Braided copper wire

Click here to load reader

-

Upload

ganpati-wires -

Category

Presentations & Public Speaking

-

view

29 -

download

0

description

Transcript of Braided copper wire

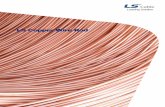

Braided Copper Wire

Copper wires wound like a hair

strand in a braid find their way

into most electrical as well as

thermo-electric applications.

Braided copper wire is

popularly called as electrolytic

copper wire owing to their

manufacturing and coating

processes. Modern day

applications include their use

in shielded cables and control

panel in switch gear. Soldering

and earthing wire assembly in

CRT channels also make use of

distinct copper wires wounded

in braids.

Contemporary braided

copper wires follow a

standard principle of

adopting two terminals

for flexible grounding. The

two terminals are made of

copper cylinders with

silver or tin coating on

the surface. The size may

vary depending on the

customer specification

and the mode of

processing used to

achieve a flexible joint.

Construction process

Braided wires are drawn in two ways:

Flat Braided Wire

Tubular Braided Wire

These wire segments are listed as

per MIL specification for products

that need to retain constant

physical as well as electrical

properties under all conditions of

varying temperature, magnetic field

and mechanical tension. The wire

strands are coated with tin and

then woven or rolled to a standard

width as per specifications given by

client. Mostly, concentric and semi-

concentric windings are used for

industrial appliances. Round

configuration ensures that they are

easy to store and transport over a

long distance.

Industrial and domestic uses of Braided wire sets

Electrical appliances working in

fluctuating voltage conditions have

braided copper wires at their

core. Mining industry with

explosive detonations and

automobile industry extensively

make use of copper wires due to

its high conductivity and anti-rust

properties in damp conditions.

Heavy duty machineries used in

saline conditions like in

submersible motors used in ships,

submarines and oil drillers also

make use of braided coppers.

Ganpati WiresC-27, Bais Godam Industrial Estate, Bais Godam,

Jaipur -302 006 (Raj.) India

Phone :141-2211977

Mobile No:9414048492

Websitehttp://www.ganpatiwires.com/braided-flexible-copper-wire-round-flat.html