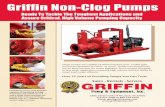

Boletin Non Clog

Transcript of Boletin Non Clog

Features and Benefits:

• Oil Filled Motors Cooler operating than air filled motors and continuous lubrication of the bearings for longer life

• Slip Fit Stators For easy of service

• Seal Cord Entrance Tripe seal protection, prevents moisture entry for longer life

SUBMERSIBLE NON-CLOG PUMPS

Also available in explosion-proof

construction.

NOW FEATURES THE H SERIES

Page 2Page 2

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Hydromatic pumps are field proven, reliable pumps.

Installations:

Municipal • Wastewatertransfer • Wastewatertreatmentplants • Wastewaterliftstations • Subdivisions • Airports • Stormwater

Commercial • Buildingwastewatersystems • Wastewater • Hospitals • Motels • Apartments • Schools • Churches • Universities • Campgrounds • Amusementparks

Industrial • Wastewater • Sump • Spraywash • Stormwater

Dependable HYDROMATIC® submersible non-clog pumps

You can depend on HYDROMATIC pumps toprovide years of reliable service. Currently, there arethousands of units operating trouble-free throughout theworld.

As one of the oldest submersible pump

manufacturers in the world, HYDROMATIC offersyou field-proven pumps and systems for all yourrequirements.

HYDROMATIC provides a 5-year warranty withproper start-up report, the most comprehensive in the industry. We also supply complete technical supportandongoingengineeringassistanceforthelifeofthepump.

Page 3Page 3

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

BENEFITS

A. Motor–Oilfilledtoefficientlydissipateheatandlockoutdamagemoisturesoyoureceivereliablepumpingservice.

B. Connection Box – Two epoxy barriers and a compression fittingpreventwatercontaminationof the motor area, assuring long-term reliable operation.Additionally,epoxyencapsulationandstrippedleadspositivelyeliminate“wicking”fromthecable.

C. Bearings–Heavy-dutyupperandlowerballbearingsaresubmergedinoiltoprovidepermanentlubricationandensurelongservicelife.

D. Seals – A dual seal system operates in an oil chamber to provide long pump service life. J.C. Type 21 seals are standard and readily available-optionalmaterialsuponrequest.

E. Shaft – The stainless steel shaft eliminates corrosion and fatigue to give longer pump life.Theminimumshaftoverhangdecreasesdeflectionandincreasesbearingandseallife.Taperedshaftallowsforeasyremovalofimpeller.

F. Impeller – Hydromatic Non Clog pumps areavailable with a wide range of impellers fordifferent applications. Pump-out vanes on the top shroud prevent the buildup of materials in thesealareaandextendthe lifeof the thrustbearingbysignificantlyreducingaxialthrust.

G.Renewable Case Wear Ring – Reduces maintenance costs while maintaining the performanceofthepump.

A

C

D

E

F

G

B

C

D

Page 4Page 4

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

High Efficiency Saves You Money

Continuingsubmersibleimpellerdesignworkand refinement spanning over 30 years givesyouthemostenergyefficientpumpsavailable.

The above chart compares electrical powercostsofHYDROMATICpumpswiththreeotherpump manufacturers. For example, withHYDROMATIC pumps you save $4,628dollars in one year of continuous operation compared with manufacturer “A”. This morethanpaysforthepump!

Hydromatic pumps... work and keep working for years.

Dependable Operation

The HYDROMATIC pump’s oil-filled motorkeeps the windings cool, eliminates moisture,

and permanently lubricatesthe bearings, to providereliablepumpingservice.

First, the oil bath keepsthemotorandbearingscoolby dissipating heat andmaintaining the correctoperatingtemperature.

The oil transfers heatgenerated in the motorwindings to the housingwhereitisdissipatedbythesurroundingwetwellmedia.

Motor Windings

Oil

Outer Housing

Media

You get long pump life because the oil-filled motor dissipates heat from the windings, through the oil, to the outer housing and then the media.

