Brazing technique

description

Transcript of Brazing technique

Brazing techniqueEric Vigeolas, Didier Ferrere, Serge Mathot,

Theodore Todorov, Pierre Delebecque LSWG Cooling meeting May the 31th 2012

ForewordHere is an interesting

summary made by Parker company concerning the joining techniques

Most of these studies are under study in our community

Swaging have never been investigated and could be developed for on site low cost fittings assembly

Fitting proposed few years ago by LBNLwww.wicksaircraft.com

IBL Brazing activityOne of the major problem we had on IBL was to produce small

local supports (1.5 m long instead of 7 m long after welding) for handling, metrology, storage and module loading activities

A welding joint in any case is necessary to permit reasonable pipe length production (this is especially for Ti a vendors limitation)

One and half year ago both Orbital welding and brazing have been investigated:Concerning orbital welding tooling is available with reasonable

envelop to permit on site welding the first test made shows current peak during the weld ignition which made us though that qualification will be tricky especially while Electronic chips was missing at this date

Concerning Titanium brazing the technique exist in industry with good results but tool had to be designed preliminary tests shows low current level during the heating phase

Orbital welding test made by Didier Ferrere and Nickhef team

The scope of the preliminary test was to investigate if Orbital welding would present a risk for a loaded stave At this period need to take a decision for the tool and technique qualification

What have we learnt?• When something is measured the current pulse and undershoot can be as high as

25A and is happening inside 10ns during a power glitch.• Otherwise during the welding revolution and for ~20s there is a periodic current

measure with up to 150mA peak and at a period of 150 µs.• When measuring the voltage across the pipe one measured a high induced voltage

in the scope probe and as high as 320V peak to peak!• The 3rd series of tests were supposed to learn us more but were confusing• Unfortunately /fortunately all the measurements made with both fixtures did not

show high current as the 1st times After more investigation we learnt that one “touch and go” technique did exist in

the industry which permit to avoid the peak ignition current but no tool available for small pipes welding

Due to available time scale we decided to investigate alternative solutions Brazing

Detail report made by Didier @ http://dpnc.unige.ch/atlas/upgrade/IBL/StaveLoading/Talk/StaveWG_2408_OrbitalWelding.pptx

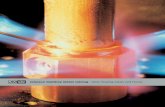

Brazing development @ CERN Development made with MME/AF

division support Specialized in Welding and brazing activities

Brazing Titanium is well known @ CERN even in industry the main difficulty of our development consists to design and tool to heat up the pipe to 800°C in a small vacuum volume

With Serge Mathot advice and Celes company help we found a way to heat the pipe using induction in a very small volume

Compount under testing: Ag 68.4%, Cu 26.6%, Pd 5% ; B-Ag68CuPd-807/810 (cf. ISO 3677)

2mm

50 mm

Existing vacuum chamber used for IBLCan be easily reduced and optimized

Tool designThe pipe brazing will be done in SR1 building prior to the stave

integration inside the detectorSequential operation to avoid long object storage and handling

Tool designLoaded stave on its holding jig

Vacuum Chamber

High frequency Power supply and cooling syst.

Pipe extension holding frame

Test and Qualification Tests are actually ongoing to qualify

and adjust the process: Induction loop optimization for

efficient heating Sleeve/pipe geometrical

adjustments for efficient capillarity Metallurgical investigations to

check the brazing compound filling efficiency

Several qualification steps are actually done (final results this summer):

Pressures tests up to 150 bars followed by He leak tests and metallographic analysis

Thermal cycles +40°C/-40°C 100 times followed by He leak tests and metallographic analysis

Thermal shocks in liquid Nitrogen followed by He leak tests and metallographic analysis

Traction tests on sample

3 s800°

C

Firsts observations and improvements A slight fusion of the Ti pipe has been observed on first sample

a new inductor is under study to reduce the heating speed (the actual inductor use on 3% of the Power supply to reach 800°C in few seconds, the new design is made to reduce it)

Many tests have been done to facilitate the brazing penetration A repeatable process has been found by applying vacuum inside the pipe and cleaning it several times with argon to prevent Oxygen presence This prevent also from brittle phase formations

Brazing impact on electronic

Final qualification is foreseen on Stave 0 program on which induction will be done to check modules behavior Jully 2012

ConclusionNot at the end of the story but very closeBrazing work fine on a lot of material (Stainless steel,

Ceramics, Titanium …)For instance this technique is compatible with modules

on local supports during operationOne of the advantage is that this permit mixture of

materials (helpful for electrical breaks for example)Parallel to all the joining techniques under

investigation and qualification we should not forget:Gluing why not safe? Good to repair thingsSwaging long qualification but interesting …