Blower Business Group TURBO BLOWERS · 2308-14/1-t.5 60 t.50-c36t1sc 3 3 2923-8-14a " 2942-8-14a 80...

Transcript of Blower Business Group TURBO BLOWERS · 2308-14/1-t.5 60 t.50-c36t1sc 3 3 2923-8-14a " 2942-8-14a 80...

Blower Business Group

TURBO BLOWERS 4-44 OSI - 55-30,000 CFM

Bulletin 2300

SELECTIONPressures and capabilities are shown on the succeedingpages of this bulletin. While motors with 1.15 service factorsare more and more available, it is wise to allow some capac-ity safety margin when picking a blower for a calculated cfmrequirements--unanticipated piping leaks, variations in burnercapacity, and other unforeseen factors could cause motoroverload unless there is some cushion. Without prior know-ledge of leakage and other conditions, a 10% safety marginis considered minimum.

It is also important to allow for pressure losses in piping,fittings, and valves, which reduce pressure available at theburner (or other end use).

Altitude and preheated air effect blower ratings--pressure,capacity, and horsepower. For blower selection/performanceat altitudes significantly above sea level, the blower sectionof the North American Combustion Handbook is recom-

mended. Generally, standard motors can be used up to 3300feet elevation; special construction is recommended above3300 feet.

See Bulletin 2600 if Blower will handle air hotter than 250°F.

CONSTRUCTIONAll metal construction including mild steel, cast aluminum,or corrosion resistant stainless steel create a nearly inde-structible blower allowing for years of trouble free service.

Specially fabricated aluminum or steel impeller designsreduce vibration, lengthen motor life, and lower energy con-sumption due to lightweight construction technology.

Individual impeller dynamics assured by either single or twoplane balancing to minimize vibration and assure longerbearing life.

Strategically positioned bolt hole locations allow for in-fieldrepositioning of air flow discharge.

Standard shaft motors on most single stage blowers reducereplacement downtime in the field.

Standard inlet includes a guard. Threaded or SW unthreadedadapters can be specified in place of the guard for mount-ing optional filters or silencers, or if a 2947 blower sleevewill be used to accommodate inlet piping.

Blowers with 8" or larger discharge are supplied with SWunthreaded adapter suitable for a flexible sleeve or welding.Blowers with 6" or smaller discharge normally have athreaded (fpt) flange, but the SW unthreaded discharge canbe specified at no extra cost.Typical 2300 Blower Installation

June 1998

FEATURES� Widest range of sizes available in the turbo blower

market to meet the needs of the combustion, drying,and process industries.

� Energy efficient 60 hertz motors on all blowers5 hp and above that meet or exceed the 1992 EnergyAct which became effective in 1997.

� High volume blowers are available in 1800 rpm or 3600rpm with single or multiple stage designs to meet theneeds of the most demanding situations.

� Horsepower and impeller selection designed to achieveflat performance curves to minimize variations overthe operating range of the blower.

� Full array of accessories include filters, silencers, filter silencers, inlet and outlet adapters, flexible sleeves,inlet vane dampers, AC frequency drives, combination motor starters and fusible disconnects. Theseoptions offer the protection needed to keep operational costs down while increasing blower life expectancy.

Blower shown withoptional 2923 Filter

BLOWER DESIGNATION EXPLANATION

example: 2308-24/1-T2D

2300 series drive: Direct (D)nominal pressure drive: Coupled (C)case designation drive: V-belt (V)number of stages horsepower

motor TEFC (T)less motor (L)

Standard discharge positions (viewed from motor side).See Supplement 2300-3 for other positions.

60 50 & 60 60cfm at Inlet Outlet Hertz Hertz Hertz

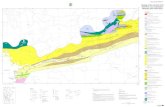

Nominal 100% of 3600 rpm nominal nominal Intake Intake Filter Direct V-Belt Coupledpressure Blower motor TEFC pipe pipe Intake Filter Silencer Silencer drive drive driveosi/"wc designation rating 1.15 SF motor size size designation 2936- designation (D) ( V ) (C)

4 osi 2304-11/1-T.3 110 T.33-C36T1SC 3 2 2923-8-11A None 2942-8-11A 40 100 1006.92"wc

2308-11/3-T.5 55 T.50-C36T1L4.0C 3 2 2923-8-11A None 2942-8-11A 50 110 1102308-14/1-T.5 60 T.50-C36T1SC 3 3 2923-8-14A " 2942-8-14A 80 230 2102308-14/1-T.75 170 T.75-C36T1SC 3 3 2923-8-14A " 2942-8-14A 80 230 2102308-17/1-T1 220 T1.0-C36T1SC 3 4 2923-8-17A " 2942-8-17A 90 320 2602308-14/1-T1 250 T1.0-C36T1SC 3 3 2923-8-14A " 2942-8-14A 80 230 210

2308-17/1-T1.5 390 T1.5-C36T1SC 4 6 2923-10-17A None 2942-10-17A 120 320 2602308-24/1-T2 460 T2.0-C36T1SC 6 6 2923-10-24A 8-24 2942-10-24A 150 470 4002308-24/1-T3 770 T3.0-C36T1SC 6 8 2923-12-24A 8-24 2942-12-24A 170 490 4202308-31/1-T5 1200 T5.0-C36T1SC 8 10 2923-18-31A 9-31 294218-31A 240 700 5002308-31/1-T7.5 1900 T7.5-C36T1SC 8 10 2923-18-31A 9-31 2942-18-31A 280 750 5502308-21/1-T10 2600 T10-C36T1SC 10 12 2923-22-21A 10-21 2942-22-21A 570 950 700

2310-11/4-T.5 80 T.50-C36T1L5.2 3 2 2923-8-11A None 2942-8-11A 60 120 2102310-19/1-T.75 70 T.75-C36T1SC 3 3 2923-8-19A " 2942-8-19A 90 300 3002310-19/1-T1 150 T1.0-C36T1SC 3 4 2923-8-19A " 2942-8-19A 90 300 3002310-19/1-T1.5 290 T1.5-C36T1SC 4 6 2923-8-19B " 2942-8-19B 130 340 340

2310-19/1-T2 400 T2.0-C36T1SC 4 6 2923-10-19A None 2942-10-19A 140 350 3502310-26/1-T3 580 T3.0-C36T1SC 6 6 2923-10-26A 8-26 2942-10-26A 190 500 5002310-26/1-T5 1000 T5.0-C36T1SC 6 8 2923-12-26A 8-26 2942-12-26A 210 520 520

10 osi 2310-35/1-T7.5 1500 T7.5-C36T1SC 8 10 2923-18-35A 9-35 2942-18-35A 430 800 60017.3"wc

