Bridas

-

Upload

pumashot20 -

Category

Documents

-

view

8 -

download

0

Transcript of Bridas

-

brides / flangesgnralits / general features

ASME B 16.5 n ASTMspcifications / specifications .............................................. 3-3

ASME B 16.5 n ASME B 16.47 Serie A n MSS-SP 44faces de brides / flange facings ........................................... 3-8usinage des portes de joint / flange facing finish................ 3-16extrmits souder / welding ends .................................... 3-18tolrances / tolerances...................................................... 3-22

DN 15 600 / NPS 1/2 to 24ASME B 16.5

dimensions et masses / dimensions and weights .................. 3-24DN 650 1500 / NPS 26 to 60

MSS-SP 44 n ASME B 16.47 Serie A n BS 3293dimensions et masses / dimensions and weights .................. 3-38

ASME B 16.47 Serie Bdimensions et masses / dimensions and weights .................. 3-48

brides orifice / orifice flangesDN 25 600 / NPS 1 to 24

ASME / ANSI B 16.36dimensions et masses / dimensions and weights .................. 3-54

brides / long welding-neck / flangesDN 15 600 / NPS 1/2 to 24

dimensions et masses / dimensions and weights .................. 3-62

brides spciales / special flangesdia. 113/16 /to 211/4

API 6A, types B et/and BXdimensions et masses / dimensions and weights .................. 3-66

obturateurs rversiblesspectacle blinds, reversible spadesobturateurs simplesline spades and spacers, line blinds

dimensions et masses / dimensions and weights .................. 3-70

boulonnerie / bolting materialsspcifications / specifications ............................................ 3-87

ASME B 16.5tiges filetes / stud bolts.................................................... 3-90

ASME / ANSI B 18.2.2 n NF EN 24032crous hexagonaux / hex nuts ........................................... 3-94

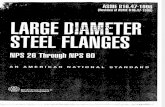

BRIDESFLANGES

joints dtanchit / sealing gasketssommaire / contents ......................................................... 3-99

CD ROM-chapitre 3-1 7/08/98 15:01 Page 1

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

American Society of Mechanical EngineersAmerican National Standard InstituteCet organisme fournit les normes dimensionnelles depuis octobre 1969. ANSI est la nouvelle appellationqui remplace USAS qui elle-mme remplaait l'ASA depuis le 24 aot 1966.Previously ASA and USAS since august 24 th 1966. Issues dimensions standards as from october 1969.American Society for Testing and MaterialsAmerican Gas AssociationManufacturers Standardization SocietyStandard PracticeAmerican Petroleum Institute

3-3

brides ptrolegnralits

flangesused by the oil industry

general information

ASME

ASTMAGA

MSS-SPAPI

SIGNIFICATION DES SIGLES / MEANING OF INITIALS

SRIES DE PRESSION AVEC DIMENSIONNEL COMMUN /PRESSURE CLASSES WITH DIMENSIONS IN COMMON

COMPARAISON DES BRIDES ASME B 16.5 ET API 6 AAPI 6 A vs ASME B 16.5 FLANGES

Pour mmoire / For memoryASAUSAS

American Standard AssociationUnited States of America Standards

300 400 600400 600900 1500300 600

Sries / Classes

Toutes les dimensions des brides API type 6 B sontconformes avec celles des brides ASME B 16.5, commeindiqu dans le tableau ci-dessous.

All dimensions of API type 6 B flanges are in agreementwith the corresponding ASME B 16.5, as shown in tablehere below.

1/2" 3/4" 1".1/2" / to 3" 1/2 inclus.1/2" / to 2" 1/2 inclus.

1" 1/4 / to 3" 1/2 inclus :mme gabarit de raccordement et diamtre extrieur

mais paisseur de plateau diffrente.same drilling and outside diameter of flange but

different thickness.

Pour diamtres / For sizes

Type de brideFlange type

Welding neck

Pleine/BlindFilete/Threaded

et/andintg./integral (1)

600900

1500600900

1500

20003000500020003000

5000

2 102 102 102 202 20

2 10

2 1/16 112 1/16 112 1/16 11

2 1/16 21 1/42 1/16 20 3/4

2 1/16 11

1 1/2 101 1/2 101 1/2 101 1/2 201 1/2 20

1 1/2 10

SriesPressure class designation

ASME ASME APIAPI

Gammede diamtres nominaux

Nominal size range

Ancienne gamme dediamtres nominaux API

Previous APInominal size range

(1) Dans certaines sries, certains diamtres de brides APIavec filetage casing ou tubing ont des hauteursplus grandes que celle requises par ASME B 16.5

(1) API flanges with casing or tubing thread in certainsizes and pressure classes have hub lengths grea-ter than required by ASME B 16.5

ANSI

CD ROM-chapitre 3-1 7/08/98 15:01 Page 2

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

70

70

70

85

70

70

75

75

70

75

70

75

75

75

75

3-5

spcificationsmatires

materialsrequirements

485

485

485

585

485

485

515

515

485

515

485

515

515

515

515

NuanceASTM

Grade

Desig.UNS

Caractristiques mcaniques / Mechanical requirementsRsistance la rupture

Tensile strength

Limitelastique 0,2 %

Yield strength 0.2 %

Allong.

Elong.

StrictionReduc.of area

DuretBrinell

Hardness

Flexion par chocImpact test

TemperatureN/mm2

miniksi

miniN/mm2

miniksi

mini%

mini%

miniHB

maxi C F

A 105 / A 105 M-96

A 181A 181 M-95 b Class 60

A 181A 181 M-95 b Class 70

485

415

485

70

60

70

250

205

250

36

30

36

22

22

18

30

35

24

187

ACIERS AU CARBONE / CARBON STEELS

415 -

585

485 -

655

485 -

655

60 - 85

70 - 95

70 - 95

205

250

260

30

36

37,5

25

22

22

38

30

35

197

197

197

28,9

45,6

101,1

20

50

150

F1

F2

F5

F9

F11 Class 2

F12 Class 2

F22 Class 3

F304

F304 L

F316

F316 L

F321

F347

F348

F310

K 12822

K 12122

K 41545

K 90941

K 11572

K 11564

K 21590

S 30400

S 30403

S 31600

S 31603

S 32100

S 34700

S 34800

S 31000

LF 1

LF 2

LF 3

A 1

82

/ A

18

2 M

-96

A 3

50/A

350

M-9

6c

275

275

275

380

275

275

310

205

170

205

170

205

205

205

205

40

40

40

55

40

40

45

30

25

30

25

30

30

30

30

20

20

20

20

20

20

20

30

30

30

30

30

30

30

30

30

30

35

40

30

30

30

50

50

50

50

50

50

50

50

143 - 192

143 - 192

143 - 217

179 - 217

143 - 207

143 - 207

156 - 207

ACIERS ALLIS HAUTE TEMPRATURE / ALLOY STEELS FOR HIGH TEMPERATURE SERVICE

ACIERS BASSE TEMPRATURE / STEELS FOR LOW TEMPERATURE SERVICE

3-4

pression tempraturepour bridesen acier au carbone(1)

pressure temperatureratings

for carbon steel(1) flangesASME B 16.5 1996 ASTM

Temperature C

29 /to 38

93

149

204

260

316

343

371

399

427

454

482

510

538

Pressions en bar pour brides PN

Pressures in bar for flanges class

150 300 400 600 900 1500 2500

20 50 68 100 150 250 420

19,6

17,9

15,8

13,8

11,7

9,6

8,6

7,6

6,5

5,5

4,5

3,4

2,4

1,3

51,0

46,5

45,2

43,8

41,4

37,9

36,9

35,8

34,8

28,3

18,6

11,7

7,2

3,4

68,2

62,0

60,3

58,2

55,1

50,3

49,3

48,9

46,2

37,9

24,5

15,8

9,6

4,8

102,0

93,1

90,7

87,6

82,7

75,5

74,1

73,4

69,6

56,9

36,9

23,8

14,1

7,2

153,1

139,6

135,8

131,0

123,8

113,1

111,0

110,3

104,1

85,1

55,5

35,5

21,4

10,7

255,4

232,7

226,1

218,6

206,5

188,6

185,1

183,7

173,7

142,0

92,4

59,3

35,5

17,9

425,4

387,8

377,1

364,0

344,0

314,4

308,5

306,1

289,6

236,5

153,7

98,6

59,3

29,6

(1)Matires ASTM groupe 1-1ASTM materials group 1-1

A 105A 216 WCB

A 515-70A 516-70A 350-LF2

A 537-C L 1

(a)(a)(a)

(a) (c)(a)(d)

(a) Autoris mais non recommand pour utilisation pro-longe au-dessus d'environ 425 C.

(c) Ne pas utiliser au-dessus de 455 C.(d) Ne pas utiliser au-dessus de 371 C.

(a) Permissible but not recommended for prolonged useabove about 800 F.

(c) Not to be used over 850 F.(d) Not to be used over 700 F.

