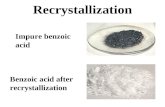

Impure benzoic acid Benzoic acid after recrystallization Recrystallization.

Benzoic acid - Emerald Performance Materials Benzoic acid Safety Data Sheet according to Regulation...

Transcript of Benzoic acid - Emerald Performance Materials Benzoic acid Safety Data Sheet according to Regulation...

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010 Revision date: 01/10/2013 Supersedes: 29/04/2013 Version: 4.0

07/10/2013 EN (English) 1/7

SECTION 1: Identification of the substance/mixture and of the company/undertaking

1.1. Product identifier Substance name : Benzoic acid

EC no : 200-618-2 CAS No : 65-85-0 REACH registration No : 01-2119455536-33-0000 Synonyms : Benzenecarboxylic acid; Benzeneformic acid; Phenylcarboxylic acid; Phenylformic acid;

Benzenemethanoic acid; Carboxybenzene

1.2. Relevant identified uses of the substance or mixture and uses advised against

1.2.1. Relevant identified uses Main use category : Industrial use,Professional use Use of the substance/mixture : ES1 : Manufacturing of the substance and industrial use as auxiliary for polymerization in a

closed continuous process, with occasional exposure, including sampling ES2 : Industrial use as an auxiliary in polymerization processes in a closed continuous process, no likelihood of exposure including storing and forwarding ES3 : Charging/discharging at non-dedicated facilities in an industrial setting ES4 : Charging/discharging at dedicated facilities in an industrial setting ES5 : Transfer of substance into small containers in an industrial setting ES6 : Industrial use in closed batch process – formulation and auxiliary in polymerization processes ES7 : Mixing or blending in batch processes for formulation of preparations and articles (multistage and/or significant contact) ES8 : Use in batch and other process (synthesis) where opportunity for exposure arises ES9 : Professional use of laboratory chemicals Most common technical function of the substance : Additives

1.2.2. Uses advised against No additional information available

1.3. Details of the supplier of the safety data sheet EMERALD KALAMA CHEMICAL B.V. Havennr. 4322 - Montrealweg 15 3197 KH Rotterdam-Botlek - THE NETHERLANDS T +31 (0)888880500 - F +31 (0)888880520 [email protected]

1.4. Emergency telephone number

Country Organisation/Company Address Emergency number UNITED KINGDOM National Poisons Information Service

(Birmingham Centre) City Hospital

Dudley Road B18 7QH Birmingham

+44 870 600 6266 (only for health professionals)

NETHERLANDS Emerald Kalama Chemical B.V. SHEQ Dept. Emerald Kalama Chemical B.V. Rotterdam

Havennr. 4322 - Montrealweg 15 3197 KH Rotterdam-Botlek

+31 (0)181 249285 For US or Canada, use only +18004249300

SECTION 2: Hazards identification

2.1. Classification of the substance or mixture

Classification according to Regulation (EC) No. 1272/2008 [CLP] Skin Irrit. 2 H315 Eye Dam. 1 H318

Full text of H-phrases: see section 16

Classification according to Directive 67/548/EEC or 1999/45/EC Xi; R41 Xi; R38 Full text of R-phrases: see section 16

Adverse physicochemical, human health and environmental effects Causes serious eye damage Causes skin irritation.

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010

07/10/2013 EN (English) 2/7

2.2. Label elements

Labelling according to Regulation (EC) No. 1272/2008 [CLP] Hazard pictograms (CLP) :

GHS05

Signal word (CLP) : Danger Hazard statements (CLP) : H315 - Causes skin irritation

H318 - Causes serious eye damage Precautionary statements (CLP) : P264 - Wash thoroughly after handling

P280 - Wear protective gloves/protective clothing/eye protection/face protection P302+P352 - IF ON SKIN: Wash with plenty of soap and water P305+P351+P338 - IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing P310 - Immediately call a POISON CENTER or doctor/physician P332+P313 - If skin irritation occurs: Get medical advice/attention P362 - Take off contaminated clothing and wash before reuse

2.3. Other hazards Other hazards not contributing to the classification

: Combustible. Potential dust explosion hazard. The product does not meet the PBT and vPvB classification criteria.

SECTION 3: Composition/information on ingredients

3.1. Substances Name Product identifier % Classification according to

Directive 67/548/EEC Benzoic acid (CAS No) 65-85-0

(EC no) 200-618-2 (REACH-no) 01-2119455536-33-0000

> 99 Xi; R41 Xi; R38

Name Product identifier % Classification according to Regulation (EC) No. 1272/2008 [CLP]

Benzoic acid (CAS No) 65-85-0 (EC no) 200-618-2 (REACH-no) 01-2119455536-33-0000

> 99 Skin Irrit. 2, H315 Eye Dam. 1, H318

Full text of R- and H-phrases: see section 16

3.2. Mixture Not applicable

SECTION 4: First aid measures

4.1. Description of first aid measures First-aid measures general : Do not attempt to take action without suitable protective equipment

Emergency eye wash fountains and safety showers should be available in the immediate vicinity of any potential exposure.

