrafts slow speed handling.

Landings are best executed with a little throttle. With throttle between ¼- ½, control your descent with throttle

and use elevator to flair 1 to 2 feet above the runway.

Bungee assisted launches can be done with a ramp, rail or dolly setup. Setup your bungee pull tension to equal

5-6 times the models ready to fly weight.

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 45 of 47

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 46 of 47

-

BAe Hawk Mk. 51 : 70mm Sport Jet

Construction Guide v1.3

Page 47 of 47