BP_08 - 2001

-

Upload

sandra-lucia -

Category

Documents

-

view

35 -

download

12

description

Transcript of BP_08 - 2001

-

Monographs

Surgical Materials

-

71-2Absorbent Cotton

revised 1/01

Absorbent Cotton complies with the requirements of the 3rd edition of the European Pharmacopoeia [0036].These requirements are reproduced after the heading Definition below.

Ph Eur ___________________________________________________________________________________________________________

DEFINITION

Absorbent cotton consists of new fibres or good quality combers obtained from the seed-coat ofvarious species of the genus Gossypium L., cleaned, purified, bleached and carefully carded. It maynot contain any compensatory colouring matter.

CHARACTERSIt is white and is composed of fibres of average length not less than 10 mm, determined by a

suitable method, and contains not more than traces of leaf residue, pericarp, seed-coat or otherimpurities. It offers appreciable resistance when pulled. It does not shed any appreciable quantity ofdust when gently shaken.

IDENTIFICATION

A. Examined under a microscope, each fibre is seen to consist of a single cell, up to about 4 cm longand up to 40 m wide, in the form of a flattened tube with thick and rounded walls and often twisted.

B. When treated with iodinated zinc chloride solution R, the fibres become violet.

C. To 0.1 g add 10 ml of zinc chloride-formic acid solution R. Heat to 40C and allow to stand for 2 h30 min, shaking occasionally. It does not dissolve.

TESTS

Solution S Place 15.0 g in a suitable vessel, add 150 ml of water R, close the vessel and allow tomacerate for 2 h. Decant the solution, squeeze the residual liquid carefully from the sample with aglass rod and mix. Reserve 10 ml of the solution for the test for surface-active substances and filterthe remainder.

Acidity or alkalinity To 25 ml of solution S add 0.1 ml of phenolphthalein solution R and to another25 ml add 0.05 ml of methyl orange solution R. Neither solution is pink.

Foreign fibres Examined under a microscope, it is seen to consist exclusively of typical cottonfibres, except that occasionally a few isolated foreign fibres may be present.

Fluorescence Examine a layer about 5 mm in thickness under ultraviolet light at 365 nm. It displaysonly a slight brownish-violet fluorescence and a few yellow particles. It shows no intense blue fluores-cence, apart from that which may be shown by a few isolated fibres.

Neps Spread about 1 g evenly between two colourless transparent plates each 10 cm square. Exam-ine for neps by transmitted light and compare with Absorbent cotton RM. The product to be examinedis not more neppy than the standard.

Absorbency

Apparatus. A dry cylindrical copper wire basket 8.0 cm high and 5.0 cm in diameter. The wire ofwhich the basket is constructed is about 0.4 mm in diameter, the mesh is 1.5 cm to 2.0 cm wide andthe mass of the basket is 2.7 0.3 g.

Sinking time. Not more than 10 s. Weigh the basket to the nearest centigram (m1). Take a total of5.00 g in approximately equal quantities from five different places in the product to be examined,place loosely in the basket and weigh the filled basket to the nearest centigram (m2). Fill a beaker11 cm to 12 cm in diameter to a depth of 10 cm with water at about 20C. Hold the baskethorizontally and drop it from a height of about 10 mm into the water. Measure with a stopwatch thetime taken for the basket to sink below the surface of the water. Calculate the result as the average ofthree tests.

Water-holding capacity. Not less than 23.0 g of water per gram. After the sinking time has beenmeasured, remove the basket from the water, allow it to drain for exactly 30 s suspended in ahorizontal position over the beaker, transfer it to a tared beaker (m3) and weigh to the nearestcentigram (m4). Calculate the water-holding capacity per gram of absorbent cotton using the follow-ing expression:

12

324 )(mm

mmm

+

Calculate the result as the average of three tests.

Ether-soluble substances Not more than 0.50 per cent. In an extraction apparatus, extract 5.00 g

-

71-3with ether R for 4 h at a rate of at least four extractions per hour. Evaporate the ether extract and drythe residue to constant mass at 100C to 105C.

Extractable colouring matter In a narrow percolator, slowly extract 10.0 g with alcohol R until50 ml of extract is obtained. The liquid obtained is not more intensely coloured (Method II, 2.2.2)than reference solution Y5, GY6 or a reference solution prepared as follows: to 3.0 ml of blue primarysolution add 7.0 ml of hydrochloric acid (10 g/l HCl). Dilute 0.5 ml of this solution to 10.0 ml withhydrochloric acid (10 g/l HCl).

Surface-active substances Introduce the 10 ml portion of solution S reserved before filtration intoa 25 ml graduated ground-glass-stoppered cylinder with an external diameter of 20 mm and a wallthickness of not greater than 1.5 mm, previously rinsed three times with sulphuric acid R and thenwith water R. Shake vigorously thirty times in 10 s, allow to stand for 1 min and repeat the shaking.After 5 min, any foam present must not cover the entire surface of the liquid.

Water-soluble substances Not more than 0.50 per cent. Boil 5.000 g in 500 ml of water R for30 min, stirring frequently. Replace the water lost by evaporation. Decant the liquid, squeeze theresidual liquid carefully from the sample with a glass rod and mix. Filter the liquid whilst hot.Evaporate 400 ml of the filtrate (corresponding to 4/5 of the mass of the sample taken) and dry theresidue to constant mass at 100C to 105C.

Loss on drying (2.2.32). Not more than 8.0 per cent, determined 5.000 g by drying in an oven at100C to 105C.

Sulphated ash (2.4.14). Not more than 0.40 per cent. Introduce 5.00 g into a previously heated andcooled, tared crucible. Heat cautiously over a naked flame and then carefully to dull redness at600C. Allow to cool, add a few drops of dilute sulphuric acid R, then heat and incinerate until all theblack particles have disappeared. Allow to cool. Add a few drops of ammonium carbonate solution R.Evaporate and incinerate carefully, allow to cool and weigh again. Repeat the incineration for periodsof 5 min to constant mass.

STORAGE

Store in a dust-proof package in a dry place.__________________________________________________________________________________________________________ Ph Eur

-

71-4

Absorbent Viscose Wadding

revised 1/01

Absorbent Viscose Wadding complies with the requirements of the 3rd edition of the European Pharmacopoeia[0034]. These requirements are reproduced after the heading Definition below.

Ph Eur ___________________________________________________________________________________________________________

DEFINITION

Absorbent viscose wadding consists of bleached, carefully carded, new fibres of regenerated celluloseobtained by the viscose process, with or without the addition of titanium dioxide, of linear density 1.0dtex to 8.9 dtex (dtex = mass of 10,000 m of fibre, expressed in grams) and cut to a suitable staplelength. It does not contain any compensatory colouring matter.

CHARACTERS

It is white or very slightly yellow, has a lustrous or matt appearance, and is soft to the touch.

IDENTIFICATION

A. Viscose rayon fibres may be solid or hollow; hollow fibres may have a continuous lumen or becompartmented. The fibres have an average length of 25 mm to 80 mm and when examined under amicroscope in the dry state, or when mounted in alcohol R and water R, the following characters areobserved. They are usually of a more or less uniform width, with many longitudinal parallel linesdistributed unequally over the width. The ends are cut more or less straight. Matt fibres containnumerous granular particles of approximately 1 m average diameter.