2310-21/1-T10 1900 T10-C36T1SC 10 12 2923-22-21A 10-21 2942-22-21A 580 950 7002310-39/1-T50 12850 T50-C36T1SD 22 24 2921-1802-8/39 18-39 2941-1802-8/39 1250 – –2310-39/1-T60 15000 T60-C36T1SD 24 24 2921-2403-12/39 24-39 2941-2403-12/39 1510 – –2310-39/1-T75 18300 T75-C36T1SD 24 24 2921-2403-12/39 24-39 2941-2403-12/39 1620 – –2310-39/1-T100 24000 T100-C36T1SD 26 26 1820 – –2310-39/1-T125 28000 T125-C36T1SD 26 30 2400 – –

2312-11/4-T.5 50 T.50-C36T1L5.2C 3 2 2923-8-11A None 2942-8-11A 60 120 1202312-19/1-T1 100 T1.0-C36T1SC 3 3 2923-8-19A " 2942-8-19A 90 300 3002312-19/1-T1.5 220 T1.5-C36T1SC 4 4 2923-8-19B " 2942-8-19B 130 340 3402312-19/1-T2 340 T2.0-C36T1SC 4 6 2923-8-19B " 2942-8-19B 140 350 350

2312-26/1-T3 450 T3.0-C36T1SC 6 6 2923-10-26A 8-26 2942-10-26A 190 500 5002312-26/1-T5D 850 T5.0-C36T1SC 6 8 2923-14-26A 8-26 2942-14-26A 210 520 5202312-35/1-T7.5 1400 T7.5-C36T1SC 8 8 2923-18-35A 9-35 2942-18-35A 430 800 600

12 osi 2312-35/1-T10 1700 T10-C36T1SC 8 10 2923-18-35A 9-35 2942-18-35A 450 820 62020.76"wc

2312-21/1-T15 2600 T15-C36T1SC 10 12 2923-22-21B 14-21 2942-22-21B 600 1000 7502312-34/1-T20 4000 T20-C36T1SD 14 16 2923-30-34A 14-34 2942-30-34A 710 – –2312-34/1-T25 4900 T25-C36T1SD 14 16 2923-30-34A 14-34 2942-30-34A 850 – –2312-34/1-T30 5500 T30-36CT1SD 16 20 2923-30-34B 16-34 2942-30-34B 1030 – –2312-34/1-T40 7300 T40-C36T1SD 16 20 2921-1602-8/34 16-34 2941-1602-8/34 1150 – –2312-37/1-T50 10100 T50-C36T1SD 18 22 2921-1802-8/37 18-37 2941-1802-8/37 1200 – –2312-37/1-T60 12050 T60-C36T1SD 18 24 2921-1802-8/37 18-37 2941-1802-8/37 1460 – –

2316-14/2-T1 90 T1.0-C36T1L5.5C 3 3 2923-8-14A None 2942-8-14A 100 250 2302316-14/2-T1.5 150 T1.5-C36T1L6.7C 3 3 2923-8-14A " 2942-8-14A 140 290 2702316-17/2-T1.5 150 T1.5-C36T1L6.7C 4 4 2923-8-17B " 2942-8-17B 110 345 2852316-19/1-T2 150 T2.0-C36T1SC 4 4 2923-8-19B " 2942-8-19B 140 350 350

2316-17/2-T2 220 T2.0-C36T1L6.7C 4 4 2923-8-17B None 2942-8-17B 140 340 3802316-26/1-T3 290 T3.0-C36T1SC 6 6 2923-8-26A 8-26 2942-8-26A 300 605 4902316-17/2-T3 340 T3.0-C36T1L6.7C 4 6 2923-10-17A None 2942-10-17A 160 360 4002316-19/1-T3 340 T3.0-C36T1SC 4 6 2923-10-19A " 2942-10-19A 160 370 370

Approx. weight, lb

8 osi13.84"wc

16 osi27.68"wc

Consult Cleveland

1 2 3 4

Bulletin 2300 Page 2

60 50 & 60 60cfm at Inlet Outlet Hertz Hertz Hertz

Nominal 100% of 3600 rpm nominal nominal Intake Intake Filter Direct V-Belt Coupledpressure Blower motor TEFC pipe pipe Intake Filter Silencer Silencer drive drive driveosi/"wc designation rating 1.15 SF motor size size designation 2936- designation (D) (V) (C)

2316-24/2-T3 350 T3.0-C36T1L7.0C 6 6 2923-8-24A 8-24 2942-8-24A 205 510 4352316-24/2-T5 600 T5.0-C36T1L7.0C 6 6 2923-10-24A 8-24 2942-10-24A 220 530 4702316-28/1-T5 600 T5.0-C36T1SC 8 6 2923-14-28A 9-28 2942-14-28A 215 720 5702316-26/1-T5 620 T5.0-C36T1SC 6 6 2923-12-26A 8-26 2942-12-26A 220 530 530

2316-31/2-T7.5 850 T7.5-C36T1L8.3C 8 8 2923-14-31A 9-31 2942-14-31A 320 790 5902316-28/1-T7.5 950 T7.5-C36T1SC 8 6 2923-14-28A 9-28 2942-14-28A 235 810 6302316-26/1-T7.5 1000 T7.5-C36T1SC 6 8 2923-14-26A 8-26 2942-14-26A 260 570 5702316-31/2-T10 1200 T10-C36T1L8.3C 8 8 2923-18-31A 9-31 2942-18-31A 340 810 610

2316-35/1-T10 1300 T10-C36T1SC 8 8 2923-18-35B 9-35A 2942-18-35B 460 830 6302316-21/1-T15 1950 T15-C36T1SC 10 10 2923-22-21A 10-21 2942-22-21A 425 1150 8852316-35/1-T15 2000 T15-C36T1SC 8 10 2923-18-35B 9-35A 2942-18-35B 490 860 6602316-21/1-T20 2700 T20-C36T1SC 10 10 2923-22-21A 10-21 2942-22-21A 670 1050 820

2316-33/1-T25 3300 T25-C36T1SC 12 12 2923-22.5-33A 12-33 2942-22.5-33A 1100 1900 14002316-33/1-T30 4100 T30-C36T1SC 12 14 2923-30-33A 12-33 2942-30-33A 1200 2000 15002316-37/1-T40 5300 T40-C36T1SD 16 18 2923-30-37A 16-37 2942-30-37A 1090 – –2316-37/1-T50 6730 T50-C36T1SC 16 18 2921-1602-8/37 16-37 2941-1602-8/37 1100 – –2316-37/1-T60 8650 T60-C36T1SD 18 24 2921-1802-8/37 16-37 2941-1802-8/37 1420 – –2316-37/1-T75 11000 T75-C36T1SD 18 24 2921-1802-8/37 18-37 2941-1802-8/37 1570 – –2316-37/1-T100 14500 T100-C36T1SD 20 24 2921-2003-12/37 20-37 2941-2003-12/37 1730 – –

