Bridging’the’Gap’Using’Gas’Assisted’Plunger’ Li5’(GAPL)’ ·...

Transcript of Bridging’the’Gap’Using’Gas’Assisted’Plunger’ Li5’(GAPL)’ ·...

Bridging the Gap Using Gas Assisted Plunger Li5 (GAPL)

Presented By: Todd Thrash Technical Data Provided By: Rusty Brown, P.E.

Overview

• What is GAPL? • Advantages of GAPL • Produc7on Analysis

• A technical review suppor=ng the implementa=on of GAPL on a well-‐by-‐well basis • Model flowing gradients • Es=mate sta=c and flowing boGom hole pressures • Calculate the wells Produc=vity Index • Es=mate increase in produc=on

• Case Studies • Increased Produc7on • Lowered Injec7on Rates • Improving Paraffin Control While Reducing Associated Costs

What is GAPL? • GAPL, or Gas Assisted Plunger LiD, is a hybrid

liD method using both gas li5 and plunger li5 to ar7ficially produce gas and/or oil wells.

• Gas Li5 • Compressor / High Pressure Gas Supply • Gas LiD Valves • With or Without a Packer • Design in place that allows for the deepest

possible point of injec7on

• Plunger Li5 • Lubricator • Control Box • Arrival Sensor • Plunger • Down-‐Hole Bumper Spring

• Design Considera;on: For GAPL design, the down-‐hole bumper spring should be set so that it’s 1 joint above the system’s opera7ng valve, or point of injec7on. This will allow for more fluid recovery and drawdown. XN

LUBRICATOR

PLUNGER ARRIVAL SENSOR

MOTOR VALVE

CONTROLLER

MANUAL/AUTO CATCH

HAMMERHEAD

TUBING STOP

BUMPER SPRING

FREE CYCLE PLUNGER

ADJUSTABLE INJECTION CHOKE

GAS LIFT VALVE

Advantages – “Bridging the Gap”

• Cost effec7ve method that “bridges the gap” between gas liD and plunger liD systems, ul7mately prolonging the requirement for more costly ar7ficial liD methods.

• As BHP’s decline in exis7ng gas liD applica7ons, the produc7on also declines. This usually means less efficient liDing as gas breaks through the fluid allowing fluid to fall back on the forma7on. The plunger prevents fluid from falling back and allows for further drawdown, maximizing produc7on.

• A more efficient seal created by the plunger, means less injec7on gas required to liD the same volume of fluid. In some cases, the injected gas can be tapered off, allowing the well to transi7on into plunger liD alone.

• Effec7ve method on paraffin and scale control, significantly reducing associated costs.

Produc>on Analysis – Gathering Produc>on Data

• Produc7on data is gathered, and outliers such as compressor down-‐7me or high line pressure are omi^ed

• GLR’s are calculated for both above and below the point of injec7on

Produc>on Analysis – Modeling Flowing Gradients and FBHP

• Producing GLR’s are used to model mul7-‐phase flowing gradients and FBHP’s • FBHP’s will be used in helping to determine the well’s current IPR • Sta7c and Flowing BHP Tests can be used in place of well modeling

Mul7-‐Phase Flowing Gradient

Modeled FBHP

Produc>on Analysis – IPR Curve

• The FBHP for each flowing gradient is plo^ed against the actual total liquid rate

• A linear trend-‐line is drawn to es7mate SBHP

• The inverse of the slope is used to es7mate PI

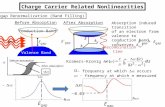

Produc>on Analysis – Region of Slug Flow

• Turner-‐Coleman’s Cri7cal Rate is plo^ed against the total actual gas rate

• Liquid loading occurs when the actual gas rate drops below cri7cal, defined as “Region of Slug Flow”

• Implemen7ng GAPL would reduce the amount of injec7on gas required to meet the cri7cal rate requirement, reducing the “Region of Slug Flow”

XN

Produc>on Analysis – An>cipated UpliK

• Calcula7ng how much of an increase in produc7on will take place is hard to accomplish with a plunger in the well

• 40-‐50% decrease in FBHP is not uncommon • A percentage decrease in FBHP can be used to es7mate the increase in fluid produc7on • Decrease in FBHP X Produc7vity Index = Total

Fluid UpliD • 112 PSI x 0.245 BPD/PSI = 27.4 bbl Total Fluid UpliD • 27.4 bbl Total Fluid UpliD x 0.27 OC = 7.3 bbl Oil

UpliD

• Assuming a constant GLR and taking into account the total fluid upliD, the increase in gas produc7on can be es7mated • Form. GLR X Total Fluid UpliD = Gas UpliD

• 6996 scf/bbl x 27.4 bbl Total Fluid UpliD = 191,690 scf Gas UpliD

Table 3.1.3 – Well #1 Anticipated Uplift Decreased FBHP Decreased FBHP Oil Uplift Gas Uplift

psi bpd mscfd

10% 28 1.8 48.0

20% 56 3.7 96.0

30% 84 5.5 143.9

40% 112 7.3 191.9

50% 140 9.1 239.9

60% 168 11.0 287.9

70% 196 12.8 335.8

80% 224 14.6 383.8

90% 252 16.5 431.8

Case Study – Gas LiK Converted to GAPL, to Plunger LiK

• Operator – Confiden7al • Well Name – Confiden7al • Region – Permian Basin • Forma7on – Wolfcamp “B” • Packer Depth – 8240’ MD / 8120’ TVD

• Tubing Size – 2-‐3/8” • Primary goal was reduce inj.

gas and keep the tubing clean • Significant increase in gas

produc7on allowed for tapering of the injec7on gas un7l the plunger could run on its own

• ROI was less than 1 week

2-‐3/8” GAPL

HIT 2-‐7/8” GL

Free Cycle Plunger LiD

Case Study – GAPL for Paraffin Control

Operator Name – Confiden7al Well Name – Confiden7al Region – Permian Basin Forma7on – Wolfcamp Packer Depth – 9250’ MD Tubing Size – 2-‐7/8” • Primary goal was to control paraffin and reduce associated costs

• Not only did GAPL lower the well’s LOE, it doubled both gas and oil produc7on

• Operator has installed addi7onal systems with similar results

Natural Flow Gas LiD GAPL

Questions?

CONTACT INFORMATION

TODD THRASH, PRIORITY ARTIFICIAL LIFT (817) 694-‐7208