Solid fibres. In longitudinal view, the surface of the fibres may be uneven or crenate. Fibres having anapproximately circular or elliptical cross section have a diameter of about 10 m to 20 m and thosethat are flattened and twisted ribbons vary in width from 15 m to 20 m as the twisting of thefilament reveals first the major axis and then the minor axis. They are about 4 m in thickness. Othersolid cross sections are Y-shaped and have protruding limbs with the major axis 5 m to 25 m inlength and the minor axis 2 m to 8 m wide.

Hollow fibres. Fibres with a continuous, hollow lumen have a diameter of up to about 30 m; they arethin-walled, with a wall thickness of about 5 m. When mounted in alcohol R and water R, the lumenis clearly indicated in many fibres by the presence of many entrapped air bubbles.

Compartmented fibres. These fibres may have a diameter of up to 80 m; they are hollow, having acentral lumen which is divided up into several compartments. Individual compartments vary in sizebut typically may be up to about 60 m in length and there may be more than one compartmentacross the width of each fibre. Some compartments show entrapped air bubbles when the fibres aremounted in alcohol R and water R.

B. When treated with iodinated zinc chloride solution R, the fibres become violet.

C. To 0.1 g add 10 ml of zinc chloride-formic acid solution R. Heat to 40C and allow to stand for 2 h30 min, shaking occasionally. It dissolves completely except for the matt variety where titaniumdioxide particles remain.

D. Dissolve the residue obtained in the test for sulphated ash by warming gently with 5 ml ofsulphuric acid R. Allow to cool and add 0.2 ml of dilute hydrogen peroxide solution R. The solutionobtained from the lustrous variety undergoes no change in colour; that from the matt variety showsan orange-yellow colour, the intensity of which depends on the quantity of titanium dioxide present.

TESTS

Solution S Place 15.0 g in a suitable vessel, add 150 ml of water R, close the vessel and allow tomacerate for 2 h. Decant the solution, squeeze the residual liquid carefully from the sample with aglass rod and mix. Reserve 10 ml of the solution for the test for surface-active substances and filterthe remainder.

Acidity or alkalinity To 25 ml of solution S add 0.1 ml of phenolphthalein solution R and to another25 ml add 0.05 ml of methyl orange solution R. Neither solution is pink.

Foreign fibres Examined under a microscope, it is seen to consist exclusively of viscose fibres,except that occasionally a few isolated foreign fibres may be present.

Fluorescence Examine a layer about 5 mm in thickness under ultraviolet light at 365 nm. It displaysonly a slight brownish-violet fluorescence. It shows no intense blue fluorescence, apart from thatwhich may be shown by a few isolated fibres.

Absorbency

Apparatus. A dry cylindrical copper-wire basket 8.0 cm high and 5.0 cm in diameter. The wire of

-

71-5which the basket is constructed is about 0.4 mm in diameter, the mesh is 1.5 cm to 2.0 cm wide andthe mass of the basket is 2.7 0.3 g.

Sinking time. Not more than 10 s. Weigh the basket to the nearest centigram (m1). Take a total of5.00 g in approximately equal quantities from five different places in the product to be examined,place loosely in the basket and weigh the filled basket to the nearest centigram (m2). Fill a beaker11 cm to 12 cm in diameter to a depth of 10 cm with water at about 20C. Hold the baskethorizontally and drop it from a height of about 10 mm into the water. Measure with a stopwatch thetime taken for the basket to sink below the surface of the water. Calculate the result as the average ofthree tests.

Water-holding capacity. Not less than 18.0 g of water per gram. After the sinking time has beenmeasured, remove the basket from the water, allow it to drain for exactly 30 s suspended in ahorizontal position over the beaker, transfer it to a tared beaker (m3) and weigh to the nearestcentigram (m4). Calculate the water-holding capacity per gram of absorbent viscose wadding usingthe following expression:

12

324 )(mm

mmm

+

Calculate the result as the average of three tests.

Ether-soluble substances Not more than 0.30 per cent. In an extraction apparatus, extract 5.00 gwith ether R for 4 h at a rate of at least four extractions per hour. Evaporate the ether extract and drythe residue to constant mass at 100C to 105C.

Extractable colouring matter In a narrow percolator, slowly extract 10.0 g with alcohol R until50 ml of extract is obtained. The liquid obtained is not more intensely coloured (Method II, 2.2.2)than reference solution Y5, GY6 or a reference solution prepared as follows: to 3.0 ml of blue primarysolution add 7.0 ml of hydrochloric acid (10 g/l HCl) and dilute 0.5 ml of this solution to 10.0 mlwith hydrochloric acid (10 g/l HCl).

Surface-active substances Introduce the 10 ml portion of solution S reserved before filtration intoa 25 ml graduated ground-glass-stoppered cylinder with an external diameter of 20 mm and a wallthickness of not greater than 1.5 mm, previously rinsed three times with sulphuric acid R and thenwith water R. Shake vigorously thirty times in 10 s, allow to stand for 1 min and repeat the shaking.After 5 min, any foam present does not cover the entire surface of the liquid.

Water-soluble substances Not more than 0.70 per cent. Boil 5.00 g in 500 ml of water R for30 min, stirring frequently. Replace the water lost by evaporation. Decant the liquid, squeeze theresidual liquid carefully from the sample with a glass rod and mix. Filter the liquid whilst hot.Evaporate 400 ml of the filtrate (corresponding to 4/5 of the mass of the sample taken) and dry theresidue to constant mass at 100C to 105C.

Hydrogen sulphide To 10 ml of solution S add 1.9 ml of water R, 0.15 ml of dilute acetic acid R and1 ml of lead acetate solution R. After 2 min, the solution is not more intensely coloured than a refer-ence solution prepared at the same time using 0.15 ml of dilute acetic acid R, 1.2 ml of thioacetamidereagent R, 1.7 ml of lead standard solution (10 ppm Pb) R and 10 ml of solution S.

Loss on drying (2.2.32). Not more than 13.0 per cent, determined on 5.000 g by drying in an ovenat 100C to 105C.

Sulphated ash (2.4.14). Not more than 0.45 per cent for the lustrous variety and not more than1.7 per cent for the matt variety. Introduce 5.00 g into a previously heated and cooled, tared crucible.Heat cautiously over a naked flame and then carefully to dull redness at 600C. Allow to cool, add afew drops of dilute sulphuric acid R, then heat and incinerate until all the black particles havedisappeared. Allow to cool. Add a few drops of ammonium carbonate solution R. Evaporate andincinerate carefully, allow to cool and weigh again. Repeat the incineration for periods of 5 min toconstant mass.

STORAGE

Store in a dust-proof package in a dry place.__________________________________________________________________________________________________________ Ph Eur

-

71-6

SUTURES

Sutures comply with the requirements of the third edition of the European Pharmacopoeia. The introduction tothese requirements is reproduced below.

Ph Eur ___________________________________________________________________________________________________________

INTRODUCTION

The following monographs apply to sutures for human use: Catgut, sterile (0317), Sutures, sterile non-absorbable (0324), Sutures, sterile synthetic absorbable braided (0667) and Sutures, sterile syntheticabsorbable monofilament (0666). They cover performance characteristics of sutures and may include methodsof identification. Sutures are medical devices as defined in Directive 93/42/EEC.