S8FX S12L

ELECTRICAL POWER COSTS$10,000

$9,000

$8,000

$7,000

$6,000

$5,000

$4,000

$3,000

$2,000

$1,000

2,117(3 months)

4,235(6 months)

8,470(1 year)

MFR "A"15.8 HP

MFR "B"15 HP

MFR "C"14.8 HP

HYDROMATIC10 HP

Operating conditions:700 GMP @ 40' THD,7.5¢ / KW HR

OPERATING HOURS

HYDROMATIC pumps save you money because of their high efficiency design.

Page 5Page 5

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Second, the oil bath locks out airborne moisture contamination which destroys motors and bearings. Air carries moisture thatcondenseswithtemperaturechangesandcausesprematuremotorandbearingfailure.

Third,theoilbathpermanentlylubricatesthebearings which minimizes heat and flushes contaminantawayfrombearingraces.

Heat and contaminant cause grease breakdown.Thisbreakdownleadstoprematurefailure of grease-packed bearings supplied byother manufacturers. Oil-filled motors ensuredependable,reliableservice!

traps any moisture that may leak through thelowerseal.Theuppersealoperatesentirelyinoil.

Thelowersealis“self-sealing”withpressuresurges because it is located outside the chamber.Pressuresurgesfromthevolutepushthelowersealtightlyagainstthestationaryfacetopreventleakageintotheoilchamber.

Long-term Operation

The Dual Seal Systemgiveslongpumpservicelife.

ThemechanicalDualSealSystem protects the motorfrom water with one shaftsealatthetopandoneshaftseal below an oil chamber.The oil chamber provideslubricationforthesealsand

HYDROMATIC pumps use high performance, lowfriction,long-lastingcarbon-ceramicseals.Some manufacturers use very expensive seals that are available only from their own factory. HYDROMATIC pumps userepairable John Crane Type 21 mechanicalsealsthatareavailableoff-the-shelfworldwide. Tungsten-Carbide and Silicon-Carbide Sealsareoptional.

The dual seal design gives the pump exceptionallylongpumpservicelifebykeepingpumpedmediaoutofthemotorhousing.

Upper Seal

Air Pocket compresses with pressure to serve as damper

Lower Seal is outside the chamber

The mechanical dual seal system protects your motor from media contamination to provide you exceptionally long pump service.

S4MXS8LA

Page 6Page 6

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Hydromatic pumps... save money and decrease downtime.

Decrease Downtime

The moisture sensor, providedasstandardonallnon-clog pumps, savesmoney and decreasesdowntime by allowing youto take corrective actionbeforeanexpensivebearingormotorfailureoccurs.

Some manufacturers puta moisture sensor in the

motorarea.Moistureisdetectedafteritbeginsaffectingthebearingsandmotoritself. Reliable Operation

Three barriers providetriple protection againstmotor-damagingwater.

Two epoxy barriers and a compression fitting keepwater out of the motor soyou get long-term, reliableoperation.

Awater-tightsealatcableentry is ensured with a

single trumpet shaped elastomer grommetflankedbyawasherandcompressiongland.

Thetopepoxybarrierkeepswateroutoftheconnection box, and the lower barrier keepsmoistureoutof themotorareawhen thecord isdisconnected.

Leadsgoingthroughbothepoxybarriersarestripped down to bare wire at staggered intervalsandeachleadisindividuallyseparated.Thislead-encasingdesignprohibitsanywickingorcapillarywatermovementinsidethecord.

Motor Sensor

Oil

Outer Housing

You get long pump life because the oil-filled motor dissipates heat from the windings, through the oil, to the outer housing and the housing and then the media.

HYDROMATIC pumps incorporate aninternal moisture sensor that detects the presence of moisture in the oil chamber. Thesensor'ssignaltothewarningsystemletsyouknowthatthelowersealisbeginningtoleak.

This allows you to schedule maintenancewithin2 to4weekswhile thepumpcontinues tooperate.

The moisture sensor allows you to performmaintenance at your convenience instead ofreactingtoanemergencybreakdown.

S3HRC S4M

Page 7Page 7

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

1st Barrier Grommet

2nd Barrier Epoxy

3rd Barrier Epoxy

Stripped lead wire

Three barriers ensure a dry motor for long-term, reliable operation.

There is no terminal board to crack andinvitemotorburnout.

