Brant Peppley Director Queen’s-RMC Fuel Cell Research Centre

description

Transcript of Brant Peppley Director Queen’s-RMC Fuel Cell Research Centre

Electrons, ions, heat, and fluids: The complex interplay of properties in porous electrodes and the porous transport layer

Brant PeppleyDirector Queen’s-RMC Fuel Cell Research Centre

CANADIAN TEAM

Queen’s-RMC Fuel Cell Research Centre NRC-IFCI, Vancouver Group University of VictoriaKunal Karan Michael Eikerling Ned Djilali Jon Pharoah John Stockie Marc Secanell Brant Peppley

Univ of Waterloo Univ British Columbia NRC-ICPET, Ottawa Group Michael Fowler Fariborz Taghipour Steven Beale Sumit Kundu

Electrons, ions, heat, and fluids: The complex interplay of properties in porous electrodes and the porous transport layer

Brant PeppleyDirector Queen’s-RMC Fuel Cell Research Centre

Macro-water management in PEM fuel cell

Hydrogen

Oxygen

WaterHydrogen

+

+

+

+Oxygen

Water

membrane

catalystporous transport layer

e e

+

+

+

+

e e

+

+

+

+

e e

wate

r co

nte

nt

Dry

Flooded

OverallPerformance

• V-I Curves• Water Transport

BulkProperties

PEFC Key Sub-Components

SpeciesTransport

&

ElectrochemicalKineticsMicrostructure

Composition

InterfaceProperties

Configuration

Ca

taly

st

La

ye

rG

as

Dif

fus

ion

M

ed

iaF

low

-Fie

ld Operating Conditions

P, T, PO2, PH2, RH, Stoich Ratio

Processes, Operating Parameters and Effects

Need for Gas Diffusion Media Optimisation+

Considerations of 2-D and 3-D Effects

2-D Effects: Current Density Distributions

0.0 0.2 0.4 0.6 0.8 1.06000

6200

6400

6600

6800

7000

0.0 0.2 0.4 0.6 0.8 1.0

7500

8500

9500

10500

11500

0.0 0.2 0.4 0.6 0.8 1.0

Cu

rre

nt

De

ns

ity (

A/m

2 )

1150

1200

1250

1300

1350

1400

GDL

Catalyst Layer

Channel Land

S. A. Freunberger et al. Electrochem. Comm. 8, (9), 2006, 1435-1438

Sun, W., Peppley, B.A.P. and Karan, K. (2005) Electrochimica Acta, 50 (16-17), 3359-3374.

Carbon Paper is Inherently Anisotropic !!

IsotropicIn-plane conductivity = Through-plane conductivity

OrthotropicIn-plane conductivity = 10 (Through-plane conductivity)isotropic

0.0 0.2 0.4 0.6 0.8 1.0

Cu

rre

nt

De

ns

ity (

A/c

m2)

3300

3400

3500

3600

3700

3800

3900

4000

=0.4V

isotro

picorthotropic

0.0 0.2 0.4 0.6 0.8 1.0

Cu

rre

nt

De

ns

ity (

A/c

m2 )

5800

6000

6200

6400

6600

6800

7000

7200

7400

=0.5V

orthotropic

isotropic

GDL

Catalyst Layer

Channel Land

Influence of GDL Conductivity

A

B

A

B

J.G. Pharoah, K. Karan, and W. Sun. (2006) J. Power Sources 161 (1), 214-224, 2006.

3D Effects: Straight Versus Serpentine Flow Fields

Maximum current under the channel

Location of maximum

current varies with

PTL permeability

3D Effects – Influence of GDM Permeability

3D Effects: Mass Transport/Convection in Channel and GDM

•The flow in the channel is greatly reduced due to convection in the PTL

•The secondary flow structures are greatly altered due to this mechanism

•Very significant for

•Transition to unsteady flow

• Liquid transport

Neutron Imaging Data Courtesy of David Jacobsen, NIST

Water is most often found in the bends!

3D Effects: Water Accumulation in Serpentine Flow Channels

• 2D and 3D Computational Fluid Dynamics (CFD) Calculations

• Numerical Effective Transport Property Estimation

Permeability Estimation Effective Conductivity Estimation

(Lattice Boltzmann Method)

FCRC Expertise/Capabilities

T

1

T

2

q”

Mark Vandoormal, MSc Thesis, Queen’s University Dan Hamilton, MSc Thesis, Queen’s University

• Experimental Characterisation of GDM– Permeameter (Gas and Liquid Permeability)– Porometer (Hydrophobic and Hydrophilic Pores)

– In-Situ Effective Permeability Measurement

GDM Characterisation - FCRC Expertise/Capabilities (cont.)

