Brewing Technology Protocol

-

Upload

ceci-cruz-palma -

Category

Documents

-

view

187 -

download

10

Transcript of Brewing Technology Protocol

Group no. 3d WiSe 2011/2012

CCP

Protocol for practical work in brewing technology

The influence of the mashing regime and hop additions during mashing on the

bitterness yield on the oxidative beer stability.

I

Table of contents

List of Abbreviations ...................................................................................................... II

List of tables and calculations ..................................................................................... III

1. Introduction ............................................................................................................. 1

2. Literature Survey .................................................................................................... 2

2.1 Beer aging ....................................................................................................................................... 2

2.1.1 Production of ROS ............................................................................................................. 3

2.2 Antioxidants ..................................................................................................................................... 5

2.2.1 Hop derived antioxidants ................................................................................................... 7

2.3 Hops and bitterness yield .............................................................................................................. 8

3. Materials and Methods ......................................................................................... 11

3.1 Wort production and fermentation ............................................................................................. 11

3.2 Laboratory analysis ...................................................................................................................... 14

4. Results ................................................................................................................... 16

4.1 Wort Analysis ................................................................................................................................ 16

4.2 Lautering control ........................................................................................................................... 28

4.3 Fermentation Control ................................................................................................................... 29

5. Discussion ............................................................................................................. 42

6. Bibliography .......................................................................................................... 47

7. Attachments .......................................................................................................... 50

II

List of Abbreviations

fig. figure

et al. et alii (= and others)

e. g. for example

SOD Superoxiddismutase

GOD Glucose oxidase

cf. related to, see

ROS Reactive oxygen species

FAN Free amino nitrogen

IBU International bitter units

EAP Endogenous antioxidant potential

III

List of tables and calculations

Table 1: Methods used for the wort and beer analysis………...………...…..….....……………..14

Calculation 1: Volume of the lauter and mashing tuns .............................................................12

Calculation 2: Calculation of hops addition during mashing .....................................................13

Calculation 3: Calculation of hops addition during boiling ........................................................13

IV

Table of Figures

Fig. 1: Effect of headspace air on the production ....................................................................... 3

Fig. 2: Effect of incubation temperatures on the ......................................................................... 3

Fig. 3: Pathway of ROS production [1] ....................................................................................... 4

Fig. 4: Oxidation schemata with possibilities of reduction [3] ..................................................... 5

Fig. 5: Reaction mechanism of sulphite oxidation [11] ............................................................... 5

Fig. 6: Ascorbic acid [13] ........................................................................................................... 6

Fig. 7: Dehydroascorbic acid [13] .............................................................................................. 6

Fig. 8: results of Wietstock et al. [5] ........................................................................................... 7

Fig. 9: Influence of wort boiling with different hop products on the antioxidative capacity .......... 7

Fig. 10: Influence of wort boiling with different amounts of α-acids on antioxidative the capacity 7

Fig. 11: Oxidative degradation influenced by different antioxidants ............................................ 8

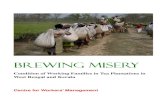

Fig. 12: Brewing equipment used for the wort production .........................................................12

Fig. 13: Sketch of the brewing equipment used to produce the wort .........................................12

Fig. 14: Original gravity of the wort at different process stages .................................................16

Fig. 15: pH of the wort at different process stages ....................................................................17

Fig. 16: Color of the wort at different process stages ................................................................18

Fig. 17: Turbidity H90 of the wort at different process stages ...................................................18

Fig. 18: Turbidity H25 of the wort at different process stages ...................................................19

Fig. 19: Viscosity of the wort at different process stages ..........................................................20

Fig. 20: FAN in the wort at different process stages .................................................................20

Fig. 21: Total Nitrogen in the wort at different process stages ..................................................21

Fig. 22: Content of polyphenols in the wort at different process stages ....................................22

Fig. 23: Anthocyanogens in the wort at different process stages ..............................................23

Fig. 24: IBU of the wort at different process stages ..................................................................24

Fig. 25: Iso-alpha-acids in each wort at different process stages ..............................................24

Fig. 26: Alpha acids of hops each wort at different process stages ...........................................25

Fig. 27: Beta acids content of each wort at different process stages .........................................26

Fig. 28: T600 value of the pitching wort ....................................................................................27

Fig. 29: ESR slopes of the worts...............................................................................................27

Fig. 30: Iron content in each wort at different process stages ...................................................28

Fig. 31: Extract course during lautering ....................................................................................29

Fig. 32: Extract content available for the yeast during fermentation ..........................................30

V

Fig. 33: pH course of the wort to young beer during fermentation .............................................30

Fig. 34: Original gravity, apparent and real extract of the different treated worts .......................31

Fig. 35: Alcohol content both in % w/w and % v/v of beers from the different treated worts ......32

Fig. 36: Final apparent attenuation degree in the different treated worts ..................................33

Fig. 37: pH values and color in EBC of the different beers ........................................................33

Fig. 38: Turbidity of the beers according to different measurement methods ............................34

Fig. 39: Carbon dioxide concentration in the different beers .....................................................35

Fig. 40: Viscosity of the beers according to different measurement methods ............................35

Fig. 41: Head foam retention of the beers according to different measurement methods ..........36

Fig. 42: FAN and total nitrogen content in the beers from different treated worts ......................37

Fig. 43: Total polyphenols concentration in the different beers .................................................38

Fig. 44: Anthocyanogens concentration in the different beers ...................................................38

Fig. 45: IBU values and iso-alpha-acids concentration in the different beers ............................39

Fig. 46: Final alpha-acids concentration in the different beers ..................................................40

Fig. 47: EAP, T600 values and SO2 concentration in the different beers ..................................40

Fig. 48: ESR slopes of the different beers ................................................................................41

Fig. 49: Final iron content in the different beers ........................................................................42

1

1. Introduction

Beer is one of the most popular beverages nowadays. Like every other beverage in the market

it is very important to produce a high quality product. One of the most important characteristics

of beer is its bitterness. This unique bitterness comes from the isomerised substances from

hops and hops products. Normally hop is added during the boiling step as the high

temperatures make the isomerisation possible, thus the yield of hops bitter substances is

influenced by boiling time, temperature, pH and others. Moreover during boiling other reactions

such as protein denaturation and flocculation take place. It is known that the bitterness yield is

greatly reduced by the loss of bitter substances bound to this protein trub. The hop bitterness

yield is an important factor influencing the final quality of the product.

But nowadays not only the production of a high quality product is demanded; it must also be

maintained after the filling and packaging. Beer is one of the most sensitive beverages when it

comes to oxidative damage and negative changes of it characteristics due to aging. This aging

process starts almost immediately after filling and packaging. Over time, one of the most

damaged characteristics by oxidation is the flavor. In the different aging stages new unwanted

flavors and aromas developed due to chemical reactions taking place in the beer. Some

examples are the dreaded cardboard flavor or other sweet, stale and sherry like aromas. The

flavor, the flavor stability and other characteristics are not only influenced by the different

production steps, but also by the raw materials used and the storage conditions once the beer is

filled and packed. Most important are the concentration of transition metals in beer and the

oxygen, light and temperature exposures. Because of the German purity law the addition of

antioxidants such as ascorbic acid is prohibited. But it has been proven that raw materials,

mostly hops, feature a high fraction of antioxidants. That is why there is the possibility to

increase the beer’s external antioxidant potential (EAP) and stability by increasing the yield of

hops substances in the final product.