2320-19/2-T1.5 100 T1.5-C36T1L6.7C 3 3 2923-8-19A None 2942-8-19A 160 370 3702320-19/2-T2 170 T2.0-C36T1L6.7C 4 4 2923-8-19B " 2942-8-19B 170 380 3802320-19/2-T3 290 T3.0-C36T1L7.0C 4 4 2923-8-19B " 2942-8-19B 190 400 4002320-26/2-T5 500 T5.0-C36T1L7.0C 6 6 2923-10-26A 8-26 2942-10-26A 260 570 5702320-26/2-T7.5 720 T7.5-C36T1L7.0C 6 6 2923-12-26A 8-26 2942-12-26A 300 610 610

2320-35/1-T10 1000 T10-C36T1SC 8 8 2923-14-35B 9-35A 2942-14-35B 470 840 6402320-21/1-T15 1500 T15-C36T1SC 10 8 2923-18-21A 10-21 2942-18-21A 625 1150 8852320-35/1-T15 1700 T15-C36T1SC 8 8 2923-18-35B 9-35A 2942-18-35B 550 920 7202320-21/1-T20 2100 T20-C36T1SC 10 10 2923-22-21A 10-21 2942-22-21A 680 1050 830

20 osi 2320-33/1-T25 2900 T25-C36T1SC 12 12 2923-22.5-33A 12-33 2942-22.5-33A 1100 1900 140034.60"wc 2320-33/1-T30 3400 T30-C36T1SC 12 12 2923-22.5-33A 12-33 2942-22.5-33A 1200 2000 1500

2320-33/1-T40 4500 T40-C36T1SC 12 14 2923-30-33A 12-33 2942-30-33A 1250 2050 15502320-33/1-T50 5800 T50-C36T1SC 12 14 2921-1202-6/33 12-33 2941-1202-6/33 1800 2400 2300

2320-37/1-T60 7700 T60-C36T1SD 18 20 2921-1802-8/37 18-37 2941-1802-8/37 1410 – –2320-37/1-T75 8900 T75-C36T1SD 18 20 2921-1802-8/37 18-37 2941-1802-8/37 1490 – –2320-37/1-T100 11830 T100-C36T1SD 18 22 2921-1802-8/37 18-37 2941-1802-8/37 1620 – –2320-37/1-T125 14800 T125-C36T1SD 20 26 2921-2003-12/37 20-37 2941-2003-12/37 2360 – –2320-37/1-T150 17800 T150-C36T1SD 22 26 2921-2403-12/37 24-37 2941-2403-12/37 2500 – –

2324-14/3-T1.5 80 T1.5-C36T1L9.0C 3 3 2923-8-14A None 2942-8-14A 160 310 2902324-14/3-T2 120 T2.0-C36T1L9.0C 3 3 2923-8-14A " 2942-8-14A 170 320 3002324-19/2-T3 210 T3.0-C36T1L7.0C 4 4 2923-8-19B " 2942-8-19B 100 400 4002324-26/2-T5 370 T5.0-C36T1L7.0C 6 6 2923-10-26A 8-26 2942-10-26A 260 570 570

2324-26/2-T7.5 600 T7.5-C36T1L7.0C 6 6 2923-12-26A 8-26 2942-12-26A 300 610 6102324-35/2-T10 810 T10-C36T1L8.3C 8 8 2923-14-35A 9-35 2942-14-35A 520 890 6902324-35/2-T15 1400 T15-C36T1L8.3C 8 8 2923-18-35A 9-35 2942-18-35A 550 920 7202324-21/1-T20 1800 T20-C36T1SC 10 10 2923-18-21A 10-21 2942-18-21A 680 1050 830

2324-33/1-T25 2400 T25-C36T1SC 12 12 2923-22-33A 12-33 2942-22-33A 1100 1900 14002324-33/1-T30 2800 T30-C36T1SC 12 12 2923-22-33A 12-33 2942-22-33A 1200 2000 15002324-33/1-T40 3700 T40-C36T1SC 12 12 2923-30-33A 12-33 2942-30-33A 1250 2050 15502324-33/1-T50 5200 T50-C36T1SC 14 14 2921-1402-6/33 12-33 2941-1202-6/33 1350 2150 1650

2324-33/1-T60 6200 T60-C36T1SC 14 14 2921-1402-8/33 14-33 2941-1402-8/33 1400 2200 17002324-37/1-T75 7300 T75-C36T1SD 16 20 2921-1602-8/37 16-37 2941-1602-8/37 1490 – –2324-37/1-T100 10000 T100-C36T1SD 18 24 2921-1802-8/37 18-37 2941-1802-8/37 1690 – –2324-37/1-T125 12400 T125-C36T1SD 18 24 2921-1802-8/37 18-37 2941-1802-8/37 2230 – –2324-37/1-T150 14800 T150-C36T1SD 22 24 2921-2403-12/37 24-37 2941-2403-12/37 2370 – –

2332-19/3-T3 90 T3.0-C36T1L10.6C 4 4 2923-8-19B None 2942-8-19B 190 400 40032 osi 2332-19/3-T5 260 T5.0-C36T1L10.6C 4 4 2923-8-19B " 2942-8-19B 210 420 42055.36"wc 2332-28/2-T7.5 330 T7.5-C36T1L8.3C 8 6 2923-14-28A 9-28 2942-14-28A 380 650 700

2332-28/2-T10 600 T10-C36T1L8.3C 8 6 2923-14-28A 9-28 2942-14-28A 400 670 720

Approx. weight, lb

24 osi41.52"wc

16 osi27.68"wc

Bulletin 2300 Page 3

60 50 & 60 60cfm at Inlet Outlet Hertz Hertz Hertz

Nominal 100% of 3600 rpm nominal nominal Intake Intake Filter Direct V-Belt Coupledpressure Blower motor TEFC pipe pipe Intake Filter Silencer Silencer drive drive driveosi/"wc designation rating 1.15 SF motor size size designation 2936- designation (D) (V) (C)

2332-28/2-T15 900 T15-C36T1L8.3C 8 6 2923-14-28A 9-28 2942-14-28A 430 700 7502332-21/2-T20 1100 T20-C36T1L10.0C 10 8 2923-18-21A 10-21 2942-18-21A 680 1050 8302332-21/2-T25 1500 T25-C36T1L10.7C 10 8 2923-18-21A 10-21 2942-18-21A 710 1100 8602332-21/2-T30 1800 T30-C36T1L10.7C 10 8 2923-18-21A 10-21 2942-18-21A 780 1150 9302332-21/2-T40 2400 T40-C36S1L10.7C 10 8 2923-22-21A 10-21 2942-22-21A 810 1200 960

32 osi55.36"wc 2332-33/2-T50 3200 T50-C36T1L12.0C 12 12 2923-22.5-33A 12-33 2942-22.5-33A 1450 2250 1750

2332-33/2-T60 3900 T60-C36T1L12.0D 12 12 2923-30-33A 12-33 2942-30-33A 1500 2300 18002332-37/1-T75 6050 T75-C36T1SD 16 20 2921-1602-8/37 16/37 2941-1602-8/37 1700 – –2332-37/1-T100 8350 T100-C36T1SD 16 24 2921-1602-8/37 16/37 2941-1602-8/37 1850 – –2332-37/1-T125 10300 T125-C36T1SD 16 24 2921-1602-8/37 16/37 2941-1602-8/37 2400 – –2332-37/1-T150 12050 T150-C36T1SD 18 24 2921-1802-8/37 18/37 2941-1802-8/37 2520 – –