First-aid measures after inhalation : Move the affected person away from the contaminated area and into the fresh air If irritation persists, consult a doctor.

First-aid measures after skin contact : Wash with soapy water Remove all contaminated clothing and footwear If case of redness or irritation, call a doctor.

First-aid measures after eye contact : Rinse immediately and thoroughly, pulling the eyelids well away from the eye (15 minutes minimum) Consult an eye specialist immediately, even if there are no immediate symptoms.

First-aid measures after ingestion : Rinse mouth out with water Never give anything by mouth to an unconscious person Get medical advice and attention if you feel unwell.

4.2. Most important symptoms and effects, both acute and delayed Symptoms/injuries after inhalation : Dust from this product may cause irritation to the respiratory tract. Cough. Exposure may

produce an allergic reaction. Symptoms/injuries after skin contact : Exposure may produce an allergic reaction. Causes skin irritation. Symptoms/injuries after eye contact : Serious damage to eyes. Symptoms/injuries after ingestion : May cause slight irritation.

4.3. Indication of any immediate medical attention and special treatment needed Treat symptomatically.

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010

07/10/2013 EN (English) 3/7

SECTION 5: Firefighting measures

5.1. Extinguishing media Suitable extinguishing media : Dry powder

Carbon dioxide (CO2) For large fire : Water spray Foam Dry powder.

5.2. Special hazards arising from the substance or mixture Fire hazard : Dust may form explosive mixture in air

During combustion : Toxic fumes may be released (Carbon oxides (CO and CO2)).

5.3. Advice for firefighters Firefighting instructions : Fight fire remotely due to the risk of explosion

Contain the extinguishing fluids by bunding Do not discharge into drains or the environment.

Protection during firefighting : Do not attempt to take action without suitable protective equipment Self-contained breathing apparatus Complete protective clothing.

SECTION 6: Accidental release measures

6.1. Personal precautions, protective equipment and emergency procedures

6.1.1. For non-emergency personnel Emergency procedures : Avoid raising powdered material due to explosion hazard

Keep away from ignition sources (including static discharges) Explosion-free electrical equipment and lighting with earth Avoid contact with skin and eyes.

6.1.2. For emergency responders Protective equipment : Do not attempt to take action without suitable protective equipment

For further information refer to section 8: "Exposure controls/personal protection".

6.2. Environmental precautions Contain the spilled material by bunding. Do not discharge into drains or rivers.

6.3. Methods and material for containment and cleaning up For containment : Sweep up or vacuum up the product

Put into a labelled container and provide safe disposal Flame proof, lighting, electrical equipment and ventilation Avoid creating or spreading dust.

Methods for cleaning up : Wash non-recoverable remainder with large amounts of water.

6.4. Reference to other sections For further information refer to section 13.

SECTION 7: Handling and storage

7.1. Precautions for safe handling Precautions for safe handling : Ensure good ventilation of the work station

Extraction to remove dust at its source Avoid contact with skin and eyes Do not breathe dust Use personal protective equipment as required Avoid raising powdered material due to explosion hazard Flame proof, lighting, electrical equipment and ventilation Keep away from ignition sources (including static discharges) Prevent wind dispersal.

Hygiene measures : Do not drink, eat or smoke in the workplace Always wash hands after handling the product.

7.2. Conditions for safe storage, including any incompatibilities Storage conditions : Keep in fireproof place

Keep container tightly closed and dry Keep in a cool, well-ventilated place away from heat Avoid the build-up of electrostatic charge Keep away from incompatible materials See Heading 10 Avoid any contamination of the product by other substances.

Incompatible products : None.

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010

07/10/2013 EN (English) 4/7

Packaging materials : Polyethylene.

7.3. Specific end use(s) Not applicable.

SECTION 8: Exposure controls/personal protection

8.1. Control parameters

Benzoic acid (65-85-0) DNEL/DMEL (Workers) Long-term - systemic effects, dermal 34,7 mg/kg bodyweight/day Long-term - local effects, dermal 4,5 mg/cm² Long-term - systemic effects, inhalation 10,4 mg/m³ Long-term - local effects, inhalation 6,3 mg/m³ DNEL/DMEL (General population) Long-term - systemic effects,oral 25 mg/kg bodyweight/day Long-term - systemic effects, inhalation 2,1 mg/m³ Long-term - systemic effects, dermal 20,8 mg/kg bodyweight/day Long-term - local effects, dermal 2,7 mg/cm² Long-term - local effects, inhalation 1,3 mg/m³

8.2. Exposure controls Appropriate engineering controls : Ensure good ventilation of the work station

Flame proof, lighting, electrical equipment and ventilation. Hand protection : Butyl-rubber protective gloves (0.5 mm)

Nitrile-rubber protective gloves (0.35 mm) Neoprene protective gloves (0.5 mm) Protective gloves made of PVC (0.5 mm) VITON gloves (0.4 mm) Breakthrough time (min) : > 480.