The goals of this practical course were both to achieve a higher hop bitterness yield and higher

beer stability. In order to do so higher mashing off temperatures were used so that the protein

trub is already formed during mashing thus decreasing the loss of bitter substances during

boiling. Furthermore different hops products were also added during mashing not only to

increase the bitterness yield but the concentration of hops antioxidants leading to a higher beer

EAP and therefore stability.

2

2. Literature Survey

2.1 Beer aging

The length of shelf life for beer is determined by several factors. Most important among those

are the flavour stability and the visual appearance of the brew. The later includes haze

formation and alteration of the colour. Those in turn are influenced by the colloidal stability and

possible microbiological growth of beer spoilage organisms (which can also highly influence the

flavor by releasing metabolic byproducts) that cloud the beer.

With the advent of modern brewing technology and the subsequent improvement of biological

and colloidal stability the focus shifted to improving flavour stability of the beer during storage.

After the beer is bottled it immediately starts to age and with that to alter its flavour in several

ways. The concentration of certain flavor active compounds is increased and new ones are

being formed which can mask other important flavour molecules or lead to off flavors when a

flavor threshold is surpassed. [1] However, the oxidation of the beer has a lag time that

corresponds to the endogenous antioxidant capacity of the beer. This means that it is protected

by antioxidants present in the beverage (e.g. SO2) for a certain time until they are oxidized.

The reactions that lead to flavour deterioration are sped up by the dissolved oxygen content in

the beer and the storage temperatures. The approximate doubling of the reaction rate by an

increase of 10K in temperature as shown by the Van’t Hoff equation applies to the reactions

occurring in bottled beer as well (see Fig. 2). Therefore in order to minimize this effect beer is

stored at the lowest temperature that is economically viable.

Other detrimental influences on the finished beer flavour include the sunstruck aroma that stems

from 3-methyl-2-butene-1-thiol which is cleaved from isohumulon by UV-light, melanoidins that

are formed during wort boiling which can oxidize the alcohol in the beer into the respective

aldehydes as well as oxidized lipids from the barley that can form fatty aldehydes.[10]

Furthermore the type of beer influences the reactions of the flavour changes and the impact of

them on the stored product as the strong flavour of dark beers tends to mask other unwanted

aromas.

3

A very high influence on the reactions has the amount of oxygen that is present in the beverage.

An example for this is shown in the work of Kaneda et al. (see Fig. 1) who reports an tenfold

increase of free radicals when air was present in the headspace of bottled beer. [2]

Fig. 1: Effect of headspace air on the production

of free radicals in beer. Beer was incubated at

60°C, ●headspace in the vial contained air, ▲

headspace air was replaced with CO [2]

Fig. 2: Effect of incubation temperatures on the

production of free radicals in beer

○ 0°C, ■ 20°C, ▲ 40°C, ● 60°C [2]

These radicals influence the production of unwanted flavour active volatiles. This includes the

formation of carbonyls like trans-2-nonenal (the dreaded cardboard flavour) and strecker

aldehydes (e.g. 2-methylbutanal) as well as vicinal diketones (e.g. diacetyl).

Compounds that are degraded during storage include esters like isoamyl acetate (banana like

flavour) and α-acids (influencing the bitterness) leading to a diminished flavour sensation. [1]

2.1.1 Production of ROS

Molecular oxygen is rather stable and does not easily react with organic compounds. This

however is not valid for the activated forms, called reactive oxygen species or short ROS

(consisting of O2ˉ, HOO•, H2O2 and HO•). The hydroxyl and peroxyl radicals (HO•, HOO•),

products of the Haber-Weiss and Fenton reactions (see Fig. 4) are highly reactive. These

reactions are catalyzed by the presence of metal ions such as Fe2+ and Cu+.

4

Fig. 3: Pathway of ROS production [1]

Several methods of reducing the oxidation of beer have been proposed and implemented. An

overview of where they reduce the production of radicals can be seen in Fig. 3.

Intermediates of hydrogen peroxide can be scavenged (for example by SO2 or ascorbic acid)

thus reducing the ROS precursors. The metals aiding the Fenton and Haber-Weiss reactions

can be chelated leading to a reduction of the ROS production. Furthermore the ROS itself can

be quenched (see Fig. 4).

5

2.2 Antioxidants

Chemical antioxidants include sulphite which can bind molecular oxygen thus forming sulphate

as seen in equation I and effectively reducing the ROS precursors in the beer.

2 SO2-3 + O2 → 2 SO2-

4 I

Fig. 5: Reaction mechanism of sulphite oxidation [11]

The overall reaction mechanism can be seen in Fig. 5, although this is just a proposition from

Bäckström. [11]

Fig. 4: Oxidation schemata with possibilities of reduction [3]

6

SO2 is produced by the yeast during fermentation but is limited by its flavour threshold and the

fact that excessive amounts can lead to allergic reactions in humans [4]. Reductones as well as

melanoidins are products of the Maillard reactions and serve (under certain conditions, e.g. at

malting temperatures below 150°C [12]) as antioxidative agents as well. They scavenge

molecular oxygen by oxidizing an endiol group to a carbonyl (as seen in Fig. 6 and Fig. 7

below). Even though ascorbic acid is not a product of a Maillard reaction it is a reductone as

well and is used throughout the food and beverage industry as a strong antioxidant. It has to be

added to most of those products as it is seldom a byproduct of the respective production

process.

Fig. 6: Ascorbic acid [13] Fig. 7: Dehydroascorbic acid [13]

Scavenging the already formed ROS radicals can be done by introducing the enzyme

Superoxiddismutase (SOD) to the brewing process. SOD is present in yeast cells and can be

enriched by genetic overexpression of certain genes or aerobe living conditions. Cell lysis

releases the enzyme. SOD catalyses the formation of hydrogen peroxide and molecular oxygen

from two superoxide ions. Limiting the antioxidative power of SOD is the low pH of wort and

beer as well as the fact that the produced radical precursors are not bound by the enzyme. [15]

Glucose oxidase (GOD) catalyses the oxidation of glucose to gluconic acid. During this process

hydrogen peroxide is formed as well and needs to be dismantled to prevent the inhibition of the

GOD. This is done by catalase that has to be present. Its antioxidative power is also dependent

on a glucose substrate, ambient oxygen levels and temperature as well as the pH value (with an

optimum around 4,5-5,5 Attachment 1).[14]

7

2.2.1 Hop derived antioxidants

The German purity law prohibits the use of any

exogenous antioxidants (e.g. ascorbic acid and

enzymes like GOD and SOD). Recent studies

indicate that hops derived antioxidants may play a

vital role for flavour stability as well.

Originally hops was added to the wort to increase the

foam stability and antimicrobiological potency as well

as for the bitterness it adds to the beverage. [5]

Wietstock et al.. showed that worts that were boiled

without the addition of hops had a much higher

amount of free radicals and that the antioxidative

effect of hop originated polyphenols compared to the

effect of the hop α- and β-acids was negligible. Fig. 8 shows this as well as the fact that iso α-

acids seem to have pro oxidative properties, aiding in the formation of ROS during the Fenton

reaction by donating electrons. This was further investigated by Wietstock et al. and the results

Fig. 8: results of Wietstock et al. [5]

Fig. 9: Influence of wort boiling with different hop

products on the antioxidative capacity

Fig. 10: Influence of wort boiling with different amounts

of α-acids on antioxidative the capacity

8

showed that a higher degree of isomerisation reduced the antioxidative power of the compound.