2344-28/3-T15 640 T15-C36T1L13.5C 8 6 2923-14-28A 9-28 2942-14-28A 510 780 830

44 osi 2344-28/3-T20 900 T20-C36T1L13.5C 8 6 2923-14-28A 9-28 2942-14-28A 580 850 900

76.12"wc 2344-21/2-T30 1400 T30-C36T1L10.7C 10 8 2923-18-21A 10-21 2942-18-21A 780 1150 9302344-21/2-T40 1900 T40-C36S1L10.7C 10 8 2923-18-21A 10-21 2942-18-21A 810 1200 9602344-21/2-T50 2500 T50-C36S1L10.7C 10 8 2923-22-21A 10-21 2942-22-21A 900 1300 1050

1800 rpm2308-44/1-T10 2700 T10-C18T1SC 16 16 2923-30-44A 16-44 2942-30-44A 1400 2100 20002308-44/1-T15 4100 T15-C18T1SC 16 16 2923-30-44A 16-44 2942-30-44A 1450 2150 20502308-44/1-T20 5500 T20-C18T1SC 16 18 2921-1602-6/44 16-44 2941-1602-6/44 1500 2200 2100

8 osi13.84"wc 2308-44/1-T25 6500 T25-C18T1SC 16 18 2921-1602-8/44 16-44 2941-1602-8/44 1650 2300 2200

2308-44/1-T30 7200 T30-C18T1SC 16 18 2921-1602-8/44 16-44 2941-1602-8/44 1650 2350 22502308-47/1-T40 10000 T40-C18T1SC 24 24 2921-2403-12/47 24/47 2941-2403-12/47 1800 2100 21002308-47/1-T50 12500 T50-C18T1SC 24 24 2921-2403-12/47 24/47 2941-2403-12/47 1850 2200 2200

10 osi 2310-47/1-T40 8000 T40-C18T1SC 24 20 2923-2403-12/47 24-47 2941-2403-12/47 1800 2100 210017.30"wc 2310-47/1-T50 10500 T50-C18T1SC 24 24 2923-2403-12/47 24-47 2941-2403-12/47 1850 2200 2200

2312-41/1-T20 4000 T20-C18T1SC 16 16 2923-30-41A 16-41 2942-30-41A 1500 2200 21002312-41/1-T25 4900 T25-C18T1SC 16 16 2923-30-41A 16-41 2942-30-41A 1600 2300 2200

12 osi 2312-41/1-T30 5500 T30-C18T1SC 16 16 2921-1602-6/41 16-41 2941-1602-6/41 1650 2350 225020.76"wc 2312-47/1-T40 7100 T40-C18T1SC 24 18 2921-2403-12/47 24-47 2941-2403-12/47 1900 2200 2200

2312-41/1-T40 7300 T40-C18T1SC 16 18 2921-1602-8/41 16-41 2941-1602-8/41 1750 2450 23502312-47/1-T50 10000 T50-C18T1SC 20 20 2921-2403-12/47 24-47 2941-2403-12/47 1950 2300 2300

2316-41/1-T20 3000 T20-C18T1SC 16 12 2923-30-41A 16/41 2942-30-41A 1500 2200 21002316-41/1-T25 3700 T25-C18T1SC 16 12 2923-30-41A 16/41 2942-30-41A 1600 2200 2100

16 osi 2316-41/1-T30 4500 T30-C18T1SC 16 16 2923-30-41A 16/41 2942-30-41A 1650 2250 215027.68"wc 2316-41/1-T40 5500 T40-C18T1SC 16 16 2921-1602-6/41 16/41 2941-1602-6/41 1750 2350 2250

2316-41/1-T50 7000 T50-C18T1SC 16 16 2921-1602-8/41 16/41 2941-1602-8/41 1800 2400 23002316-47/1-T75V 11500 T75-C18T1SD 20 24 2921-2403-12/47 24/47 2941-2403-12/47 – 2400 –

2320-41/1-T25 2600 T25-C18T1SC 16 12 2923-30-41A 16-41 2942-30-41A 1600 2200 2100

20 osi 2320-41/1-T30 3300 T30-C18T1SC 16 12 2923-30-41A 16-41 2942-30-41A 1650 2250 2150

34.6"wc 2320-41/1-T40 4500 T40-C18T1SC 16 16 2923-30-41A 16-41 2942-30-41A 1750 2350 22502320-41/1-T50 5800 T50-C18T1SC 16 16 2921-1602-6/41 16-41 2941-1602-6/41 1800 2400 23002320-41/1-T60 7300 T60-C18T1SD 16 16 2921-1602-8/41 16-41 2941-1602-8/41 1900 2500 2400

2324-41/1-T30V 2300 T30-C18T1SC 16 12 2923-30-41A 16-41 2942-30-41A – 2250 –2324-41/1-T40V 3500 T40-C18T1SC 16 12 2923-30-41A 16-41 2942-30-41A – 2350 –2324-41/1-T50V 4700 T40-C18T1SC 16 16 2923-30-41A 16-41 2942-30-41A – 2400 –

2324-41/1-T60V 6200 T60-C18T1SD 16 16 2921-1602-8/41 16-41 2941-1602-8/41 – 2500 –2324-41/1-T75V 7900 T75-C18T1SD 16 16 2921-1602-8/41 16-41 2941-1602-8/41 – 2550 –

32 osi 2332-41/2-T75C 4500 T75-C18T1SD 16 12 2923-30-41A 16-41 2942-30-41A – – 2850

55.36"wc 2332-41/2-T100C 6200 T100-C18T1SD 16 16 2921-1602-8/41 16-41 2941-1602-8/41 – – 29002332-41/2-T125C 7100 T125-C18T1SD 16 16 2921-1602-8/41 16-41 2941-1602-8/41 – – 3100

38 osi 2338-41/2-T75C 3800 T75-C18T1SD 16 12 2923-30-41A 16-41 2942-30-41A – – 285065.74"wc 2338-41/2-T100C 5600 T100-C18T1SD 16 12 2921-1602-6/41 16-41 2941-1602-6/41 – – 2900

Printed in USA NA700-B2300

Approx. weight, lb

24 osi41.52"wc

WARNING: Situations dangerous to personnel and property can develop from incorrect operation of combustion equipment.North American urges compliance with National Safety Standards and Insurance Underwriters recommendations, and care in operation.

North American Mfg. Co., 4455 East 71st Street, Cleveland, OH 44105-5600 USA, Phone 216-271-6000, Facsimile 216-641-7852E-mail [email protected] l www.namfg.com

Bulletin 2300Page 4

November 2000

Series 2300 DIRECT DRIVE TURBO BLOWERS

Dimensions 2300-D

All dimensions are in inches. Dimensions shown apply only to blowers with T-frame motors. Consult North American Mfg. Co. for dimensionsof blowers with other motors.