Eye protection : Safety spectacles with side shields. Skin and body protection : Protective clothing. Respiratory protection : Dust production: dust mask with filter type P2. Environmental exposure controls : Take all necessary precautions to avoid the accidental release of the product outside, due to the

rupture of containers or transfer systems.

SECTION 9: Physical and chemical properties

9.1. Information on basic physical and chemical properties Physical state : Solid

Colour : White.

Odour : Characteristic.

Odour threshold : Not established

pH : 2,8 (25 °C)

pH solution : Saturated solution Melting point : 122,4 °C (101325 Pa) (Handbook)

Boiling point : 249,2 °C (760 mmHg) (Handbook)

Flash point : Not applicable Solid

Relative evaporation rate (butylacetate=1) : No data available

Flammability (solid, gas) : Non flammable (EC A.10) Not flammable in contact with water (EC A.12, based on structure) Not flammable in contcat with air (EC A.13, based on structure)

Explosive limits : No data available

Vapour pressure : 1,3 hPa (96 °C) (Handbook)

Relative vapour density at 20 °C : No data available

Relative density : 1,32 (20 °C) (Handbook)

Solubility : Water: 2,9 g/l (20 °C) (Handbook)

Log Pow : 1,87 (Handbook)

Self ignition temperature : Not applicable

Decomposition temperature : No data available

Viscosity, kinematic : Not applicable

Viscosity, dynamic : No data available

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010

07/10/2013 EN (English) 5/7

Explosive properties : Not explosive (EC A.14).

Oxidising properties : Non oxidizing material according to EC criteria (EC A.17/21).

9.2. Other information Minimum ignition energy : 3 - 10 mJ (test performed using a similar product, milled sample, median value of the tested

sample < 0,063 mm, EN13821) Product sample: median value of the tested sample > 0,5 mm does not ignite The Minimum Ignition Energy (MIE) of a dust/air mix depends on the particle size the water content and the temperature of the dust. The finer and the dryer the dust the lower the MIE.

Other properties : Surface tension : 67.5 mN/m (20 °C) (1 g/l) (OECD 115, EC A.5).

SECTION 10: Stability and reactivity

10.1. Reactivity To our knowledge, the product does not present any particular risk.

10.2. Chemical stability Stable at ambient temperature and under normal conditions of use.

10.3. Possibility of hazardous reactions None to our knowledge.

10.4. Conditions to avoid No flames, no sparks. Eliminate all sources of ignition Moisture.

10.5. Incompatible materials Strong bases Strong oxidizing agents Reducing materials metals.

10.6. Hazardous decomposition products On thermal decomposition (pyrolysis) : Phenol Benzene In case of fire: See Heading 5.

SECTION 11: Toxicological information

11.1. Information on toxicological effects Acute toxicity : Not classified (Based on available data, the classification criteria are not met)

Benzoic acid (65-85-0) LD50 oral rat 2565 mg/kg (OECD 423, EC B.1 tris) LD50 dermal rabbit 2000 mg/kg (OECD 402, EC B.3) LC50 inhalation rat 12,2 mg/l (OECD 403, EC B.3)

Skin corrosion/irritation : Causes skin irritation. (OECD 404)

Serious eye damage/irritation : Causes serious eye damage. (OECD 405)

Respiratory or skin sensitisation : Not classified (Based on available data, the classification criteria are not met) Germ cell mutagenicity : Not classified (Based on available data, the classification criteria are not met)

Bacterial reverse mutation test (S.typhimurium) : Not mutagenic (OECD 471, EC B.13/14) In vitro Mammalian Chromosome aberration (Chinese hamster fibroblasts) : negative

Carcinogenicity : Not classified (Lack of data)

Reproductive toxicity : Not classified (Based on available data, the classification criteria are not met) 4 generation study in rats : NOAEL (oral,rat) : > 500 mg/kg/d

Specific target organ toxicity (single exposure) : Not classified (Based on available data, the classification criteria are not met)

Benzoic acid (65-85-0) NOAEL (dermal,rat/rabbit) 2500 mg/kg bodyweight/day NOAEL (inhalation,rat,vapour) 250 mg/m³

Specific target organ toxicity (repeated exposure)

: Not classified (Based on available data, the classification criteria are not met)

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010

07/10/2013 EN (English) 6/7

Benzoic acid (65-85-0) NOAEL (oral,rat,90 days) 500 mg/kg bodyweight/day

Aspiration hazard : Not classified (Technical impossibility to obtain the data)

SECTION 12: Ecological information

12.1. Toxicity

Benzoic acid (65-85-0) LC50 fish > 100 mg/l/96h EC50 Daphnia > 100 mg/l/48h (Daphnia magna) EC50 other aquatic organisms > 1000 mg/l/3h Micro-organisms ErC50 (algae) > 100 mg/l/72h

12.2. Persistence and degradability

Benzoic acid (65-85-0) Persistence and degradability Readily biodegradable (OECD 301, EC C.4).

