Bridge sections from China to Norway BIG BOAT – SMALL PIER

Transcript of Bridge sections from China to Norway BIG BOAT – SMALL PIER

Mar

tin H

aag

THE SAL HEAVY LIFT MAGAZINE | NO. 1 / 2019

Shipunloader for renewable energy plant

Three shiploaders in one shipment

26 metre lifting beams in a fork lift configuration

Bridge sections from China to Norway

B IG BOAT –

SMALL PIER

Ale

xand

er T

emp

el

2CONTENTS

IN THIS ISSUE

4 BIG BOAT, SMALL PIERBridge sections from China to Norway

10 POWERING 600 000 HOMESDelivering a shipunloader for a renewable energy plant

14 ALL GOOD THINGS COME IN THREESThree shiploaders in one shipment

18 A LONG DEBUT26 metre lifting beams in fork lift configuration

20 BIG CRANES ON THE MOVETwo of the largest LHM cranes on MV Anne-Sofie

22 SNAPSHOT

24 EVENT REVIEWS

29 UPCOMING EVENTS

30 CHARITY

31 INSIDE SAL

33 UP CLOSE Up close with Mika Eerola

34 BEST OF SOCIAL MEDIA

FROM THE CEO DESK

Dear reader,We have greeted a new year since our last issue of Newsbreeze and a very short winter already seems behind us. Sunny days and milder winds are blessing us from early on here in the north. If we draw a parallel to our shipping environment, days have be-come brighter compared to the dark and stormy days of 2016 and 2017. However, fierce competition and lack of larger industrial projects continues to set the landscape in 2019. But the Beaufort scale points towards calmer winds as we move further ahead. This year also marks a significant milestone, where we as an industry prepare ourselves for the new IMO emissions regulations. SAL is having clear green ambitions, working on fleet, technologies and markets where we can leave a green footprint – just as our corporate colour.

This issue is however all about heavy lifting in its core sense. Ship-loaders, cranes and bridge sections make this Newsbreeze and once more show how SAL is equal to Engineered Marine Transportation.

Enjoy your reading,

Martin Harren CEO

Jan

Mei

er

3

SAL Heavy Lift delivers bridge sections from China to Norway

Mar

tin H

aag

A total of 12 bridge sections for the Beitstadsundbrua bridge were shipped from China to Norway

by SAL. The final bridge is part of the largest road construction project in northern Trøndelag, and will measure 580 metres in length and will connect the municipalities of Steinkjer and Malm, crossing the Beitstadfjorden. The bridge will make travelling between northern parts of Trøndelag county considerably safer, as well as reduce travelling time significantly.

INFRASTRUCTURE

BIG BOAT – SMALL PIER

4

In a mountainous country like Norway, which is cut apart by deep fjords, bridge building is a virtue of necessity. Today there are over 18 000 bridges, summing up to 446 kilometres and each with an average length of 250 metres, spread across Norway. The latest addition will be the 580 metres long “Beitstadsundbrua”.

Connecting the municipalities of Steinkjer and Malm, whilst crossing the Beitstadfjorden, the Beitstadsundbrua will not only be longer than the average bridge in Norway, but also ensure increased road safety and accessibility. All whilst helping locals to cut down travel times and benefiting the local economy and environment.

“The new County Road (FV 17 and 720) including Beit-stadsundet Bridge, will eliminate the distance challenges the region has. The new road and bridge significant increases the municipality of Verran’s opportunities to further develop existing industries and attract new industry. The municipality is now, due to the new road and bridge, in dialogue with indus-trial companies exploiting establishment of industry in Verran”, states Jacob Almlid, Special Advisor Industry & Commerce at Verran Kommune.

SAL’s heavy lift vessel MV Trina (Type 176) was appointed to support the construction of the new bridge by shipping twelve bridge sections from Nantong, China to Malm, Norway. All twelve sections weigh a total of 2 800 tons, with the heaviest unit weigh-ing 426 tons (73.8 × 9 × 5.8 metres) and the longest unit measur-ing 75 × 5.9 × 5.8 metres (327 tons).

With a total of four single lifts and eight tandem lifts, the SAL experts were able to stow all twelve bridge sections in two layers under deck, and another layer on deck of the vessel.