BlowerDesignation« A B C D E F G H J K L P Q R S T� U� V Z* F+K G+K

2304-11/1-�.3D 2§ 15/16 105/8 137/16 73/16 99/16§ 83/4 59/16 81/2 7 23/8 n � 3/4 3 4 1611/163/4 � 169/16§ 153/4

2304-44/1-�10D 18� 115/8 51/2 321/16 28 425/16� 311/2 187/8 34 277/16 233/4 93/4 177/8 1 16 33/4 321/8 311/16 � 693/4� 5815/16

2308-11/3-T.5D 2§ 31/2 105/8 159/16 73/16 99/16§ 83/4 59/16 81/2 7 23/8 n � 3/4 3 4 1813/163/4 � 169/16§ 153/4

2308-14/1-�.5D 3§ 21/8 6 133/8 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 169/1613/16 � 235/8§ 2213/16

2308-14/1-�.75D 3§ 21/8 6 133/8 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 169/1613/16 � 235/8§ 2213/16

2308-14/1-�1D 3§ 21/8 6 133/8 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 169/1613/16 � 235/8§ 2213/16

2308-17/1-�1D 4§ 211/16 6 145/16 11 131/16§ 121/4 81/4 111/2 109/16 51/2 4 � 3/4 3 4 171/213/16 � 235/8§ 2213/16

2308-17/1-�1.5D 6§ 211/16 6 145/16 12 167/8§ 121/4 81/4 111/2 109/16 51/2 4 � 3/4 4 4 171/213/16 � 277/16§ 2213/16

2308-24/1-�2D 6§ 37/8 47/8 16 131/8 155/16§ 133/4 9 131/2 125/16 6 51/4 � 3/4 6 4 1813/16 13/16 � 275/8§ 261/16

2308-24/1-�3D 8� 37/8 47/8 16 135/16 1911/16� 133/4 9 131/2 125/16 6 51/4 � 3/4 6 4 1813/16 13/16 � 32� 261/16

2308-31/1-�5D 10� 35/16 51/4 173/4 155/8 303/8� 181/4 101/4 18 147/8 63/8 67/8 � 3/4 8 4 201/4 11/2 7/8 451/4� 331/82308-31/1-�7.5dD 10� 35/16 51/4 173/4 155/8 303/8� 181/4 101/4 18 147/8 63/8 67/8 � 3/4 8 4 201/4 11/2 � 451/4� 331/82308-31/1-�7.5tD 10� 35/16 73/4 201/4 155/8 303/8� 181/4 101/4 18 147/8 7 67/8 � 3/4 8 4 223/4 11/2 7/8 451/4� 331/82308-21/1-�10D 12� 315/16 53/4 215/16 205/8 387/16� 251/2 137/8 25 193/4 71/4 89/16 � 3/4 10 4 231/16 21/4 21/4 583/16� 451/42308-44/1-�10D 16� 111/2 51/2 3115/16 28 457/16� 311/2 187/8 34 277/16 233/4 93/4 177/8 1 16 33/4 32 311/16 � 727/8� 5815/16

2308-44/1-�15D 16� 111/2 51/2 3115/16 28 457/16� 311/2 187/8 34 277/16 233/4 93/4 177/8 1 16 33/4 32 311/16 � 727/8� 5815/16

2308-44/1-�20D 18� 111/2 51/2 3115/16 28 457/16� 311/2 187/8 34 277/16 233/4 93/4 177/8 1 16 33/4 32 311/16 11/2 727/8� 5815/16

2308-44/1-�25D 18� 111/2 71/2 3315/16 28 457/16� 311/2 187/8 34 277/16 233/4 93/4 177/8 1 16 33/4 32 311/16 � 727/8� 5815/16

2308-44/1-�30D 18� 111/2 71/2 3315/16 28 457/16� 311/2 187/8 34 277/16 233/4 93/4 177/8 1 16 33/4 32 311/16 21/2 727/8� 5815/16

2308-47/1-�40D 24� 123/8 8 393/16 331/2 547/16� 35 201/2 38 313/16 267/8 13 223/4 1 24 6 407/8 45/161/2 855/8� 663/16

2308-47/1-�50D 24� 123/8 8 393/16 331/2 547/16� 35 201/2 38 313/16 267/8 13 223/4 1 24 6 407/8 45/16 2 855/8� 663/16

« Explanation of designation: 2304-11/1-�.3D means Series 2300, 4 osi pressure, inner housing no. 11, 1 stage, 1/3 hp motor, direct drive.d With drip-proof motor, if dimensions are different from TEFC. t With TEFC motor, if dimensions are different from drip-proof.* Z = Motor overhang for TEFC motors. There is no overhang for drip-proof motors, except 2320-33/1-�40D and 2324-33/1-�40D which overhang 1/2".� Listed T & U dimensions are for SW inlet. For threaded inlet, T is 5/16" for inner housing no. 11, 1/2" for others. If S is greater than 6", threaded inlet is

not available.� SW discharge (unthreaded pipe) is standard and is included in F. nDischarge C is 109/16" from farthest base hole, for inner housing no. 11.§ Female pipe thread is standard. If SW discharge (unthreaded pipe) is specified, add 31/4" to F.I 5 holes when No. 4 discharge is furnished.¨ Number 4 discharge position, straight down, can be furnished on special order, a notch having to be cut out of the base at time of assembly, except

for blowers with #11 or #35 cases, no modification is required.

DIMENSIONS SHOWN ARE SUBJECT TO CHANGE. PLEASE OBTAIN CERTIFIED PRINTS FROM NORTH AMERICAN MFG. CO.IF SPACE LIMITATIONS OR OTHER CONSIDERATIONS MAKE EXACT DIMENSION(S) CRITICAL.

A� Discharge Nominal Pipe Size--female pipe thread for 6" and smaller,unthreaded pipe (SW) for 8" and larger.

CL

L

All dimensions are in inches. Dimensions shown apply only to blowers with T-frame motors. Consult North American Mfg. Co. for dimensionsof blowers with other motors.