12.3. Bioaccumulative potential

Benzoic acid (65-85-0) BCF Not established Log Pow 1,87 (Handbook)

12.4. Mobility in soil

Benzoic acid (65-85-0) Ecology - soil The substance is expected to have a low adsorption potential based on the low log Pow.

12.5. Results of PBT and vPvB assessment

Benzoic acid (65-85-0) Results of PBT assessment The product does not meet the PBT and vPvB classification criteria

12.6. Other adverse effects No additional information available

SECTION 13: Disposal considerations

13.1. Waste treatment methods Waste treatment methods : Dispose of in accordance with relevant local regulations.

SECTION 14: Transport information

No dangerous good in sense of transport regulations

SECTION 15: Regulatory information

15.1. Safety, health and environmental regulations/legislation specific for the substance or mixture

15.1.1. EU-Regulations No additional information available

15.1.2. National regulations No additional information available

15.2. Chemical safety assessment A chemical safety assessment has been carried out.

SECTION 16: Other information

Indication of changes : This sheet was updated (refer to the date at the top of this page). Revision : 2-3-4-9-11-16. Data sources : CSR (Chemical safety report).

Full text of R-, H- and EUH-phrases:: ------ Eye Dam. 1 Serious eye damage/eye irritation, Category 1 ------ Skin Irrit. 2 Skin corrosion/irritation, Category 2 ------ H315 Causes skin irritation ------ H318 Causes serious eye damage ------ R38 Irritating to skin ------ R41 Risk of serious damage to eyes

Benzoic acid Safety Data Sheet according to Regulation (EC) No. 453/2010

07/10/2013 EN (English) 7/7

------ Xi Irritant This information is based on our current knowledge and is intended to describe the product for the purposes of health, safety and environmental requirements only. It should not therefore be construed as guaranteeing any specific property of the product

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 1 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (1)

Manufacturing of the substance and industrial use as auxiliary for polymerization in a closedcontinuous process, with occasional exposure, including sampling

Use descriptors related to the life cycle stage SU3/8/9

PC19/32

PROC2

ERC1/6a/6d

Name of contributing environmental scenario (1)and corresponding ERC

1. Manufacture of substances (ERC1)

2. Industrial use resulting in manufacture of another

substance (use of intermediates) (ERC6a)

3. Industrial use of process regulators for polymerisation

processes in production of resins, rubbers, polymers

(ERC6d)

List of names of contributing worker scenarios (2)and corresponding PROC

1. Use in closed, continuous process with occasionalcontrolled exposure (PROC2)

2.1 Contributing scenario (1) controlling environmental exposure

Manufacture of substances (ERC1)Industrial use resulting in manufacture of another substance (use of intermediates) (ERC6a)Industrial use of process regulators for polymerisation processes in production of resins, rubbers, polymers(ERC6d)An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

2.2 Contributing scenario (2) controlling worker exposure

Use in closed, continuous process with occasional controlled exposure (PROC2)

Product characteristic

Product related conditions, e.g. the concentration ofthe substance in a mixture, the physical state of thatmixture (solid, liquid; if solid: level of dustiness),package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or per shift);note: sometimes this information is not needed forassessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift) andfrequency (e.g. single events or repeated) ofexposure

More than 4 hours per day, repeated exposure(working life)

Human factors not influenced by risk management

Particular conditions of use, e.g. body partspotentially exposed as a result of the nature of theactivity :

Exposed skin surface (cm²) : 480 (two hands, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g. technologyor process techniques determining the initial release

Indoors

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 1 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

of substance from process into workers environment;room volume, whether the work is carried outoutdoors/indoors, process conditions related totemperature and pressure:

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases andhence exposure of workers; this in particular includesconditions ensuring rigorous containment;performance of containment to be specified (e.g. byquantification of residual losses or exposure)

Not applicable

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation,general ventilation; specify effectiveness of measure:

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training and supervision).Those measures need to be reported in particular fordemonstrating strictly controlled conditions (to justifyexposure based waiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure; specifythe suitable material for the PPE (where relevant)and advise how long the protective equipment can beused before replacement (if relevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 1

An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 0,2 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,01 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 1,37 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,01 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACH

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 1 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

Chemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 2 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (2)

Industrial use as an auxiliary in polymerization processes in a closed continuous process, no likelihoodof exposure including storing and forwarding

