Book Gearbox

Transcript of Book Gearbox

-

8/12/2019 Book Gearbox

1/25

Transmission

Gearbox

-

8/12/2019 Book Gearbox

2/25

Preface

This training module introduces the concept of gearbox.

The training module is part of a series of modules

designed for the Transmission Basic Training Program.

This module should be studied right after the modules:

General Information and Clutch.

While studying this module, you will have the

opportunity to learn the gearbox functions, its main

components as well as how these components

work individually or within the gearbox assembly.

Contedo

General Information 3

Types of gearboxes 4

Manual gearbox - main models 5

Types of gearboxes 6

Clutch bell housing 7

Basic gearbox 8

Basic gearbox - input shaft and main shaft 9

Basic gearbox - intermediate shaft and

reverse shaft 10

Basic gearbox - selector forks and oil pump 11

Range gear 12

High range (A) 13

Range gear operation 14

Split gear 15

Split gear operation 16

Split gear - high gear 17

Split gear - low 19

Manual gearbox - synchronisation of components 21

Synchronising operation 22

Synchronisation devices operation 23

Gearbox external components 24

Manual gear shift 25

-

8/12/2019 Book Gearbox

3/25

Global TrainingTP95850 3

General Information

A gearbox is a transmission component responsible for the control of the torque changes in a

vehicle. The torque is altered according to the selected gear in the gearbox.

In the absence of a gearbox in a vehicle, that is, if the engine were connected directly to the

driven wheels, the vehicle speed would not exceed 8 km/h. this because the torque variations

would be insignificant.

SummaryThe gearbox control the torque ratios in a vehicle. The higher the torque, the lower the gear. The

higher the speed, the higher the gear.

Summary

The gearbox control the torque shifts in a vehicle. The higher the torque, the lower the gear. The

higher the speed, the higher the gear.

-

8/12/2019 Book Gearbox

4/25

Global TrainingTP95850 4

Types of gearboxes

In the last few of years, transmission development has been focused towards gearboxes.

The aim has been to improve the vehicles driving characteristics and simplify the drivers job.

A series of gearbox models have been developed that adapt themselves to vehicles depending

on the tasks to be accomplished by the vehicle.

Gearboxes are basically divided into three types:

Manual gearbox (1):gear shifting is carried out by the driver.

Automatic gearbox (2):gear shifting is fully automatic with the help of information from sensors

in the gearbox control unit and other control units in the vehicle.

Semi-automatic gearbox (3):the driver selects the gear and an electronic system controls gear

shifting.

-

8/12/2019 Book Gearbox

5/25

-

8/12/2019 Book Gearbox

6/25

Global TrainingTP95850 6

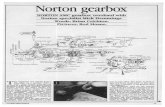

Manual gearbox - main parts

This gearbox is basically divided into four parts:

Clutch bell housing (C)- this housing connects the gearbox to the engine and protects the

clutch.

Split gear (S)- the split gear splits the gears and makes it possible to use high and low gears.

Basic gearbox (B)- the basic gearbox contains basic gears, reduced gears and reverse gears.

Range gear (R)- the range gear consists of a planetary gear set that double the number of

gears in the basic gearbox (B).

-

8/12/2019 Book Gearbox

7/25

Global TrainingTP95850 7

Clutch bell housing

The clutch bell housing connects the gearbox to the engine.

It also protects the clutch.

-

8/12/2019 Book Gearbox

8/25

Global TrainingTP95850 8

Basic gearbox

The basic gearbox contains the gears and shafts that permit gear shifting.

The main shafts are:

- input shaft (1)

- main shaft (2)

- intermediate shaft (3)

- reverse shaft (4)

The gears are positioned on the shafts. There are five gears with synchronised gearshifts, plusthe reduced gear and the non-synchronised reverse gear.

Note: The reduced gear is also known as CRAWL.

-

8/12/2019 Book Gearbox

9/25

Global TrainingTP95850 9

Basic gearbox - input shaft and main shaft

Input shaft (1)

Also called as primary shaft, the input shaft is responsible for transferring torque from the engine

to the gearbox.