Brian Tysoe, MSc Thesis, Queen’s University

CONCLUSION-1: GDM Can Strongly Affect FC Performance !!

RECOMMENDATION-1: Proper Characterisation of GDM Transport and Physical Properties is Essential

OverallPerformance

• V-I Curves• Water Transport

BulkProperties

FC Sub-Components(geometry/material)

SpeciesTransport

&

ElectrochemicalKineticsMicrostructure

Composition

InterfaceProperties

Configuration

Ca

taly

st

La

ye

rG

as

Dif

fus

ion

M

ed

iaF

low

-Fie

ld Operating Conditions

P, T, PO2, PH2, RH, Stoich Ratio

Need for Catalyst Layer Optimisation

Cathode Agglomerate Model: Effectiveness Factor

xz

GDL

Catalyst Layer

Channel Land

z

x

Underutilized core of catalyst agglomerate

O2 diffusion path

Sun, W., Peppley, B.A.P. and Karan, K. (2005) Electrochimica Acta, 50 (16-17), 3359-3374.

Anode Agglomerate Model: Transport Limitations at Two-Scales

0.0

0.2

0.4

0.6

0.8

1.0

0 0.2 0.4 0.6 0.8 1

r/ragg

CH

2/C

H2,

s

0.01 mV

0.1 mV

0.5 mV

1 mV

5 mV

10 mV

0

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

0 2 4 6 8 10

Distance along catalyst layer (mm)

Ra

te o

f H

2 C

on

su

mp

tio

n (

mo

l/cm

2 -s)

0.1 mV

0.5 mV

1.0 mV

5.0 mV

10 mV

Underutilized core of catalyst

agglomerate

ragg

K. Karan (2007) Electrochem Comm. 9, 747-753; K. Karan Structural Modeling of PEMFC Anodes. 211th ECS Meeting - Chicago, Illinois, May 6-11, 2007

Only 40% of the outer core of the agglomerate is active Only 30% of the catalyst layer is utilized

Catalyst Layer Optimisation

M. Secanell, K. Karan, A. Suleman and N. Djilali (2007) Electrochimica Acta, 52, 22, 6318-6337.

3D Catalyst Layer Modeling

Slide titleOther Effects of Liquid Water in Catalyst Layer

Porous Transport Layer Catalyst Layer Membrane

platinum particle (2-3 nm)

carbon particle (~40 nm)

secondary pore

agglomerate (~ ?? nm, ~ particles)

primary pore

ionomer

Electronically insulated agglomerate due to ionomer expansion (water intake)

Detection: decrease in ESA* decrease in electronic conductivity

Ionically insulated agglomerate due to ionomer contraction (drying)

Detection: decrease in ESA* decrease in ionic conductivity

Poor ionic conductivity due to imbalanced water drag and water back diffusion (anode)

wat

er d

rag

wat

er b

ack

dif

fusi

on

Detection: little to none decrease in ESA* decrease in ionic conductivity

*ESA – electrochemically active surface area

• Microstructural Modeling– NRC-IFC– FCRC

• CCL Optimisation– U. Victoria

• Catalyst Layer Properties– FCRC

• Catalyst Preparation– FCRC– NRC-IFCI

FCRC-NRC Capabilities

Catalyst Layer Preparation

Dimatix DMP2800 material printer

printed catalyst layer

Nafion-112 membrane

Carbon paper with microporous layer

1 mm

1 mm

Fabrication of Catalyst Layer of Controlled Compositionand Microstructure (?)