Use descriptors related to the life cycle stage SU3

PC19/32

PROC1

ERC6a/6d

Name of contributing environmental scenario (1)and corresponding ERC

1. Industrial use resulting in manufacture of another

substance (use of intermediates) (ERC6a)

2. Industrial use of process regulators for polymerisation

processes in production of resins, rubbers, polymers

(ERC6d)

List of names of contributing worker scenarios (2)and corresponding PROC

1. Use in closed process, no likelihood of exposure(PROC1)

2.1 Contributing scenario (1) controlling environmental exposure

Industrial use resulting in manufacture of another substance (use of intermediates) (ERC6a)Industrial use of process regulators for polymerisation processes in production of resins, rubbers, polymers(ERC6d)An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

2.2 Contributing scenario (2) controlling worker exposure

Use in closed process, no likelihood of exposure (PROC1)

Product characteristic

Product related conditions, e.g. the concentration ofthe substance in a mixture, the physical state of thatmixture (solid, liquid; if solid: level of dustiness),package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or per shift);note: sometimes this information is not needed forassessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift) andfrequency (e.g. single events or repeated) of exposure

More than 4 hours per day, repeated exposure(working life)

Human factors not influenced by risk management

Particular conditions of use, e.g. body parts potentiallyexposed as a result of the nature of the activity :

Exposed skin surface (cm²) : 240 (one hand, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g. technology orprocess techniques determining the initial release ofsubstance from process into workers environment;room volume, whether the work is carried outoutdoors/indoors, process conditions related totemperature and pressure:

Indoors

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 2 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases and henceexposure of workers; this in particular includesconditions ensuring rigorous containment;performance of containment to be specified (e.g. byquantification of residual losses or exposure)

Not applicable

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation, generalventilation; specify effectiveness of measure :

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training and supervision).Those measures need to be reported in particular fordemonstrating strictly controlled conditions (to justifyexposure based waiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure; specifythe suitable material for the PPE (where relevant) andadvise how long the protective equipment can beused before replacement (if relevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 1

An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 0,1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,01 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 0,343 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,01 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 2 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 3 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (3)

Charging/discharging at non-dedicated facilities in an industrial setting

Use descriptors related to the life cycle stage SU3

PROC8a

Name of contributing environmental scenario(1) and corresponding ERC

1. Not relevant, covered by industrial uses

List of names of contributing workerscenarios (2) and corresponding PROC

1. Transfer of substance or preparation(charging/discharging) from/to vessels/large containers atnon-dedicated facilities (PROC8a)

2.1 Contributing scenario (1) controlling environmental exposure

Not relevant

2.2 Contributing scenario (2) controlling worker exposure

Transfer of substance or preparation (charging/discharging) from/to vessels/large containers at non-dedicated facilities (PROC8a)

Product characteristic

Product related conditions, e.g. the concentrationof the substance in a mixture, the physical stateof that mixture (solid, liquid; if solid: level ofdustiness), package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or pershift); note: sometimes this information is notneeded for assessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift)and frequency (e.g. single events or repeated) ofexposure

More than 4 hours per day, repeated exposure (workinglife)

Human factors not influenced by risk management

Particular conditions of use, e.g. body partspotentially exposed as a result of the nature ofthe activity :

Exposed skin surface (cm²) : 960 (two hands)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g.technology or process techniques determining theinitial release of substance from process intoworkers environment; room volume, whether thework is carried out outdoors/indoors, processconditions related to temperature and pressure:

Indoors

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases andhence exposure of workers; this in particularincludes conditions ensuring rigorouscontainment; performance of containment to bespecified (e.g. by quantification of residual lossesor exposure)

Not applicable

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 3 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation,general ventilation; specify effectiveness ofmeasure :

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training andsupervision). Those measures need to bereported in particular for demonstrating strictlycontrolled conditions (to justify exposure basedwaiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure;specify the suitable material for the PPE (whererelevant) and advise how long the protectiveequipment can be used before replacement (ifrelevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,5 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 13,7 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,5 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 3 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 4 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (4)

Charging/discharging at dedicated facilities in an industrial setting

Use descriptors related to the life cycle stage SU3

PROC8b

Name of contributing environmental scenario(1) and corresponding ERC

1. Not relevant, covered by industrial uses

List of names of contributing workerscenarios (2) and corresponding PROC

1. Transfer of substance or preparation(charging/discharging) from/to vessels/large containers atdedicated facilities (PROC8b)

2.1 Contributing scenario (1) controlling environmental exposure

Not relevant

2.2 Contributing scenario (2) controlling worker exposure

Transfer of substance or preparation (charging/discharging) from/to vessels/large containers atdedicated facilities (PROC8b)

Product characteristic

Product related conditions, e.g. the concentrationof the substance in a mixture, the physical stateof that mixture (solid, liquid; if solid: level ofdustiness), package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or pershift); note: sometimes this information is notneeded for assessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift)and frequency (e.g. single events or repeated) ofexposure