Other trials showed that adding hop products during wort boiling resulted in an immediate drop

of ESR signal intensity and therefore a rise in the antioxidative capacity of the wort (see Fig. 9)

which is dependent on the amount of hops added (see Fig. 10). Further results of this study

were that hopped beers contained lower values of Strecker aldehydes, an index for aging

related off flavours, than the unhopped reference and that longer exposure to heat (e.g. lower

heating rates) lead to an increase of ROS formation.

Ting et al. [7] and Liu et al. [8] proposed that its antioxidative properties were linked to the ability

to chelate metals and the scavenging of hydroxyl radicals respectively.

Further studies done by Wietstock et al.

determined that α- and iso α-acids deriving

from hops are able to chelate transition metals

such as iron and copper rather than scavenge

hydroxyl radicals. This can be seen in Fig. 11

that shows the overall oxidative degradation of

a solution containing hydroxyl radicals that

were formed before the addition of the

antioxidants. α- and iso α-acids show no

scavenging activities. The chelating of iron

(Fe2+) was attributed to an increase of the

autoxidation rather than to the formation of iron

complexes, demonstrated by further trials. [9]

The role of polyphenols remains ambiguous.

While polyphenols such as flavan-3-ols have

the property to scavenge ROS and to chelate transition metals and therefore serve as

antioxidants there are also polyphenols that can reduce Fe3+ to Fe2+ and Cu2+ to Cu+ and thus

aiding the catalysis of the Fenton reaction. Aron et al. suggests that polyphenols deliver the

majority of the reducing potential to the final beer. [6]

2.3 Hops and bitterness yield

In the process of wort boiling the extraction and isomerisation of hops substances plays a major

role, since hops and hop products are one of the most expensive raw materials of the beer

Fig. 11: Oxidative degradation influenced by different

antioxidants

9

production. Though hops or rather bitter substances and α-acids are really high priced and the

yield of these products is rather low. Under normal conditions an average yield of bitter

substances is about 30% of the total bitter substance content of the hops or the hop product.

There are several possible causes for this fact. The bitter substances of the hops are defined as

the amount of α-acids, β-acids and the total of resins in the hops. While boiling these

substances dissolve in to the wort and the α-acids are isomerised. The β-acids play a minor role

since these substances have a bad solubility. That is why the amount of β-acids in the wort is

about 10% of the amount of alpha acids. [20]

To raise the yield of bitter substances in beer it is important to have an intensive extraction. To

improve the extraction it is possible to increase the boiling temperature and time. But this also

causes a loss of wort quality. Another way to improve the extraction is to reduce the hops or hop

products to small pieces in order to get an enlargement of the surface of these substances. So if

an extract is used it dissolves better if the drops are as small as possible. A possible way to

ensure this is to intensify the stirring during boiling. However this will cause more turbidity and

therefore trub which adsorbs the bitter substances and causes a decrease of the yield. [16]

Furthermore a high concentration gradient is needed. This gradient decreases when more bitter

substances are in solution until the equilibrium level is reached. That is why a complete

extraction of bitter substances cannot be reached with the normal addition of hop products to

the wort. Moreover the extraction decelerates with declining concentration gradient. That is why

it is also possible that the equilibrium level is not reached at the normal wort boiling process.

Also the use of improved hop products does not improve the yield of bitter substances. These

products just speed up the dissolution of bitter substances in the wort and so the reaching of the

equilibrium level, too. To lower the amount of dissolved α-acids a quick isomerisation of these

substances is needed.

Temperature is a factor of large importance at solution of (bitter) substances. For example is the

solubility of α-acids at 60°C 50% higher than at 25%. [17] This shows quite well that the

solubility limit depends on the temperature. That is why the α-acids which are dissolved while

boiling sediment while cooling down to pitching temperature down to the “new” solubility limit.

The solubility limit is reached sooner if the amount of hop products added to the wort is higher

and / or the pH of the wort is a bit higher. And since the solubility limit is a characteristic of every

mixture there is according to the German purity law no possibility to influence this factor.

10

Also the pH-value is important. That is why dissolved bitter substances sediment at the lowering

of the pH while fermentation. These α-acids are adsorbent bound to the turbidity molecules

such as proteins and are removed while filtration. A higher pH value does not only improve the

solubility of the bitter substances but does also increase the isomerisation of these substances.

Isomerised α-acids also remain in solution if the pH drops while fermentation.

A great source of loss of bitter substances is the adsorbent binding to turbidity molecules. The

more turbidity molecules are in the wort the more bitter substances are removed. And since a

higher original gravity level and / or malts which have a high amount of proteins cause more

turbidity these factors also cause a high loss of bitter substances. A possible method to

decrease the formation of turbidity is to lower the intensity of boiling and / or the boiling

temperature. But this also causes a decrease of the quality of the wort. For example an

enhancement of 4-5 ° Plato causes a decrease in the yield of bitter substances of 5%.[19] Since

α-acids are less polar these substances are more often bound to the turbidity molecules.

Another possible cause for loss of bitter substances is their evaporation as bitter substances are

detectable in the excess vapor. But these detectable amounts are only the 0.003 times of total

amount of bitter substances. In other words, if the total evaporation is about 15% it causes a

loss of bitter substances of about 0.5%. So this cause for the loss of bitter substances is

insignificant.

Since the measures of updating a sub process in order to decrease the loss of bitter substances

causes a decrease of efficiency of another sub process, other ideas are needed. For example

does the company Hertel GmbH produce a pre-isomeriser which promises a yield of bitter

substances up to 60%. [19, 21] Overall it can be said there are a lot factors that influence the

yield of bitter substances all with a varying degree of importance.

11

3. Materials and Methods

The students were divided in four groups. Each group did one brewing run which differs from

the other runs either in the time of hops addition or in the hop product which was added or in the

temperature at which the run was mashed off.

Following methods were tested:

1. Reference run

2. Mashing off at 95 °C

3. Mashing with addition of CO2extract

4. Mashing with addition of spent hops

3.1 Wort production and fermentation

Wort was produced in the pilot brewery of the TU Berlin (see Fig. 12). In each run 20 kg of malt

were been milled and mashed in with 60 L of water and 15 g of CaCl2. In one run also 420 g of

spent hops was added and in another run instead of spent hops 12 g of CO2 extract was added

(see equation 3). After mashing in the mash was heated to 66 °C and this temperature was kept

for 30 minutes. The next step was to heat the mash to 72 °C which was also kept for 20

minutes. After this the mash in three of the four runs was heated to 78 °C and pumped in the

lauter tun. One run was heated to 95 °C before it was pumped in to the lauter tun. After this the

mashing kettle was purged with 10 L water and the lautering break was held for 15 minutes.

Then the lautering took place with two additions of 40 L sparging water and one times 20 L.

After heating this liquor it was boiled for 60 minutes under addition of hops (see Calculation 3).

Then it was pumped to the whirlpool there separated from the trub and then cooled down for the

fermentation.