BlowerDesignation« A B C D E F G H J K L P Q R S T� U� V Z* F+K G+K

2310-11/4-T.5D 2§ 411/16 105/8 163/4 73/16 99/16§ 83/4 59/16 81/2 7 23/8 n � 3/4 3 4 20 3/4 � 169/16§ 153/4

2310-19/1-�.75D 3§ 213/16 61/4 15 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 3 4 183/1613/16 � 287/8§ 285/16

2310-19/1-�1D 4§ 213/16 61/4 15 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 3 4 183/1613/16 � 287/8§ 285/16

2310-19/1-�1.5D 6§ 213/16 61/4 15 141/2 193/8§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 183/1613/16 � 3211/16§ 285/16

2310-19/1-�2D 6§ 213/16 61/4 15 141/2 193/8§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 183/1613/16 � 3211/16§ 285/16

2310-26/1-�3D 6§ 37/8 51/4 169/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 � 329/16§ 312310-26/1-�5D 8� 37/8 51/4 169/16 1513/16 223/16� 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 1 3615/16� 312310-35/1-�7.5D 10� 23/4 73/4 193/4 183/4 353/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 221/4 11/2 13/16 543/4� 393/16

2310-21/1-�10D 12� 315/16 53/4 215/16 205/8 387/16§ 251/2 137/8 25 193/4 71/4 89/16 � 3/4 10 4 231/16 21/4 23/8 583/16� 451/42310-47/1-�40D 20� 123/8 8 393/16 331/2 547/16� 35 201/2 38 313/16 267/8 13 223/4 1 24 � � 45/16

9/16 855/8� 663/16

2310-47/1-�50D 24� 123/8 8 393/16 331/2 547/16� 35 201/2 38 313/16 267/8 13 223/4 1 24 � � 45/16 2 855/8� 663/16

2312-11/4-T.5D 2§ 411/16 105/8 163/4 73/16 99/16§ 83/4 59/16 81/2 7 23/8 n � 3/4 3 4 20 3/4 � 169/16§ 153/4

2312-19/1-�1D 3§ 213/16 61/4 15 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 3 4 183/1613/16 � 287/8§ 285/16

2312-19/1-�1.5D 4§ 213/16 61/4 15 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 183/1613/16 � 287/8§ 285/16

2312-19/1-�2D 6§ 213/16 61/4 15 131/2 193/8§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 183/1613/16 � 3211/16§ 285/16

2312-26/1-�3D 6§ 37/8 51/4 169/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 � 329/16§ 312312-26/1-�5D 8� 37/8 51/4 169/16 1513/16 223/16� 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 1 3615/16� 312312-35/1-�7.5D 8� 23/4 73/4 193/4 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 221/4 11/2 13/16 543/4� 393/16

2312-35/1-�10D 10� 23/4 73/4 193/4 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 221/4 11/2 21/4 543/4� 393/16

2312-21/1-�15dD 12� 37/8 53/4 221/4 205/8 387/16� 251/2 137/8 25 193/4 71/4 89/16 � 3/4 14 33/4 223/4 31/4 � 583/16� 451/42312-21/1-�15tD 12� 37/8 93/4 263/4 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 14 33/4 271/4 31/4 1/2 583/16� 451/42312-41/1-�20D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 � 825/8� 7111/16

2312-41/1-�25D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 � 825/8� 7111/16

2312-41/1-�30D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/165/8 825/8� 7111/16

2312-47/1-�40D 18� 123/8 8 393/16 331/2 547/16� 35 201/2 38 313/16 267/8 13 223/4 1 24 � � 45/161/2 855/8� 663/16

2312-41/1-�40D 18� 125/16 8 367/8 341/4 4513/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 11/2 791/2� 7111/16

2312-47/1-�50D 20� 123/8 8 393/16 331/2 547/16� 35 201/2 38 313/16 267/8 13 223/4 1 24 � � 45/16 2 855/8� 663/16

2316-14/2-�1D 3§ 53/8 6 165/8 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 1913/1613/16 � 235/8§ 2213/16

2316-14/2-�1.5D 3§ 53/8 6 165/8 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 1913/1613/16 � 235/8§ 2213/16

2316-17/2-�1.5D 4§ 515/16 6 179/16 11 131/16§ 121/4 81/4 111/2 109/16 51/2 4 � 3/4 4 4 203/413/16 � 235/8§ 2213/16

2316-17/2-�2D 4§ 515/16 6 179/16 11 131/16§ 121/4 81/4 111/2 109/16 51/2 4 � 3/4 4 4 203/413/16 � 235/8§ 2213/16

2316-19/1-�2D 4§ 31/4 61/4 157/16 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 185/813/16 � 287/8§ 285/16

2316-19/1-�3D 6§ 31/4 61/4 157/16 141/2 193/8§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 185/813/16 � 3211/16§ 285s/16

2316-26/1-�3D 6§ 37/8 51/4 169/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 � 329/16§ 312316-17/2-�3D 6§ 515/16 6 179/16 11 167/8§ 121/4 81/4 111/2 109/16 51/2 4 � 3/4 4 4 203/4

13/16 � 277/16§ 2213/16

2316-24/2-�3D 6§ 73/8 47/8 191/2 131/8 155/16§ 133/4 9 131/2 125/16 6 51/4 � 3/4 6 4 225/16 13/161/8 275/8§ 261/16

2316-28/1-�5D 6§ 315/16 7 195/16 17 2113/16§ 201/4 127/8 20 165/16 71/4 63/16 � 3/4 8 4 2115/16 13/8 � 381/8§ 369/16

2316-24/2-�5D 6§ 73/8 47/8 191/2 131/8 155/16§ 133/4 9 131/2 125/16 6 51/4 � 3/4 6 4 225/16 13/16 � 275/8§ 261/16

2316-26/1-�5D 6§ 37/8 51/4 169/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/167/8 329/16§ 31

2316-31/2-�7.5dD 8� 713/16 51/4 221/4 155/8 303/8� 181/4 101/4 18 147/8 63/8 67/8 � 3/4 8 4 243/4 11/2 � 451/4� 331/82316-31/2-�7.5tD 8� 713/16 73/4 243/4 155/8 303/8� 181/4 101/4 18 147/8 7 67/8 � 3/4 8 4 271/4 11/2 7/8 451/4� 331/8

2316-28/1-�7.5D 6§ 315/16 7 195/16 17 2113/16§ 201/4 127/8 20 165/16 71/4 63/16 � 3/4 8 4 2115/16 13/813/16 381/8§ 369/16

2316-26/1-�7.5dD 8� 37/8 51/4 169/16 1513/16 2213/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 � 3615/16� 312316-26/1-�7.5tD 8� 37/8 51/4 169/16 1513/16 223/16� 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 193/8 13/16 213/16 3615/16� 312316-31/2-�10D 8� 713/16 73/4 243/4 155/8 303/8� 181/4 101/4 18 147/8 7 67/8 � 3/4 8 4 271/4 11/2 23/8 451/4� 331/82316-35/1-�10D 8� 41/16 73/4 211/16 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 239/16 11/2 21/4 543/4� 393/16

A� Discharge Nominal Pipe Size--female pipe thread for 6" and smaller,unthreaded pipe (SW) for 8" and larger.