Temperature F

20 /to 100

200

300

400

500

600

650

700

750

800

850

900

950

1000

CD ROM-chapitre 3-1 7/08/98 15:01 Page 3

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

F1

F2

F5

F9

F11 Class 2

F12 Class 2

F22 Class 3

F304

F304 L

F316

F316 L

F321

F347

F348

F310

ASTM ASTM

3-7

materialsrequirements

0,50 maxi

8,0 11,0

8,0 13,0

10,0 14,0

10,0 15,0

9,0 12,0

9,0 13,0

9,0 13,0

19,0 22,0

0,44 0,65

0,44 0,65

0,44 0,65

0,90 1,10

0,44 0,65

0,44 0,65

0,87 1,13

2,00 3,00

2,00 3,00

5 C Ti 0,70 %

10 C Cb + Ta 1,10 %

10 C Cb + Ta 1,10 %

Ta 0,10 %

NuanceASTMGrade

Chemical requirements in percentNickelNickel

MolybdneMolybdenum

CuivreCopper

Ni Mo Cu

VanadiumVanadium

V

NiobiumColumbium

Nb/Cb

AutresOthers

A 105 / A 105 M-96

A 181A 181 M-95 b Class 60

A 181A 181 M-95 b Class 70

0,40 maxi 0,12 maxi 0,40 maxi 0,05 maxi 0,02 maxi

CARBON STEELS

0,40 maxi

0,40 maxi

3,3 3,7

0,12 maxi

0,12 maxi

0,12 maxi

0,40 maxi

0,40 maxi

0,40 maxi

0,05 maxi

0,05 maxi

0,03 maxi

0,02 maxi

0,02 maxi

0,02 maxi

F1

F2

F5

F9

F11 Class 2

F12 Class 2

F22 Class 3

F304

F304 L

F316

F316 L

F321

F347

F348

F310

LF 1

LF 2

LF 3

A 1

82

/ A

18

2 M

-96

A 3

50/A

350

M-9

6c

ALLOY STEELS FOR HIGH TEMPERATURE SERVICE

STEELS FOR LOW TEMPERATURE SERVICE

3-6

spcificationsmatires

0,28 maxi

0,05 0,21

0,15 maxi

0,15 maxi

0,10 0,20

0,10 0,20

0,05 0,15

0,08 maxi

0,035 maxi

0,08 maxi

0,035 maxi

0,08 maxi

0,08 maxi

0,08 maxi

0,15 maxi

0,60 0,90

0,30 0,80

0,30 0,60

0,30 0,60

0,30 0,80

0,30 0,80

0,30 0,60

2,00 maxi

2,00 maxi

2,00 maxi

2,00 maxi

2,00 maxi

2,00 maxi

2,00 maxi

2,00 maxi

0,15 0,35

0,10 0,60

0,50 maxi

0,50 1,00

0,50 1,00

0,10 0,60

0,50 maxi

1,00 maxi

1,00 maxi

1,00 maxi

1,00 maxi

1,00 maxi

1,00 maxi

1,00 maxi

1,00 maxi

0,045 maxi

0,040 maxi

0,030 maxi

0,030 maxi

0,040 maxi

0,040 maxi

0,040 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,045 maxi

0,040 maxi

0,030 maxi

0,030 maxi

0,040 maxi

0,040 maxi

0,040 maxi

0,030 maxi

0,030 maxi

0,030 maxi

0,030 maxi

0,030 maxi

0,030 maxi

0,030 maxi

0,030 maxi

0,50 0,81

4,0 6,0

8,0 10,0

1,00 1,50

0,80 1,25

2,00 2,50

18,0 20,0

18,0 20,0

16,0 18,0

16,0 18,0

17,0 mini

17,0 20,0

17,0 20,0

24,0 26,0

NuanceASTMGrade

Desig.UNS

Composition chimique %CarboneCarbon

ManganseManganese

SiliciumSilicon

PhosphorePhosphorus

SoufreSulfur

ChromeChromium

C Mn Si P S Cr

A 105 / A 105 M-96

A 181A 181 M-95 b Class 60

A 181A 181 M-95 b Class 70

0,35 maxi

0,35 maxi

0,35 maxi

0,60 1,05

1,10 maxi

1,10 maxi

0,10 0,35

0,10 0,35

0,10 0,35

0,035 maxi

0,050 maxi

0,050 maxi

0,040 maxi

0,050 maxi

0,050 maxi

0,30 maxi

ACIERS AU CARBONE

0,35 maxi

0,35 maxi

0,20 maxi

0,60 1,35

0,60 1,35

0,90 maxi

0,15 0,30

0,15 0,30

0,20 0,35

0,035 maxi

0,035 maxi

0,035 maxi

0,040 maxi

0,040 maxi

0,040 maxi

0,30 maxi

0,30 maxi

0,30 maxi

K 12822

K 12122

K 41545

K 90941

K 11572

K 11564

K 21590

S 30400

S 30403

S 31600

S 31603

S 32100

S 34700

S 34800

S 31000

LF 1

LF 2

LF 3

A 1

82

/ A

18

2 M

-96

A 3

50/A

350

M-9

6c

ACIERS ALLIS HAUTE TEMPRATURE

ACIERS BASSE TEMPRATURE

CD ROM-chapitre 3-1 7/08/98 15:01 Page 4

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-9

flange facings

ASME B 16.5 1996

C

C

0.19"5 mm

0.25"6,4 mm

E

0.19"5 mm

Epaisseur de la brideThickness of flange

Epaisseur de la brideThickness of flange

Embotementfemelle troit

(sur extrmit de tube)PN 20 et plus

Small female face(on end of pipe)

class 150 and higher

Embotementdouble mle

large ou troitPN 50 et plus

Large or smalltongue face

class 300 and higher

Embotementdouble femellelarge ou troitPN 50 et plus

Large or smallgroove face

class 300 and higher

Face usinepour joint annulaire

PN 20 et plus

Ring joint faceclass 150 and higher

X

Ztroit

et largesmall

and large

Utroit

et largesmall

and large

Ttroitsmall

Rlargelarge

L

PK

WYK

troitsmall

largelarge

3-8

faces de joint de brides

ASME B 16.5 1996

C

0.06"1,6 mm

0.25"6,4 mm

0.25"6,4 mm

0.25"6,4 mm

0.19"5 mm

Epaisseur de la brideThickness of flange

Face surlevePN 20 et PN 50

Raised faceclass 150 and 300

Face surlevePN 68 et plus

Raised faceclass 400 and higher

Embotementsimple mle

large ou troitPN 50 et plus

Large or smallmale face

class 300 and higher

Embotementsimple femellelarge ou troitPN 50 et plus

Large or smallfemale face

class 300 and higher

Embotementmle troit

(sur extrmit de tube)PN 20 et plus

Small male face(on end of pipe)

class 150 and higher

R

R

S

Rlargelarge

Stroitsmall

LWXK

troitsmall

largelargel

CD ROM-chapitre 3-1 7/08/98 15:01 Page 5

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

DN 25 600 / NPS 1 to 24 n ASME B 16.5 1996

3-11

dimensionsdes faces de brides PN 20 joint annulaire

dimensionsof class 150

ring joint facings

ASME B 16.5 1996

DiamtreSize

DN NPS K

253240506580

100125150200250300350400450500600

Diamtrede face

surleveDiameter of

raised portion

63,573,282,5

101,6120,7133,4154,0171,5193,5219,0273,0330,2406,4425,5482,6546,1596,9711,2

47,6257,1565,0782,55

101,60114,30131,78149,22171,45193,68247,65304,80381,00396,88454,02517,52558,80673,10

6,356,356,356,356,356,356,356,356,356,356,356,356,356,356,356,356,356,35

8,748,748,748,748,748,748,748,748,748,748,748,748,748,748,748,748,748,74

0,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,8

4,14,14,14,14,14,14,14,14,14,14,14,14,13,03,03,03,03,0

R15R17R19R22R25R29R33R36R40R43R48R52R56R59R64R68R72R76

11 1/41 1/2

22 1/2

33 1/2

456810121416182024

P E

Diamtremoyen

de la rainurePitch diameter

of groove

Profondeurde la rainure

Depthof groove

F

Largeurde la rainure

Widthof groove

r

Rayondu cong

Radiusat bottom

Distancemoyenne

entre bridesApproximatedist. between

flanges

Numrodu joint

Ringnumber

E

F

P

K

r

23

TolrancesDiamtre moyen P : 0,13 mmProfondeur E : + 0,4 mm 0 mmLargeur F : 0,2 mmRayon r ( 1,6 mm) : + 0,8 mm 0 mm

r (> 1,6 mm) : 0,8 mmAngle 23 1/2

TolerancesPitch diameter P : 0.005Depth E : + 0.016 0Width F : 0.008Radius r ( 0.06) : + 0.03 0

r (> 0.06) : 0.03Angle 23 1/2

3-10

dimensions des facesde joint de brides(sauf faces usines pour joint annulaire)

toutes sries

dimensionsof flange facings

(other than ring joints)

all pressure rating classesASME B 16.5 1996

DiamtreSize

DN NPS R S T U K L W X Y Z

1520253240506580

100125150200250300350400450500600

Diamtre extrieurOutside diameter

Dia. ext. minimal de lasaillie de lembotement

femelle (1) (2)Minimum outside diameter

of raised portion (1) (2)