The fermentation lasts 7 days and samples were taken every day to measure the extract and

the pH. After maturation it the beer was filled into bottles and then analysed

12

Fig. 12: Brewing equipment used for the wort production

Fig. 13: Sketch of the brewing equipment used to produce the wort

Calculation 1: Volume of the lauter and mashing tuns

The sketch has been interpreted to that the volume under the false bottom and the volume of

the cone both comes to addition to the V1, so that the lauter tun has a larger volume than the

mash tun.

13

𝑉 =𝑑² × 𝜋

4× ℎ

𝑉1 = 5,45 𝑑𝑚 2 × 𝜋

4 × 7,05 𝑑𝑚

𝑉1 = 164,46 𝐿

Mash tun:

𝑉𝑀𝑎𝑠ℎ 𝑡𝑢𝑛 = 𝑉1 + 𝑉𝐶𝑜𝑛𝑒 = 164,46 𝐿 + 4,5 𝐿

𝑉𝑀𝑎𝑠ℎ 𝑡𝑢𝑛 = 168,96 𝐿

Lauter tun:

𝑉𝐿𝑎𝑢𝑡𝑒𝑟 𝑡𝑢𝑛 = 𝑉1 + 𝑉𝐶𝑜𝑛𝑒 + 𝑉𝐹𝑎𝑙𝑠𝑒 𝑏𝑜𝑡𝑡𝑜𝑚 = 164,46 𝐿 + 5 𝐿 + 8 𝐿

𝑉𝐿𝑎𝑢𝑡𝑒𝑟 𝑡𝑢𝑛 = 177, 46 𝐿

Calculation 2: Calculation of hops addition during mashing

Hops addition calculation on the example of group 3.

200 ppm of CO2extract was added to the mash which was produced with 60 L water.

200 𝑝𝑝𝑚 = 200 𝑚𝑔

𝐿 × 60 𝐿 = 12 𝑔

So 12 g of CO2extract were added to the mash

Calculation 3: Calculation of hops addition during boiling

Hops calculation on the example of group 3.

1𝐵𝐸 = 1 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑

𝐿

It was aimed to have 30 BE in the beer and the usual bitterness yield is 1/3.

30 𝐵𝐸 = 30 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑

𝐿 →1

3 𝑌𝑖𝑒𝑙𝑑

14

→ 30 𝐵𝐸 = 90 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑

𝐿

The extract which was used has an α-acid content of 44.3 %.

1 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡 = 0.443 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑

𝑥 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡 = 1 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑

𝑥 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡 = 1 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑 × 1 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡

0.443 𝑚𝑔 𝛼 − 𝑎𝑐𝑖𝑑= 2.257 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡

So 2.257 mg of the used extract have 1 mg α-acid in content and 90 mg of α-acid is needed in

1 L beer.

2.257 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡 × 90 𝑚𝑔 α − acid

𝐿 = 203.16 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡

𝐿

To get a bitterness value of 30 BE 203.16 mg extract per liter are needed. The calculated

volume of the cast wort was 119 L.

203.16 𝑚𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡

𝐿 × 119 𝐿 = 24.2 𝑔 𝑒𝑥𝑡𝑟𝑎𝑐𝑡

So 24.2 g extract had to been added to the wort to get a bitterness value of 30 BE.

3.2 Laboratory analysis

Analyses were done in the laboratories of the TU Berlin. The next table summarizes all

measurements conducted.

Table 1: Methods used for the wort and beer analysis

Parameter Method

Original gravity [%] cf. MEBAK 2.9.2.3

pH cf. MEBAK 2.13

Color [°EBC] cf. MEBAK 2.12.2

15

Turbidity H90 cf. MEBAK 2.14.1.2

Turbidity H25 cf. MEBAK 2.14.1.2

Viscosity [mm²/s] cf. MEBAK 2.25.3

Free Amino Nitrogen [ppm] cf. Skalar, Kat.-Nr.: 149-202

Total Nitrogen [ppm] cf. MEBAK 2.6.1

Total polyphenols [ppm] cf. Skalar, Kat.-Nr.: 521-004

Anthocyanogens [ppm] cf. Skalar, Kat.-Nr.: 176-003

IBU cf. Skalar, Kat.-Nr.: 191-001

c(iso-alpha-acids) [ppm]

c(beta-acids) [ppm]

c(alpha-acids) [ppm]

cf. American Society of Brewing

Chemists, Beer 23-C. Iso-alpha-

acids by solid phase extraction

and HPLC. In Methods of

Analysis, 9th ed.; American

Society of Brewing Chemists: St.

Paul, MN, 2004.

T600 value [ESR signal intensity *10^6] cf. MEBAK 2.15.3

Iron content [ppm] cf. MEBAK 2.24.6.1

Alcohol [% v/v]

Head foam

cf. MEBAK 2.9.6.3

cf. MEBAK 2.18.2

Carbon dioxide [g/l] cf. MEBAK 2.26.1.3

SO2 [g/l] cf. MEBAK 2.21.8.3

16

4. Results

4.1 Wort Analysis

All worts where analyzed in the laboratory according to the methods mentioned above. From all

four experiments (reference, mashing off at 95°C, mashing with CO2 extract and mashing with

spent hops) wort samples at three different stages of the process were taken and directly frozen

for later analysis. Analyzed were first of all the so called “full kettle wort” before boiling, then the

wort after boiling “end of boiling” and finally the wort before yeast was added “pitching wort”.

Original gravity of the wort

Fig. 14: Original gravity of the wort at different process stages

The original gravity of the wort gets higher as the boiling process advances. This pattern can be

observed in the diagram as the full kettle worts show the lowest gravity followed by worts at the

end of boiling and finishing with higher gravity of the pitching worts. This pattern is observed in

the majority of the worts, independent from the mashing conditions temperature and hops

addition as the only exception is the pitching wort when mashing was done with spent hops.

pH of the wort

9.5

10

10.5

11

11.5

12

Full kettle wort End of boiling Pitching wort

Ori

gin

al g

ravi

ti [

%]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

17

Fig. 15: pH of the wort at different process stages

The diagram shows that independent from the experiment the pH of the wort always drops after

boiling and then again shortly before pitching. The reference wort and the one mashed off at

95°C show an extremely similar pH tendency. On the other hand wort treated with CO2 hops

extract shows an unusual higher pH and contrary to this the one treated with spent hops shows

an unusual lower pH on all stages of the process.

Color of the wort

5.0

5.2

5.4

5.6

5.8

6.0

Full kettle wort End of boiling Pitching wort

pH

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

18

Fig. 16: Color of the wort at different process stages

As expected the color of the wort rises after boiling, the values also show that the pitching wort

had a color value increase from the freshly boiled wort. It can be distinguished that on average

wort mashed of at 95°C and mashed with spent hops addition show higher EBC values than the

others.

Turbidity H90 of the wort

Fig. 17: Turbidity H90 of the wort at different process stages

0

2

4

6

8

10

12

Full kettle wort End of boiling Pitching wort

Co

lor

[°EB

C]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

1

2

3

4

5

6

Full kettle wort End of boiling Pitching wort

Turb

idit

y H

90

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

19

Only the turbidity according to H90 of the pitching wort was measured. It can be observed that

when mashing at such a high temperature as 95°C the turbidity of the wort increases noticeably,

on the other hand the turbidity values decreases on worts to which hops extract and spent hops

were added. This decreasing trend can be observed as well when mashing with the addition of

spent hops.