CL

Dimensions 2300-D Page 2

BlowerDesignation« A B C D E F G H J K L P Q R S T� U� V Z* F+K G+K

2316-21/1-�15dD 10� 37/8 53/4 211/4 205/8 387/16� 251/2 137/8 25 193/4 71/4 89/16 � 3/4 10 4 23 21/4 � 583/16� 451/4

2316-21/1-�15tD 10� 37/8 93/4 253/4 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 271/2 21/4 1/ 2 583/16� 451/4

2316-35/1-�15dD 10� 41/16 73/4 211/16 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 239/16 11/2 � 543/4� 393/16

2316-35/1-�15tD 10� 41/16 9 239/16 183/4 357/8� 203/8 133/8 23 1813/16 91/2 83/16 � 3/4 8 4 261/16 11/2 25/16 543/4� 393/16

2316-21/1-�20D 10� 37/8 93/4 253/4 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 271/2 21/4 23/16 583/16� 451/4

2316-41/1-�20D 12� 125/16 8 367/8 341/4 5015/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 � 845/8� 7111/16

2316-33/1-�25D 12� 57/8 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 31/4 305/8 31/4 21/4 7215/16� 602316-41/1-�25D 12� 125/16 8 367/8 341/4 5015/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 � 845/8� 7111/16

2316-33/1-�30D 14� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 31/4 33/4 7215/16� 602316-41/1-�30D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 5/8 825/8� 7111/16

2316-41/1-�40D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 11/2 825/8� 7111/16

2316-41/1-�50D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 3 825/8� 7111/16

2320-19/2-�1.5D 3§ 67/8 61/4 191/16 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 3 4 221/4 13/16 � 287/8§ 285/16

2320-19/2-�2D 4§ 67/8 61/4 191/16 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 221/413/16 � 287/8§ 285/16

2320-19/2-�3D 4§ 67/8 61/4 191/16 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 221/413/16 � 287/8§ 285/16

2320-26/2-�5D 6§ 7 51/4 1911/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 221/2 13/16 � 329/16§ 312320-26/2-�7.5dD 6§ 7 51/4 1911/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 221/2 13/16 � 329/16§ 312320-26/2-�7.5tD 6§ 7 51/4 1911/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 221/2 13/16 213/16 329/16§ 31

2320-35/1-�10D 8� 41/16 73/4 211/16 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 239/16 11/2 21/4 543/4� 393/16

2320-35/2-�10D 8� 73/8 73/4 243/8 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 267/8 11/2 21/4 543/4� 393/16

2320-35/2-�15dD 8� 73/8 73/4 243/8 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 267/8 11/2 � 543/4� 393/16

2320-35/2-�15tD 8� 73/8 9 267/8 183/4 357/8� 203/8 133/8 23 1813/16 91/2 83/16 � 3/4 8 4 293/8 11/2 25/16 543/4� 393/16

2320-21/1-�15dD 8� 37/8 53/4 211/4 205/8 387/16� 251/2 137/8 25 193/4 71/4 89/16 � 3/4 10 4 23 21/4 � 583/16� 451/4

2320-21/1-�15tD 8� 37/8 93/4 253/4 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 271/2 21/4 1/ 2 583/16� 451/4

2320-35/1-�15dD 8� 41/16 73/4 211/16 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 239/16 11/2 � 543/4� 393/16

2320-35/1-�15tD 8� 41/16 9 239/16 183/4 357/8� 203/8 133/8 23 1813/16 91/2 83/16 � 3/4 8 4 261/16 11/2 213/16 543/4� 393/16

2320-21/1-�20D 10� 37/8 93/4 253/4 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 271/2 21/4 23/16 583/16� 451/4

2320-41/1-�25D 12� 125/16 8 367/8 341/4 5015/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 � 845/8� 7111/16

2320-33/1-�25D 12� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 33/4 21/4 7215/16� 602320-33/1-�30D 12� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 31/4 33/4 7215/16� 60

2320-41/1-�30D 12� 125/16 8 367/8 341/4 5015/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/165/ 8 845/8� 7111/16

2320-33/1-�40dD 14� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 31/4 1/ 2 7215/16� 602320-33/1-�40tD 14� 57/16 12 325/8 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 12 33/4 331/8 31/4 23/4 7215/16� 602320-41/1-�40D 16� 125/16 8 367/8 341/4 5015/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 11/2 845/8� 7111/16

2320-33/1-�50D 14� 57/16 12 325/8 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 12 33/4 331/8 31/4 41/4 7215/16� 602320-41/1-�50D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 3 825/8� 7111/16

2320-41/1-�60D 16� 125/16 8 367/8 341/4 4815/16� 38 251/8 371/2 3311/16 297/8 113/8 193/4 1 16 33/4 3615/16 311/16 41/8 825/8� 7111/16

2324-14/3-�1.5D 3§ 81/2 6 193/4 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 2215/1613/16 � 235/8§ 2213/16

2324-14/3-�2D 3§ 81/2 6 193/4 103/8 131/16§ 121/4 83/8 111/2 109/16 51/2 35/8 � 3/4 3 4 2215/16 13/16 � 235/8§ 2213/16

2324-19/2-�3D 4§ 67/8 61/4 191/16 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 221/413/16 � 287/8§ 285/16

2324-26/2-�5D 6§ 7 51/4 1911/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 221/2 13/16 1 329/16§ 312324-26/2-�7.5dD 6§ 7 51/4 1911/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 221/2 13/16 � 329/16§ 312324-26/2-�7.5tD 6§ 7 51/4 1911/16 155/8 1713/16§ 161/4 113/4 16 143/4 7 57/16 � 3/4 6 4 221/2 13/16 213/16 329/16§ 312324-35/2-�10D 8� 73/8 73/4 243/8 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 267/8 11/2 21/4 543/4� 393/16

2324-35/2-�15dD 8� 73/8 73/4 243/8 183/4 357/8� 203/8 133/8 23 1813/16 81/2 615/16 � 3/4 8 4 267/8 11/2 � 543/4� 399/16

2324-35/2-�15tD 8� 73/8 9 267/8 183/4 357/8� 203/8 133/8 23 1813/16 91/2 83/16 � 3/4 8 4 293/8 11/2 25/16 543/4� 393/16

2324-21/1-�20D 10� 35/8 93/4 251/2 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 271/4 21/4 23/16 583/16� 451/4

2324-33/1-�25D 12� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 31/4 21/4 7215/16� 602324-33/1-�30D 12� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 31/4 33/4 7215/16� 602324-33/1-�40dD 12� 57/16 91/2 301/8 267/8 4715/16� 341/2 175/8 34 251/2 10 111/8 � 7/8 12 33/4 305/8 31/4 1/ 2 7215/16� 602324-33/1-�40tD 12� 57/16 12 325/8 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 12 33/4 331/8 31/4 23/4 7215/16� 602324-33/1-�50D 14� 7 12 343/16 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 14 33/4 3411/16 31/4 41/4 7215/16� 602324-33/1-�60D 14� 7 12 343/16 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 14 33/4 3411/16 31/4 55/8 7215/16� 60

2332-19/3-�3D 4§ 1011/16 61/4 227/8 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 261/1613/16 � 287/8§ 285/16