More than 4 hours per day, repeated exposure (workinglife)

Human factors not influenced by risk management

Particular conditions of use, e.g. body partspotentially exposed as a result of the nature ofthe activity :

Exposed skin surface (cm²) : 480 (two hands, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g.technology or process techniques determining theinitial release of substance from process intoworkers environment; room volume, whether thework is carried out outdoors/indoors, processconditions related to temperature and pressure:

Indoors

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases andhence exposure of workers; this in particularincludes conditions ensuring rigorouscontainment; performance of containment to bespecified (e.g. by quantification of residual lossesor exposure)

Not applicable

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 4 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation,general ventilation; specify effectiveness ofmeasure :

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training andsupervision). Those measures need to bereported in particular for demonstrating strictlycontrolled conditions (to justify exposure basedwaiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure;specify the suitable material for the PPE (whererelevant) and advise how long the protectiveequipment can be used before replacement (ifrelevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,1 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 6,86 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,1 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 4 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 5 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 2

1 Exposure scenario (5)

Transfer of substance into small containers in an industrial setting

Use descriptors related to the life cycle stage SU3

PROC9

Name of contributing environmental scenario (1)and corresponding ERC

1. Not relevant

List of names of contributing worker scenarios (2)and corresponding PROC

1. Transfer of substance or preparation into smallcontainers (dedicated filling line, including weighing)(PROC9)

2.1 Contributing scenario (1) controlling environmental exposure

Not relevant

2.2 Contributing scenario (2) controlling worker exposure

Transfer of substance or preparation into small containers (dedicated filling line, including weighing)(PROC9)

Product characteristic

Product related conditions, e.g. the concentration ofthe substance in a mixture, the physical state of thatmixture (solid, liquid; if solid: level of dustiness),package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or per shift);note: sometimes this information is not needed forassessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift) andfrequency (e.g. single events or repeated) of exposure

More than 4 hours per day, repeated exposure(working life)

Human factors not influenced by risk management

Particular conditions of use, e.g. body parts potentiallyexposed as a result of the nature of the activity :

Exposed skin surface (cm²) : 480 (two hands, faceside only)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g. technology orprocess techniques determining the initial release ofsubstance from process into workers environment;room volume, whether the work is carried outoutdoors/indoors, process conditions related totemperature and pressure:

Indoors

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases and henceexposure of workers; this in particular includesconditions ensuring rigorous containment;performance of containment to be specified (e.g. byquantification of residual losses or exposure)

Not applicable

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation, general Not applicable

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 5 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 2

ventilation; specify effectiveness of measure :

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measures neededto support the functioning of particular technicalmeasures (e.g. training and supervision). Thosemeasures need to be reported in particular fordemonstrating strictly controlled conditions (to justifyexposure based waiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure; specifythe suitable material for the PPE (where relevant) andadvise how long the protective equipment can be usedbefore replacement (if relevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,1 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 6,86 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,1 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 6 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (6)

Industrial use in closed batch process – formulation and auxiliary in polymerization processes

Use descriptors related to the life cyclestage

SU3/10

PC0/4/8/19/20/29/32/39

PROC3

ERC2/6a/6d

Name of contributing environmentalscenario (1) and corresponding ERC

1. Formulation of preparations (ERC2)

2. Industrial use resulting in manufacture of another substance

(use of intermediates) (ERC6a)

3. Industrial use of process regulators for polymerisation

processes in production of resins, rubbers, polymers

(ERC6d)

List of names of contributing workerscenarios (2) and corresponding PROC

1. Use in closed batch process (synthesis or formulation)(PROC3)

2.1 Contributing scenario (1) controlling environmental exposure

Formulation of preparations (ERC2)Industrial use resulting in manufacture of another substance (use of intermediates) (ERC6a)Industrial use of process regulators for polymerisation processes in production of resins, rubbers, polymers(ERC6d)An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

2.2 Contributing scenario (2) controlling worker exposure

Use in closed batch process (synthesis or formulation) (PROC3)

Product characteristic

Product related conditions, e.g. the concentrationof the substance in a mixture, the physical stateof that mixture (solid, liquid; if solid: level ofdustiness), package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or pershift); note: sometimes this information is notneeded for assessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift)and frequency (e.g. single events or repeated) ofexposure

More than 4 hours per day, repeated exposure (workinglife)

Human factors not influenced by risk management

Particular conditions of use, e.g. body partspotentially exposed as a result of the nature ofthe activity :

Exposed skin surface (cm²) : 240 (one hand, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g.technology or process techniques determiningthe initial release of substance from process into

Indoors

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 6 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

workers environment; room volume, whether thework is carried out outdoors/indoors, processconditions related to temperature and pressure:

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases andhence exposure of workers; this in particularincludes conditions ensuring rigorouscontainment; performance of containment to bespecified (e.g. by quantification of residual lossesor exposure)