Turbidity H25

Fig. 18: Turbidity H25 of the wort at different process stages

For the turbidity values according to H25 the same trends as the H90 turbidity can be observed.

Again only the values of the pitching wort were measured. The turbidity increment when

mashing at 95°C is not that extreme, as is the drop on worts to which hops extract and spent

hops were added.

Viscosity of the wort

0

1

2

3

4

5

6

7

Full kettle wort End of boiling Pitching wort

Turb

idit

y H

25

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

20

Fig. 19: Viscosity of the wort at different process stages

The pitching worts viscosity was measured and it can be concluded that when mashing off at a

higher temperature than usual the viscosity experiences a small increment. It can also be

observed that when mashing with the hops addition no noticeable change on the turbidity takes

place.

Free amino Nitrogen (FAN) in the wort

Fig. 20: FAN in the wort at different process stages

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

Full kettle wort End of boiling Pitching wort

Vis

cosi

ty [

mm

3/s

]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

20

40

60

80

100

120

140

160

180

200

Full kettle wort End of boiling Pitching wort

FAN

[p

pm

]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

21

In this diagram it is shown that the amount of FAN in the wort is affected by the mashing

conditions. The average FAN in all the reference worts is 176 ppm. On every process stage it is

observed that when mashing off at high temperatures or adding CO2 hops extract to the mash

the FAN content decreases. Overall it decreases to an average of 146 ppm. On the other hand

when adding spent hops to the mash there is a little increment of the FAN to an overall average

of 178 ppm. Moreover it can be recognized that the final pitching wort has a higher content of

FAN compared to the first wort of the process, the full kettle wort.

Total Nitrogen in the wort

Fig. 21: Total Nitrogen in the wort at different process stages

The total nitrogen reflects the same trend behavior as the FAN. The processes of mashing off at

a high temperature and adding CO2 extract the decrease nitrogen values to an average of 871

ppm. On the other hand when adding spent hops the values slightly increase to 1037 ppm.

These values are almost identical to the average nitrogen normal value in reference worts, 1035

ppm.

Total polyphenol content in the wort

0

200

400

600

800

1000

1200

Full kettle wort End of boiling Pitching wort

Tota

l Nit

roge

n [

pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

22

Fig. 22: Content of polyphenols in the wort at different process stages

As the process advances an increased polyphenol concentration can be measured. From the

diagram it can be read that there is a small significant difference in the polyphenol content

between the different treated worts. A slight increase is notices for when mashing off at high

temperature and when treating the mash with spent hops, values of the pitching wort increase

from the reference 204 ppm to a 236 and 228 ppm respectively. As for when adding CO2 extract

to the mash no significant difference is recorded compared to the reference.

Anthocyanogens in the wort

0

50

100

150

200

250

Full kettle wort End of boiling Pitching wort

Tota

l po

lyp

he

no

ls [

pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

23

Fig. 23: Anthocyanogens in the wort at different process stages

The anthocyanogene levels correspond to the total polyphenol levels. The content in the

reference wort and the wort treated with CO2 extract during mashing is almost identical and

changes only slightly during the boiling process. Compared to these the other worts show a

higher anthocyanogene content. All levels rise between 2 and 4 ppm.

International bitter units (IBU) of the wort

0

10

20

30

40

50

60

70

Full kettle wort End of boiling Pitching wort

An

tho

cyan

oge

ns

[pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

5

10

15

20

25

30

35

40

45

50

Full kettle wort End of boiling Pitching wort

IBU

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

24

Fig. 24: IBU of the wort at different process stages

The IBU values of all worts increase as the process advances. The major increase of the IBU

values occurs while boiling but there is also a small increase while cooling down to pitching

temperature. It is noticeable that the relationships between the worts remain constant excluding

the corelation between mashing off 95 °C and mashing w/ spent hops. While the mashing off 95

°C full kettle wort has a lower IBU value than the mashing w/ spent hops full kettle wort, it

increases more while boiling. So at the end of the boiling the mashing off 95 °C wort has a

higher IBU value. The diagram also shows that the wort mashing off 95 °C always has a higher

IBU value than the reference wort, which has the lowest value of all. The mashing w/ CO2-

extract has the highest IBU value.

Isomerized alpha acids of hops in the wort

Fig. 25: Iso-alpha-acids in each wort at different process stages

The Iso-alpha-acids-value also increases as the process advances. The diagram also shows

that in the full kettle worts mashing w/ spent hops and w/ CO2-extract already isomerised alpha-

acids exists. It is also noticeable that the mashing off 95 °C wort has a higher amount of iso-

alpha-acids than the reference wort.

Alpha acids of hops in the wort

0

5

10

15

20

25

30

35

40

45

Full kettle wort End of boiling Pitching wort

[iso

-alp

ha-

acid

s] [

pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

25

Fig. 26: Alpha acids of hops each wort at different process stages

The diagram shows that only in the mashing w/ CO2 extract- full kettle wort alpha acids are

already dissolved. At the end of the boiling process the amount of alpha-acids in all worts is

similar. Except for the mashing w/ spent hops run all other worts show an increase in the

amount of alpha acids in the wort after the end of the boiling process.

Beta acids content of the wort

0

5

10

15

20

25

30

35

Full kettle wort End of boiling Pitching wort

[alp

ha-

acid

s] [

pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

26

Fig. 27: Beta acids content of each wort at different process stages

The diagram shows that only when mashing w/ CO2 extract in the full kettle wort the alpha acids

are already dissolved. At the end of the boiling process the amount of alpha-acids in all worts is

similar. Except for the mashing w/ spent hops pitching wort, the amount of alpha acids in the

wort increases after the end of the boiling process.

T600 value of the pitching wort

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

Full kettle wort End of boiling Pitching wort

[be

ta-a

cid

s] [

pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

0.5

1

1.5

2

2.5

Full kettle wort End of boiling Pitching wort

T60

0 v

alu

e [

ESR

sig

nal

inte

nsi

ty *

10

^6]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

27

Fig. 28: T600 value of the pitching wort

The T600 value was only measured in the pitching wort. It is lowest with the CO2 extract wort

and highest with the reference wort. The wort with the spent hops treatment lies just below that

value and is slightly higher than the 95°C mashing off wort.

ESR slope of the worts

Fig. 29: ESR slopes of the worts

The diagram shows that the reference wort and nearly similar the wort which was produced with

addition of spent hops to the mash have the highest T600 value followed by the wort which was

mashed off at 95 °C. The lowest T600 value has the wort which was produced with addition of

CO2extract tot the mash.

Iron content in the wort

28

Fig. 30: Iron content in each wort at different process stages

Initial levels of iron in the different worts differ substantially in some cases. While the iron

content of the 95°C mashing off wort and the wort with the added spent hops is virtually identical

and the iron of the reference wort exceeding those two, the content of the wort treated with the

CO2 extract shows much lower levels at the beginning of the wort boiling step. The overall iron

content of all worts decreases notably during the boiling process but shows only minuscule

changes during the cooling down of the wort. This does not include the 95°C mashing off wort

as its iron content increases during this last step and exceeds all the other samples. The iron

levels of the reference wort and the wort treated with the spent hops are almost identical and

twice as high as the iron in the wort with the added CO2 extract.