Diamtre extrieurOutside diameter

35,042,950,863,573,191,9

104,6127,0139,7157,2185,7215,9269,7323,8381,0412,8469,9533,4584,2692,2

18,323,930,238,144,557,268,384,196,8

109,5136,7162,1212,8266,7317,5349,3400,1450,8501,7603,3

35,142,947,757,263,582,695,3

117,3130,0144,6173,0203,2254,0304,8362,0393,7447,5511,0558,8666,8

25,433,238,147,753,873,285,9

108,0120,6131,8160,3190,5238,3285,8342,9374,7425,5489,0533,4641,4

44,552,357,266,573,292,0

104,6127,0139,7157,2185,7215,9269,7323,9381,0412,8469,9533,4584,2692,2

46,053,862,074,784,1

103,1115,8138,2150,9168,1196,9227,0281,0335,0392,2424,0481,0544,6595,4703,3

36,644,452,365,074,793,7

106,4128,5141,2158,9186,5217,4271,5325,4382,5414,3471,4534,9585,7693,7

19,825,431,739,646,058,769,985,998,6

111,3138,2163,6214,4268,2319,0350,8401,6452,4503,2604,8

36,644,449,258,765,084,196,8

119,1131,8146,1174,8204,7255,5306,3363,5395,2449,3512,8560,3668,3

23,931,736,646,052,371,484,1

106,4119,1130,0158,8183,0236,5284,2341,4373,1424,0487,4531,9639,8

Dimensions : mm(1) Sauf spcification la commande, peut tre livr avec

saillie ou face pleine / Raised portion or full face may befurnished unless otherwise specified on order.

(2) Les embotements simple et double mle et femelle larges nepeuvent tre usins sur les brides PN 20 / Large male andfemale faces and large tongue and groove are not appliableto class 150 because of potential dimensional conflicts.

1/23/41

1 1/41 1/2

22 1/2

33 1/2

4568

10121416182024

Face

sur

leve

des

em

bote

men

tssim

ple

ml

e la

rge

et do

uble

ml

e la

rge

Raise

d fa

ce la

rge

male

and

larg

e to

ngue

Embo

tem

ent s

impl

e m

le

troi

tSm

all m

ale

Embo

tem

ent d

oubl

e m

le

troi

tSm

all t

ongu

e

Embo

tem

ent d

oubl

e fe

mell

e tr

oit

Smal

l fem

ale

and

groo

ve

Embo

tem

ent d

oubl

e fe

mell

e la

rge

Larg

e fe

male

and

groo

ve

Embo

tem

ents

simpl

e fe

mell

e la

rge

et do

uble

fem

elle

larg

eLa

rge

fema

le an

d la

rge

groo

ve

Embo

tem

ent s

impl

e fe

mell

e tr

oit

Smal

l fem

ale

Embo

tem

ent d

oubl

e fe

mell

e tr

oit

Smal

l gro

ove

Diam

tre

intr

ieur

de

lem

bote

men

tdo

uble

ml

e la

rge

et tr

oit

Insid

e di

amete

r of l

arge

and

smal

l gro

ove

Diam

tre

intr

ieur

de

lem

bote

men

tdo

uble

fem

elle

larg

e et

troi

tIns

ide

diam

eter o

f lar

ge a

nd sm

all g

roov

e

Dimensions : mm

CD ROM-chapitre 3-1 7/08/98 15:01 Page 6

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-13

DN 15 600 / NPS 1/2 to 24 n ASME B 16.5 1996

DN 650 900 / NPS 26 to 36 n ASME B 16.47 1996 Sries A n MSS SP 44 1996

dimensionsdes faces de bridesPN 150(3) joint annulaire

dimensionsof class

900(3)ring joint facings

DiamtreSize

DN NPS K

1520253240506580

100125150200250300350400450500600

650700750800850900

Diamtrede face

surleveDiameter of

raised portion

60,566,571,481,091,9

123,9136,7155,4180,8215,9241,3307,8362,0419,1466,9523,7593,9647,7771,7

831,9889,0946,2

1003,31066,81124,0

39,6744,4550,8060,3268,2895,25

107,95123,82149,22180,98211,12269,88323,85381,00419,10469,90533,40584,20692,15

749,30800,10857,25914,40965,20

1022,35

6,356,356,356,356,357,927,927,927,927,927,927,927,927,92

11,1311,1312,7012,7015,88

17,4817,4817,4817,4820,6220,62

8,748,748,748,748,74

11,9111,9111,9111,9111,9111,9111,9111,9111,9116,6616,6619,8419,8426,97

30,1833,3233,3233,3236,5336,53

0,80,80,80,80,80,80,80,80,80,80,80,80,80,81,61,61,61,62,3

2,32,32,32,32,32,3

R100R101R102R103R104R105

4,14,14,14,14,13,03,04,14,14,14,14,14,14,14,14,14,84,85,6

R12R14R16R18R20R24R27R31R37R41R45R49R53R57R62R66R70R74R78

1/23/41

1 1/41 1/2

22 1/2

3456810121416182024

262830323436

P E

Diamtremoyen

de la rainurePitch diameter

of groove

Profondeurde la rainure

Depthof groove

F

Largeurde la rainure

Widthof groove

r

Rayondu cong

Radiusat bottom

Distancemoyenne

entre bridesApproximatedist. between

flanges

Numrodu joint

Ringnumber

ASME B 16.5 1996 ASME B 16.47 1996 sries A n MSS SP 44 1996

DN 15 600 / NPS 1/2 to 24 n ASME B 16.5 1996

DN 650 900 / NPS 26 to 36 n ASME B 16.47 1996 Series A n MSS SP 44 1996

3-12

dimensionsdes faces de bridesPN 50 68(1) 100 joint annulaire

dimensionsof class

300 400(1) 600ring joint facings

DiamtreSize

DN NPS K

1520253240506580

100125150200250300350400450500600

650700750800850900

Diamtrede face

surleveDiameter of

raised portion

50,863,569,979,290,4

108,0127,0146,1158,8174,8209,6241,3301,8355,6412,8457,2508,0574,5635,0749,3

809,8860,5917,4984,3

1035,01092,2

34,1442,2850,8060,3268,2882,55

101,60123,83131,78149,22180,98211,12269,88323,85381,00419,10469,90533,40584,20692,15

749,30800,10857,25914,40965,20

1022,35

5,566,356,356,356,357,927,927,927,927,927,927,927,927,927,927,927,927,929,52

11,13

12,7012,7012,7014,2714,2714,27

7,148,748,748,748,74

11,9111,9111,9111,9111,9111,9111,9111,9111,9111,9111,9111,9111,9113,4916,66

19,8419,8419,8423,0123,0123,01

0,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,80,81,61,6

1,61,61,61,61,61,6

R93R94R95R96R97R98

3,04,14,14,14,15,65,65,65,65,65,65,65,65,65,65,65,65,65,66,4

3,04,14,14,14,14,84,84,84,84,84,84,84,84,84,84,84,84,84,85,6

R11R13R16R18R20R23R26R31(2)R34R37R41R45R49R53R57R61R65R69R73R77

1/23/41

1 1/41 1/2

22 1/2

33 1/2

4568

10121416182024

262830323436

P E

Diamtremoyen

de la rainurePitch diameter

of groove

Profondeurde la rainure

Depthof groove

F

Largeurde la rainure

Widthof groove

rClasses

300 400Classes

600

Rayondu cong

Radiusat bottom

Distance moyenneentre brides

Approximate dist.between flanges

Numrodu joint

Ringnumber

E

F

P

K

r

23 Tolrances : Voir page 3-11Tolerances : See page 3-11

E

F

P

K

r

23 Tolrances : Voir page 3-11Tolerances : See page 3-11

ASME B 16.5 1996 ASME B 16.47 1996 sries A n MSS-SP 44 1996

Dimensions : mmMSS-SP 44 1996 / NPS 12 24 identique ASME B 16.5MSS-SP 1996 / NPS 12 to 24 are the same as ASME B 16.5(1) Utiliser PN 100 pour NPS 1/2 3 1/2 du PN 68 / Use class

600 in sizes NPS 1/2 to 3 1/2 for class 400.(2) Pour les brides tournantes en PN 50 et 100, utiliser le R 30 la

place du R31 / For ring joints with lapped flanges in classes 300and 600, ring and groove number R30 are used instead of R31.

Dimensions : mmMSS-SP 44 1996 / NPS 12 24 identique ASME B 16.5MSS-SP 1996 / NPS 12 to 24 are the same as ASME B 16.5

(3) Utiliser les dimensions de PN 250 pour NPS 1/2 2 1/2 de PN 150 / Use class 1500 in. sizes NPS 1/2 to2 1/2 for class 900.