Not applicable

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation,general ventilation; specify effectiveness ofmeasure :

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training andsupervision). Those measures need to bereported in particular for demonstrating strictlycontrolled conditions (to justify exposure basedwaiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure;specify the suitable material for the PPE (whererelevant) and advise how long the protectiveequipment can be used before replacement (ifrelevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 1

An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 0,1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,1 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 0,343 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,1 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guarantee

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 6 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

safe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 7 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (7)

Mixing or blending in batch processes for formulation of preparations and articles (multistage and/orsignificant contact)

Use descriptors related to the life cycle stage SU10

PC0/4/8/20/29/39

PROC5

ERC2

Name of contributing environmental scenario(1) and corresponding ERC

1. Formulation of preparations (ERC2)

List of names of contributing worker scenarios(2) and corresponding PROC

1. Mixing or blending in batch processes for formulation ofpreparations and articles (multistage and/or significantcontact) (PROC5)

2.1 Contributing scenario (1) controlling environmental exposure

Formulation of preparations (ERC2)An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

2.2 Contributing scenario (2) controlling worker exposure

Mixing or blending in batch processes for formulation of preparations* and articles (multistage and/orsignificant contact) (PROC5)

Product characteristic

Product related conditions, e.g. the concentration ofthe substance in a mixture, the physical state ofthat mixture (solid, liquid; if solid: level ofdustiness), package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or per shift);note: sometimes this information is not needed forassessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift) andfrequency (e.g. single events or repeated) ofexposure

More than 4 hours per day, repeated exposure (workinglife)

Human factors not influenced by risk management

Particular conditions of use, e.g. body partspotentially exposed as a result of the nature of theactivity :

Exposed skin surface (cm²) : 480 (two hands, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g. technologyor process techniques determining the initialrelease of substance from process into workersenvironment; room volume, whether the work iscarried out outdoors/indoors, process conditionsrelated to temperature and pressure:

Indoors

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases and Not applicable

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 7 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

hence exposure of workers; this in particularincludes conditions ensuring rigorous containment;performance of containment to be specified (e.g. byquantification of residual losses or exposure)

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation,general ventilation; specify effectiveness ofmeasure :

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training and supervision).Those measures need to be reported in particularfor demonstrating strictly controlled conditions (tojustify exposure based waiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure; specifythe suitable material for the PPE (where relevant)and advise how long the protective equipment canbe used before replacement (if relevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 1

An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 2 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,5 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 13,7 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,5 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 7 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 8 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (8)

Use in batch and other process (synthesis) where opportunity for exposure arises

Use descriptors related to the life cycle stage SU3

PC19/32

PROC4

ERC6a/6d

Name of contributing environmental scenario (1)and corresponding ERC

1. Industrial use resulting in manufacture of another

substance (use of intermediates) (ERC6a)

2. Industrial use of process regulators for polymerisation

processes in production of resins, rubbers, polymers

(ERC6d)

List of names of contributing worker scenarios(2) and corresponding PROC

1. Use in batch and other process (synthesis) whereopportunity for exposure arises (PROC4)

2.1 Contributing scenario (1) controlling environmental exposure

Industrial use resulting in manufacture of another substance (use of intermediates) (ERC6a)Industrial use of process regulators for polymerisation processes in production of resins, rubbers, polymers(ERC6d)An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

2.2 Contributing scenario (2) controlling worker exposure

Use in batch and other process (synthesis) where opportunity for exposure arises (PROC4)

Product characteristic

Product related conditions, e.g. the concentration ofthe substance in a mixture, the physical state of thatmixture (solid, liquid; if solid: level of dustiness),package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or per shift);note: sometimes this information is not needed forassessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift) andfrequency (e.g. single events or repeated) ofexposure

More than 4 hours per day, repeated exposure(working life)

Human factors not influenced by risk management

Particular conditions of use, e.g. body partspotentially exposed as a result of the nature of theactivity :

Exposed skin surface (cm²) : 480 (two hands, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g. technologyor process techniques determining the initial releaseof substance from process into workers environment;room volume, whether the work is carried outoutdoors/indoors, process conditions related to

Indoors

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 8 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

temperature and pressure:

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases andhence exposure of workers; this in particular includesconditions ensuring rigorous containment;performance of containment to be specified (e.g. byquantification of residual losses or exposure)

Not applicable

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation,general ventilation; specify effectiveness of measure:

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measuresneeded to support the functioning of particulartechnical measures (e.g. training and supervision).Those measures need to be reported in particular fordemonstrating strictly controlled conditions (to justifyexposure based waiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure; specifythe suitable material for the PPE (where relevant)and advise how long the protective equipment canbe used before replacement (if relevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 1

An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,5 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 6,86 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,5 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicated

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 8 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

through Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCsfollowed;- Training staff on good practice;- Good standard of personal hygiene

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 9 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page1 of 3

1 Exposure scenario (9)

Professional use of laboratory chemicals

Use descriptors related to the life cycle stage SU22

PC21

PROC15

ERC8a

Name of contributing environmental scenario (1)and corresponding ERC

1. Wide dispersive indoor use of processing aids in open

systems (ERC8a)

List of names of contributing worker scenarios (2)and corresponding PROC

1. Use as laboratory reagent (PROC15)

2.1 Contributing scenario (1) controlling environmental exposure

Wide dispersive indoor use of processing aids in open systems (ERC8a)An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

2.2 Contributing scenario (2) controlling worker exposure

Use as laboratory reagent (PROC15)

Product characteristic

Product related conditions, e.g. the concentration ofthe substance in a mixture, the physical state of thatmixture (solid, liquid; if solid: level of dustiness),package design affecting exposure:

SolidFlakesLow dustinessSubstance as such

Amounts used

Amounts used at a workplace (per task or per shift);note: sometimes this information is not needed forassessment of worker’s exposure

Not applicable (ECETOC TRA Tier I)

Frequency and duration of use/exposure

Duration per task/activity (e.g. hours per shift) andfrequency (e.g. single events or repeated) of exposure

More than 4 hours per day, repeated exposure(working life)

Human factors not influenced by risk management

Particular conditions of use, e.g. body parts potentiallyexposed as a result of the nature of the activity :

Exposed skin surface (cm²) : 240 (one hand, face sideonly)

Other given operational conditions affecting workers exposure

Other given operational conditions: e.g. technology orprocess techniques determining the initial release ofsubstance from process into workers environment;room volume, whether the work is carried outoutdoors/indoors, process conditions related totemperature and pressure:

Indoors

Technical conditions and measures at process level (source) to prevent release

Process design aiming to prevent releases and henceexposure of workers; this in particular includesconditions ensuring rigorous containment;performance of containment to be specified (e.g. byquantification of residual losses or exposure)

Not applicable

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 9 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page2 of 3

Technical conditions and measures to control dispersion from source towards the worker

Engineering controls, e.g. exhaust ventilation, generalventilation; specify effectiveness of measure :

Not applicable

Organisational measures to prevent /limit releases, dispersion and exposure

Specific organisational measures or measures neededto support the functioning of particular technicalmeasures (e.g. training and supervision). Thosemeasures need to be reported in particular fordemonstrating strictly controlled conditions (to justifyexposure based waiving) :

Not applicable

Conditions and measures related to personal protection, hygiene and health evaluation

Personal protection, e.g. wearing of gloves, faceprotection, full body dermal protection, goggles,respirator; specify effectiveness of measure; specifythe suitable material for the PPE (where relevant) andadvise how long the protective equipment can be usedbefore replacement (if relevant) :

Chemical gogglesBreathing apparatus

3 Exposure information and reference to its source

Information for contributing scenario 1

An environmental assessment has not been performed as the substance does not meet the criteria for beingclassified as dangerous for the environment

Information for contributing scenario 2

Workers exposure estimation has been calculated using ECETOC TRA

Workers exposure Exposure estimation DNEL

Long-term - local effects, dermal 0,1 mg/cm²/day 4,5 mg/cm²

Long-term - local effects, inhalation 0,1 mg/m³ 6,3 mg/m³

Long-term - systemic effects, dermal 0,343 mg/kg bw/day 34,7 mg/kgbodyweight/day

Long-term - systemic effects, inhalation 0,1 mg/m³ 10,4 mg/m³

4 Guidance to DU to evaluate whether he works inside the boundaries set by the ES

Using the first tier model of ECETOC TRA and assuming worst case operational conditions (no LEV, no PPEand 4/8 hours exposure), the substance does not pose a risk to human health for workers in this scenario.No additional risk management measures, besides those that are mentioned above, are needed to guaranteesafe use for workers.

5 Additional good practice advice beyond the REACH CSA

Additional good practices (Operational Conditions and Risk Management Measures) beyond the REACHChemical Safety Assessment established within Chemical Industry are also advised and communicatedthrough Safety Data Sheets. Such as:- Containment as appropriate;- Minimise number of staff exposed;- Segregation of the emitting process;- Effective contaminant extraction;- Good standard of general ventilation;- Minimisation of manual phases;- Avoidance of contact with contaminated tools and objects;- Regular cleaning of equipment and work area;- Management/supervision in place to check that RMMs in place are being used correctly and OCs

ANNEX TO THE SAFETY DATA SHEETBenzoic acid SDS Reference

SubstanceExposure scenario 9 Version 1

Explanation ofacronyms

SU: Sector of use

PROC: Process category

ERC: Environmental release category

PPE: Personal protection equipment

PC: Product category

Page3 of 3

followed;- Training staff on good practice;- Good standard of personal hygiene