These monographs can be applied to show compliance with essential requirements as defined in Article 3 ofDirective 93/42/EEC covering the following:

Physical performance characteristics: diameter, breaking load, needle attachment, packaging, sterility,information supplied by the manufacturer (see Section 13 of Annex 1 of Directive 93/42/EEC), labelling.

To show compliance with other essential requirements, the application of appropriate harmonised standards asdefined in Article 5 of Directive 93/42/EEC may be considered.

__________________________________________________________________________________________________________ Ph Eur

-

71-7

Sterile Catgut

Sterile Catgut complies with the requirements of the 3rd edition of the European Pharmacopoeia [0317].These requirements are reproduced after the heading Definition below.

Ph Eur ___________________________________________________________________________________________________________

DEFINITION

Sterile catgut consists of sutures prepared from collagen taken from the intestinal membranes ofmammals. After cleaning, the membranes are split longitudinally into strips of varying width, which,when assembled in small numbers, according to the diameter required, are twisted under tension,dried, polished, selected and sterilised. The sutures may be treated with chemical substances such aschromium salts to prolong absorption and glycerol to make them supple, provided such substancesdo not reduce tissue acceptability.

Appropriate harmonised standards may be considered when assessing compliance with respect toorigin and processing of raw materials and with respect to biocompatibility.

Sterile catgut is a surgical wound-closure device. Being an absorbable suture it serves toapproximate tissue during the healing period and is subsequently metabolised by proteolytic activity.

PRODUCTION

Appropriate harmonised standards may apply with respect to appropriate validated methods ofsterilisation, environmental control during manufacturing, labelling and packaging.

It is essential for the effectiveness and the performance characteristics during use and during thefunctional lifetime of catgut that the following physical properties are specified: consistent diameter,sufficient initial strength and firm needle attachment.

The requirements outlined below have been established, taking into account stresses which occurduring normal conditions of use. These requirements can be used to demonstrate that individualproduction batches of sterile catgut are suitable for wound closure according to usual surgicaltechniques.

TESTS

If stored in a preserving liquid, remove the sutures from the sachet and measure promptly and in succession thelength, diameter and breaking load. If stored in the dry state, immerse the sutures in alcohol R or a 90 percent V/V solution of 2-propanol R for 24 h and proceed with the measurements as indicated below.

Length Measure the length without applying to the suture more tension than is necessary to keep itstraight. The length of each suture is not less than 90 per cent of the length stated on the label anddoes not exceed 350 cm.

Diameter Carry out the test on five sutures. Use a suitable instrument capable of measuring with anaccuracy of at least 0.002 mm and having a circular pressor foot 10 mm to 15 mm in diameter. Thepressor foot and the moving parts attached to it are weighted so as to apply a total load of 100 10 gto the suture being tested. When making the measurement, lower the pressor foot slowly to avoidcrushing the suture. Measure the diameter at intervals of 30 cm over the whole length of the suture.For a suture less than 90 cm in length, measure at three points approximately evenly spaced along thesuture. The suture is not subjected to more tension than is necessary to keep it straight duringmeasurement. The average of the measurements carried out on the sutures being tested and not lessthan two-thirds of the measurements taken on each suture are within the limits given in the columnsunder A in Table 3171 for the gauge number concerned. None of the measurements is outside thelimits given in the columns under B in Table 3171 for the gauge number concerned.

-

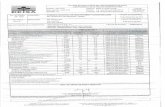

71-8Table 3171 Diameters and Breaking Loads

Diameter (millimetres) Breaking load(newtons)

Gaugenumber

A B C D

min. max. min. max.

0.1 0.010 0.019 0.005 0.025 0.2 0.020 0.029 0.015 0.035

0.3 0.030 0.039 0.025 0.045 0.20 0.05

0.4 0.040 0.049 0.035 0.060 0.30 0.10

0.5 0.050 0.069 0.045 0.085 0.40 0.20

0.7 0.070 0.099 0.060 0.125 0.70 0.30

1 0.100 0.149 0.085 0.175 1.8 0.40

1.5 0.150 0.199 0.125 0.225 3.8 0.70

2 0.200 0.249 0.175 0.275 7.5 1.8

2.5 0.250 0.299 0.225 0.325 10 3.8

3 0.300 0.349 0.275 0.375 12.5 7.5

3.5 0.350 0.399 0.325 0.450 20 10

4 0.400 0.499 0.375 0.550 27.5 12.5

5 0.500 0.599 0.450 0.650 38.0 20.0

6 0.600 0.699 0.550 0.750 45.0 27.5

7 0.700 0.799 0.650 0.850 60.0 38.0

8 0.800 0.899 0.750 0.950 70.0 45.0

Minimum breaking load The minimum breaking load is determined over a simple knot formed byplacing one end of a suture held in the right hand over the other end held in the left hand, passing oneend over the suture and through the loop so formed (see Fig. 3171) and pulling the knot tight. Carryout the test on five sutures. Submit sutures of length greater than 75 cm to two measurements andshorter sutures to one measurement. Determine the breaking load using a suitable tensilometer. Theapparatus has two clamps for holding the suture, one of which is mobile and is driven at a constantrate of 30 cm per minute. The clamps are designed so that the suture being tested can be attachedwithout any possibility of slipping. At the beginning of the test the length of suture between theclamps is 12.5 cm to 20 cm and the knot is midway between the clamps. Set the mobile clamp inmotion and note the force required to break the suture. If the suture breaks in a clamp or within 1 cmof it, the result is discarded and the test repeated on another suture. The average of all the results,excluding those legitimately discarded, is equal to or greater than the value given in column C inTable 3171 and no individual result is less than that given in column D for the gauge numberconcerned.

Fig. 3171 Simple knot

Soluble chromium compounds Place 0.25 g in a conical flask containing 1 ml of water R per 10 mgof catgut. Stopper the flask, allow to stand at 37 0.5C for 24 h, cool and decant the liquid.Transfer 5 ml to a small test tube and add 2 ml of a 10 g/l solution of diphenylcarbazide R in alcohol Rand 2 ml of dilute sulphuric acid R. The solution is not more intensely coloured than a standardprepared at the same time using 5 ml of a solution containing 2.83 g of potassium dichromate R permillilitre, 2 ml of dilute sulphuric acid R and 2 ml of a 10 g/l solution of diphenylcarbazide R in alcohol R(1 ppm of Cr).

Needle attachment If the catgut is supplied with an eyeless needle attached that is not stated to bedetachable, it complies with the test for needle attachment. Carry out the test on five sutures. Use asuitable tensilometer, such as that described for the determination of the minimum breaking load. Fixthe needle and suture (without knot) in the clamps of the apparatus in such a way that the swaged

-

71-9part of the needle is completely free of the clamp and in line with the direction of pull on the suture.Set the mobile clamp in motion and note the force required to break the suture or to detach it fromthe needle. The average of the five determinations and all individual values are not less than therespective values given in Table 317-2 for the gauge number concerned. If not more than oneindividual value fails to meet the individual requirement, repeat the test on an additional ten sutures.The catgut complies with the test if none of these ten values is less than the individual value in Table3172 for the gauge number concerned.