Slide titleElectrochemically active surface area (ESA) measurement: cyclic voltammetry

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9-2.0

-1.5

-1.0

-0.5

0.0

0.5

1.0

1.5

I / A

E / V

-SO3H + Pt -SO3- + PtH

-SO3- + PtH -SO3H + Pt

+1e-

-1e-

2(-SO3H) 2(-SO3-) + H2

+2e-

Pt + H2O PtO + 2H+-2e-

Hydro

gen

Hydro

gen

Nit

rogen

Nit

rogen

Potentiostat

working electrodecounter&reference electrode

Slide titleElectronic conductivity of catalyst layer in PEM fuel cell

platinum wires

catalyst layer

membrane

Teflon mesh

porous transport layer

platinum wire

DABC

CDABDABCCDAB

R

Rf

RRd

,

,,,

2*

2ln

*

Slide titleIonic conductivity of catalyst layer in PEM fuel cell

Z 'Z'

'

anode cathode charge transferoxygen gas phase diffusion

0

ohmic resistance

RpA RpC

CPEACPEC

WCRohm

Catalyst layers

membranes

- =

Electrochemical Impedance Spectroscopy of PEM fuel cell

porous transport layers

CONCLUSION-2 Transport and kinetics in catalyst layer strongly influence FC performance and water transport

RECOMMENDATION-2 Proper characterisation (microstructural and transport properties) and modeling of catalyst layer is key to optimising FC performance and water transport

Micro-Porous Layer (MPL) as a Catalyst Layer-Gas Diffusion Media Interface:

Need for MPL Optimisation

porous carbon backing

microporous layer catalyst layer

200mm200mm 1mm

Proton Exchange Membrane (PEM)

Porous Transport Layer (PTL) (gas diffusion layer)

Catalyst Coated Membrane (CCM)

PEMFC with Microporous Layers (MPLs)

Not to scale

Role of MPL on Water Transport: Two Schools of Thoughts

CathodeCL

+

+

+ +

+

+ Water

MembraneAnodeCL

water drag with proton

water back diffusion

MPL PorousCarbonBacking

MPL retains liquid water in Cathode CL and aids back diffusion MPL helps remove water from Cathode CL to Cathode GDM

• J.H. Nam, M. Kaviany, Int. J. Heat Mass Transfer, 46 (2003) 4595-4611.

• U. Pasaogullari, C.-Y. Wang, Electrochim. Acta, 49 (2004) 4359-4369.

• A.Z. Weber, J. Newman, J. Electrochem. Soc., 152 (2005) A677-A688.

• G. Lin, T.V. Nguyen, J. Electrochem. Soc., 153 (2006) A372-A382.

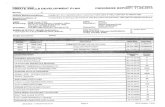

Effect of MPL on Water Drag

H. K. Atiyeh, K. Karan, B. Peppley, A. Phoenix, E. Halliop and J. Pharoah (2007) J. of Power Sources, 170, 1, 111-K. Karan, H. Atiyeh, E. Halliop, A. Phoenix, B. Peppley, J. Pharoah, (2007) Electrochem Solid State Lett. 10, 2, B34-B38.

Effect of MPL on Electrochemical Perfomance & Durability

H. K. Atiyeh, K. Karan, B. Peppley, A. Phoenix, E. Halliop and J. Pharoah (2007) J. of Power Sources, 170, 1, 111K. Karan, H. Atiyeh, E. Halliop, A. Phoenix, B. Peppley, J. Pharoah, (2007) Electrochem Solid State Lett. 10, 2, B34

Cells with no MPLs Cells with MPL on at least one side

0.0

1.0

2.0

3.0

4.0

5.0

250 350 450 550 650 750Current Density (mA cm-2)

Flu

orid

e R

elea

se R

ate

(um

ol h

-1)

Anode

Cathode

Total

0.00

0.05

0.10

250 350 450 550 650 750Current Density (mA cm-2)

Tot

al F

luor

ide

Rel

ease

Rat

e (u

mol

h-1

) Anode

Cathdoe

Total

MPL Reduces Fluoride Release Rate !!

S. Kundu, K. Karan, M. Fowler, L C Simon, B A Peppley, and E. Halliop, (Accepted Nov 2007). Influence of Micro-porous Layer and Operating Conditions on the Fluoride Release Rate and Degradation of PEMFC Membrane Electrode Assemblies, Journal of Power Sources.

MPL on anode only

MPL on cathode and anode

ThinnedMembrane

!!

Z' ( cm2)0.0 0.1 0.2 0.3 0.4 0.5 0.6

Z''

( c

m2)

-0.2

-0.1

0.0123

0.1 Hz

1 Hz

3 Hz12 Hz

600 Hz

60000 Hz

Impedance diagrams for PEMFC with (2,3) and without (1) MPL fed with H2/Air (1,2) and H2/(20%O2 in He) (3). Current density – 0.21 A cm-2.