CD ROM-chapitre 3-1 7/08/98 15:01 Page 7

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-15

DN 15 300 / NPS 1/2 to 12 n ASME B 16.5 1996

dimensionsdes faces de bridesPN 420 joint annulaire

dimensionsof class

2500ring joint facings

ASME B 16.5 1996

DiamtreSize

DN NPS K

15

20

25

32

40

50

65

80

100

125

150

200

250

300

Diamtrede face

surleveDiameter of

raised portion

65,0

73,2

82,6

101,6

114,3

133,4

149,4

168,1

203,2

241,3

279,4

339,9

425,5

495,3

42,88

50,80

60,32

72,24

82,55

101,60

111,12

127,00

157,18

190,50

228,60

279,40

342,90

406,40

6,35

6,35

6,35

7,92

7,92

7,92

9,52

9,52

11,13

12,70

12,70

14,27

17,48

17,48

8,74

8,74

8,74

11,91

11,91

11,91

13,49

13,49

16,66

19,84

19,84

23,01

30,18

33,32

0,8

0,8

0,8

0,8

0,8

0,8

1,6

1,6

1,6

1,6

1,6

1,6

2,3

2,3

4,1

4,1

4,1

3,0

3,0

3,0

3,0

3,0

4,1

4,1

4,1

4,8

6,4

7,9

R13

R16

R18

R21

R23

R26

R28

R32

R38

R42

R47

R51

R55

R60

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

3

4

5

6

8

10

12

P E

Diamtremoyen

de la rainurePitch diameter

of groove

Profondeurde la rainure

Depthof groove

F

Largeurde la rainure

Widthof groove

r

Rayondu cong

Radiusat bottom

Distancemoyenne

entre bridesApproximatedist. between

flanges

Numrodu joint

Ringnumber

E

F

P

K

r

23

TolrancesDiamtre moyen P : 0,13 mmProfondeur E : + 0,4 mm 0 mmLargeur F : 0,2 mmRayon r ( 1,6 mm) : + 0,8 mm 0 mm

r (> 1,6 mm) : 0,8 mmAngle 23 1/2

TolerancesPitch diameter P : 0.005Depth E : + 0.016 0Width F : 0.008Radius r ( 0.06) : + 0.03 0

r (> 0.06) : 0.03Angle 23 1/2

3-14

DN 15 600 / NPS 1/2 to 24 n ASME B 16.5 1996

dimensionsdes faces de bridesPN 250 joint annulaire

dimensionsof class

1500ring joint facings

ASME B 16.5 1996

DiamtreSize

DN NPS K

1520253240506580

100125150200250300350400450500600

Diamtrede face

surleveDiameter of

raised portion

60,566,571,481,091,9

123,9136,7168,1193,5228,6248,0318,0371,0438,0489,0546,0613,0673,0794,0

39,6744,4550,8060,3268,2895,25

107,95136,52161,92193,68211,12269,88323,85381,00419,10469,90533,40584,20692,15

6,356,356,356,356,357,927,927,927,927,929,52

11,1311,1314,2715,8817,4817,4817,4820,62

8,748,748,748,748,74

11,9111,9111,9111,9111,9113,4916,6616,6623,0126,9730,1830,1833,3236,53

0,80,80,80,80,80,80,80,80,80,81,61,61,61,62,32,32,32,32,3

4,14,14,14,14,13,03,03,03,03,03,04,14,14,85,67,97,99,7

11,2

R12R14R16R18R20R24R27R35R39R44R46R50R54R58R63R67R71R75R79

1/23/41

1 1/41 1/2

22 1/2

34568

10121416182024

P E

Diamtremoyen

de la rainurePitch diameter

of groove

Profondeurde la rainure

Depthof groove

F

Largeurde la rainure

Widthof groove

r

Rayondu cong

Radiusat bottom

Distancemoyenne

entre bridesApproximatedist. between

flanges

Numrodu joint

Ringnumber

E

F

P

K

r

23

TolrancesDiamtre moyen P : 0,13 mmProfondeur E : + 0,4 mm 0 mmLargeur F : 0,2 mmRayon r ( 1,6 mm) : + 0,8 mm 0 mm

r (> 1,6 mm) : 0,8 mmAngle (23 1/2

TolerancesPitch diameter P : 0.005Depth E : + 0.016 0Width F : 0.008Radius r ( 0.06) : + 0.03 0

r (> 0.06) : 0.03Angle 23 1/2

Dimensions : mm Dimensions : mm

CD ROM-chapitre 3-1 7/08/98 15:01 Page 8

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-17

Les qualits d'usinage requises sont indiques ci-des-sous. Tout autre usinage pourra tre ralis aprsaccord entre le fabricant et le client.

The finishes required are given below. Other finishesmay be furnished by agreement between user andmanufacturer.

Faces de joint embotement simple ou doubleRa compris entre 3,2 mm maxi et 0,8 mm mini.

Face de joint annulaireRa compris entre 1,6 mm maxi et 0,8 mm mini.

Male and female or tongue and groovefacesRa between 3.2 mm maxi and 0.8 mm mini.

Ring joint faceRa between 1.6 mm maxi and 0.8 mm mini.

Faces de joint surlevesrainures spirales ou centriques

Raised facesconcentric or spiral serrated

ISO PN

20 et 50

100 420

150 and 300

400 to 2500

6,3

3,2

12,5

6,3

1,6 mm

0,8 mm

0,6 /to 0,8 mm

0,35 /to 0,45 mm

ClassRa mm Usinage par tournage / Machining by turning

Rayon d'outil / Radius of cutting tool Avance / Pitchmini maxi

usinagedes portes de joint

flange facingfinish

NFE 29203 JUILLET 1989 / NFE 29203 JULY 1989

3-16

L'tat de surface des faces de brides sera dterminpar comparaison visuelle avec le standard Ra (voirASME B 46.1).Les qualits d'usinage requises sont indiques ci-des-sous. Tout autre type d'usinage pourra tre ralisaprs accord entre fabricant et utilisateur.

Brides embotement double mle etfemelle et embotement simple mle etfemelle troitLe degr de finition ne dpassera pas 125 microinch(3,2 mm).

Brides joint annulaireLe degr de finition des flancs de gorge de joint annu-laire ne dpassera pas 63 microinch (1,60 mm).

Autres faces de bride (brides face surleve et embotement simple mle et femelle larges).Le rsultat final du degr de rugosit Ra par usinageconcentrique ou spiral sera de 125 min. 250 min.(3,2 6,3 mm). Ceci correspond lutilisation dunoutil bout rond de rayon 0,06 in (1,6 mm) mini et45 55 rainures par pouces.

Autres types de finitions :Smooth finish ou finition lisse : aucune trace d'outilne doit apparatre l'il nu(1).Cold water finish ou finition glace : la surface estplane, a l'apparence d'un miroir, gnralement utili-se sans joint (contact mtal sur mtal).(1) Suivant MSS SP-6-1996 , trois classes :

Smooth 250 microinch (6,3 mm) maxiSmooth 125 microinch (3,2 mm) maxiSmooth 63 microinch (1,6 mm) maxi

The finish of contact face of pipe flanges shall be jud-ged by visual comparison with Ra standards (seeASME B 46.1).The finishes required are given below. Other finishesmay be furnished by agreement between user andmanufacturer.

Tongue and groove and small, male andfemale

The gasket contact surface shall not exceed 125microinch (3.2 mm) roughness.

Ring jointThe side wall surface of gasket groove shall notexceed 63 microinch (1.60 mm) roughness.

Other flange facings (raised face flanges andlarge male or female faces).Either a serrated concentric or serrated spiral finishhaving a resultant surface finish from 125 min. to 250min. average roughness shall be furnished. The cuttingtool employed should have an approximate 0.06 in.or larger radius, and there should be from 45grooves/in. through 55 grooves/in.

Other flange facing finishes :Smooth finish : no definite tool marking must beapparent with the naked eye (1).Cold water finish : the flange face appears asmirrorlike, usually expected to be used without gasket(metal to metal contact).(1) According to MSS SP-6-1996, three classes :

Smooth 250 microinch (6.3 mm) maxiSmooth 125 microinch (3.2 mm) maxiSmooth 63 microinch (1.6 mm) maxi

125 / to 250 microinch (3,2 / to 6,3 mm)

45 55 rainures par pouce(soit pas : 0,46 0,56 mm)45 to 55 grooves per inch(0.46 to 0.56 mm pitch)

r mini 0.06 in.(1,6 mm)radius mini

Rainure concentrique ou spirale / Either concentric or spiral serrated

usinagedes portes de joint

flange facingfinish

ASME B 16.5 1996 n MSS SP-44 1996 n ASME B 16.47 1996

CD ROM-chapitre 3-1 7/08/98 15:01 Page 9

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-18

extrmits souderpour brides welding neck

a

A B X

45 maxi

0.25 mini

(6,4 mm)

0.06 0.03

(1,6 mm 0,8 mm)

7maxi

t

37 1/2

2 1/2

A B X

45 maxi

0.25 mini

(6,4 mm)

0.06 0.03

(1,6 mm 0,8 mm)

7maxi

t

10 1

0.75(19 mm)

RayonRadiusr mini = 0,12(3 mm)

BC0.5 min.

0.12 min. radius

30 max.

welding endsfor welding neck flanges

ASME B 16.5 1996BS 3293 1960

ASME B 16.5 1996MSS SP-44 1996

MSS SP-44 1996

CHANFREIN pour paisseurs (t)de 5 mm 22 mm inclus

BEVEL for wall thicknesses (t)0.19 to 0.88 inclusive

a = 37,5 ( 2,5)

USINAGE INTERNE pour utilisation dun anneau de centrageINSIDE CONTOUR for use with backing ring

Rectangulaire / Rectangular

C

0.22 min.

