Bez názvu – 1€¦ · 1 Body - upper part Ductile iron 0.7043 (GGG40.3) *) 10 Belleville spring...

Transcript of Bez názvu – 1€¦ · 1 Body - upper part Ductile iron 0.7043 (GGG40.3) *) 10 Belleville spring...

www.abovalve.com

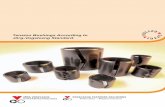

PTFE LINED BUTTERFLY VALVES

we make processes work

chemical line

Flanged WAFER (Body with t )hrough holesBody type

Nominal size DN50 - DN400

Working pressure 6 bar / 10 bar

Flange connection PN6 / PN10 / PN16 / Class 150 / JIS10K / JIS16K

Working temperature -40°C / +200°C

Working media Purified industrial water Potable water Industrial cleaners

Food

Toxic media Caustic media

Dyes

Chemicals Beverages

Aggressive liquids

Drugs and pharmaceuticals Chlorine / Alkalines / Acids

Paper mill stock

Split body

FDA certification

Features Concentric design

PTFE seat for high-temperature

Simple maintenance

Bidirectional tightness

High-performance valve for high demanding industries

Tightness Class A

working settings

SERIES 500SERIES 500

2 / ABO valve Czech

§ pure industrial water treatment

High-performance concentric shut-off butterfly valves of Series 500 with PTFE sealing are offered for very clean manufactu g environments and are riused in various industries like:

§ chemical industry (acids, alkalines)§ pharmaceutical/sanitary industry

a

§ corrosive, toxic and caustic media

§ extended neck design allows for piping insulation and enables easy access for actuator mounting

§ upper flange according to standard ISO m5211 enables variable control by eans of various actuator types

§ production of chlorine

§ red acc. epoxy coating RAL 2002 - 80 μm

§ suitable as end-stop and control valve

§a

Based on customers' particular

§ valve is demountable§ actuating stem sealing prevents media leaking to environs

requirements we offer§ other body coating grade

a

§ material certificates 3.1/3.2

§ dyes manufacturing and processing

§ paper industry

§ WRAS ioncertificat for potable water

§ compact PTFE „TRIM” assembly

§ on pressure tests

a

§ -steel PTFE impregnated bearings pro vide exact support of stem and pivot

a

§ food industry

§ 3 mm PTFE coated disc

§ (stem, disc, pivot)

§ pulp processing

§ epoxy coated body

§ concentric design

§ -possible both vertical and horizontal pi pe mounting

Basic properties

§ fully tight in shut position

Type designation

5 9 9 B 100 Nominal sizeDN50 - DN400a

Body designB - wafer with through holes (two pieces body)a

Seat material9 - teflone (PTFE)a

Disc material9 - duplex steel 1.4469 PTFE coated *)7 - duplex steel 1.4469 with polished edges a

Series markingSeries 500a

*) teflone is applied on metal surface like powder or liquid subsequently heated by its successive cooling up to 400°C; it is heat hardened and adheres to metal surfaceStandards

Hydraulic test ČSN EN 12266-1, Class A ISO 5208, Class Aa

Face-to-face length ČSN EN 558, Series 20 ISO 5752, Series 20a

Flange connection ČSN EN 1092-1 DIN 2631

a

Top flange ISO 5211 a

Wordking standard EN 593 + A1a

Marking EN 19

ASME B16.5

Design „B”

WAFER

GENERAL DESCRIPTION/ DESIGN MODELS Czech Industrial Valve Manufacturer

valves are delivered in a wide range of control elements

§ single-piece lined with PTFE coating thick at TRIMleast 3 mm. All the sealing surfaces are machined.

7. Functional areas

8. Pressure element

6. Teflon seat

9. Disc / stem / pivot

§ precise machining and exact alignment of the sea-ling components provides sealing around the stem in the functional areas.

§ provides constant pressure around the perimeter of the seat.

§ with min. thickness of 3 mm PTFE is manufactured by isostatic hot pressing. The sealing strips func-tion as double-sided flange seals.

10. Safety elements§ the valve is fitted with a stuffing box fully isolating

the valve body and stem from the work media. The seal bushing consists of a stainless sealing ring and silicone straining ring.

5. Profiled disc

§ sealing surface of the teflon liner in the stem area has a defined ball geometry exactly reproducing the disc geometry. There are no critical transitions. Thus fluent and reliable operation is ensured.

§ lower pressure drops and higher Kv values.

1. Top flange

3. Preloaded seal

4. Ball sealing priciple

§ dust protection O-ring protects stem and pivot bea-rings against entering abrasive articles.

abrasive articles

§ b ensure the seal elleville springs in the valve neck presure to disc . Double seals on both stem/pivot passages are standard equipment. The stuffing system with a preloaded set of elle ville springs is b -supplemented with a silicone straining ring.

2. Protection from penetrating

§ according to standard ISO 5211 enables to directly assemble any type of actuator. Flange high neck enables to insulate the actuator on the ISO flange.

DESIGNADVANTAGES

www.abovalve.com / 3

3

6

9

8

10

1

2

4

5

7

4 / ABO valve Czech

MATERIALS Czech Industrial Valve Manufacturer

3 Disc with stem Stainless steel 1.4469 + PTFE a

4 Seat PTFE

7 Washer Stainless steel A2 a

8 O-ring NBRa

13 Thrust washer Stainless steel 1.4021 a

9 Sliding cover Steel + PTFE

12 Gasket ring Silikonová pryža

6 Support ring Stainless steel A2 a

14 Screw Stainless steel A4

5 Pressure element Silicone rubber / VITONa

Pos. Item Material

2 Body - lower part Ductile iron 0.7043 (GGG40.3) *) 1 Body - upper part Ductile iron 0.7043 (GGG40.3) *)

10 Belleville spring Steel 1.8159

11 Ring seat Stainless steel 1.4021a

Quality control§ manufacturing at ABO valve is certified

according to quality control standard ISO 9001:2015 (14001, 18001)

§ production in accordance with the Pre-ssure Equipment Directive 2014/68/ EU - -Equipment operating under pressure (Category III, module H)

§ all the certificates are downloadable from www.abovalve.com

§ valve actuators, if delivered, are adjus-ted and tested while assembled

§ all the ABO valves are tested under the pressure of 110% work pressure to ensure leak tightness according to standards - the 2.2/3.1/3.2 pressure test certificates can be issued

§ tightness tests according to standards: ČSN EN 12266-1, ISO 5208, ANSI/FCI 70-2

§ all the input materials are tested accor-ding to PMI to verify material origin

§ ABO offers epoxy coated valve bodies providing excellent abrasion and at-mosphere corrosion resistance

§ coating colour is RAL 2002, 80 red acc.µm thick

§ resistance to chemicals including strong acids and alkalines

§ (cracking and peeling) § resistance to shocks

§ resistance to solvents, alcohols, greases and oils

§ excellent abrasion and corrosion resistance

§ on request valve bodies can be finished with another colour or a thicker coating layer

Valve coating

§ resistance to humidity and water

§

*) stainless steel body upon request

Design „B”

WAFER

Pure PTFE properties§ the parts coming to contact with work media (seat, disc) are lined with pure PTFE. Thus their long lifespan and valve quality stability are

provided. Pure PTFE characteristics are high chemical resistance, toughness and flexibility, low friction coefficient, low water absorption and non-adhesiveness. All the mentioned properties provide increased protection against leakage of media. Low friction coefficient value reduces valve opening torque.

10

11

5

3

13

12

4

1

8

6

7

9

2

14

VALVE ACTUATION

www.abovalve.com / 5

Working conditions

Max. working pressure

DN50-DN400: 10 bar

Temperature rating

- 40°C do +200°C *)

Installation between flanges DN50 - DN400 standard

DN 50 65 80 100 125 150 200 250 300 350 400

PN6

PN10

Class 150

JIS 10 K

JIS 16 K

p 10barmax

DN 50 65 80 100 125 150 200 250 300 350 400

Operating torgues (Nm) vs. working pressure (bar)

35 40 50 85 130 230 250 350 530 850 1000

325 335

599

579 p 10barmax

*p - mmax aximum working pressure. For pressure of 10 bar - only water at temperature of 20°C. Torques are declared without safety coefficients.

-40

„TRIM” from duplex steel 1.4469 + pure PTFE

„TRIM” from one piece only

(stem + disc + pivot)

PN16

*) depending on medium

ACTUATION POSSIBILITIES Czech Industrial Valve Manufacturer

Handlever

All ABO handlevers, manual worm-gear units, pneumatic or electric actuators can be mounted directly to ABO butterfly valves, which ensures compatibility between the actuator and the valve.

For manual actuation, com-pany ABO offers handlevers in carbon steel material with protective coating for excel-lent corrosion, abrasion and impact resistance. A lever in stainless steel material is an option.

Manual gearbox with handwheel

ABO gearbox series manual actuators combine state of art production technology, with cast iron and pressed steel construction, to provide a smooth and trouble-free operation for heavy duty on/off and throttling service of ABO valves. The rugged, cast iron body seals weatherproof to IP67. A self-locking gearing holds the valve in the desired position. Further features include a readily accessible handwheel, adjustable stopscrew for closed position, removable splined drive bush with indexing facility and a facility to lock handwheel with padlock and chain. Gearboxes, as well as handlevers, can be supplemented with contacts for endpoint switches.

6 / ABO valve Czech

DN 50-65 80-150 200-300 350-400

A

B

C

D

E

F

Gearbox

Wheel

Kg

69,5 127,5 133,5 287,5

35 46 57 67

91 139 156 275

38 59 59,5 181

84 141 155 319

100 200 200 500

CD100 CD200 CD200 SG500

1,24 2,85 4,56 10,2

242-10M 242-20M 242-30M 242-40M

Wo

rm g

ea

rbo

x

Ha

nd

leve

r

DN 50-65 80-125 150 200

A

B

Kg

225 270 360 360

75 75 75 75

1,2 1,35 1,5 1,5

A

B

ISO top flange connection is F05 for DN50 - DN65 and F07 for DN 80 - DN125, respectively.

Dimensions are mentioned in mm.

B C

A

F

D E

Dimensions are mentioned in mm.

www.abovalve.com / 7

Actuators

EElectric actuators are designed quarter-turn. Electric actuators can be installed for voltages of 24 V, 230 V or 400 V.

a

a

ABO valves can be equipped with pneumatic actuators of two optional designs: single-action or double-action.

Special actuator types

Pneumatic actuators

Electric actuators

Valves are equipped with special actuator types from ma-jor world suppliers (Auma, Regada, Valpes etc.).

Sp

eci

al a

ctu

ato

rs

Pn

eu

ma

tic

act

ua

tor

Ele

ctri

c a

ctu

ato

r

ACTUATION POSSIBILITIES

BASICDIMENSIONS

DN 50 65 80 100 125 150 200 250 300 350 400

Valvedimension

A

B

C

D

F

G

I

J

K

L

M

H

Endshaftdimensions

ISO Top flange

Flange dimensions

ISO Flange 5211

DN

120 128 135 145 164 176,5 234 274 299 331 361

61 74 78 90 106 126 152 186 214 245 280

43 46 46 52 56 56 60 70 76 78 102

96 115 131 152 181 207 257 314 364 408 468

25 25 25 25 25 25 25 31 31 42 42

11 11 14 14 14 14 17 22 22 27 27

50 50 70 70 70 70 70 102 102 125 125

4 4 4 4 4 4 4 4 4 4 4

7 7 9 9 9 9 9 12 12 14 14

70 70 90 90 90 90 90 125 125 155 155

14 14 14 14 14 14 14 18 20 20 20

F05 F05 F07 F07 F07 F07 F07 F10 F10 F12 F12

Weight (kg) 2,3 3,0 3,5 5,0 6,5 7,8 13,2 23,6 30,9 40,1 59,7

www.abovalve.com

Follow us on:

Czech RepublicABO valve, s.r.o.Dalimiliova 285/54783 35 Olomouctel.: +420 585 224 [email protected]

RussiaABO Armatura LLCSmolensktel.: +7 (4812) 240 [email protected]

UkraineABO Ukraine LLCDniprotel.: +38 056 733 95 [email protected]

ChinaABO Flow ControlShanghaitel.: +86 136 01 522 [email protected]

IndiaABO Controls Pvt. Ltd.Mumbaitel.: +91 99 2002 [email protected]

TurkeyABO Armaturen LTD STIIstanbultel.: +90 216 527 36 [email protected]

United Arab EmiratesSales representationAbu Dhabitel.: +971 56 [email protected]

Slovak RepublicABO Slovakia, s.r.o.Banská Bystricatel.: +421 484 145 [email protected]

GermanyABO Armaturen GmbHMonchengladbachtel.: +49 (0)152 262 [email protected]

SingaporeABO Valve Pte. Ltd.Singaporetel.: +65 9169 [email protected]

BahrainSales representationManamatel.: +973 3444 [email protected]

The technical information described in this leaflet is teantive and for general use only and does not constitute a recommendation or guarantee for any specific service or application requirement. Please consult ABO representative or factory for specific requirements and material selection for your intended application. The right to change or modify product design or product without prior notice is reserved. ABO valve accepts no liability for damages caused by bad interpretation or use of the information included in this brochure.

14 14 16 16 18 20 22 30 30 35 40

L

D C

FA

B

DN

M

H

G

J x K

I

Czech Industrial Valve Manufacturer