Single Cell Impedance Response – With and Without MPL

Step 2.

Step 3.

Step 4.

Step 1. adsOeffO R

dx

CdD

dt

dC

2

2

22

22

2 adsOdessOadsads CkCPkR

Rdx

CdD

dt

dCads

ads

OeffO

Oads 2

2

sObVOfOads CCkCCkdt

dCoOads

Impedance Modeling Example: Porous SOFC Cathode (LSM/YSZ)

-0.50

-0.40

-0.30

-0.20

-0.10

0.000.80 0.90 1.00 1.10 1.20 1.30

Z' (ohm cm2)

Z" (

oh

m c

m2

)

Experimental

Faradaic impedance

Model

-9-8-7-6-5-4-3-2-101

0.1 10 1000 100000

Freq (Hz)P

hase (

Hz)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0.1 10 1000 100000

Freq (Hz)

|Z|

(oh

m c

m2

)

/sm102.7 2522

effNOD s-mol-/atmm101.9 28adsk

s-mol-/atmm107.8 28desk/sm103.9 29effOadsD

s-/molm107.5 42fk1/s8.2bk

Impedance Model – Comparison with Experimental Data

-1.0-0.9-0.8-0.7-0.6-0.5-0.4-0.3-0.2-0.10.0

1 1.2 1.4 1.6 1.8 2

Z' (ohm cm2)

Z" (

oh

m c

m2

)

Zf - DO2-N2/10

Zf - DO2-N2/100

Zf - DO2-N2

-20-18-16-14-12-10

-8-6-4-200.1 10 1000 100000

Freq (Hz)

Ph

ase (

deg)

Zf - DO2-N2/10

Zf - DO2-N2/100

Zf - DO2-N2

Gas DiffusivityEffect

Surface DiffusivityEffect

Absorption/Desorption Rate Constant Effect

-1.00

-0.60

-0.20

0.201 1.2 1.4 1.6 1.8 2

Z' (ohm cm2)

Z" (

ohm

cm

2)

Zf - DOads/10

Zf - DOads/100

Zf - DOads

-14

-12

-10

-8

-6

-4

-2

00.1 10 1000 100000

Freq (Hz)

Ph

ase

(deg

)

Zf - DOads/10Zf - DOads/100Zf - DOads

-1.00

-0.80

-0.60

-0.40

-0.20

0.001 1.2 1.4 1.6 1.8 2

Z' (ohm cm2)

Z"

(oh

m c

m2

)

Zf - kads/kdes/10Zf - kads/kdes/100Zf - kads/kdes

-12

-10

-8

-6

-4

-2

00.1 10 1000 100000

Freq (Hz)

Ph

ase

(deg

)

Zf - kads/kdes/10Zf - kads/kdes/100Zf - kads/kdes

CONCLUSION-3 Interfaces and interfacial layers (MPL) play a crucial role in

water transport

MPL can reduce membrane degradation !!

Impedance modeling can help identify MPL’s role in water transport

RECOMMENDATION-3

Proper characterisation (microstructural and transport properties) and modeling of MPL effects is important

Optimisation of MPL is required for – improved water management – reduced membrane degradation

Project partners & their tasks

• Modeling at cell level• Mixed wettability characterization (exp.)

• Novel GDL,MPL• Surface properties (ESEM)• Application to stacks

• Structure property relation CL, MPL

• Free surface flow in GDL/BPP• Robust design optimization • Microfluidic ex-situ experiments

• Neutron imaging

• Two-phase catalyst layer modeling, Interface conditions•

• Microstructural Catalyst Layer Modeling• 2D and 3D CFD Modeling of Half and Unit Cells•Numerical & Experimental Characterization of GDL and CL Properties

•Impedance Characterizarion – Experimental & Simulation

•MPL Characterisation•Mathematical Optimisation (Collaboration with UVic)

Network of collaboration• Surface data (ESEM)• Modified GDLs, MPLs

• Optimized design (GDL,BPP)• Surface modified BPPs (plasma etching)

• stacks incl. novel GDL&BPP• re-structured GDLs

NI analysis

MPL/CL properties

Free surface model GDL/channelGDL

wettability data

NI analysis

•GDL/MPL/CL Property Characterisation (Numerical & Simulation)

•CL Modeling•Impedance Characterisation

and Modeling•Mathematical Optimisation

GDL wettability data

Interface conditions

Interface conditions