10

Conique / Taper

CHANFREIN / BEVEL a = 30 (+ 5 0)

CHANFREIN pour paisseurs (t)suprieures 22 mm

BEVEL for wall thicknesses (t)greater than 0.88

A = Diamtre extrieur nominal du tubeNominal outside diameter of pipe

B = Diamtre intrieur nominal du tube (B = A 2 t)Nominal inside diameter of pipe

t = Epaisseur nominale du tubeNominal wall thickness of pipe

Pour / for NPS 24, a = 37,5 2,5 loption du fabricant / at option of manufacturer

3-19

dimensionsof weldings ends

dimensionsdes extrmits souder

ASME B 16.5 1996

5,157,009,55

14,005,507,60

11,1515,25

5,758,056,008,55

11,1513,5017,10

6,559,55

12,7015,9019,05

7,1010,9514,2518,2521,95

8,2010,3012,7015,0518,2520,6022,2523,00

0.2030.2760.3750.5520.2160.3000.4380.6000.2260.3160.2370.3370.4380.5310.6740.2580.3750.5000.6250.7500.2800.4320.5620.7180.8640.3220.4060.5000.5930.7180.8120.8750.906

62,9559,7055,3047,4578,2574,5068,4061,2090,5586,40

102,7098,2593,8089,6583,30

128,80123,60118,05112,45106,90154,80148,05142,25135,30128,85203,70199,95195,80191,65186,10181,95179,15177,75

2.4792.3512.1781.8683.0812.9342.6922.4093.5643.4024.0443.8693.6923.5303.2795.0704.8664.6474.4284.2096.0945.8285.6005.3275.0728.0207.8737.7097.5467.3277.1637.0536.998

62,759,054,045,077,973,766,758,490,185,4

102,397,292,087,380,1

128,2122,0115,9109,6103,2154,1146,3139,7131,8124,4202,7198,5193,7189,0182,6177,8174,6173,1

2.4692.3232.1251.7713.0682.9002.6242.3003.5483.3644.0263.8263.6243.4383.1525.0474.8134.5634.3134.0636.0655.7615.5015.1894.8977.9817.8137.6257.4397.1897.0016.8756.813

4080

160XXS4080

160XXS40804080

120160XXS4080

120160XXS4080

120160XXS406080

100120140XXS160

Diamtrenominal

Nominalpipe size

poucesinches

mmpoucesinches

mmpoucesinches

mmpoucesinches

mm

Epaisseur ouschedule (1)

Wall thicknessor schedule (1)

A B C(2) t

4 1/2

3

3 1/2

4

5

6

8

73,0

88,9

101,6

114,3

141,3

168,1

218,9

2.88

3.50

4.00

4.50

5.56

6.62

8.62

(1) STD = Standard wall thicknessXS = Extra strong wall thicknessXXS = Double extra strong wall thickness

(2) C in = (A 0.031 1.75 t 0.010) in.

ANSIB 36.10](1) STD = Epaisseur StandardXS = Epaisseur Extra-fortXXS = Epaisseur Double extra-fort

(2) C mm = (A 0,8 1,75 t 0,3) mm.

suivantANSI

B 36.10]

CD ROM-chapitre 3-1 7/08/98 15:01 Page 10

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-21

dimensions of weldings endsASME B 16.5 1996

36,55

40,45

9,55

12,70

14,25

19,05

23,80

29,35

34,95

39,65

45,25

9,55

12,70

15,05

20,60

26,20

32,55

38,10

44,45

50,00

9,55

12,70

14,25

17,45

24,60

30,95

38,90

46,00

52,35

59,50

1.438

1.593

0.375

0.500

0.562

0.750

0.937

1.156

1.375

1.562

1.781

0.375

0.500

0.593

0.812

1.031

1.281

1.500

1.750

1.968

0.375

0.500

0.562

0.687

0.968

1.218

1.531

1.812

2.062

2.343

341,45

334,55

439,50

433,95

431,15

422,80

414,50

404,75

395,05

386,70

377,00

490,30

484,75

480,60

470,85

461,15

450,00

440,30

429,15

419,50

591,90

586,35

583,55

578,05

565,55

554,40

540,50

528,00

516,90

504,40

13.442

13.171

17.303

17.084

16.975

16.646

16.319

15.936

15.553

15.225

14.842

19.303

19.084

18.921

18.538

18.155

17.717

17.334

16.896

16.515

23.303

23.084

22.975

22.757

22.265

21.827

21.280

20.788

20.350

19.859

333,3

325,5

438,2

431,8

428,7

419,1

409,6

398,5

387,4

377,9

366,7

489,0

482,6

477,9

466,8

455,6

443,0

431,8

419,1

408,0

590,6

584,2

581,1

574,7

560,4

547,7

531,8

517,6

504,9

490,6

13.124

12.814

17.250

17.000

16.876

16.500

16.126

15.688

15.250

14.876

14.438

19.250

19.000

18.814

18.376

17.938

17.438

17.000

16.500

16.064

23.250

23.000

22.876

22.626

22.064

21.564

20.938

20.376

19.876

19.314

140

160

STD

XS

40

60

80

100

120

140

160

STD

XS

40

60

80

100

120

140

160

STD

XS

30

40

60

80

100

120

140

160

Diamtrenominal

Nominalpipe size

poucesinches

mmpoucesinches

mmpoucesinches

mmpoucesinches

mm

Epaisseur ouschedule (1)

Wall thicknessor schedule (1)

A B C(2) t

16

18

20

24

(1) STD = Standard wall thicknessXS = Extra strong wall thicknessXXS = Double extra strong wall thickness

ANSI B 36.10] (2) C in = (A 0.031 1.75 t 0.010) in.

16.00

18.00

20.00

24.00

406,4

457,0

508,0

610,0

3-20

dimensions des extrmits souderASME B 16.5 1996

9,25

12,70

15,05

18,25

21,40

25,40

28,60

9,55

10,30

12,70

14,25

17,45

21,40

25,40

28,60

33,30

9,55

11,15

12,70

15,05

19,05

23,80

27,75

31,75

35,70

9,55

12,70

16,65

21,40

26,20

30,95

0.365

0.500

0.593

0.718

0.843

1.000

1.125

0.375

0.406

0.500

0.562

0.687

0.843

1.000

1.125

1.312

0.375

0.438

0.500

0.593

0.750

0.937

1.093

1.250

1.406

0.375

0.500

0.656

0.843

1.031

1.218

255,80

249,80

245,65

240,10

234,55

227,55

222,00

306,15

304,75

300,60

297,80

292,30

285,35

278,35

272,80

264,50

337,90

335,10

332,35

328,20

321,20

312,90

305,95

299,00

292,05

388,70

383,15

376,20

367,90

359,55

351,20

10.070

9.834

9.671

9.452

9.234

8.959

8.740

12.053

11.999

11.834

11.725

11.507

11.234

10.959

10.740

10.413

13.303

13.192

13.084

12.921

12.646

12.319

12.046

11.771

11.498

15.303

15.084

14.811

14.484

14.155

13.827

254,5

247,7

242,9

236,6

230,2

222,3

215,9

304,8

303,2

298,5

295,3

289,0

281,0

273,1

266,7

257,2

336,6

333,3

330,2

325,5

317,5

308,0

300,1

292,1

284,2

387,4

381,0

373,1

363,6

354,0

344,5

10.020

9.750

9.564

9.314

9.064

8.750

8.500

12.000

11.938

11.750

11.626

11.376

11.064

10.750

10.500

10.126

13.250

13.124

13.000

12.814

12.500

12.126

11.814

11.500

11.188

15.250

15.000

14.688

14.314

13.938

13.564

40

60

80

100

120

140

160

STD

40

XS

60

80

100

120

140

160

STD

40

XS

60

80

100

120

140

160

STD

40

60

80

100

120

Diamtrenominal

Nominalpipe size

poucesinches

mmpoucesinches

mmpoucesinches

mmpoucesinches

mm

Epaisseur ouschedule (1)

Wall thicknessor schedule (1)

A B C(2) t

10

12

14

16

(1) STD = Epaisseur StandardXS = Epaisseur Extra-fortXXS = Epaisseur Double extra-fort

suivantANSI B 36.10] (2) C mm = (A 0,8 1,75 t 0,3) mm.