4.2 Lautering control

Samples were taken after a definite volume of 12 liters and were analysed for extract. Extract content of the lautered wort

0.000

0.050

0.100

0.150

0.200

0.250

0.300

Full kettle wort End of boiling Pitching wort

[Iro

n]

[pp

m]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

29

Fig. 31: Extract course during lautering

As expected the first wort out contains a higher extract amount which then decreases as water

sparging is done. The more water is sparged in the less extract containing wort is lautered out.

This pattern can be observed on all samples and can be recognized on the diagram showing

the extract course during lautering performed by all groups.

4.3 Fermentation Control

Samples were taken each day and analyzed for extract and pH values.

Extract content during fermentation process

0

2

4

6

8

10

12

14

16

18

0 25 50 75 100 125

Extr

act

[%]

Filling quantity [l]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

30

Fig. 32: Extract content available for the yeast during fermentation

It can be recognized that the longer the fermentation goes on the less extract is found in the

beer. The extract content of all worts decreases similarly without major differences. All groups

started with an extract on the range of 11.6% and 11.8% and ended with an average of 3.5%.

pH value during the fermentation process

Fig. 33: pH course of the wort to young beer during fermentation

0

2

4

6

8

10

12

14

0 2 4 6 8 10

Extr

act

%

Fermentation days

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

3

3.5

4

4.5

5

5.5

6

0 2 4 6 8

pH

Fermentation days

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

31

A pH drop can be observed within the fermentation days. The slope of the drop of the reference

and the mashing off at 95° are really similar. Here the pH drop is observed mostly from

fermentation day 1 to day 3. When mashing with CO2 hops extract a milder pH slope drop can

be observed as the major drop occurs within 4 and not 3 days. When mashing with spent hops

the pH drop occurs rapidly from fermentation day 1 to day 2 and after that only drops mildly.

Overall the diagram describes the normal pH drop that wort shows when turning into beer. All

groups measured an average pH of 5.8 at the beginning and ended up with a drop to 4.4.

4.4 Beer analysis

The beer samples were analyzed according to the MEBAK methods listed above. This took

place in the laboratories of the TU Berlin and were conducted by the pratical training assistants.

Original gravity and extract content

Fig. 34: Original gravity, apparent and real extract of the different treated worts

The original gravity of the three different produced beers show no real significant difference

compared to the reference. Only a really small increase of gravity on CO2 hops extract treated

beer can be noticed. The real extract is higher than the apparent extract on all cases. Between

beers are both extract contents very similar and do not show any significant differences.

Average of real extract in all beers is 4.7% when of apparent extract only 3.1%.

0

2

4

6

8

10

12

14

Original gravity [%]

E (app.) [%] E (real) [%]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

32

Alcohol content

Fig. 35: Alcohol content both in % w/w and % v/v of beers from the different treated worts

In the reference beer there was a final alcohol content of 3.44% w/w or 4.4% v/v. The beers

from worts mashed off at 95°C and treated with spent hops show almost the exact results. Only

the beer whose wort was treated with CO2 hops extract shows a slight increase in alcohol

content to a final percentage of 3.71% w/w or 4.75% v/v.

Attenuation Degree

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

Alc. [% w/w] Alc. [% v/v]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

33

Fig. 36: Final apparent attenuation degree in the different treated worts

All beer’s attenuation degrees vary from the reference 74%. In case of the beer whose wort was

mashed off at 95°C the attenuation degree decreases significantly to nearly 70%. As for the

other two beers no significant difference is noticed in the attenuation degree.

pH and color of the beer

Fig. 37: pH values and color in EBC of the different beers

67

68

69

70

71

72

73

74

75

76A

tte

nu

atio

n D

egr

ee

(a

pp

.) [

%]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

1

2

3

4

5

6

7

8

9

pH Colour [°EBC]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

34

The pH measurements of the different beers show that there is absolutely no significant pH

value difference between them. As the diagram shows the pH values are almost identical for all

three beers against the reference beer. The color of the three different treated beers increases

slightly against the reference; still there is no significant change. The highest increase in color is

shown by the beer from spent hops treated wort which is 8.15 °EBC compared to the 7.4 °EBC

reference.

Turbidity

Fig. 38: Turbidity of the beers according to different measurement methods

The turbidity of the 95°C mashing of beer lies below the rest of the brews and all the values rise

slightly when measured at 0°C. This increase is more prominent in the experimental brews than

in the reference beer.

CO2 concentration

0

1

2

3

4

5

6

Turbidity 20°C Turbidity 0°C

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

35

Fig. 39: Carbon dioxide concentration in the different beers

The CO2 content of the beer lies between 4.74 and 4.54 g per liter. The beers produced with

wort mashed with hops show lower values than the reference beer, specifically wort treated with

CO2 extract shows the lowest value. On the other hand beer whose wort was mashed off at high

temperatures is the one with the highest values with 0.17 grams per liter more than the

reference beer.

Viscosity of the beers

Fig. 40: Viscosity of the beers according to different measurement methods

0

1

2

3

4

5

6C

O2

[g/

l]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

1.000

1.100

1.200

1.300

1.400

1.500

1.600

Vis

cosi

ty [

mm

2 /s]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

36

The diagram shows that there is no significant difference between the reference and the beers

treated with hops during the mash. All three find themselves in a range between 1.513 mm2/s

and 1.520 mm2/s. The only beer that stands out and shows a significant but still low viscosity

increase is the one mashed off at high temperatures. This beer shows a viscosity of 1.560

mm2/s

Head foam

Fig. 41: Head foam retention of the beers according to different measurement methods

All three different measurement points of the head foam show the same results trend for the

beers. The head of reference beer is the most stable when the head stability of the other beers

decreases minimally. When mashing with spent hops the decrease is the highest. For example

when comparing head foam at 30 s the reference value decreases from 226 to 211 when using

spent hops in the mash.

FAN and total nitrogen content

0

50

100

150

200

250

Head 10 s Head 20 s Head 30 s

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

37

Fig. 42: Free amino nitrogen and total nitrogen content in the beers from different treated worts

The FAN values in the beers vary from the lowest 96.7 ppm and 139.2 ppm. The lowest value is

read from the beer mashed off at high temperature. There is really no significant difference

between both beers whose worts were treated with hops addition during the mash. As for the

total nitrogen content there is no significant difference only between the reference and the beer

whose wort was mashed with spent hops. In the other two beers lower values in nitrogen

content were measured. The reference is 827 ppm as the other show a value around 710 ppm.

Total polyphenols

0

100

200

300

400

500

600

700

800

Free Amino Nitrogen [ppm]

Total Nitrogen [ppm]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

38

Fig. 43: Total polyphenols concentration in the different beers

The concentrations of total polyphenols in the final beer in all experimental runs are higher than

the one in the reference brew. During fermentation all concentrations dropped. The level of the

beer with the added CO2 extract during mashing is higher than the 95°C mashing off beer and

is exceeded by the spent hops treated beer.

Anthocyanogens

Fig. 44: Anthocyanogens concentration in the different beers

0

50

100

150

200

250To

tal p

oly

ph

en

os

[pp

m] Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

5

10

15

20

25

30

35

40

45

50

An

tho

cyan

oge

ns

[pp

m] Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

39

The anthocyanogene concentration, again, correspond to the total polyphenol level. The data

shows that all trial brews exceed the reference beers anthocyanogene concentration in the

same order the total polyphenol concentrations do. Also, the concentration dropped slightly

compared to the pitching wort.