The torque is transferred through the clutch disc.

This shaft is supported by roller bearings in the clutch bell housing.

Main shaft (2)

The main shaft carries the five gears with synchronised gearshifts. These gears operate freely

through needle bearings and roller bearings.

This shaft is supported on the input shaft and on the basic gearbox housing by roller bearings.

-

8/12/2019 Book Gearbox

10/25

Global TrainingTP95850 10

Basic gearbox - intermediate shaft and reverse shaft

Intermediate shaft (1)

Also called as secondary shaft, the intermediate shaft contains fixed gears only, that is, all gears

are pressed onto the shaft and always turn at the shaft speed.

The secondary shaft receives the torque transferred from the input shaft and it is supported on

the clutch bell housing and on the gearbox rear housing.

Reverse shaft (2)

The reverse gear is installed on that shaft.The reverse gear is positioned between its driving gear, located in the main shaft, and a takeoff

gear, installed in the intermediate shaft.

The purpose of the reverse gear is to change the direction of revolution of the main shaft and _

output shaft.

When the reverse gear changes the direction of revolution of the main shaft, this reverse force is

transferred through the output shaft to the drive wheels and the vehicle moves backward.

-

8/12/2019 Book Gearbox

11/25

Global TrainingTP95850 11

Basic gearbox - selector forks and oil pump

Besides shafts and gears, the basic gearbox also contains selector forks and the oil pump.

Selector forks (1)

Selector forks are responsible for the movement of the coupling sleeves on the main shaft so

that different gears are engaged.

Selector forks receive the selector motion through the selector shafts.

They are installed with the help of retainers that, together, make up the selector unit.

Oil pump (2)

Larger gearboxes are lubricated through the use of an oil pump that forces the oil to all the

gearbox lubrication points.

The oil pump is fastened to the inside of the gearbox. It is driven by a gear connected to the

intermediate shaft, via the reverse gear.

-

8/12/2019 Book Gearbox

12/25

Global TrainingTP95850 12

Range gear

The gearbox is supplemented with a double speed range gear:

- High range

- Low range

Using the range gear doubles the gearbox basic gears, as required by modern trucks.

The range gear consists of a planetary system that transfer torque from the main shaft directly

to the driving gears:

1. planetary gear2. ring gear

3. coupling ring

4. sun gear

5. planetary carriers

Gear shifting in the range gear is carried out through a pneumatic cylinder (6).

-

8/12/2019 Book Gearbox

13/25

Global TrainingTP95850 13

High range (A)

When the ring gear (1) is locked to the planetary gear carrier by a coupling ring (2), the entire

planetary rear rotates.

Torque coming from the basic gearbox goes directly through the planetary gear.

This means the gearbox operates in high gears.

Low range (B)

The ring gear (3) is locked in the gearbox housing and forces the planetary gears to turnbetween the ring gear (3) and the sun gear (4).

The planetary gear carrier (5) turns on the same direction of the sun gear but _ a lower speed.

This means that the torque coming from the basic gearbox is transferred through the planetary

gears and operates with low gears.

-

8/12/2019 Book Gearbox

14/25

Global TrainingTP95850 14

Range gear operation

A switch located on the gear lever knob operates the range gear.

To select the low range, push the switch down (1). It affect 1st and 3rd gears.

To select the high range, push the switch up (2). It affect 4th and 6th gears.

-

8/12/2019 Book Gearbox

15/25

Global TrainingTP95850 15

Split gear

The purpose of the split gear is to split the gears in the gearbox.

Thus, both the first gear and the other gears have a low and a high gear.

CONCLUSION

Gearboxes with both the split gear and the range gear like SR and VT gearboxes have 12

synchronised gears, two crawling speed gears and four non-synchronised reverse gears.

-

8/12/2019 Book Gearbox

16/25

Global TrainingTP95850 16

Split gear operation

Like the range gear, a switch located on the gear lever knob operates the split gear.

Note:

The split gear switch is not the same one as the range gear switch.

To select the high gears put the switch on H (High).