273,0

323,8

355,6

406,4

10.75

12.75

14.00

16.00

CD ROM-chapitre 3-1 7/08/98 15:01 Page 11

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

20

10

3-23

flanges tolerances

DsignationDescription

CotesDimensions Tolerances

pouces/inches mm

Diamtre nominalNominal pipe size

(NPS)

pouces/inches

Suivant ASME B 16.5 - 1996 / According to ASME B 16.5 - 1996

5

6 / 24

5

6 / 24

4

10

12

Boreof

flanges

Nominal inside diameter ofwelding end of welding neckflanges and smaller boreof socket welding flanges

Slip-on flanges

Lapped flanges

0.03

0.06

+ 0.12 0.06+ 0.03

0+ 0.06

0

0,8

1,6

+ 3,2 1,6+ 0,8

0+ 1,6

0

Nominaloutside diameterof welding end

Diameter of hub

Overall length of hub

Thickness

of hub

t

A

X

+ 0.09 0.03+ 0.16 0.03

+ 2,4 0,8+ 4,0 0,8

Y

0.06

+ 0.06 0.12+ 0.12 0.18

1,6

+ 1,6 3,2+ 3,2 4,6

Threadedflanges

Counterbore

Thread length

Bolt circle diameter

Diameter of bolt holes

Center to centerof adjacent bolt holesEccentricity between boltcircle diameter andmachined facing diameters

Q

T

+ 0.030

+ 0.060

mini

+ 0.80

+ 1.60

mini

0.06

0.03

0.03 0.06

1.6

0.8

0.8 1.6

Spot facing diameter

Back facing diam. (2)

Drillingand

facing

10

12

12

10

12

24 DDepth of socket for socketwelding flanges

R

S

T

U

L

K

W

X

Y

Z

0.02

0.02

0.02

0.02

mini

mini

0.02

0.02

0.02

0.02

0.5

0.5

0.5

0.5

mini

mini

0.5

0.5

0.5

0.5

12

14

3-22

tolrances sur brides

DsignationDescription

CotesDimensions Tolerances

pouces/inches mm

Diamtre nominalNominal pipe size

(NPS)

pouces/inches

Suivant ASME B 16.5 1996 / According to ASME B 16.5 1996

Outside diameter 0.06 in.(1,6 mm) raised face

Outside diameter 0.25 in.(6,4 mm) raised face

Outside diameter of flange

K

E

F

P

r

0.03

0.02

mini

+ 0.016

0

0.008

0.005

( 0.06) + 0.03 0

(> 0.06) 0.03

0.8

0.5

mini

+ 0,0400

0,20

0,13

( 1,6) + 0,8 0

(> 1,6) 0,8

C

+ 0.12

0

+ 0.19

0

+ 3,0

0

+ 4,8

0

All

NPS

Diameter of raised portion

Depth of groove

Width of groove

Pitch diameter of groove

Radius at bottom

Angle (23)

Ringjointflanges

18

20

Flange thickness (1)

(1) L'paisseur C et la hauteur Y ne comprennent la partie surle-ve de la face que dans le cas de la surlvation de 1,6 mm.

(2) La face arrire de la bride doit tre parallle la face du joint 1 prs. cet effet, la face arrire peut tre usine, dans lalimite de la tolrance concernant C, ou les portes d'crouslames.

(1) Only the 0.06 in. (1,6 mm) raised face is included in theflange thickness C and in the overall length of hub Y.

(2) Bearing surfaces for bolting of flanges shall be parallel to theflange face within 1 degree. To accomplish parallelism backfacing or spot facing may be required but shall not reduce theflange thickness C below the dimensions required.

1/2

R

Inside and outside diameter

of large and small tongue

and groove

and female

O

Welding

neck

flanges

B

Regardless of tolerances specified for dimensions A and B, thethickness of hub at the welding end shall never be less than 871/2 percent of the nominal thickness of the pipe to which theflange is to be attached

in accordance with MSS SP-9

CD ROM-chapitre 3-1 7/08/98 15:01 Page 12

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-25

class 150 flanges NPS 1/2 to 24 ASME B 16.5 1996

XB2

Y2 C

r

X

B

B3

R

YC

0.06 (1,6 mm)

0.06 (1,6 mm)

C

R

PLEINE / BLIND

SOCKET WELDINGTARAUDE / THREADED

TOURNANTE / LAPPED

X

R

Y TC

0.06 (1,6 mm)

DiamtreSize

DNNPS

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

Weldingneck Lapped Threaded Blind Socket welding

Y1

mm

485256576263707071768989

102102114127127140144152

MasseWeight

B2mini

kg

0,60,81,11,41,82,74,04,56,27,08,6

10,818,024,037,047,058,064,077,0

118,0

mm

22,928,235,043,750,062,575,491,4

104,1116,8144,5171,4222,2277,4328,2360,2411,2462,3514,4616,0

B3

mm

15,820,826,735,040,952,662,778,0

D

mm

1011131416171921

Y2

mm

161617212225293032333740444956798797

103111

r

mm

3335688

10111111131313131313131313

Tmini

mm

1616182122252930323337404449565764687383

MasseWeight

kg

0,80,91,01,31,52,33,74,25,35,97,08,5

13,519,529,039,047,054,070,095,0

MasseWeight

kg

1,21,31,41,82,22,84,75,56,88,09,0

12,020,032,040,059,077,095,0

123,0186,0

MasseWeight

kg

0,80,91,01,31,42,33,03,5

MasseWeight

kg

0,80,91,01,31,52,33,74,25,35,97,08,5

13,519,529,045,058,066,084,0

118,0Weights are approximate

B1 : to be specified by purchaser T : thread length B3 : inside diameter of pipe for STD wall pipe idem sch 40

3-24

brides PN 20 DN 15 600ASME B 16.5 1996

XB

RO

dC

0.06 (1,6 mm)G

A

Y1

R

X

C

K 0.06 (1,6 mm)0.25 (6,35 mm)

CC

R

0.06 0.03 (1,6 mm 0,8 mm)

37,5 2,5

Y

0.06 (1,6 mm)

rB1

SLIP ON

WELDING NECKRFRTJ

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

8999

108117127152178190216229254279343406483533597635698813

11,212,714,315,717,519,122,323,923,923,923,925,428,530,231,835,036,639,742,947,7

34,942,950,863,573,092,1

104,8127,0139,7157,2185,7215,9269,9323,8381,0412,8469,9533,4584,2692,2

K

mm

63,573,282,5

101,6120,7133,4154,0171,5193,5219,0273,0330,2406,4425,5482,6546,1596,9711,2

Perage / Drilling BminiNombreNumber

4444444488888

12121216162020

Gmm

60,369,879,488,998,4

120,6139,7152,4177,8190,5215,9241,3298,4362,0431,8476,2539,8577,8635,0749,3

dmm

15,815,815,815,815,819,019,019,019,019,022,222,222,225,425,428,528,531,831,835,0

mm

22,427,734,543,249,562,074,790,7

103,4116,1143,8170,7221,5276,4327,2359,2410,5461,8513,1616,0

X

mm

30384959657890

108122135164192246305365400457505559664

Y

mm

1616172122252930323337404449565763687383

MasseWeight

Slip on Weldingneck

kg

0,80,91,01,31,52,33,74,25,35,97,08,5

13,519,529,039,047,054,070,095,0

A

mm

21,326,733,442,248,360,373,088,9

101,6114,3141,3168,3219,1273,0323,9355,6406,4457,0508,0610,0

Les masses indiques sont approximatives

B1 : prciser par lacheteur T : longueur de la partie filete B3 : diamtre intrieur des tubes paisseurs STD idem sch 40

CD ROM-chapitre 3-1 7/08/98 15:01 Page 13

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

1,51,62,02,53,03,55,57,09,0

12,015,823,037,058,083,0

107,0139,0177,0223,0342,0

1,21,31,41,92,83,34,66,37,8

10,212,918,026,038,052,074,0

100,0127,0147,0213,0

3-27

class 300 flanges NPS 1/2 to 24 ASME B 16.5 1996

X

B2

Y2 C

r

X

B

B3

R

YC

0.06 (1,6 mm)

0.06 (1,6 mm)

C

R

PLEINE / BLIND

SOCKET WELDINGTARAUDE / THREADED

TOURNANTE / LAPPED

X

Q

R

Y T C

0.06 (1,6 mm)

Q : suralsageQ : counterboreT : longueur de la partie fileteT : thread length

DiamtreSize

DNNPS

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

Welding neck Lapped Threaded Blind Socket welding

A

mm

21,326,733,542,248,360,373,088,9

101,6114,3141,3168,3219,1273,0323,9355,6406,4457,0508,0610,0

Y1

mm

525762656870767981869898

111117130143146159162168

MasseWeight

B2mini

kg

1,51,82,02,53,54,05,07,09,2

11,014,019,030,041,062,084,0

111,0138,0171,0247,0

mm

22,928,235,043,750,062,575,491,4

104,1116,8144,5171,4222,2277,4328,2360,2411,2462,3514,4616,0

B3

mm

D

mm

15,820,826,735,040,952,662,778,0

1011131416171921

Y2

mm

2225272730333843444851526295

102111121130140152

r

mm

3335688

10101111131313131313131313

Tmini

mm

1616182122293232373743465156616468707383

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

1,21,31,41,82,53,04,56,0

MasseWeight

kg

1,21,31,41,82,53,04,56,07,5

10,112,517,526,041,063,086,0

109,0138,0170,0241,0

Weights are approximate

B1 : to be specified by purchaser T : thread length B3 : inside diameter of pipe for STD wall pipe idem sch 40

3-26

brides PN 50 DN 15 600ASME B 16.5 1996

XB

RO

dC

0.06 (1,6 mm)G

A

Y1

R

X

C

K 0.06 (1,6 mm)