2332-19/3-�5D 4§ 1011/16 61/4 227/8 131/2 159/16§ 15 103/4 14 135/16 63/4 45/16 � 3/4 4 4 261/16 13/16 � 287/8§ 285/16

2332-28/2-�7.5D 6§ 87/8 7 241/4 17 2113/16§ 201/4 127/8 20 165/16 71/4 63/16 � 3/4 8 4 267/8 13/813/16 381/8§ 369/16

2332-28/2-�10D 6§ 87/8 7 241/4 17 2113/16§ 201/4 127/8 20 165/16 71/4 63/16 � 3/4 8 4 267/8 13/8 21/4 381/8§ 369/16

2332-28/2-�15dD 6§ 87/8 7 241/4 17 2113/16§ 201/4 127/8 20 165/16 71/4 63/16 � 3/4 8 4 267/8 13/8 � 381/8§ 369/16

2332-28/2-�15tD 6§ 87/8 103/4 28 17 2113/16§ 201/4 127/8 20 165/16 81/2 63/16 � 3/4 8 4 305/8 13/8 � 381/8§ 369/16

2332-21/2-�20D 8� 91/8 93/4 31 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 323/4 21/4 23/16 583/16� 451/4

2332-21/2-�25dD 8� 91/8 93/4 31 205/8 387/16� 251/2 137/8 25 193/4 81/2 91/16 � 3/4 10 4 323/4 21/4 � 583/16� 451/4

2332-21/2-�25tD 8� 91/8 121/2 341/2 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 361/4 21/4 1/ 2 583/16� 451/4

2332-21/2-�30D 8� 91/8 121/2 341/2 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 361/4 21/4 2 583/16� 451/4

2332-21/2-�40D 8� 91/8 121/2 341/2 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 361/4 21/4 21/4 583/16� 451/4

2332-33/2-�50D 12� 117/8 12 391/16 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 12 33/4 399/16 31/4 41/4 7215/16� 602332-33/2-�60D 12� 117/8 12 391/16 267/8 4715/16� 341/2 175/8 34 251/2 113/4 111/8 � 7/8 12 33/4 399/16 31/4 55/8 7215/16� 60

«Explanation of designation: 2304-11/1-�.3D means Series 2300, 4 osi pressure, inner housing no. 11, 1 stage, 1/3 hp motor, direct drive.d With drip-proof motor, if dimensions are different from TEFC. t With TEFC motor, if dimensions are different from drip-proof.* Z = Motor overhang for TEFC motors. There is no overhang for drip-proof motors, except 2320-33/1-�40D and 2324-33/1-�40D which overhang 1/2".� Listed T & U dimensions are for SW inlet. For threaded inlet, T is 5/16" for inner housing no. 11, 1/2" for others. If S is greater than 6", threaded inlet

is not available.� SW discharge (unthreaded pipe) is standard and is included in F. nDischarge C is 109/16" from farthest base hole, for inner housing no. 11.§ Female pipe thread is standard. If SW discharge (unthreaded pipe) is specified, add 31/4" to F.I 5 holes when No. 4 discharge is furnished.¨ Number 4 discharge position, straight down, can be furnished on special order, a notch having to be cut out of the base at time of assembly, except

for blowers with #11 or #35 cases, no modification is required.

L

Dimensions 2300-D Page 3

Prin

ted

in U

SA

NA

1100

-Dim

s230

0-D

All dimensions are in inches. Dimensions shown apply only to blowers with T-frame motors. Consult North American Mfg. Co. for dimensionsof blowers with other motors.

BlowerDesignation« A B C D E F G H J K L P Q R S T� U� V Z* F+K G+K

2344-28/3-�15dD 6§ 143/8 7 297/8 17 2113/16§ 201/4 127/8 20 165/16 71/4 63/16 � 3/4 8 4 323/8 11/2 � 381/8§ 369/16

2344-28/3-�15tD 6§ 143/8 103/4 335/8 17 2113/16§ 201/4 127/8 20 165/16 81/2 63/16 � 3/4 8 4 361/8 11/2 15/16 381/8§ 369/16

2344-28/3-�20D 6§ 143/8 103/4 335/8 17 2113/16§ 201/4 127/8 20 165/16 81/2 63/16 � 3/4 8 4 361/8 11/2 3 381/8§ 369/16

2344-21/2-�30D 8� 1015/16 121/2 365/16 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 381/16 21/4 2 583/16� 451/4

2344-21/2-�40dD 8� 1015/16 121/2 365/16 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 381/16 21/4 � 583/16� 451/4

2344-21/2-�40tD 8� 1015/16 121/2 365/16 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 381/16 21/4 27/8 583/16� 451/4

2344-21/2-�50D 8� 1015/16 121/2 365/16 205/8 387/16� 251/2 137/8 25 193/4 101/2 913/16 � 3/4 10 4 381/16 21/4 43/8 583/16� 451/4

«Explanation of designation: 2304-11/1-�.3D means Series 2300, 4 osi pressure, inner housing no. 11, 1 stage, 1/3 hp motor, direct drive.d With drip-proof motor, if dimensions are different from TEFC. t With TEFC motor, if dimensions are different from drip-proof.* Z = Motor overhang for TEFC motors. There is no overhang for drip-proof motors, except 2320-33/1-�40D and 2324-33/1-�40D which overhang 1/2".� Listed T & U dimensions are for SW inlet. For threaded inlet, T is 5/16" for inner housing no. 11, 1/2" for others. If S is greater than 6", threaded inlet

is not available.� SW discharge (unthreaded pipe) is standard and is included in F. nDischarge C is 109/16" from farthest base hole, for inner housing no. 11.§ Female pipe thread is standard. If SW discharge (unthreaded pipe) is specified, add 31/4" to F.I 5 holes when No. 4 discharge is furnished.¨ Number 4 discharge position, straight down, can be furnished on special order, a notch having to be cut out of the base at time of assembly, except

for blowers with #11 or #35 cases, no modification is required.

L

WARNING: Situations dangerous to personnel andproperty can develop from incorrect operation of com-bustion equipment. North American urges compliancewith National Safety Standards and Insurance Under-writers recommendations, and care in operation.

"SW" means sleeve or weld. A flex-ible rubberized sleeve (Bulletin 2947)can be slipped over an SW connec-tion and clamped to prevent leaks. Aflexible connection does not transmitvibrations or stresses as do welded orthreaded connections.

Fig. 1. Fig. 2. Fig. 3.

Discharge Connections: A threaded (female) flange (Fig. 1)is furnished as standard with blowers of 6" and smallerdischarge pipe size. An SW connection (Fig. 2) is standardfor 8" and larger, or may be specified (at no extra cost) forsmaller sizes (Fig. 3).

Inlet Connections: A heavy wire guard (Fig. 1) is standard.An SW inlet (unthreaded, Fig. 2) for sleeve or welding con-nection may be specified at extra cost. A threaded femaleinlet may be specified for 3" through 6" inlet at no extra cost(Fig. 3).

A� Discharge Nominal Pipe Size--female pipe thread for 6" and smaller,unthreaded pipe (SW) for 8" and larger.

CL

Dimensions 2300-DPage 2

North American Mfg. Co., 4455 East 71st Street, Cleveland, OH 44105-5600 USA, Phone 216-271-6000, Facsimile 216-641-7852E-mail [email protected] l www.namfg.com