IBU and iso-alpha acids concentration

Fig. 45: International bitter units values and iso-alpha-acids concentration in the different beers

The diagram shows that the IBU values of the beers from the experimental trials are similar and

higher than the value of the reference beer. This is also valid for the amounts of iso-alpha-acids

in those beers. It is noticeable that the amount of iso-alpha-acids in the beer is higher than IBU-

value of the beer.

Alpha-acids concentration

0

5

10

15

20

25

30

35

IBU [iso-alpha-acids] [ppm]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

40

Fig. 46: Final alpha-acids concentration in the different beers

It is shown that the highest amount alpha-acids is in the beer which was mashed off at 95 °C.

The amounts in the other beers are lower but approximately comparable to another.

EAP, T600 values and SO2 concentration

Fig. 47: Endogenous antioxidative potential, T600 values and SO2 concentration in the different beers

There was no detectable EAP value in any beer and only the brew that carried the added CO2

extract from the mashing process showed noticeable SO2 levels. The T400 value of the

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8[a

lph

a-ac

ids]

[p

pm

]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

0

0.1

0.2

0.3

0.4

0.5

0.6

EAP value [min] T400 value [ESR signal intensity

*10^6]

SO2 [ppm]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

41

reference beer was 20% higher than that of the beers of the 95°C mashing of run and the one

with the added CO2 extract. Furthermore it was 10% higher than the brew with the spent hops

treatment.

ESR slopes of the beers

Fig. 48: ESR slopes of the different beers

The diagram shows as the esr slope of the worts, too, that the reference beer has the highest

T400 value. It is followed by the beer which was produced with the addition of spent hops to the

mash. The beers which were produced with the addition of CO2 extract to the mash and a

mashing off temperature of 95 °C show a quite similar T400 value.

Iron content

42

Fig. 49: Final iron content in the different beers

The final iron levels of the 95°C mashing off beer and the CO2 extract treated beer are identical

to each other and half as high as the iron content of the reference beer. The beer from the spent

hops run shows an iron content between those two.

5. Discussion

As mentioned before the two goals of this practical course were to increase the hop bitterness

yield and also to improve the beer stability to extend the shelf life.

To increase the hops yield in the beer the first hops addition was already done during the

mashing process leading to an expected increase of the bitterness yield. Moreover a special

experiment was conducted in which a higher mashing off temperature was used so that proteins

precipitate already during mashing. It was expected that because the protein trub is removed

before boiling thus before adding hops the bitter acids would not have proteins to bind to and

therefore no way to precipitate leading to a decreased bitter substance loss during boiling.

Generally results show that the content of the bitter substances and other substances spent by

hops such as polyphenols are higher when altering the mashing process according to the

experiments conducted. As mentioned in the results the content of bitter substances such as

alpha-acids in the wort increases as the process advances. Meaning that the boiling process

and thus temperature plays a major role in the dissolution of these substances leading to higher

contents in the pitching worts. The bitter substances content drops during fermentation because

0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0.045

0.05[I

ron

] [p

pm

]

Reference beer

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ Spent Hops

43

of different factors such as the pH drop leading to a decreased dissolution and to the binding of

these substances to yeast and other turbidity molecules. Nevertheless the experimental runs

still show higher bitterness values in the finished beer compared to the reference beer. Even

though the values of the runs with the added hops during the mashing process increased it does

not mean that the yield is higher; because more hops was added in total the yield is not

comparable to the other experiment. This is also shown in the IBU values of the wort and the

beer. The experiments show that when treating the mash wit CO2 extract the IBU value is the

highest of them all (fig. ibu) because the extract contains the least amount of polyphenols which

are directly responsible for the trub formation during the wort boiling; this trub is then

responsible for the loss of bitter and isomerised bitter acids. In other words the less polyphenols

the less trub and therefore less bitter acids loss.

The initial goal of increasing bitterness yield was reached with the method of mashing off at

95°C. This is shown in the increased IBU compared to the reference and stunningly similar

values to the experiments with the extra added hops during mashing. In other words even

though no extra hops was added the bitterness values were increased to the levels of the other

methods.

Other quality aspects were also analyzed as they are more important than the bitterness yield to

guarantee a sellable product. Viscosity, turbidity, total nitrogen, CO2, head retention and color

show no significant difference to the reference and lie within or at least almost within normal

ranges from literature. The especially important parameter pH lies perfectly within the normal

range of 4.2 – 4.6. The average alcohol content of 4.8-5.1 could not be reached probably

because the FAN content in the pitching wort was below the needed amount of between 200-

250 ppm leading to a possible decrease in the yeast metabolism and therefore lowered alcohol

production. Another possibility is that because both the original gravity and the extract content of

the beers are within the literature ranges of 10.87 – 13.06 and 3.52-5.17 respectively and still no

normal alcohol values were reached that a microbiological contamination occurred. Generally

the parameters lie between normal ranges (Literature values Attachment 1) considering that

the methods and equipment to brew were not ideal. The wort was continuously in contact with

the ambient air and the brewers themselves increasing the risk of a microbiological infection.

Furthermore no microbiological analyses and above all no sensory analyses were conducted

proving otherwise.

44

Another goal of the course was to achieve a higher antioxidative capacity in the beer by adding

different hop products during mashing in order to decrease the iron content in the beer thus

decreasing the rate of Fenton reactions that lead to ROS which in turn oxidize beer components

and produce off flavours.

The metal chelating properties of hop products such as α- and iso α-acids were shown by

Wietstock et al. [9]. This can also be seen in our trials as the iron content in the beers are

generally lower in the runs that had elevated levels of α- and iso α-acids as well as IBU

compared to the reference beer. In that regard the addition of CO2 extract paradoxically seems

to be superior at reducing the iron content and lowering the T600 values compared to the spent

hops treatment even though the α- and iso α-acids concentration in the later are higher. This

contradicts the results of Wietstock et al. shown in Fig. 10. Furthermore the IBU of the CO2

extract trial are higher than those of the spent hops trial. This might be attributed to faulty

analytical data,differences in the production process or the influence of another compound on

the decrease of iron.

Fig. 50: Overall reduction of iron content in each wort during wort boiling

The reduction of the iron in the different worts in percent differs only slightly lingering around

68% except for the 95°C mashing off wort, which shows a bigger drop of 10% compared to the

worts that were treated with hops during mashing. This might be explained by the unrealistically

high iron content of the 95°C mashing-out run in the pitching wort seen in Fig. 21 which in turn

might be the result of a mistake that was made while collecting the sample as mentioned in the

brew protocol of that respective group.

0

10

20

30

40

50

60

70

80

90

100

Val

ue

s [%

]

Reference

Mashing off 95°C

Mashing w/ CO2 Extract

Mashing w/ spent Hops

45

Fig. 51: Iron content reduction during fermentation in percent

This error might also be responsible for the high reduction of iron in the 95°C mashing off run

during fermentation seen in Fig. 51. The beer with the added CO2 extract during mashing

showed no change in iron levels at all while the drop of the reference and the spent hops

treated beer varied between 23% and 33%.

