Blast wave through rat hrad

-

Upload

deep-lahaka -

Category

Documents

-

view

220 -

download

0

description

Transcript of Blast wave through rat hrad

Weekly Report Fall 2015 2/2/2015Experiments in the blast lab consisted of exposing a rat to shockwaves of various amplitudes. The experiments were conducted with variations in endplate thickness and number of membranes. Data from the lab for the different experiments was taken and used to simulate the experiment in Abaqus. Material properties for the shock tube and the rat head is shown below:

The rat head model was constrained at the bottom surface, while the shocktube surfaces were constrained respective to real life conditions. The shockwave was applied as an amplitude with values obtained from the actual experiments. The figures are shown below:

The different variations for the experiment consisted of the following:MembraneEnd Plate (inches)

122

242

362

424

544

664

Experiment with membranes (2) and endplate (2 in) was simulated.

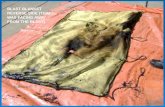

Shocktube with shockwave starting to propogate

Shocktube with shockwave passing through the rat head Pressure profile at an arbitrary node near the rat head for the shock tube

Pressure distribution on the rat head

Pressure profile on an arbitrary node on the rat head

This simulation took nearly 20 hours to run which is unacceptable. Modifications have been made in the meshing and number of data points to reduce the running time, which has been reduced to 8 hours.

Plan for this week (2/2/2015 2/9/2015): Make similar modifications in other variations (different membranes, endplate distance) and reduce simulation time, comparison of results Work on cantilever beam for strain gauge measurements

Sudeepto Kahali