Table 3172 Minimum Strengths of Needle Attachment

Gaugenumber

Mean value(newtons)

Individual values(newtons)

0.5 0.50 0.250.7 0.80 0.40

1 1.7 0.80

1.5 2.3 1.1

2 4.5 2.3

2.5 5.6 2.8

3 6.8 3.4

3.5 11.0 4.5

4 15.0 4.5

5 18.0 6.0

STORAGE (PACKAGING)

Sterile catgut sutures are presented in individual sachets that maintain sterility and allow thewithdrawal and use of the sutures in aseptic conditions. Sterile catgut may be stored dry or in apreserving liquid to which an antimicrobial agent but not an antibiotic may be added.

Sutures in their individual sachets (primary packaging) are kept in a protective cover (box) whichmaintains the physical and mechanical properties until the time of use.

The application of appropriate harmonised standards for packaging of medical devices shall beconsidered.

LABELLING

Reference may be made to the appropriate harmonised standards for labelling of medical devices.The details strictly necessary for the user to identify the product properly are indicated on or in

each sachet (primary packaging) and on the protective cover (box) and include at least: gauge number, length in centimetres or metres, if appropriate, that the needle is detachable, name of the product, intended use (surgical suture, absorbable).

__________________________________________________________________________________________________________ Ph Eur

-

71-10

Sterile Synthetic Absorbable Braided Sutures

Sterile Synthetic Absorbable Braided Sutures comply with the requirements of the 3rd edition of the EuropeanPharmacopoeia [0667]. These requirements are reproduced after the heading Definition below.

Ph Eur ___________________________________________________________________________________________________________ .

DEFINITION

Sterile synthetic absorbable braided sutures consist of sutures prepared from a synthetic polymer,polymers or copolymers which, when introduced into a living organism, are absorbed by thatorganism and cause no undue tissue irritation. They consist of completely polymerised material.They occur as multifilament sutures consisting of elementary fibres which are assembled by braiding.The sutures may be treated to facilitate handling and they may be coloured.

Appropriate harmonised standards may be considered when assessing compliance with respect toorigin and processing of raw materials and with respect to biocompatibility.

Sterile synthetic absorbable braided sutures are wound-closure devices. Being absorbable they serveto approximate tissue during the healing period and subsequently lose tensile strength by hydrolysis.

PRODUCTION

Appropriate harmonised standards may apply with respect to appropriate validated methods ofsterilisation, environmental control during manufacturing, labelling and packaging.

It is essential for the effectiveness and the performance characteristics during use and during thefunctional lifetime of these sutures that the following physical properties are specified: consistentdiameter, sufficient initial strength and firm needle attachment.

The requirements below have been established, taking into account stresses which occur duringnormal conditions of use. These requirements can be used to demonstrate that individual productionbatches of these sutures are suitable for wound closure according to usual surgical techniques.

TESTS

Carry out the following tests on the sutures in the state in which they are removed from the sachet.

Length Measure the length of the suture without applying more tension than is necessary to keep itstraight. The length of each suture is not less than 95 per cent of the length stated on the label anddoes not exceed 400 cm.

Diameter Unless otherwise prescribed, measure the diameter by the following method, using fivesutures in the condition in which they are presented. Use a suitable instrument capable of measuringwith an accuracy of at least 0.002 mm and having a circular pressor foot 10 mm to 15 mm indiameter. The pressor foot and the moving parts attached to it are weighted so as to apply a total loadof 100 10 g to the suture being tested. When making the measurements, lower the pressor footslowly to avoid crushing the suture. Measure the diameter at intervals of 30 cm over the whole lengthof the suture. For a suture less than 90 cm in length, measure at three points approximately evenlyspaced along the suture. During the measurement, submit the sutures to a tension not greater thanone-fifth of the minimum breaking load shown in column C of Table 6671 appropriate to the gaugenumber and type of material or 10 N whichever is the less. For sutures of gauge number above 1.5make two measurements at each point, the second measurement being made after rotating the suturethrough 90. The diameter of that point is the average of the two measurements. The average of themeasurements carried out on the sutures being tested and not less than two-thirds of the measure-ments taken on each suture are within the limits given in the columns under A in Table 6671 for thegauge number concerned. None of the measurements is outside the limits given in the columns underB in Table 6671 for the gauge number concerned.

-

71-11Table 6671 Diameters and Breaking Loads

Diameter (millimetres) Breaking load(newtons)

Gaugenumber

A B C D

min. max. min. max.

0.01 0.001 0.004 0.008 0.005 0.05 0.005 0.009 0.003 0.012 0.1 0.010 0.019 0.005 0.025 0.2 0.020 0.029 0.015 0.035 0.3 0.030 0.039 0.025 0.045 0.45 0.230.4 0.040 0.049 0.035 0.060 0.70 0.350.5 0.050 0.069 0.045 0.085 1.4 0.70.7 0.070 0.099 0.060 0.125 2.5 1.31 0.100 0.149 0.085 0.175 6.8 3.41.5 0.150 0.199 0.125 0.225 9.5 4.82 0.200 0.249 0.175 0.275 17.7 8.92.5 0.250 0.299 0.225 0.325 21.0 10.53 0.300 0.349 0.275 0.375 26.8 13.43.5 0.350 0.399 0.325 0.450 39.0 18.54 0.400 0.499 0.375 0.550 50.8 25.45 0.500 0.599 0.450 0.650 63.5 31.86 0.600 0.699 0.550 0.750 7 0.700 0.799 0.650 0.850

Minimum breaking load The minimum breaking load is determined over a simple knot formed byplacing one end of a suture held in the right hand over the other end held in the left hand, passingone end over the suture and through the loop so formed (see Fig. 6671) and pulling the knot tight.

Fig. 6671 Simple knot

Carry out the test on five sutures. Submit sutures of length greater than 75 cm to two measurementsand shorter sutures to one measurement. Determine the breaking load using a suitable tensilometer.The apparatus has two clamps for holding the suture, one of which is mobile and is driven at aconstant rate of 25 cm to 30 cm per minute. The clamps are designed so that the suture being testedcan be attached without any possibility of slipping. At the beginning of the test the length of suturebetween the clamps is 12.5 cm to 20 cm and the knot is midway between the clamps. Set the mobileclamp in motion and note the force required to break the suture. If the suture breaks in a clamp orwithin 1 cm of it, the result is discarded and the test repeated on another suture. The average of allthe results excluding those legitimately discarded is equal to or greater than the value given in columnC in Table 6671 and no individual result is less than that given in column D for the gauge numberconcerned.

Needle attachment If the suture is supplied with an eyeless needle attached that is not stated to bedetachable the attachment, it complies with the test for needle attachment. Carry out the test on fivesutures. Use a suitable tensilometer, such as that described for the determination of the minimumbreaking load. Fix the needle and suture (without knot) in the clamps of the apparatus in such a waythat the swaged part of the needle is completely free of the clamp and in line with the direction of pullon the suture. Set the mobile clamp in motion and note the force required to break the suture or todetach it from the needle. The average of the five determinations and all individual values are not lessthan the respective values given in Table 6672 for the gauge number concerned. If not more thanone individual value fails to meet the individual requirement, repeat the test on an additional tensutures. The attachment complies with the test if none of the ten values is less than the individualvalue in Table 6672 for the gauge number concerned.