HYDROMATIC epoxy barriers are the mostprovensealingmethodavailable.

Low Maintenance

HYDROMATIC pumps are virtuallymaintenance free because the oil-filled designkeepsthemotorandbearingsbothfully lubricated and operating in the proper temperature range for very long life. You schedule and perform periodic maintenanceforbearingsandsealslessoftenthanrequiredbyothermanufacturers.

Easy-To-Service

The volute-mounted wear ring is easilyreplaceable. It is made of bronze or optionalstainless steel to give you long impeller life.HYDROMATIC pumps use a true wear ring,not a media lubricated bushing used by somemanufacturers.

The top pullout design makes it easy to disassemble the pump in one operation inordertoreplaceworncomponents,includingthe impeller. This reduces repair time anddowntime.

ThetaperedshaftavailableonmodelsS4Mand larger allows the impeller to be easilyremovedwithoutspecialtools.

Stators are easily field replaceable with standard tools. Stators are reliably held inplace with keys and a clamp ring. Somemanufacturers with press fit stators requirecompleteshopfacilitiesforreplacement.

The H Series

TheHseriesnon-clogpumpsprovidegreaterpump efficiency and steeper non-overloadingperformances while passing up to a full 3" spherical solid as is required by the “TenStates Standards” policy for submersible non-clog pumps. These pumps are availablewith horsepower ratings from 7.5 to 15 andspeeds up to 1750 RPM. These pumps are alsoavailablewithadependableHYDROMATIC pultruded lift-out railormetal-to-metal lift-outrailsystem.

The enhanced geometry of the mono-vaneimpeller creates a smoother design, allowingthe HYDROMATIC H series to passa full 3" spherical solid while maintaining highefficiency.

Page 8Page 8

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Hydromatic pumps... meet your special requirements.

Explosion-proof Pumps

ClassI,Division1,GroupCand/orD

When government regulations or area classificationsrequireexplosion-proofpumps,you can depend on HYDROMATIC submersiblenon-clogpumps.

You Get Rugged, Safe Pumps

Now you can get certified explosion-proofpumps for applications such as sewage wetwellswhereflammablegasesexist.

You Get Reliability and High Efficiency

With HYDROMATIC explosion-proofpumps, you get the same reliability and highefficiency designed into the non-explosion-proof pumps. Plus, you get added safetyadvantageswithFMapproved,explosion-proof,HYDROMATIC pumps.

Reliable,safeoperation isensuredbecauseall castingsare inspected forporositybefore,during and after machining. After assemblyeach explosion-proof pump is thoroughlyinspectedtoensurereliableperformance.

S4LVX

Page 9Page 9

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Recessed Impeller Option

HYDROMATIC pumps are available withrecessed impellerswhicharevirtually impossibleto clog and they perform up to shut-off head withoutdamage.

FLAME-PROOF JOINTS –Flame-proofjointshave 1-1/4" flame paths. These closetolerance jointspreventany internalsparkorfirefromescapingintotheenvironment.

MOTOR HOUSING – Theexplosion-proofhousingwallisthickerthroughoutthecasetogiveyouextracontainmentcapability.

HEAVY-DUTY BEARINGS – HYDROMATIC pumps provide you heavy-duty bearings(minimumB-10lifeof50,000hours)forlong pumplife.

2 MOISTURE SENSORS – Two moisturesensors in the oil chamber provide extrasecurity. The sensors are electrically isolated and made with stainless steel connectionsandstainlesssteelprobes.

LABYRINTH JOINT –Thespecial labyrinthjoint gives you added protection bypreventing flameor spark travel to themediabeingpumped.

Recessed Impeller

Recessed impeller pumps are ideal for a broadrangeofsewageandspecialwaste-handlingsituations includinghighheadandlowflowsandwherelargesolidsarepresent.

Therecessedimpellercreatesaliquidvortexinthevolutewhichdirectsallsphericalsolids,slurry,sludge,grit,stringyorfibrousmaterialthroughthepump without clogging. The pumps are virtuallyimpossibletoclog.

Flame-proof Joints

Recessed Impeller

You can also order the explosion-proof HYDROMATIC pump with the recessed impeller that's virtually impossible to clog.