The iron content in the beer correlates with the T600 values (see Fig. 47, Fig. 49), meaning a

lower level of iron results in lower final ESR values. The antioxidative capacity in all

experimental brews was improved with the 95°C mashing off regime and addition of CO2 being

the most efficient since they both share basically the same low T600 value. This leads to the

assumption that the increased yield of the 95°C mashing off trial is as effective at increasing the

antioxidative properties of the beer by 20% as the addition of the CO2 extract which has to be

verified in further trials since the addition of CO2 extract is also the only brew that yielded a

notable SO2 concentration in the beer that acts as an antioxidant as well. No EAP value was

recorded as the oxidation started almost immediately. Nevertheless a reduction of the T600

value means a slower and weaker oxidation process.

The two initial goals of this trial, increasing the yield of the hops by altering the mashing off

temperature and increasing the antioxidative capacity by reducing iron through hops addition,

were reached. The quality of the resulting beers stayed mostly within the standard range and

was similar to the reference beer. The increased yield of bitter substances of the 95°C mashing

off trial provided results similar to the trial with the added CO2 extract. Further trials with higher

volumes are needed to guarantee the possibility of scaling up the results. The addition of spent

0

10

20

30

40

50

60

70

Reference Mashing off 95°C Mashing w/ CO2 Extract

Mashing w/ spent Hops

Val

ue

s [

%]

46

hops during mashing with regard to increasing the antioxidative capacity was only half as

efficient as the addition of the CO2 extract. In the wort it had almost no effect on the ESR slope

whatsoever and the CO2 extract run proved to be superior by decreasing the T600 by 68% and

is to be preferred.

Because of the rather “robust” equipment used and the fact that the 4 trials were done by 4

different groups consisting of at least 9 people the results in general are up for debate. The low

tech approach to the trials and the plethora of ways to involuntarily slightly alter the process

undermine the comparability of the resulting data. Mistakes during bottling and sample taking

can lead to increased O2 intake that might alter the data relevant to this experiment. Moreover

since the brewing took place under atmospheric conditions oxygen was present throughout the

entire process. Insufficient documentation of the brewing process because of the many people

involved hinders tracing errors back to the experiment. The error made by group 2 during the

sample collecting of the pitching wort for example might have had a direct impact on the

analytical data. Furthermore false storage conditions or excessive handling of the samples

(shaking etc.) might influence the results as well. As hops and barley are natural products

fluctuations in the composition can occur that can alter the resulting beer quality and might

influence the overall process, especially in small scale trials like this one.

Possible errors made during the analysis of the samples itself might have had an additional

influence. Since no mistakes made during the analytical steps were reported the inaccuracies in

the data cannot be traced back to this but because samples were only analyzed just once for

each parameter finding possible faulty data is next to impossible.

47

6. Bibliography

1. Vanderhaegen, B., Neven, H., Verachtert, H., Derdelinckx, G.

“The chemistry of beer aging – a critical review”

Food Chemistry 95, 2006, 357-381

2. Kaneda, H., et al..

“The Role of Free Radicals in Beer Oxidation”

ASBC Journal, Vol. 47, Nr. 2, 1989, 29-53

3. Slide 3 of the file PR-Besprechung_WS2011.pdf, provided by Philip Wietstock

4. Martinez-Perinan, E., et al..

“Estimation of beer stability by sulphur dioxide and polyphenol determination”

Food Chemistry 127, 2011, 234-239

5. Wietstock, P., Kunz, T., Shellhammer, T., Schön, T., Methner, F.-J.,

“Behavior of Antioxidants Derived from Hops During Wort Boiling”

J. Inst. Brew. 116(2), 2010, 157-166

6. Aron, P.M., Shellhammer, T.

“A Disscussion of Polyphenols in Beer Physical and Flavour Stability”

J. Inst. Brew. 116(4), 2010, 369-380

7. Ting, P., Lusk, L., Refling, J., Ryder, D.

“Identification of antiradical hop compounds”

J. Am. Soc. Brew. 66, 2008, 116-126

8. Liu, Y., Gu, X., Tang, J., Liu, K.

“Antioxidant activities of hops (Humulus lupulus) and their products”

J. Am. Soc. Brew. 65, 2007, 116-121

9. Wietstock, P., Shellhammer, T.

“Chelating Properties and Hydroxyl-scavenging Activities of Hop α- and Iso α-acids”

ASBC Journal, Vol. 69, Nr. 3, 2011, 133-138

10. Hardwick, W.A.

48

“Beer Flavor Stability”

The Brewers Digest, October, 1978, 42-44

11. Ilett, D.R

“Aspects of the Analysis, Role, and fate of Sulphur Dioxide in Beer · A Review”

MBAA Technical Quaterly Vol.32 No.4, 1995, 213-221

12. Coghe, S., Gheeraert, B.,Michiels, A., Delvaux, F.R.

“Development of Maillard Reaction Related Characteristics During Malt Roasting”

J. Inst. Brew. 112(2), 2006, 148–156

13. Wikipedia Article “Vitamin C“

http://en.wikipedia.org/wiki/Vitamin_C

Accessed: March 21, 2012

14. Hartmeier, W., Willox, I.C.

“Immobilized glucose oxidase and its use for oxygen removal from beer “

MBAA Technical Quaterly Vol.18, 1981, 145-149

15. Prieels, J.P., Maschelein, C., Heilporn, M.

“Process for removing oxygen in foodstuffs and drinks”

United States Patent Nr. 4,957,749, 18.9.1990

16. Hertel, M.; Dillenburger, M.

“Measures for raising yield of bitter substances in beer brewing (Part 1)”

Brauwelt International, 2010/II; pp. 92 – 95

17. Hertel, M.; Dillenburger, M.

“Measures for raising yield of bitter substances in beer brewing (Part 2)”

Brauwelt International, 2010/III; pp. 148 – 152

18. Hertel, M.; Dillenburger, M.

“Measures for raising yield of bitter substances in beer brewing (Part 3)”

49

Brauwelt International, 2010/IV; pp. 190 – 192

19. Hertel, M.; Dillenburger, M.

“Measures for raising yield of bitter substances in beer brewing (Part 4)”

Brauwelt International, 2010/V; pp. 278 – 282

20. Hanke, S.; Back, W.; Tauscher, F.

“Die Bittere ist entscheidend – Einflüsse auf die Hopfenausbeute und Trubbildung bei der Würzekochung.”

Brauindustrie 2 / 2008, pp. 34 – 37

21. Hertel, M.; Dillenburger, M.

“Controlled isomerisation – commercial brews using the hop yield enhancer”

Brauwelt International, 2012/I; pp. 47 – 49

50

7. Attachments

Attachment 1: Literature values of beer

Parameter Normal Values Reference

Original gravity [°Plato] 10.87 – 13.06 Jurado 2002a

pH 4,2 - 4,6 Jurado 2002a

Color [°EBC] 2.9 - 8.8 Jurado 2002a

Free Amino Nitrogen [ppm] 80 - 120 MEBAK

Total Nitrogen [ppm] 600-1100 MEBAK

Attenuation degree 56 – 70.2 Jurado 2002a

Anthocyanogens [ppm] 5 – 50 Jurado 2002a

IBU 3.1 – 51.2 Jurado 2002a

Alcohol [% v/v] 4.8–5.1 MEBAK

SO2 [mg/l] 3 - 5 MEBAK