-

71-12Table 6672 Minimum Strengths of Needle Attachment

Gaugenumber

Mean value(newtons)

Individual value(newtons)

0.4 0.50 0.250.5 0.80 0.400.7 1.7 0.801 2.3 1.11.5 4.5 2.32 6.8 3.42.5 9.0 4.53 11.0 4.53.5 15.0 4.54 18.0 6.05 18.0 7.0

STORAGE (PACKAGING)

Sterile synthetic absorbable braided sutures are presented in a suitable sachet that maintains sterilityand allows the withdrawal and use of the sutures in aseptic conditions. The sutures must be storeddry.

They are intended to be used only on the occasion when the sachet is first opened.Sutures in their individual sachets (primary packaging) are kept in a protective cover (box) which

maintains the physical and mechanical properties until the time of use.The application of appropriate harmonised standards for packaging of medical devices may be

considered in addition.

LABELLING

Reference may be made to the appropriate harmonised standards for the labelling of medical devices.The details strictly necessary for the user to identify the product properly are indicated on or in

each sachet (primary packaging) and on the protective cover (box) and include at least: gauge number, length in centimetres or metres, if appropriate, that the needle is detachable, name of the product, intended use (surgical absorbable suture), if appropriate, that the suture is coloured, the structure (braided).

__________________________________________________________________________________________________________ Ph Eur

-

71-13Sterile Synthetic Absorbable Monofilament Sutures

Sterile Synthetic Absorbable Monofilament Sutures comply with the requirements of the 3rd edition of theEuropean Pharmacopoeia [0666]. These requirements are reproduced after the heading Definition below.

Ph Eur ___________________________________________________________________________________________________________

DEFINITION

Sterile synthetic absorbable monofilament sutures consist of sutures prepared from a synthetic poly-mer, polymers or copolymers which, when introduced into a living organism, are absorbed by thatorganism and cause no undue tissue irritation. They consist of completely polymerised material.They occur as monofilament sutures. The sutures may be treated to facilitate handling and they maybe coloured.

Appropriate harmonised standards may be considered when assessing compliance with respect toorigin and processing of raw materials and with respect to biocompatibility.

Sterile synthetic absorbable monofilament sutures are wound-closure devices. Being absorbablethey serve to approximate tissue during the healing period and subsequently lose tensile strength byhydrolysis.

PRODUCTION

The appropriate harmonised standards may apply with respect to appropriate validated methods ofsterilisation, environmental control during manufacturing, labelling and packaging.

It is essential for the effectiveness and the performance characteristics during use and during thefunctional lifetime of these sutures that the following physical properties are specified: consistentdiameter, sufficient initial strength and firm needle attachment.

The requirements below have been established, taking into account stresses which occur duringnormal conditions of use. These requirements can be used to demonstrate that individual productionbatches of these sutures are suitable for wound closure according to usual surgical techniques.

TESTS

Carry out the following tests on the sutures in the state in which they are removed from the sachet.

Length Measure the length of the suture without applying more tension than is necessary to keep itstraight. The length of each suture is not less than 95 per cent of the length stated on the label anddoes not exceed 400 cm.

Diameter Unless otherwise prescribed, measure the diameter by the following method, using fivesutures in the condition in which they are presented. Use a suitable instrument capable of measuringwith an accuracy of at least 0.002 mm and having a circular pressor foot 10 mm to 15 mm indiameter. The pressor foot and the moving parts attached to it are weighted so as to apply a total loadof 100 10 g to the suture being tested. When making the measurements, lower the pressor footslowly to avoid crushing the suture. Measure the diameter at intervals of 30 cm over the whole lengthof the suture. For a suture less than 90 cm in length, measure at three points approximately evenlyspaced along the suture. During the measurement, submit the sutures to a tension not greater thanthat required to keep them straight. The average of the measurements carried out on the suturesbeing tested and not less than two-thirds of the measurements taken on each suture are within thelimits given in the columns under A in Table 666-1 for the gauge number concerned. None of themeasurements is outside the limits given in the columns under B in Table 666-1 for the gaugenumber concerned.

Table 6661 Diameters and Breaking Loads

Diameter (millimetres) Breaking load(newtons)

Gaugenumber

A B C D

min. max. min. max.

0.5 0.050 0.094 0.045 0.125 1.4 0.70.7 0.095 0.149 0.075 0.175 2.5 1.31 0.150 0.199 0.125 0.225 6.8 3.41.5 0.200 0.249 0.175 0.275 9.5 4.72 0.250 0.339 0.225 0.375 17.5 8.93 0.340 0.399 0.325 0.450 26.8 13.43.5 0.400 0.499 0.375 0.550 39.0 18.54 0.500 0.570 0.450 0.600 50.8 25.45 0.571 0.610 0.500 0.700 63.5 31.8

-

71-14Minimum breaking load The minimum breaking load is determined over a simple knot formed byplacing one end of a suture held in the right hand over the other end held in the left hand, passingone end over the suture and through the loop so formed (see Figure 6661) and pulling the knottight.

Fig. 6661 Simple knot

Carry out the test on five sutures. Submit sutures of length greater than 75 cm to two measurementsand shorter sutures to one measurement. Determine the breaking load using a suitable tensilometer.The apparatus has two clamps for holding the suture, one of which is mobile and is driven at aconstant rate of 25 cm to 30 cm per minute. The clamps are designed so that the suture being testedcan be attached without any possibility of slipping. At the beginning of the test the length of suturebetween the clamps is 12.5 cm to 20 cm and the knot is midway between the clamps. Set the mobileclamp in motion and note the force required to break the suture. If the suture breaks in a clamp orwithin 1 cm of it, the result is discarded and the test repeated on another suture. The average of allthe results excluding those legitimately discarded is equal to or greater than the value given in columnC in Table 6661 and no individual result is less than that given in column D for the gauge numberconcerned.

Needle attachment If the suture is supplied with an eyeless needle attached that is not stated to bedetachable, the attachment complies with the test for needle attachment. Carry out the test on fivesutures. Use a suitable tensilometer, such as that described for the determination of the minimumbreaking load. Fix the needle and suture (without knot) in the clamps of the apparatus in such a waythat the swaged part of the needle is completely free of the clamp and in line with the direction of pullon the suture. Set the mobile clamp in motion and note the force required to break the suture or todetach it from the needle. The average of the five determinations and all individual values are not lessthan the respective values given in Table 6662 for the gauge number concerned. If not more thanone individual value fails to meet the individual requirement, repeat the test on an additional tensutures. The attachment complies with the test if none of the ten values is less than the individualvalue in Table 6662 for the gauge number concerned.

Table 6662 Minimum Strengths of Needle Attachment

Gaugenumber

Mean value(newtons)

Individual value(newtons)

0.5 0.80 0.400.7 1.7 0.801 2.3 1.11.5 4.5 2.32 6.8 3.42.5 9.0 4.53 11.0 4.53.5 15.0 4.54 18.0 6.05 18.0 7.0

STORAGE (PACKAGING)

Sterile synthetic absorbable monofilament sutures are presented in a suitable sachet that maintainssterility and allows the withdrawal and use of the sutures in aseptic conditions. The sutures must bestored dry.

They are intended to be used only on the occasion when the sachet is first opened.Sutures in their individual sachets (primary packaging) are kept in a protective cover (box) which

maintains the physical and mechanical properties until the time of use.The application of appropriate harmonised standards for packaging of medical devices may be

considered in addition.