CC

ER

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

Y

0.06 (1,6 mm)

rB1

SLIP ON

WELDING NECKRFRTJ

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

95117124133156165190210229254279318381444521584648711775914

14,215,717,519,020,622,425,428,430,231,835,036,641,147,850,853,857,260,563,569,9

34,942,950,863,573,092,1

104,8127,0139,7157,2185,7215,9269,9323,8381,0412,8469,9533,4584,2692,2

K

mm

50,863,569,979,290,4

108,0127,0146,1158,8174,8209,6241,3301,8355,6412,8457,2508,0574,5635,0749,3

E

mm

5,566,356,356,356,357,927,927,927,927,927,927,927,927,927,927,927,927,929,52

11,13

Perage / Drilling BminiNombreNumber

44444888888

121216162020242424

Gmm

66,782,688,998,4

114,3127,0149,2168,3184,1200,0235,0269,9330,2387,4450,8514,4571,5628,6685,8812,8

dmm

15,819,019,019,022,219,022,222,222,222,222,222,225,428,531,831,835,035,035,041,1

mm

22,427,734,543,249,562,074,790,7

103,4116,1143,8170,7221,5276,4327,2359,2410,5461,8513,1616,0

X

mm

384854637084

100117133146178206260320375425483533587701

Y

mm

22252727303338434448515262667376838995

106

MasseWeight

Slip on

kg

1,21,31,41,82,53,04,56,07,5

10,112,517,526,038,052,074,0

100,0127,0147,0208,0

Les masses indiques sont approximatives

B1 : prciser par lacheteur T : longueur de la partie filete B3 : diamtre intrieur des tubes paisseurs STD idem sch 40

CD ROM-chapitre 3-1 7/08/98 15:01 Page 14

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-29

X

B2

Y2 C

r0.25 (6,4 mm)

C

R

PLEINE / BLIND

TARAUDE / THREADED

TOURNANTE / LAPPED

X

Q

R

Y T C

0.25 (6,4 mm)

Q : suralsageQ : counterboreT : longueur de la partie fileteT : thread length

DiamtreSize

DNNPS

Welding neck Lapped Threaded Blind

A

mm

Y1

mm

MasseWeight

B2mini

kg mm

Y2

mm

r

mm

Tmini

mm

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

Weights are approximate

MasseWeight

Slip on

kg

152128436595

126163206256387

15202837607693

132165205285

class 400 flanges NPS 4 to 24ASME B 16.5 1996

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

114,3141,3168,3219,1273,0323,9355,6406,4457,0508,0610,0

89102103117124137149152165168175

161926405780

105131159190275

116,8144,5171,4222,2277,4328,2360,2411,2462,3514,4616,0

51545768

102108117127137146159

1111131313131313131313

3743465156606468707383

13,018,525,034,051,069,095,0

127,0157,0191,0279,0

13,018,525,034,054,070,085,0

120,0150,0185,0260,0

B1 : to be specified by purchaser T : thread length

Use class 600 dimensions in these sizes

3-28

XB

RO

dC

0.25 (6,4 mm)G

A

Y1

R

X

C

K 0.25 (6,4 mm)

CC

ER

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

Y

0.25 (6,4 mm)

rB1

SLIP ON

WELDING NECKRFRTJ

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

K

mm

E

mm

Perage / Drilling BminiNombreNumber

Gmm

dmm mm

X

mm

Y

mm

Les masses indiques sont approximatives

brides PN 68 DN 100 600ASME B 16.5 1996

254279318381444521584648711775914

35,038,141,147,853,857,260,563,566,569,976,2

157,2185,7215,9269,9323,8381,0412,8469,9533,4584,2692,2

174,8209,6241,3301,8355,6412,8457,2508,0574,5635,0749,3

7,927,927,927,927,927,927,927,927,929,52

11,13

88

121216162020242424

200,1235,0269,9330,2387,4450,8514,4571,5628,6685,8812,8

25,425,425,428,531,835,035,038,138,141,147,8

116,1143,8170,7221,5276,4327,2359,2410,5461,8513,1616,0

146178206260320375425483533587701

515457687379849498

102114

B1 : prciser par lacheteur T : longueur de la partie filete

Utiliser les dimensions de PN 100

CD ROM-chapitre 3-1 7/08/98 15:01 Page 15

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

1,41,62,12,63,34,46,07,49,5

17,027,032,046,074,090,0

108,0150,0188,0230,0325,0

525762677073798386

102114117133152156165178184190203

22252729323741464954606776

111117127140152165184

3335688

10101111131313131313131313

1616182122293235404148515765707378798292

1,31,41,82,13,14,05,47,08,9

16,025,030,043,089,0

109,0132,0182,0213,0274,0393,0

1,41,62,12,63,34,46,07,49,5

17,027,032,046,074,090,0

108,0150,0188,0230,0325,0

21,326,733,442,248,360,373,088,9

101,6114,3141,3168,3219,1273,0323,9355,6406,4457,0508,0610,0

1,52,02,53,24,55,58,0

10,515,619,031,037,053,086,0

102,0150,0190,0240,0295,0365,0

22,929,235,043,750,062,575,491,4

104,1116,8144,5171,4222,2277,4328,2360,2411,2462,3514,4616,0

1011131416171921

1,31,41,82,63,14,05,57,0

3-31

class 600 flanges NPS 1/2 to 24 ASME B 16.5 1996

X

B2

Y2 C

r

X

B

B1

R

YC

0.25 (6,4 mm)

0.25 (6,4 mm)

C

R

PLEINE / BLIND

SOCKET WELDINGTARAUDE / THREADED

TOURNANTE / LAPPED

X

Q

R

Y T C

0.25 (6,4 mm)

Q : suralsageQ : counterboreT : longueur de la partie fileteT : thread length

DiamtreSize

DNNPS

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

Welding neck Lapped Threaded Blind Socket welding

A

mm

Y1

mm

MasseWeight

B2mini

kg mm

D

mm

Y2

mm

r

mm

Tmini

mm

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

Weights are approximate

B1 : to be specified by purchaser T : thread length

3-30

brides PN 100 DN 15 600ASME B 16.5 1996

XB

RO

dC

0.25 (6,4 mm)G

A

Y1

R

X

C

K 0.25 (6,4 mm)

CC

ER

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

Y

0.25 (6,4 mm)

rB1

SLIP ON

WELDING NECKRFRTJ

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

33 1/2

456810121416182024

K

mm

E

mm

Perage / Drilling BminiNombreNumber

Gmm

dmm mm

X

mm

Y

mm

MasseWeight

Slip on

kg

95117124133156165190210229273330356419508559603686743813940

14,215,717,520,622,425,428,431,835,038,144,547,855,663,566,569,976,282,688,9

101,6

34,942,950,863,573,092,1

104,8127,0139,7157,2185,7215,9269,9323,8381,0412,8469,9533,4584,2692,2

50,863,569,979,290,4

108,0127,0146,1158,8174,8209,6241,3301,8355,6412,8457,2508,0574,5635,0749,3

5,566,356,356,356,357,927,927,927,927,927,927,927,927,927,927,927,927,929,52

11,13

44444888888

121216202020202424

66,782,688,998,4

114,3127,0149,2168,3184,1215,9266,7292,1349,2431,8489,0527,0603,2654,0723,9838,2

15,819,019,019,022,219,022,222,225,425,428,528,531,835,035,038,141,144,544,550,8

22,427,734,543,249,562,074,790,7

103,4116,1143,8170,7221,5276,4327,2359,2410,5461,8513,1616,0

384854647084

100118133152189222273343400432495546610718

22252729323741464954606776869294

106117127140

1,31,41,82,13,14,05,47,08,9

16,025,030,043,070,086,0

100,0142,0175,0221,0315,0

Les masses indiques sont approximatives

B1 : prciser par lacheteur T : longueur de la partie filete

CD ROM-chapitre 3-1 7/08/98 15:01 Page 16

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-33

class 900 flanges NPS 3 to 24 ASME B 16.5 1996

X

B2

Y2 C

r0.25 (6,4 mm)

C

R

PLEINE / BLIND

TARAUDE / THREADED

TOURNANTE / LAPPED

X

Q

R

Y T C

0.25 (6,4 mm)

Q : suralsageQ : counterboreT : longueur de la partie fileteT : thread length

DiamtreSize

DNNPS

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

3456810121416182024

Welding neck Lapped Threaded Blind

A

mm

Y1

mm

MasseWeight

B2mini

kg mm

Y2

mm

r

mm

Tmini

mm

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

Weights are approximate

MasseWeight

Slip on

kg

14,524,039,051,089,0

130,0175,0206,0259,0367,0463,0875,0

11,920,033,042,072,0

101,0134,0154,0186,0260,0320,0611,0

88,9114,3141,3168,3219,1273,0323,9355,6406,4457,0508,0610,0

102114127140162184200213216229248292

14,523,037,050,085,0

118,0163,0186,0224,0300,0373,0680,0

91,4116,8144,5171,4222,2277,4328,2360,2411,2462,3514,4616,0

54707986

114127143155165190210267

101111131313131313131313

4148545764717683868992

102

11,619,832,041,085,0

126,0168,0180,0222,0304,0394,0753,0

11,619,832,041,071,0

100,0133,0152,0184,0258,0317,0608,0

Use class 1500 dimensions in these sizes

B1 : to be specified by purchaser T : thread length

3-32

brides PN 150 DN 80 600ASME B 16.5 1996

XB

RO

dC

0.25 (6,4 mm)G

A

Y1

R

X

C

K 0.25 (6,4 mm)

CC

ER

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

Y

0.25 (6,4 mm)

rB1

SLIP ON

WELDING NECKRFRTJ

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

3456810121416182024

K

mm

E

mm

Perage / Drilling BminiNombreNumber

Gmm

dmm mm

X

mm

Y

mm

241292349381470546610641705787857

1041

38,144,550,855,663,569,979,285,988,9

101,6108,0139,7

127,0157,2185,7215,9269,9323,8381,0412,8469,9533,4584,2692,2

155,4180,8215,9241,3307,8362,0419,1466,9523,7593,9647,7771,7

7,927,927,927,927,927,927,92

11,1311,1312,7012,7015,88

888

121216202020202020

190,5235,0279,4317,5393,7469,9533,4558,8616,0685,8749,3901,7

25,431,835,031,838,138,138,141,144,550,853,866,5

90,7116,1143,8170,7221,5276,4327,2359,2410,5461,8513,1616,0

127159190235298368419451508565622749

54707986

102108117130133152159203

Les masses indiques sont approximatives

Utiliser les dimensions de PN 250

B1 : prciser par lacheteur T : longueur de la partie filete

CD ROM-chapitre 3-1 7/08/98 15:01 Page 17

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

1,82,74,05,86,5

11,515,522,033,060,072,0

122,0210,0315,0460,0610,0835,0

1062,01712,0

1,82,43,54,05,5

10,013,9

21,326,733,442,248,360,373,088,9

114,3141,3168,3219,1273,0323,9355,6406,4457,0508,0610,0

6070737383

102105118124155171213254283298311327356406

2,03,04,04,66,5

11,515,822,030,058,070,0

119,0204,0303,0426,0567,0737,0930,0

1510,0

22,929,235,043,750,062,575,491,4

116,8144,5171,4222,2277,4328,2360,2411,2462,3514,4616,0

10111314161719

323541414457637390

105119143178219241260276292330

3335688

101111131313131313131313

22252930323848

1,72,33,43,95,49,8

13,7

1,72,33,43,95,4

11,315,921,334,063,077,0

129,0219,0285,0360,0460,0621,0772,0

1236,0

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

3456810121416182024

3-353-34

brides PN 250 DN 15 600ASME B 16.5 1996

class 1500 flanges NPS 1/2 to 24 ASME B 16.5 1996

XB

RO

dC

0.25 (6,4 mm)G

A

Y1

R

X

C

K 0.25 (6,4 mm)

CC

ER

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

Y

0.25 (6,4 mm)

rB1

SLIP ON

WELDING NECKRFRTJ

X

B2

Y2 C

r

X

B

B1

R

YC

0.25 (6,4 mm)

0.25 (6,4 mm)

C

R

PLEINE / BLIND

SOCKET WELDINGTARAUDE / THREADED

TOURNANTE / LAPPED

X

Q

R

Y T C

0.25 (6,4 mm)

Q : suralsageQ : counterboreT : longueur de la partie fileteT : thread length

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1520253240506580

100125150200250300350400450500600

1/23/41

1 1/41 1/2

22 1/2

3456810121416182024

DiamtreSize

DNNPS

K

mm

E

mm

Perage / Drilling BminiNombreNumber

Gmm

dmm mm

X

mm

Y

mm

MasseWeight

Slip on Welding neck Lapped Threaded Blind Socket welding

kg

121130149159178216244267311375394483584673749826914984

1168

22,425,428,428,431,838,141,147,853,873,282,691,9

108,0124,0133,4146,0162,0177,8203,2

34,942,950,863,573,092,1

104,8127,0157,2185,7215,9269,7323,8381,0412,8469,9533,4584,2692,2

60,566,571,481,091,9

123,9136,7168,1193,5228,6248,0318,0371,0438,0489,0546,0613,0673,0794,0

6,356,356,356,356,357,927,927,927,927,929,52

11,1311,1314,2715,8817,4817,4817,4820,62

4444488888

121212161616161616

82,688,9

101,6111,1123,8165,1190,5203,2241,3292,1317,5393,7482,6571,5635,0704,8774,7831,8990,6

22,222,225,425,428,525,428,531,835,041,138,144,550,853,860,566,573,279,291,9

22,427,734,543,249,562,074,7

3844526370

105124133162197229292368451495552597641762

32354141445763

1,82,43,54,05,5

10,013,9

A

mm

Y1

mm

MasseWeight

B2mini

kg mm

D

mm

Y2

mm

r

mm

Tmini

mm

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

Les masses indiques sont approximatives Weights are approximate

B1 : to be specified by purchaser T : thread lengthB1 : prciser par lacheteur T : longueur de la partie filete

CD ROM-chapitre 3-1 7/08/98 15:01 Page 18

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

3-37

class 2500 flanges NPS 1/2 to 12 ASME B 16.5 1996

X

B2

Y2 C

r0.25 (6,4 mm)

C

R

PLEINE / BLIND

TARAUDE / THREADED

TOURNANTE / LAPPED

X

Q

R

Y2 T C

0.25 (6,4 mm)

Q : suralsage / counterboreT : longueur de la partie filete / thread length

DiamtreSize

DNNPS

15

20

25

32

40

50

65

80

100

125

150

200

250

300

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

3

4

5

6

8

10

12

Welding neck Lapped Threaded Blind

A

mm

Y1

mm

MasseWeight

B2mini

kg mm

Y2

mm

r

mm

Tmini

mm

MasseWeight

kg

MasseWeight

kg

MasseWeight

kg

Weights are approximate

3,3

3,9

5,0

8,1

11,5

17,6

26,0

39,0

60,0

100,0

140,0

236,0

450,0

650,0

73

79

89

95

111

127

143

168

190

229

273

317

419

464

3,6

4,0

6,0

9,0

13,0

19,0

24,0

43,0

66,0

111,0

172,0

261,0

485,0

730,0

22,9

28,2

35,0

43,7

50,0

62,5

75,4

91,4

116,8

144,5

171,4

222,2

277,4

328,2

40

43

48

52

60

70

79

92

108

130

152

178

229

254

3

3

3

5

6

8

8

10

11

11

13

13

13

13

3

4

5

8

11

17

24

36

55

93

142

214

407

573

3,0

4,0

5,0

8,0

11,0

17,0

25,0

29

32

35

38

44

51

57

21,3

26,7

33,4

42,2

48,3

60,3

73,0

88,9

114,3

141,3

168,3

219,1

273,0

323,9

15

20

25

32

40

50

65

80

100

125

150

200

250

300

3-36

brides PN 420 DN 15 300ASME B 16.5 1996

O

d

G

A

Y1

R

X

C

K 0.25 (6,4 mm)

CC

ER

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

0.25 (6,4 mm)

rB1

WELDING NECKRFRTJ

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

3

4

5

6

8

10

12

K

mm

E

mm

Perage / Drilling

NombreNumber

Gmm

dmm

X

mm

133

140

159

184

203

235

267

305

356

419

483

552

673

762

30,2

31,8

35,0

38,1

44,5

50,8

57,2

66,5

76,2

91,9

108,0

127,0

165,1

184,2

34,9

42,9

50,8

63,5

73,0

92,1

104,8

127,0

157,2

185,7

215,9

269,9

323,8

381,0

65,0

73,2

82,6

101,6

114,3

133,4

149,4

168,1

203,2

241,3

279,4

339,9

425,5

495,3

6,35

6,35

6,35

7,92

7,92

7,92

9,52

9,52

11,13

12,70

12,70

14,27

17,48

17,48

4

4

4

4

4

8

8

8

8

8

8

12

12

12

88,9

95,3

108,0

130,0

146,0

171,5

196,9

228,6

273,0

323,9

368,3

438,2

539,8

619,3

22,2

22,2

25,4

28,5

31,8

28,5

31,8

35,0

41,1

47,8

53,8

53,8

66,5

73,2

43

51

57

73

79

95

114

133

165

203

235

305

375

441

Les masses indiques sont approximatives

B1 : to be specified by purchaser T : thread lengthB1 : prciser par lacheteur T : longueur de la partie filete

CD ROM-chapitre 3-1 7/08/98 15:01 Page 19

Dear UserTypewritten TextNo.4 , First floor , Iran bok Build , Malek-Alshoara Bahar , Taleghani Ave , Tehran

-

869,9927,1984,2

1060,41111,21168,41238,21289,01346,21403,31454,11511,31568,51625,61682,81746,31803,41854,2

650700750800850900950

10001050110011501200125013001350140014501500

262830323436384042444648505254565860

class 150 flangesNPS 26 to 48 BS 3293 - 1960

class 150 flangesNPS 26 to 60

MSS-SP 44 1996ASME B 16.47 1996 Serie A

3-39

A

Y

R

X

C

0.06 0.03 (1,6mm 0,8 mm)

37,5 2,5

0.06 (1,6 mm)

rB(1)

WELDING NECK

0.06 (1,6 mm)

C

R

PLEINE / BLIND

DiamtreSize

DNNPS

650700750800850900950

10001050110011501200125013001350140014501500

262830323436384042444648505254565860

Welding neck Welding neck Blind

A

mm

Y

mm

MasseWeight C

kg mm

R

mm mm mm mm kg

MasseWeight

kg

Weights are approximate

3-38

brides PN 20DN 650 1200BS 3293 1960

brides PN 20DN 650 1500MSS-SP 44 1996ASME B 16.47 1996 Srie A

X

B

R

O

d

C

0.06 (1,6 mm)

GY

SLIP ON

DiamtreSize

DN NPS

O

mm

Cmini

mm

R

mm