To select the low gears put the switch on L (Low).

-

8/12/2019 Book Gearbox

17/25

Global TrainingTP95850 17

Split gear - high gear

Switching to H (High) on the gear lever knob activates a relay valve (2).

The relay valve (2) is positioned in such a way that permits the passage of compressed air to a

pneumatic cylinder (3).

-

8/12/2019 Book Gearbox

18/25

Global TrainingTP95850 18

Split gear - high gear (continuation)

When the clutch pedal is depressed, the split gear operating valve (1) sends the air to the

pneumatic cylinder (2).

The air displaces the cylinder piston to engages the high gears.

Then, the operating valve shaft in the split gear (1) actuates a switch and lights up a lamp in the

panel indicating to the driver the high gear is selected.

-

8/12/2019 Book Gearbox

19/25

Global TrainingTP95850 19

Split gear - low

Switching to L (Low) on the gear lever knob (1) activates a relay valve (2).

The relay valve (2) is positioned in such a way that permits the passage of compressed air to a

pneumatic cylinder (3).

-

8/12/2019 Book Gearbox

20/25

Global TrainingTP95850 20

Split gear - low (continuation)

When the clutch pedal is depressed, the split gear operating valve (1) sends the air to the

pneumatic cylinder (2).

The air displaces the cylinder piston to engages the low gears.

-

8/12/2019 Book Gearbox

21/25

Global TrainingTP95850 21

Manual gearbox - synchronisation of components

The purpose of the synchronisation is to facilitate gearshifts by adapting the speed between the

main shaft and intermediate shaft during the shifts.

The gearbox is equipped with many synchronisation devices:

1. coupling sleeve

2. coupling ring

3. gear

4. synchronizer ring

5. engaging body

-

8/12/2019 Book Gearbox

22/25

Global TrainingTP95850 22

Synchronising operation

The engaging body is connected to the main shaft through splines. The coupling sleeve is

geared around the engaging body. The purpose of this sleeve is to displace the engaging body

towards the synchroniser ring and connect it to the coupling ring.

The synchroniser ring is pressed between the engaging body and the coupling ring by the

coupling sleeve. The resulting friction in the synchroniser ring matches the speed of the

engaging body and the coupling sleeve. Upon reaching the same speed, the coupling sleeve

meshes _ with the coupling ring.

In this position, the gear is fully engaged to the main shaft through the engaging body and can

transmit the torque from the engine to the driven wheels through the output shaft.

-

8/12/2019 Book Gearbox

23/25

Global TrainingTP95850 23

Synchronisation devices operation

The synchronisation set operates as follows:

The synchroniser ring (4) is pressed between the engaging body (5) and the coupling ring (2) by

the coupling sleeve (1).

The resulting friction in the synchroniser ring matches the speed of the engaging body to the

coupling sleeve.

Upon reaching the same speed, the coupling sleeve engages it self with the coupling ring.

In this position, the gear (3) is fully engaged to the main shaft through the engaging body and can

transfer the torque from the engine to the driven wheels through the output shaft.

-

8/12/2019 Book Gearbox

24/25

Global TrainingTP95850 24

Gearbox external components

The gearbox is provided with a series of external components to avoid damage to the gearbox

and facilitate the shifting of gears.

These components vary according to the gearbox model.

Basically, gearboxes are composed of:

1. an inhibitor valve

2. relief valves

3. relay valves4. solenoid valves

5. an inhibitor valve

6. electrical contacts

7. a sensor

8. a control cylinder

A more detailed description of these components will be reviewed in specific modules on

gearboxes.

-

8/12/2019 Book Gearbox

25/25

Manual gear shift

Manual gearshift is operated by a gear lever (1).

The gear lever (1) is supported on a guide bearer (2).

When the gear lever is moved (1), the motion is transferred to the selector-shaft housing (5) with

the help of a driving bar (3) and the control arm (4).

The control arm is connected to the side control shaft (6) in the selector-shaft housing (2).

The selector-shaft housing (2), in turn, operates the gearbox shafts.