-

71-15LABELLING

Reference may be made to appropriate harmonised standards for the labelling of medical devices.The details strictly necessary for the user to identify the product properly are indicated on or in

each sachet (primary packaging) and on the protective cover (box) and include at least: gauge number, length in centimetres or metres, if appropriate, that the needle is detachable, name of the product, intended use (surgical absorbable suture), if appropriate, that the suture is coloured, the structure (monofilament).

__________________________________________________________________________________________________________ Ph Eur

-

71-16Sterile Non-absorbable SuturesSterile Non-absorbable Ligatures

Sterile Braided Silk Suture, Sterile Linen Thread (Suture), Sterile Polyethylene Terephthalate (Polyester)Suture, Sterile Polyamide 6 Suture, Sterile Polyamide 6/6 Suture and Sterile Polypropylene Suture complywith the requirements of the 3rd edition of the European Pharmacopoeia for Sterile Synthetic Non-absorbableSutures [0324]. These requirements are reproduced after the heading Definition below.

NOTE: The name Nylon 6 as a synonym for Polyamide 6 and Nylon 6/6 as a synonym for Polyamide6/6 may be used freely in many countries, including the United Kingdom, but exclusive proprietaryrights in this name are claimed in certain other countries.

Ph Eur ___________________________________________________________________________________________________________

DEFINITION

Sterile non-absorbable sutures are sutures which, when introduced into a living organism, are notmetabolised by that organism. Sterile non-absorbable sutures vary in origin, which may be animal,vegetable, metallic or synthetic. They occur as cylindrical monofilaments or as multifilament suturesconsisting of elementary fibres which are assembled by twisting, cabling or braiding; they may besheathed; they may be treated to render them non-capillary, and they may be coloured.

Appropriate harmonised standards may be considered when assessing compliance with respect toorigin and processing of raw materials and with respect to biocompatibility.

Sterile non-absorbable surgical sutures serve to approximate tissue during the healing period andprovide continuing wound support.

Commonly used materials include the following:

Silk (Filum Bombycis)

Sterile braided silk suture is obtained by braiding a number of threads, according to the diameterrequired, of degummed silk obtained from the cocoons of the silkworm Bombyx mori L.

Linen (Filum Lini)

Sterile linen thread consists of the pericyclic fibres of the stem of Linum usitatissimum L. Theelementary fibres, 2.5 cm to 5 cm long, are assembled in bundles 30 cm to 80 cm long and spun intocontinuous lengths of suitable diameter.

Poly(ethylene Terephthalate) (Filum Ethyleni Polyterephthalici)

Sterile poly(ethylene terephthalate) suture is obtained by drawing poly(ethylene terephthalate)through a suitable die. The suture is prepared by braiding very fine filaments in suitable numbers,depending on the gauge required.

Polyamide 6 (Filum Polyamidicum-6)

Sterile polyamide 6 suture is obtained by drawing through a suitable die a synthetic plastic materialformed by the polymerisation of e-caprolactam. It consists of smooth, cylindrical monofilaments orbraided filaments, or lightly twisted sutures sheathed with the same material.

Polyamide 6/6 (Filum polyamidicum 6/6)

Sterile polyamide 6/6 suture is obtained by drawing through a suitable die a synthetic plastic materialformed by the polycondensation of hexamethylenediamine and adipic acid. It consists of smooth,cylindrical monofilaments or braided filaments, or lightly twisted sutures sheathed with the samematerial.

Polypropylene (Filum polypropylenicum)

Polypropylene suture is obtained by drawing polypropylene through a suitable die. It consists ofsmooth cylindrical monofilaments.

IDENTIFICATION

Non-absorbable sutures may be identified by chemical tests. Materials from natural origin may alsobe identified by microscopic examination of the morphology of these fibres. For synthetic materials,identification by infrared spectrophotometry (2.2.24) or by differential scanning calorimetry may beapplied.

Identification of silkA. Dissect the end of a suture, using a needle or fine tweezers, to isolate a few individual fibres. Thefibres are sometimes marked with very fine longitudinal striations parallel to the axis of the suture.Examined under a microscope, a cross-section is more or less triangular to semi-circular, withrounded edges and without a lumen.

B. Impregnate isolated fibres with iodinated potassium iodide solution R. The fibres are coloured paleyellow.

-

71-17Identification of linen

A. Dissect the end of a suture, using a needle or fine tweezers, to isolate a few individual fibres.Examined under a microscope, the fibres are seen to be 12 m to 31 m wide and, along the greaterpart of their length, have thick walls, sometimes marked with fine longitudinal striations, and anarrow lumen. The fibres gradually narrow to a long, fine point. Sometimes there are unilateralswellings with transverse lines.

B. Impregnate isolated fibres with iodinated zinc chloride solution R. The fibres are coloured violet-blue.

Identification of poly(ethyleneterephthalate)

It is practically insoluble in most of the usual organic solvents, but is attacked by strong alkalinesolutions. It is incompatible with phenols.

A. It dissolves with difficulty when heated in dimethylformamide R and in dichlorobenzene R.

B. To about 50 mg add 10 ml of hydrochloric acid R1. The material remains intact even afterimmersion for 6 h.

Identification of polyamide 6

It is practically insoluble in the usual organic solvents; it is not attacked by dilute alkaline solutions(for example a 100 g/l solution of sodium hydroxide R) but is attacked by dilute mineral acids (forexample a 20 g/l solution of sulphuric acid R), by hot glacial acetic acid R and by a 70 per cent m/msolution of anhydrous formic acid R.

A. Heat about 50 mg with 0.5 ml of hydrochloric acid R1 in a sealed glass tube at 110C for 18 h andallow to stand for 6 h. No crystals appear.

B. It dissolves in a 70 per cent m/m solution of anhydrous formic acid R.

Identification of polyamide 6/6

It is practically insoluble in the usual organic solvents; it is not attacked by dilute alkaline solutions(for example a 100 g/l solution of sodium hydroxide R) but is attacked by dilute mineral acids (forexample a 20 g/l solution of sulphuric acid R), by hot glacial acetic acid R and by an 80 per cent m/msolution of anhydrous formic acid R.

A. In contact with a flame it melts and burns, forming a hard globule of residue and gives off acharacteristic odour resembling that of celery.

B. Place about 50 mg in an ignition tube held vertically and heat gently until thick fumes are evolved.When the fumes fill the tube, withdraw it from the flame and insert a strip of nitrobenzaldehydepaper R. A violet-brown colour slowly appears on the paper and fades slowly in air; it disappearsalmost immediately on washing with dilute sulphuric acid R.

C. To about 50 mg add 10 ml of hydrochloric acid R1. The material disintegrates in the cold anddissolves within a few minutes.

D. It does not dissolve in a 70 per cent m/m solution of anhydrous formic acid R but dissolves in an80 per cent m/m solution of anhydrous formic acid R.

Identification of polypropylene

Polypropylene is soluble in decahydronaphthalene, 1-chloronaphthalene and trichloroethylene. It isnot soluble in alcohol, ether and cyclohexanone.

A. It softens at temperatures between 160C and 170C. It burns with a blue flame giving off anodour of burning paraffin wax and of octyl alcohol.

B. To 0.25 g add 10 ml of toluene R and boil under a reflux condenser for about 15 min. Place a fewdrops of the solution on a disc of sodium chloride R slide and evaporate the solvent in an oven at 80C.Examine by infrared absorption spectrophotometry (2.2.24), comparing with the spectrum obtainedwith polypropylene CRS.