Page 10

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Hydromatic pumps cover all your requirements.

5

10

TOTA

L D

YNA

MIC

HEA

D-F

EET

CAPACITY-G.P.M.

10

15

20

2530

40

5060708090

100

25 40 60 80 100 150 200 400 600 1000 2000 4000 8000

S8L

S4L

S4B

S3HX

S6A

S6L

S12L

S8FS4FS4N

S3N S3NXS

SHS4M

5

TOTA

L D

YNA

MIC

HEA

D-F

EET

CAPACITY-G.P.M.

10

15

202530

405060708090

100

80 150 250

150

200250300

40 60 100 400 600 1000 1500 2500 4000 6000

S4BS4L

S4M

S3HXS8FH4H

S6L

S4K

S4T

S6A

S8L S8LA

S12L

SH

S4FS4NS3N S3NX

S

H3H

S4P

H4Q

1750 RPM

1150 RPM

Page 11

Submersible Non-Clog Pumps Submersible Non-Clog Pumps

Hydromatic pumps cover all your requirements.

10

1520

3040

6080

TOTA

L D

YNA

MIC

HEA

D-F

EET

100120140

1750 RPM

CAPACITY-G.P.M.

15 25 40 60 100 150 250 400 600 1000 1300

S4MRCS4NRC

S4LRC

10

15

20

25

30

40

50

60

100 150 250 400 600 800 1000 1500 2500 4000 6000

TOTA

L D

YNA

MIC

HEA

D-F

EET

CAPACITY-G.P.M.

S6L

S12L

S8L

S4LS8F

S4B

S6A

3450 RPM

15 25 40 60 100 250 400 600 800

20

3040

6080

120160

TOTA

L D

YNA

MIC

HEA

D-F

EET

200240280

CAPACITY-G.P.M.

S4HRC

S4LRC

S3HRC

870 RPM

RANGE CHARTS FOR THE RECESSED IMPELLER

3450 RPM 1750 RPM

Submersible Non-Clog Pumps

System Operations

Item#:E-02-647005/09

Rail Systems for Easy Pump RetrievalTo easily raise and lower your pump(s) for

service and maintenance, you can choose fromamongthreerailsystems.

MTM Rail System

Hydr-O-Rail System

Pultruded Rail System

© 2009 Hydromatic® Ashland, Ohio. All Rights Reserved.

– Your Authorized Local Distributor –

USA740 East 9th Street, Ashland, Ohio 44805Tel: 419-289-3042 Fax: 419-281-4087 www.hydromatic.com

CANADA269 Trillium Drive, Kitchener, Ontario, Canada N2G 4W5

Tel: 519-896-2163 Fax: 519-896-6337

A New GenerationCustombuilttoyourspecificationsandindividually

tested,theHYDROMATICNOVUSSeriesisavailablein five different models: 1000, 1000 Plus, 2000,3000and4000.TheseriesstartswiththedependableyetinexpensiveHYDROMATICNOVUS1000SerieswhichfeaturesbasicrelaylogiccontrolsinaqualityNEMA3Rpaintedsteelenclosure.Thenextmodelis the HYDROMATIC NOVUS 1000 Plus SeriesofferingadditionalfeaturesinaNEMA4XenclosureforHydromatic2HPgrinderpackages.

The HYDROMATIC NOVUS 2000, 3000, and4000 Series offer more advanced features. Theseseriesutilizestate-of-the-artdigitalcontrollersthatare optimized for submersible pumps in simplex,duplexortriplexwastewaterliftstations.

Novus 2000 Simplex Controller Unit

Novus 2000 Duplex Controller Unit

![MPKWP NON-CLOG PUMPS - intMPEintmpe.com/Images/mpkwp.pdf · Type series booklet int MPE MPKWP NON-CLOG PUMP ... KWP K 100 - 250 Type series ... NPSH R η [%] Qmin Qmax ø500 84 ...](https://static.fdocuments.in/doc/165x107/5b362fdd7f8b9abc218e3944/mpkwp-non-clog-pumps-type-series-booklet-int-mpe-mpkwp-non-clog-pump-kwp.jpg)