“It only took us 35 days to directly sail to Malm from Nan-tong in China,” Tina Yi, Senior Manager Marketing & Sales at SAL China explains, “despite the unique conditions in the port of Malm, with an only 20 metre wide jetty and 2 metre tidal range, it took just six days until we were able to successfully and smoothly deliver 20 668 cbm of cargo to our client.” »

5 BRIDGE PARTS

Using a fork lift arrangement with 26 metre traverses to load two shiploaders

S A L

10°

COG

of S

hipl

oade

r: 17

150

COG

SL a

nd L

ift F

rame

:1500

8

Lift

ing

heig

ht a

bout

: 218

08

Woo

den

Dunn

age:

75

COG

of S

hipl

oade

r: 17

150

COG

SL a

nd L

ift F

rame

:1500

8

Woo

den

Dunn

age:

75

Lift

ing

heig

ht a

bout

: 223

75

9°

Subject to- further technical details- masters decisions on site

18-2378-200 REV.2Document No:

Date

Shipment:

Paper Size:Scale:

Description: Vessel:

SAL Engineering GmbHBrooktorkai 2020457 HamburgGermany

THIS DOCUMENT AND ALL INFORMATION THEREON ARE THE EXCLUSIVE PROPERTY OF SAL ENGINEERING GMBH AND CAN NOT BE COPIED, REPRODUCED, MADE PUBLIC OR USED FOR ANY PURPOSE OTHER THANTHAT FOR WHICH THE DRAWING IS PROVIDED, WITHOUT WRITTEN AUTHORISATION OF SAL ENGINEERING GMBH.

Description Prepared Checked ApprovedRev.

BEDESCHIType 116

La Spezia to Barcelona

Rigging ArrangementShiploader 380t A21:175

2 2018-10-23 Grommets changed Stuckert Schmidt

HOOK LOADcargo 190t

lifting gear 60ttotal 250t

Boom inclination of 48,1°for shifting the cog into thecenter of the lifting Frame

1

Rigging Arrangement List

Pos Qty Description SWL [t] Dimension Comment

1 2 Grommet 290 L: 16m; ∅114mm2 1 Lifting Frame 2000 L: 26m3 2 Grommet 290,6 L: 12m; ∅114mm4 2 Shackle 250 Opening 170mm; ∅135mm; L542mm P-60335 2 Grommet 290,6 L: 4m; ∅114mm

HOOK LOADcargo 190t

lifting gear 60ttotal 250t

3

Boom inclination of 48,1°for shifting the cog into thecenter of the lifting Frame

2 2

4

5

INFRASTRUCTURE

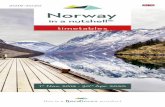

Isn’t it always exciting to add something to a list of firsts? When our experts at SAL Engineering were trusted with the lift of two shiploaders it quickly became clear that only a

unique rigging arrangement with two 26 metre lifting beams would do the job.

“It was the first time that we executed the loading of a 380 ton shiploader, measuring 12 × 25.6 × 53.3 metres, with our 26 metre traverses in a fork lift configuration,” explains Arthur Stuckert, Project Engineer at SAL Engineering. “We already have lots of experience in similar lifts, but we always used different and much shorter lifting beams to carry out such lifts,” he adds.

Above all it was a very time-sensitive shipment. To save time, the client decided to attach all lashings before the arrival of our Type 116 vessel MV Palabora, which worked out very well.

“For us the two 26 metre lifting beams are a great investment in the future,” says Karsten Behrens, General Manager at SAL Engineering, “with this tools at hand, we will be much more flex-ible in carrying out lifts of this kind. We can now realize lifts with a modular lifting frame of up to 18 metres width and 26 metres length and are excited for many interesting business opportuni-ties to come.” D

A LONGDEBUT

18

TWO SHIPLOADERS

Client UTC MEDITERRANEAN SRLU

Vessel MV Palabora, Type 116

Weight 380 t

Dimensions 12 × 25.6 × 53.3 m each

POL La Spezia, Italy

POD Barcelona, Spain

Specials • First time loading shiploader with a 26 m lifting beam as a fork lift

• Lashing were attached to cargo before loading to save time

Scope of work

• Fork lift of two shiploaders two 26 metre lifting beams

Engineering scope

• Lifting• Securing• Weight spreading

Methods / Software

• AutoCAD• Autodesk Inventor• RFEM

“We are proud to see how the supplied

2000 tons lifting arrangement, in one of its

many configurations, facilitates the job, as

a result of our successful collaboration.”

Robert Vaessen, Commercial Director, Eager.one BV

USING 26 METRE LIFTING BEAMS

A LONGDEBUT

19

ImprintEditors: Frederike Blömker, Christian HoffmannContact: [email protected] Design: Claudia BadouinPhotos (if not stated otherwise): SAL staff Published by: SAL Heavy Lift GmbH, Brooktorkai 20, 20457 Hamburg, Germany– A member of the Harren & Partner Group –www.sal-heavylift.com© SAL Heavy Lift 2019 • All rights reserved

Follow us on

WE INNOVATE SOLUTIONS

Ale

xand

er T

emp

el