C. To 2 g add 100 ml of water R and boil under a reflux condenser for 2 h. Allow to cool. Therelative density (2.2.5) of the material is 0.89 g/ml to 0.91 g/ml, determined using a hydrostaticbalance.

PRODUCTION

The appropriate harmonised standards may apply with respect to appropriate validated methods ofsterilisation, environmental control during manufacturing, labelling and packaging.

It is essential for the effectiveness and the performance characteristics during use and during thefunctional lifetime of these sutures that the following physical properties are specified: consistentdiameter, sufficient initial strength and firm needle attachment.

The requirements below have been established, taking into account stresses which occur duringnormal conditions of use. These requirements can be used to demonstrate that individual productionbatches of these sutures are suitable for wound closure in accordance with usual surgical techniques.

-

71-18TESTS

Remove the sutures from the sachet and measure promptly and in succession the length, diameter and mini-mum load.

If linen is tested the sutures are conditioned as follows: if stored in the dry state, expose to an atmos-phere with a relative humidity of 65 5 per cent at 20 2C for 4 h immediately before measuringthe diameter and for the determination of minimum breaking load immerse in water R at roomtemperature for 30 min immediately before carrying out the test.

Length Measure the length in the condition in which the sutures are presented and without applyingmore tension than is necessary to keep them straight. The length of the suture is not less than 95 percent of the length stated on the label and does not exceed 400 cm.

Diameter Unless otherwise prescribed, measure the diameter by the following method using fivesutures in the condition in which they are presented. Use a suitable mechanical instrument capable ofmeasuring with an accuracy of at least 0.002 mm and having a circular pressor foot 10 mm to 15 mmin diameter. The pressor foot and the moving parts attached to it are weighted so as to apply a totalload of 100 10 g to the suture being tested. When making the measurements, lower the pressor footslowly to avoid crushing the suture. Measure the diameter at intervals of 30 cm over the whole lengthof the suture. For a suture less than 90 cm in length, measure at three points approximately evenlyspaced along the suture. During the measurement submit monofilament sutures to a tension notgreater than that required to keep them straight. Submit multifilament sutures to a tension notgreater than one-fifth of the minimum breaking load shown in column C of Table 324-1 appropriateto the gauge number and type of material concerned or 10 N whichever is the less. For multifilamentsutures of gauge number above 1.5 make two measurements at each point, the second measurementbeing made after rotating the suture through 90. The diameter of that point is the average of the twomeasurements. The average of the measurements carried out on the sutures being tested and not lessthan two-thirds of the measurements taken on each suture are within the limits given in the columnunder A in Table 3241 for the gauge number concerned. None of the measurements is outside thelimits given in the columns under B in Table 3241 for the gauge number concerned.

Table 3241 Diameters and Minimum Breaking Loads

Diameter (millimetres) Minimum breaking load (newtons)

Gaugenumber

A B Linen thread All other nonabsorbable strands

min max min max C D C D

0.05 0.005 0.009 0.003 0.012 0.01 0.1 0.010 0.019 0.005 0.025 0.03 0.15 0.015 0.019 0.012 0.025 0.06 0.010.2 0.020 0.029 0.015 0.035 0.1 0.3 0.030 0.039 0.025 0.045 0.35 0.060.4 0.040 0.049 0.035 0.060 0.60 0.150.5 0.050 0.069 0.045 0.085 1.0 0.350.7 0.070 0.099 0.060 0.125 1.0 0.3 1.5 0.601 0.100 0.149 0.085 0.175 2.5 0.6 3.0 1.01.5 0.150 0.199 0.125 0.225 5.0 1.0 5.0 1.52 0.200 0.249 0.175 0.275 8.0 2.5 9.0 3.02.5 0.250 0.299 0.225 0.325 9.0 5.0 13.0 5.03 0.300 0.349 0.275 0.375 11.0 8.0 15.0 9.03.5 0.350 0.399 0.325 0.450 15.0 9.0 22.0 13.04 0.400 0.499 0.375 0.550 18.0 11.0 27.0 15.05 0.500 0.599 0.450 0.650 26.0 15.0 35.0 22.06 0.600 0.699 0.550 0.750 37.0 18.0 50.0 27.07 0.700 0.799 0.650 0.850 50.0 26.0 62.0 35.08 0.800 0.899 0.750 0.950 65.0 37.0 73.0 50.0

Minimum breaking load Unless otherwise prescribed, determine the minimum breaking load bythe following method using sutures in the condition in which they are presented. The minimumbreaking load is determined over a simple knot formed by placing one end of a suture held in theright hand over the other end held in the left hand, passing one end over the suture and through theloop so formed (see Figure 3241) and pulling the knot tight.

-

71-19

Fig. 3241 Simple knot

Carry out the test on five sutures. Submit sutures of length greater than 75 cm to two measurementsand shorter sutures to one measurement. Determine the breaking load using a suitable tensilometer.The apparatus has two clamps for holding the suture, one of which is mobile and is driven at aconstant rate of 30 cm per minute. The clamps are designed so that the suture being tested can beattached without any possibility of slipping. At the beginning of the test the length of suture betweenthe clamps is 12.5 cm to 20 cm and the knot is midway between the clamps. Set the mobile clamp inmotion and note the force required to break the suture. If the suture breaks in a clamp or within 1 cmof it, the result is discarded and the test repeated on another suture. The average of all the results,excluding those legitimately discarded, is equal to or greater than the value given in column C inTable 3241 and no value is less than that given in column D for the gauge number and type ofmaterial concerned.

Table 3242 Minimum Strengths of Needle Attachment

Gaugenumber

Mean value(newtons)

Individual value(newtons)

0.4 0.50 0.250.5 0.80 0.400.7 1.7 0.801 2.3 1.11.5 4.5 2.32 6.8 3.42.5 9.0 4.53 11.0 4.53.5 15.0 4.54 18.0 6.05 18.0 7.0

Needle attachment If the sutures are supplied with an eyeless needle attached that is not stated tobe detachable, they comply with the test for needle attachment. Carry out the test on five sutures.Use a suitable tensilometer, such as that described for the determination of the minimum breakingload. Fix the needle and suture (without knot) in the clamps of the apparatus in such a way that theswaged part of the needle is completely free of the clamp and in line with the direction of pull on thesuture. Set the mobile clamp in motion and note the force required to break the suture or to detach itfrom the needle. The average of the five determinations and all individual values are not less than therespective values given in Table 3242 for the gauge number concerned. If not more than oneindividual value fails to meet the individual requirement, repeat the test on an additional ten sutures.The attachment complies with the test if none of these ten values is less than the individual value inTable 3242 for the gauge number concerned.

Extractable colour Sutures that are dyed and intended to remain so during use comply with the testfor extractable colour. Place 0.25 g of the suture to be examined in a conical flask, add 25.0 ml ofwater R and cover the mouth of the flask with a short-stemmed funnel. Boil for 15 min, cool andadjust to the original volume with water R.

Depending on the colour of the suture, prepare the appropriate reference solution as described inTable 3243 using the primary colour solutions (2.2.2).

The test solution is not more intensely coloured than the appropriate reference solution.

-

71-20Table 3243 Colour Reference Solutions

Colour ofstrand

Composition of reference solution(parts by volume)

Redprimarysolution

Yellowprimarysolution

Blueprimarysolution

Water

Yellowbrown

0.2 1.2 8.6

Pinkred 1.0 9.0Greenblue 2.0 8.0Violet 1.6 8.4

Monomer and oligomers Polyamide 6 suture additionally complies with the following test formonomer and oligomers. In a continuous-extraction apparatus, treat 1.00 g with 30 ml of methanol Rat a rate of at least three extractions per hour for 7 h. Evaporate the extract to dryness, dry theresidue at 110C for 10 min, allow to cool in a desiccator and weigh. The residue weighs not morethan 20 mg (2 per cent).

STORAGE (PACKAGING)

Sterile non-absorbable sutures are presented in a suitable sachet that maintains sterility and allowsthe withdrawal and use of a suture in aseptic conditions. They may be stored dry or in a preservingliquid to which an antimicrobial agent but no antibiotic may be added.

Sterile non-absorbable sutures are intended to be used only on the occasion when the sachet is firstopened.

Sutures in their individual sachets (primary packaging) are kept in a protective cover (box) whichmaintains the physical and mechanical properties until the time of use.

The application of appropriate harmonised standards for packaging of medical devices shall beconsidered in addition.

LABELLING

Reference may be made to the appropriate harmonised standards for the labelling of medical devices.The details strictly necessary for the user to identify the product properly are indicated on or in

each sachet (primary packaging) and on the protective cover (box) and include at least: gauge number, length in centimetres or metres, if appropriate, that the needle is detachable, name of the product, intended use (surgical suture, non-absorbable), if appropriate, that the suture is coloured, if appropriate, the structure (braided, monofilament, sheathed).

__________________________________________________________________________________________________________ Ph Eur

-

Infrared Reference Spectra

-

Preparation of Infrared Reference Spectra

All spectra presented in this section were recorded using either aPerkin-Elmer model 682 dispersive infrared spectrophotometer or aPerkin Elmer model 16PC Fourier transform infraredspectrophotometer.

Pressed discs, 13 mm in diameter, were prepared usingpotassium bromide or potassium chloride. Liquid paraffin mullsand thin films were prepared between potassium bromide plates,and gas and solution spectra were prepared using cells withpotassium bromide windows. Solution spectra were preparedagainst a solvent reference and all other spectra were recordedagainst air.

For solution spectra the regions of the spectrum within which thesolvent shows strong absorption should be disregarded. Solventcut-offs in the reference spectra may be recorded as horizontalstraight lines or may appear as blank regions on the spectrum.

S2 Infrared Reference Spectra

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

Instrument: Dispersive

4000 3600 3200 2800 2400 20000

Polystyrene

Wavenumber (cm-1)

Tran

smitt

ance

Phase: Thin film Thickness 0.038mm

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

Instrument: Fourier transform

4000 3600 3200 2800 2400 2000

Polystyrene

Tran

smitt

ance

Wavenumber (cm-1)

Phase: Thin film Thickness 0.038mm

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 002: Acetazolamide

Tran

smitt

ance

Wavenumber (cm-1)

RS 001: Acenocoumarol (Nicoumalone)

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 004: Adrenaline (Epinephrine)

4000 3600 3200 2800 2400 2000

Instrument: Dispersive

Dispersive

Phase: Potassium bromide discRS 003: Acetyl-cysteine

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 006: Amantadine

Phase: 10% w/v solution in chloroform Thicknesss: 0.1mm

RS 007: Aminobenzoic Acid

Instrument: DispersiveRS 005: Alimemazine(Trimeprazine)

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 008: Amiodarone Phase: 15% w/v solution in dichloromethane Thickness: 0.1mm

RS 010: Amoxicillin Sodium

Instrument: Dispersive

Fourier TransformRS 009: AmmoniumGlycyrrhizinate

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 011: Amoxicillin Trihydrate

RS 012: Amphotericin

RS 013: Ampicillin Trihydrate

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 014: Amylmetacresol Phase: Thin Film

RS 015: Atenolol

RS 016: Azapropazone

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 017: Anhydrous Azapropazone

RS 018: Azelastine Hydrochloride Fourier transform

RS 019: Azlocillin Sodium

chloride

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

Phase: 5% w/v solution in chloroform Thickness: 0.1mm

RS 022: Benethamine Penicillin

Instrument: Fourier transform

RS 020: BeclometasoneDipropionate (1)

RS 021: Beclometasone DipropionateMonohydrate

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 023: Benorilate

RS 025: Benzoic Acid

chlorideRS 024: Benzhexol Hydrochloride(TrihexyphenidylHydrochloride)

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 026: Benzatropine Mesilate Phase: Liquid paraffin mull

RS 028: Benzyl Hydroxybenzoate

chlorideFourier transformRS 027: BenzydamineHydrochloride

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 029: Betamethasone

RS 031: Bronopol

Fourier transformRS 030: Bretylium Tosilate

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 032: Buclizine Hydrochloride

RS 032: Bumetanide

RS 034: Bupivacaine Phase: Liquid paraffin mull

chloride

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide discRS 037: Calcium PolystyreneSulphonate

RS 035: Busulfan

RS 036: Butyl Hydroxybenzoate

Fourier transform

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 038: Captopril

RS 039: Carbaryl

RS 040: Carbenicillin Sodium

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 041: Carbenoxolone

RS 042: Carbimazole

RS 043: Carteolol Hydrochloride Fourier transform chloride

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 044: Cefotaxime Sodium

RS 045: Cefoxitin Sodium

RS 046: Ceftriaxone Sodium

Fourier transform

Fourier transform

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 047: Cefuroxime Axetil

RS 048: Cefuroxime Sodium

RS 049: Cefalexin

Fourier transform

Fourier transform

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 050: Cefradine

RS 051: Clomethiazole Phase: Thinfilm

RS 052: Clomethiazole Edisilate Phase: Liquid paraffin mull

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 053: Chloroform Phase: 0.1mm Layer

RS 054: Chloroquine Phase: 5% w/v solution in chloroform Thickness: 0.1mm

RS 055: Chloroxylenol

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 056: Chlorpromazine Phase: 5% w/v solution in chloroform Thickness: 0.1mm

RS 057: Chlorpropamide

RS 058: Chlortalidone

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 059: Choline Salicylate Phase: Thin film

RS 060: Choline Theophyllinate

RS 061: Cimetidine

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 064: ClindamycinHydrochloride

RS 062: Cinnamic Acid

RS 063: Clemastine Fumarate

chloride

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument:

Instrument:

Dispersive

Dispersive

0

0

0Tran

smitt

ance

Wavenumber (cm-1)

Dispersive Phase: Potassium bromide disc

RS 065: Clioquinol

RS 066: Clobazam

RS 067: Clobetasol Propionate

-

100

80

60

40

20

02000 1800 1600 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument:

Instrument: Dispersive

Instrument:

Dispersive

Dispersive

0

0Tran

smitt

ance

Wavenumber (cm-1)

1400

RS 068: Clofazimine Phase: Liquid Paraffin mull

RS 069: ClomipramineHydrochloride

Phase: Potassium chloride disc

RS 070: Cloxacillin Sodium

-

100

80

60

40

20

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

100

80

40

2000 1800 1600 1400 1200 1000 800 600 400

60

20

20

60

Phase: Potassium bromide disc

Phase: Potassium bromide disc

Instrument: