Bearing en a035-048

-

Upload

jesus-b-rodriguez -

Category

Documents

-

view

224 -

download

0

Transcript of Bearing en a035-048

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 1/14A-35

●Bearing Tolerances

6.1 Dimensional accuracy and running accuracy

Bearing “tolerances” or dimensional accuracy and

running accuracy, are regulated by ISO and JIS B 1514standards (rolling bearing tolerances). For dimensional

accuracy, these standards prescribe the tolerances

necessary when installing bearings on shafts or in

housings. Running accuracy is defined as the allowable

limits for bearing runout during operation.

Dimensional accuracy

Dimensional accuracy constitutes the acceptable values

for bore diameter, outer diameter, assembled bearing

width, and bore diameter uniformity as seen in chamfer

dimensions, allowable inner ring tapered bore deviation

and shape error. Also included are, average bore diameter

variation, outer diameter variation, average outer diameter

unevenness, as well as raceway width and height variation

(for thrust bearings).

Running accuracy

Running accuracy constitutes the acceptable values for

inner and outer ring radial runout and axial runout, inner

ring side runout, and outer ring outer diameter runout.Allowable rolling bearing tolerances have been

established according to precision classes. Bearing

precision is stipulated as JIS class 6, class 5, class 4, or

class 2, with precision rising from ordinary precision

indicated by class 0.

Table 6.1 indicates which standards and precision

classes are applicable to the major bearing types. Table

6.2 shows a relative comparison between JIS B 1514

precision class standards and other standards. For greater

detail on allowable limitations and values, refer to Tables

6.3 - 6.8. Allowable values for chamfer dimensions are

shown in Table 6.9, and allowable limitations and values

for radial bearing inner ring tapered bores are shown in

Table 6.10.

Table 6.1 Bearing types and applicable tolerance

Table 6.2 Comparison of tolerance classifications of national standards

Bearing type

Deep groove ball bearings

Spherical roller thrust bearings

Thrust ball bearings

Spherical roller bearings

Taperedrollerbearings

Cylindrical roller bearigns

Self-aligning ball bearings

Angular contact ball bearings

Needle roller bearings

Applicable standard Tolerance class Tolerance table

metric

Inch

J series

JIS B 1514

(ISO492)

JIS B 1514

ANSI/ABMA Std.19

ANSI/ABMA Std.19.1

JIS B 1514(ISO199)

class 0

class 0

class 0

class 0

class 0

class 0

class 0,6X

class 4

class K

class 0

class 0

class 6

class 6

class 6

class 6

class 6

class 2

class N

class 6 class 5

class C

class 3

class 5

class 5

class 5

class 5

class 5 class 4

class 4

class 4

class 4

class 4

class 0

class B

class 4

class A

class 00

class 2

class 2

class 2

ー ー ー ー

ー

ー

ー

ー

ーーーー

ーーー

Table 6.3

Table 6.4

Table 6.5

Table 6.6

Table 6.7

Table 6.8

Standard Applicable standerd

Japanese industrialstandard (JIS)

Tolerance Class Bearing Types

Class 0,6X Class 6 Class 2

International Organizationfor Standardization (ISO)

Deutsches Institutfur Normung(DIN)

American NationalStandards Institute (ANSI)

Class 5 Class 4JIS B 1514

ISO 492

ISO 199

ISO 578

ISO 1224

DIN 620

ANSI/ABMA Std.20

ANSI/ABMA Std.19.1

ANSI/ABMA Std.19

Normalclass

Class 6XClass 6

Class 6

Class N

Class 2

NormalClass

Class 4

P0

ABEC-1RBEC-1

Class K

Class 4

Class 5 Class 4 Class 2

Class 5 Class 4

Class 3 Class 0 Class 00

Class 5A Class 4A

Class C Class B Class A

Class 3 Class 0 Class 00

ABEC-3RBEC-3

ABEC-5RBEC-5

ABEC-7 ABEC-9

P6 P5 P4 P2

ー

ーー ー

ー

All type

Radial bearings

Thrust ball bearings

Tapered roller bearings (Inch series)

Precision instrument bearings

All type

Radial bearings(Except tapered roller bearings)

Tapered roller bearings (Metric series)

Tapered roller bearings (Inch series)

American Bearing

Manufacturer's Association(ABMA)

1

1 "ABEC" is applied for ball bearings and "RBEC" for roller bearings.

Notes 1: JIS B 1514, ISO 492 and 199, and DIN 620 have the same specification level.

2: The tolerance and allowance of JIS B 1514 are a little different from those of ABMA standards.

6. Bearing Tolerances

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 2/14

●Bearing Tolerances

A-36

Table 6.3 Tolerance of radial bearings (Except tapered roller bearings)Table 6.3 (1) Inner rings

Table 6.3 (2) Outer rings

Nominal

bore diameter

d

mm

over incl.

Dimensional tolerance of mean

bore diameter within plane

∆dmp

Bore diameter variation

V dp

1 The dimensional difference ∆ds of bore diameter to applied for class 4 and 2 is the same as the tolerance of dimentional difference ∆dmp of average bore diameter.

However, the dimensional difference is applied to diameter series 0, 1, 2, 3 and 4 against Class 4, and to all the diameter series against Class 2.

4

1 1

high low high low high low high low high low

class 0 class 6 class 5 class 4 class 2

diameter series 9

class0

class6

class5

class4

class2

max

diameter series 0.1

class0

class6

class5

class4

class2

max

diameter series 2.3.4

class0

class6

class5

class4

class2

max

0.6

2.5

10

18

30

50

80

120150

180

250

315

400

500

630

800

1 000

1 250

1 600

2.5

10

18

30

50

80

120

150180

250

315

400

500

630

800

1 000

1 250

1 600

2 000

0

0

0

0

0

0

0

00

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

00

0

0

0

0

0

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

0

0

ー

ー

ー

ー

ー

ー

ー

-5

-5

-5

-6

-8

-9

-10

-13-13

-15

-18

-23

ー

ー

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

ー

ー

ー

ー

ー

ー

ー

ー

ー

-4

-4

-4

-5

-6

-7

-8

-10-10

-12

ー

ー

ー

ー

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

ー

ー

ー

ー

ー

ー

ー

ー

ー

-2.5

-2.5

-2.5

-2.5

-2.5

-4

-5

-7-7

-8

ー

ー

ー

ー

ー

ー

ー

ー

ー

-8

-8

-8

-10

-12

-15

-20

-25-25

-30

-35

-40

-45

-50

-75

-100

-125

-160

-200

-7

-7

-7

-8

-10

-12

-15

-18-18

-22

-25

-30

-35

-40

ー

ー

ー

ー

ー

10

10

10

13

15

19

25

3131

38

44

50

56

63

ー

ー

ー

ー

ー

9

9

9

10

13

15

19

2323

28

31

38

44

50

ー

ー

ー

ー

ー

5

5

5

6

8

9

10

1313

15

18

23

ー

ー

ー

ー

ー

ー

ー

4

4

4

5

6

7

8

1010

12

ー

ー

ー

ー

ー

ー

ー

ー

ー

2.5

2.5

2.5

2.5

2.5

4

5

77

8

ー

ー

ー

ー

ー

ー

ー

ー

ー

8

8

8

10

12

19

25

3131

38

44

50

56

63

ー

ー

ー

ー

ー

7

7

7

8

10

15

19

2323

28

31

38

44

50

ー

ー

ー

ー

ー

4

4

4

5

6

7

8

1010

12

14

18

ー

ー

ー

ー

ー

ー

ー

3

3

3

4

5

5

6

88

9

ー

ー

ー

ー

ー

ー

ー

ー

ー

2.5

2.5

2.5

2.5

2.5

4

5

77

8

ー

ー

ー

ー

ー

ー

ー

ー

ー

6

6

6

8

9

11

15

1919

23

26

30

34

38

ー

ー

ー

ー

ー

5

5

5

6

8

9

11

1414

17

19

23

26

30

ー

ー

ー

ー

ー

4

4

4

5

6

7

8

1010

12

14

18

ー

ー

ー

ー

ー

ー

ー

3

3

3

4

5

5

6

88

9

ー

ー

ー

ー

ー

ー

ー

ー

ー

2.5

2.5

2.5

2.5

2.5

4

5

77

8

ー

ー

ー

ー

ー

ー

ー

ー

ー

Nominal outside

diameter

D

mm

over incl.

Dimensional tolerance of mean outsidediameter within plane

∆ Dmp

Outside diameter variation

V Dp

open type

5 The dimensional difference ∆ Ds of outer diameter to be applied for classes 4 and 2 is the same as the tolerance of dimensional difference ∆ Dmp of average outer

diameter. However, the dimensional difference is applied to diameter series 0, 1, 2, 3 and 4 against Class 4, and also to all the diameter series against Class 2.

8

5 5

6

high low high low high low high low high low

class 0 class 6 class 5 class 4 class 2

diameter series 9

class0

class6

class5

class4

class2

max

diameter series 0.1

class0

class6

class5

class4

class2

max

diameter series 2.3.4

class0

class6

class5

class4

class2

max

2.5

6

18

30

50

80

120

150

180

250

315

400

500

630

800

1 0001 250

1 600

2 000

6

18

30

50

80

120

150

180

250

315

400

500

630

800

1 000

1 2501 600

2 000

2 500

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

00

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

ーー

ー

ー

0

0

0

0

0

0

0

0

0

0

0

0

0

0

ー

ーー

ー

ー

-5

-5

-6

-7

-9

-10

-11

-13

-15

-18

-20

-23

-28

-35

ー

ー ー

ー

ー

0

0

0

0

0

0

0

0

0

0

0

ー

ー

ー

ー

ーー

ー

ー

-4

-4

-5

-6

-7

-8

-9

-10

-11

-13

-15

ー

ー

ー

ー

ー ー

ー

ー

0

0

0

0

0

0

0

0

0

0

0

ー

ー

ー

ー

ーー

ー

ー

-2.5

-2.5

-4

-4

-4

-5

-5

-7

-8

-8

-10

ー

ー

ー

ー

ー ー

ー

ー

-8

-8

-9

-11

-13

-15

-18

-25

-30

-35

-40

-45

-50

-75

-100

-125-160

-200

-250

-7

-7

-8

-9

-11

-13

-15

-18

-20

-25

-28

-33

-38

-45

-60

ー ー

ー

ー

10

10

12

14

16

19

23

31

38

44

50

56

63

94

125

ー ー

ー

ー

9

9

10

11

14

16

19

23

25

31

35

41

48

56

75

ーー

ー

ー

5

5

6

7

9

10

11

13

15

18

20

23

28

35

ー

ーー

ー

ー

4

4

5

6

7

8

9

10

11

13

15

ー

ー

ー

ー

ーー

ー

ー

2.5

2.5

4

4

4

5

5

7

8

8

10

ー

ー

ー

ー

ーー

ー

ー

8

8

9

11

13

19

23

31

38

44

50

56

63

94

125

ー ー

ー

ー

7

7

8

9

11

16

19

23

25

31

35

41

48

56

75

ー ー

ー

ー

4

4

5

5

7

8

8

10

11

14

15

17

21

26

ー

ー ー

ー

ー

3

3

4

5

5

6

7

8

8

10

11

ー

ー

ー

ー

ー ー

ー

ー

6

6

7

8

10

11

14

19

23

26

30

34

38

55

75

ー ー

ー

ー

5

5

6

7

8

10

11

14

15

19

21

25

29

34

45

ー ー

ー

ー

4

4

5

5

7

8

8

10

11

14

15

17

21

26

ー

ー ー

ー

ー

3

3

4

5

5

6

7

8

8

10

11

ー

ー

ー

ー

ーー

ー

ー

2.5

2.5

4

4

4

5

5

7

8

8

10

ー

ー

ー

ー

ーー

ー

ー

2.5

2.5

4

4

4

5

5

7

8

8

10

ー

ー

ー

ー

ーー

ー

ー

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 3/14

A-37

●Bearing Tolerances

Mean bore diameter

variation

V dmp

Inner ring

radial runout

K ia

Unitμm

Side runout

with bore

Sd

Inner ring

axial runout

Sia

Inner ring width deviation

∆ Bs

Inner ring width

variation

V Bs

2 Applies to ball bearings such as deep groove ball bearings and angular ball bearings.

3 To be applied for individual raceway rings manufactured for combined bearing use.4 Nominal bore diameter of bearings of 0.6 mm is included in this dimensional division.

23

class0

class6

class5

class4

class2

max

class0

class6

class5

class5

class4

class2

class4

class2

max max

class5

class4

class2

max high low high lowhigh low

normal

class 0,6 class 5,4

high low high low

class 0,6 class 5,4class 2

modified

class0

class6

class5

class4

class2

max

6

6

6

8

9

11

15

1919

23

26

30

34

38

55

75

94

120

150

5

5

5

6

8

9

11

1414

17

19

23

26

30

ー

ー

ー

ー

ー

3

3

3

3

4

5

5

77

8

9

12

ー

ー

ー

ー

ー

ー

ー

2

2

2

2.5

3

3.5

4

55

6

ー

ー

ー

ー

ー

ー

ー

ー

ー

1.5

1.5

1.5

1.5

1.5

2

2.5

3.53.5

4

ー

ー

ー

ー

ー

ー

ー

ー

ー

10

10

10

13

15

20

25

3030

40

50

60

65

70

80

90

100

120

140

5

6

7

8

10

10

13

1818

20

25

30

35

40

ー

ー

ー

ー

ー

4

4

4

4

5

5

6

88

10

13

15

ー

ー

ー

ー

ー

ー

ー

2.5

2.5

2.5

3

4

4

5

66

8

ー

ー

ー

ー

ー

ー

ー

ー

ー

1.5

1.5

1.5

2.5

2.5

2.5

2.5

2.55

5

ー

ー

ー

ー

ー

ー

ー

ー

ー

7

7

7

8

8

8

9

1010

11

13

15

ー

ー

ー

ー

ー

ー

ー

3

3

3

4

4

5

5

66

7

ー

ー

ー

ー

ー

ー

ー

ー

ー

1.5

1.5

1.5

1.5

1.5

1.5

2.5

2.54

5

ー

ー

ー

ー

ー

ー

ー

ー

ー

7

7

7

8

8

8

9

1010

13

15

20

ー

ー

ー

ー

ー

ー

ー

2.5

2.5

2.5

2.5

3

4

4

55

6

ー

ー

ー

ー

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

0

0

0

0

0

0

0

0

0

-40

-120

-120

-120

-120

-150

-200

-250-250

-300

-350

-400

-450

-500

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

0

0

ー

ー

ー

ー

ー

ー

ー

-40

-40

-80

-120

-120

-150

-200

-250-250

-300

ー

ー

ー

ー

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

ー

ー

ー

ー

ー

ー

ー

ー

ー

-40

-40

-80

-120

-120

-150

-200

-250-250

-300

ー

ー

ー

ー

ー

ー

ー

ー

ー

ー

-250

-250

-250

-250

-380

-380

-500-500

-500

-500

-630

ー

ー

ー

ー

ー

ー

ー

ー

0

0

0

0

0

0

00

0

0

0

ー

ー

ー

ー

ー

ー

ー

0

0

0

0

0

0

0

00

0

0

0

ー

ー

ー

ー

ー

ー

ー

-250

-250

-250

-250

-250

-250

-380

-380-380

-500

ー

ー

ー

ー

ー

ー

ー

ー

ー

12

15

20

20

20

25

25

3030

30

35

40

50

60

70

80

100

120

140

12

15

20

20

20

25

25

3030

30

35

40

45

50

ー

ー

ー

ー

ー

5

5

5

5

5

6

7

88

10

13

15

ー

ー

ー

ー

ー

ー

ー

1.5

1.5

1.5

1.5

1.5

1.5

2.5

2.54

5

ー

ー

ー

ー

ー

ー

ー

ー

ー

1.5

1.5

1.5

2.5

2.5

2.5

2.5

2.55

5

ー

ー

ー

ー

ー

ー

ー

ー

ー

3

3

3

4

4

5

5

77

8

ー

ー

ー

ー

ー

ー

ー

ー

ー

2,3,4 0,1,2,3,4

10

10

12

16

20

26

30

38

―

―――

―――

――――

9

9

10

13

16

20

25

30

―

―――

―――

――――

6

6

7

8

10

11

14

19

23

26

30

34

38

55

75

――――

5

5

6

7

8

10

11

14

15

19

21

25

29

34

45

――――

3

3

3

4

5

5

6

7

8

9

10

12

14

18

―

――――

2

2

2.5

3

3.5

4

5

5

6

7

8

―

―――

――――

1.5

1.5

2

2

2

2.5

2.5

3.5

4

4

5

―

―――

――――

Mean bore diametervariationV Dmp

Unit μm

Outer ring radial runout

K ea

2.5

2.5

2.5

2.5

3

4

5

5

7

7

8

―

―――

――――

Outside surfaceinclination

SD

class 0,6

5

5

5

5

6

8

8

8

10

11

13

15

18

20

―

――――

1.5

1.5

1.5

1.5

1.5

2.5

2.5

2.5

4

5

7

―

―――

――――

6 To be applied in case snap rings are not installed on the bearings.

7 Applies to ball bearings such as deep groove ball bearings and angular ball bearings.

8 Nominal outer diameter of bearings of 2.5 mm is included in this dimensional division.

15

15

15

20

25

35

40

45

50

60

70

80

100

120

140

160190

220

250

8

8

9

10

13

18

20

23

25

30

35

40

50

60

75

――――

5

5

6

7

8

10

11

13

15

18

20

23

25

30

―

――――

3

3

4

5

5

6

7

8

10

11

13

―

―――

――――

1.5

1.5

2.5

2.5

4

5

5

5

7

7

8

―

―――

――――

8

8

8

8

8

9

10

10

11

13

13

15

18

20

―

――――

4

4

4

4

4

5

5

5

7

8

10

―

―――

――――

1.5

1.5

1.5

1.5

1.5

2.5

2.5

2.5

4

5

7

―

―――

――――

Outside ringaxial runout

Sea

8

8

8

8

10

11

13

14

15

18

20

23

25

30

―

――――

5

5

5

5

5

6

7

8

10

10

13

―

―――

――――

1.5

1.5

2.5

2.5

4

5

5

5

7

7

8

―

―――

――――

Outer ringwidth

deviation

∆Cs

all type

Depends on

tolerance of

∆ Bs in relationto d of same

bearing

Depends

on

toleranceof ∆ Bs in

relation to

d of same

bearing

6

7

class0class 0 class 6

class6

class5

class4

class2

max

class0

class6

class5

class4

class2

max

class5

class4

class2

max

class5

class4

class2

max

class5

class4

class2

maxmax

Outside diametervariation V DP

Sealed/shieldbearings

diameter series

Outer ring widthvariation

V Cs

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 4/14

●Bearing Tolerances

A-38

Table 6.4 Tolerance of tapered roller bearings (Metric series)

Table 6.4 (1) Inner rings

Table 6.4 (2) Outer rings

Nominal

bore diameter

d

mm

over incl.

10

18

30

50

80

120

180

250315

400

500

630

800

18

30

50

80

120

180

250

315400

500

630

800

1,000

Dimensional tolerance of mean

bore diameter within plane

∆dmp

0

0

0

0

0

0

0

00

―――

―

0

0

0

0

0

0

0

――

―――

―

0

0

0

0

0

0

0

――

―――

―

-5

-6

-8

-9

-10

-13

-15

――

―――

―

-12

-12

-12

-15

-20

-25

-30

-35-40

―――

―

-7

-8

-10

-12

-15

-18

-22

――

―――

―

1 The dimensional difference ∆ds of bore diameter to be applied for class 4 is the same as the tolerance of dimensional difference ∆dmp of average bore diameter.

Bore diameter

variation

V dp

12

12

12

15

20

25

30

3540

―――

―

7

8

10

12

15

18

22

――

―――

―

5

6

8

9

11

14

17

――

―――

―

4

5

6

7

8

10

11

――

―――

―

Mean bore diameter

variation

V dmp

9

9

9

11

15

19

23

2630

―――

―

5

6

8

9

11

14

16

――

―――

―

5

5

5

6

8

9

11

――

―――

―

4

4

5

5

5

7

8

――

―――

―

Inner ring radial runout

K ia

15

18

20

25

30

35

50

6070

―――

―

7

8

10

10

13

18

20

――

―――

―

5

5

6

7

8

11

13

――

―――

―

3

3

4

4

5

6

8

――

―――

―

Side

runoutwith bore

Sd

7

8

8

8

9

10

11

――

―――

―

3

4

4

5

5

6

7

――

―――

―

1class 0,6X class 5,6

high low high low high low

class 4class0,6X

class6

class5

class4

max

class0,6X

class6

class5

class4

max

class0,6X

class6

class5

class4

class5

class4

max max

Nominaloutside

diameter

D mm

over incl.

18

30

50

80

120

150

180

250

315

400

500

30

50

80

120

150

180

250

315

400

500

630

Dimensional tolerance of meanoutside diameter within plane

∆ Dmp

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

――

0

0

0

0

0

0

0

0

0

――

-6

-7

-9

-10

-11

-13

-15

-18

-20

――

-12

-14

-16

-18

-20

-25

-30

-35

-40

-45

-50

-8

-9

-11

-13

-15

-18

-20

-25

-28

――

2 Does not apply to bearings with flange.3 The dimensional difference ∆ Ds of outside diameter to be applied for class 4 is the same as the tolerance of dimensional difference D Dmp of average outside diameter.

Outside diametervariation

V Dp

12

14

16

18

20

25

30

35

40

45

50

8

9

11

13

15

18

20

25

28

――

6

7

8

10

11

14

15

19

22

――

5

5

7

8

8

10

11

14

15

――

Mean bore diametervariation

V Dmp

9

11

12

14

15

19

23

26

30

34

38

6

7

8

10

11

14

15

19

21

――

5

5

6

7

8

9

10

13

14

――

4

5

5

5

6

7

8

9

10

――

Outer ring radial runout

K ea

18

20

25

35

40

45

50

60

70

80

100

9

10

13

18

20

23

25

30

35

――

6

7

8

10

11

13

15

18

20

――

4

5

5

6

7

8

10

11

13

――

Outsidesurface

inclination

SD

8

8

8

9

10

10

11

13

13

――

4

4

4

5

5

5

7

8

10

――

2

3class 0,6X class 5,6 class 4

class0,6X

class6

class5

class4

max

class0,6X

class6

class5

class4

max

class0,6X

class6

class5

class4

max

class5

class4

maxhigh low high low high low

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 5/14

●Bearing Tolerances

A-39

Table 6.4 (3) Effective width of outer and inner rings with roller

Inner ring

axial runout

Sia

Inner ring width deviation

∆ Bs

∆T s

Combination width

deviation of doublerow bearings

∆ B1s, ∆C1s

Combination width

deviation of 4-rowbearings

∆ B2s, ∆C2s

Unitμm

class 4

max

class 0,6 class 6X class 4,5

high low high low high low

class 0,6 class 6X class 4,5

high low high low high low

class 0,6,5

high low

class 0,6,5

high low

Assembly width deviation of single-row

tapered roller bearings

0

0

0

0

0

0

0

00

ー

ー

ー

ー

0

0

0

0

0

0

0

00

ー

ー

ー

ー

0

0

0

0

0

0

0

ー

ー

ー

ー

ー

ー

-200

-200

-240

-300

-400

-500

-600

ー ー

ー

ー

ー

ー

-120

-120

-120

-150

-200

-250

-300

-350-400

ー

ー

ー

ー

-50

-50

-50

-50

-50

-50

-50

-50-50

ー

ー

ー

ー

+200

+200

+200

+200

+200

+350

+350

+350+400

ー

ー

ー

ー

0

0

0

0

-200

-250

-250

-250-400

ー

ー

ー

ー

ー

ー

+240

+300

+400

+500

+600

+700+800

+900

+1 000

+1 500

+1 500

3

4

4

4

5

7

8

ー

ー

ー

ー

ー

ー

+100

+100

+100

+100

+100

+150

+150

+200+200

ー

ー

ー

ー

0

0

0

0

0

0

0

00

ー

ー

ー

ー

+200

+200

+200

+200

+200

+350

+350

ー ー

ー

ー

ー

ー

-200

-200

-200

-200

-200

-250

-250

ー ー

ー

ー

ー

ー

ー

ー

-240

-300

-400

-500

-600

-700-800

-900

-1 000

-1 500

-1 500

ー

ー

ー

ー

+500

+600

+750

+900+1 000

+1 200

+1 200

+1 500

+1 500

ー

ー

ー

ー

-500

-600

-750

-900-1 000

-1 200

-1 200

-1 500

-1 500

Outer ring axialrunout

Sea

Outer ring width deviation

∆Cs

0

0

0

0

0

0

0

0

0

0

0

-100

-100

-100

-100

-100

-100

-100

-100

-100

-100

-100

5

5

5

6

7

8

10

10

13

――

Depends on

tolerance of

∆ Bs in

relation to d

of same

bearing

Unitμm

4class 0,6,5,4 class 6Xclass 4

max sup. inf. sup. inf.

4 Applies to bearing where d is greater than 10 mmbut is less than or equal to 400 mm.

Nominal bore diameter

d mm

over incl.

Effective width deviationof roller and inner ring assemblyof tapered roller bearing

∆T 1s

+100

+100

+100

+100

+100

+150

+150

+150

+200

10

18

30

50

80

120

180

250

315

Unitμm

18

30

50

80

120

180

250

315

400

0

0

0

0

-100

-150

-150

-150

-200

+50

+50

+50

+50

+50

+50

+50

+100

+100

0

0

0

0

0

0

0

0

0

Tapered roller bearing outerring effective width deviation

∆T 2s

+100

+100

+100

+100

+100

+200

+200

+200

+200

0

0

0

0

-100

-100

-100

-100

-200

+50

+50

+50

+50

+50

+100

+100

+100

+100

0

0

0

0

0

0

0

0

0

class 0 class 6X

high low high low

class 0 class 6X

high low high low

Master conesub-unit

Master cupsub-unitT 1 T 2

φd φd

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 6/14

●Bearing Tolerances

A-40

Table 6.5 Tolerance of tapered roller bearings (Inch series)

Table 6.5 (1) Inner rings

Table 6.5 (2) Outer rings

Table 6.5 (3) Single-row tapered roller bearing assembly width, combination width of 4-row bearings,effective width of inner ring with rollers, effective width of outer ring

Table 6.5 (4) Radial deflection of inner and outer rings

Single bore diameter deviation

∆ds

Class 4

+13

+25

+25

+51

+76

+102

+127

0

0

0

0

0

0

0

+13

+25

+25

+51

――

―

0

0

0

0

――

―

+13

+13

+13

+25

+38

+51

+76

0

0

0

0

0

0

0

+13

+13

+13

―――

―

0

0

0

―――

―

+8

+8

―

―――

―

0

0

―

―――

―

Class 2 Class 3 Class 0 Class 00

Unitμm

Nominal bore diameter

d

mm (inch)

over incl. high low high low high low high low high low

76.2

266.7

304.8

609.6

914.4

1 219.2

−

( 3 )

(10.5)

(12 )

(24 )

(36 )

(48 )

( 3 )

(10.5)

(12 )

(24 )

(36 )

(48 )

−

76.2

266.7

304.8

609.6

914.4

1 219.2

Nominal outside diameter

D

mm (inch)

Single outside diameter deviation

∆ Ds

+25

+25

+51

+76+102

+127

0

0

0

00

0

+25

+25

+51

+76――

0

0

0

0――

+13

+13

+25

+38+51

+76

0

0

0

00

0

+13

+13

―

―――

0

0

―

―――

+8

――

―――

0

――

―――

Unitμm

over incl.

Class 4 Class 2 Class 3 Class 0 Class 00

high low high low high low high low high low

266.7

304.8

609.6914.4

1 219.2

266.7

304.8

609.6

914.41 219.2

−

(10.5)

(12 )

(24 )(36 )

(48 )

(10.5)

(12 )

(24 )

(36 )(48 )

−

Nominalbore

diameter

d

mm (inch)

Overall width deviation of assembled single row tapered roller bearing

∆T s

+203+356

+381

+381

+381

0-254

-381

-381

-381

+203+203

+381

+381

―

00

-381

-381

―

+203+203

+203

+381

+381

-203-203

-203

-381

-381

+203+203

―

――

-203-203

―

――

Class 4,2,3,0

Nominaloutside

diameter

D

mm (inch)

− 508.0 (20)

508.0 (20)

−

Overall width deviation

of assembled 4-row

tapered roller bearings

∆ B2s, ∆C2s

over incl. over incl. high low

Class 4

high low

Class 2

high low

Class 3

high low high low

Class 0,00

− 101.6 ( 4)

304.8 (12)

304.8 (12)

609.6 (24)

101.6 ( 4)304.8 (12)

609.6 (24)

609.6 (36)

−

+1 524+1 524

+1 524

+1 524

+1 524

-1 524-1 524

-1 524

-1 524

-1 524

51

51

76

76

38

38

51

―

8

18

51

76

4

――

―

2

――

―

Class 2 Class 0

Unitμm

Nominal outside diameter

D

mm (inch)

Inner ring radial runout K ia

Outer ring radial runout K ea

Class 4 Class 3

max

Class 00

over incl.

―

304.8 (14)

609.6 (24)

914.4 (36)

304.8 (14)

609.6 (24)

914.4 (36)

―

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 7/14

A-41

●Bearing Tolerances

Effective width deviation of roller and innerring assembly of tapered roller bearing

∆T 1s

+102+152

―

――

0-152

―

――

+102+102

+178

――

00

-178

――

+102+102

+102

――

-102-102

-102

――

Unitμm

Tapered roller bearing outer ring effective width deviation

∆T 2s

+102+203

―

――

0-102

―

――

+102+102

+203

――

00

-203

――

+102+102

+102

――

-102-102

-102

――

1 To be applied for nominal bore diameters d of 406.400 mm (16 inch) or less.

1 1 1 1

Class 4

high low

Class 2

high low

Class 3

high low

Class 4

high low

Class 2

high low

Class 3

high low

Master conesub-unit

Master cupsub-unitT 1 T 2

φd φd

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 8/14

●Bearing Tolerances

A-42

Table 6.6 Tolerance of tapered roller bearings of J series (Metric series)

Table 6.6 (1) Inner rings

Table 6.6 (2) Outer rings

Table 6.6 (3) Effective width of inner and outer rings

10

18

30

50

80

120

180

18

30

50

80

120

180

250

0

0

0

0

0

0

0

-12

-12

-12

-15

-20

-25

-30

0

0

0

0

0

0

0

-12

-12

-12

-15

-20

-25

-30

0

0

0

0

0

0

0

-7

-8

-10

-12

-15

-18

-22

0

0

0

0

0

0

0

-5

-6

-8

-9

-10

-13

-15

12

12

12

15

20

25

30

12

12

12

15

20

25

30

4

4

4

5

5

5

6

3

3

3

3

3

3

4

9

9

9

11

15

19

23

9

9

9

11

15

19

23

5

5

5

5

5

5

5

4

4

5

5

5

7

8

Nominal

borediameter

d

mm

Bore diameter variation

V dp

Mean bore diameter

variation

V dmp

Mean bore diameter deviation

∆dmp

Class

K

Class

N

Class

C

Class

B

Class

K

Class

N

Class

C

Class

B

Class

K

Class

N

Class

C

Class

B

Note: Please consult NTN Engineering for Class A bearings.

over incl. high low high low high low high low max max

18

3050

80

120

150

180

250

315

30

5080

120

150

180

250

315

400

0

00

0

0

0

0

0

0

-12

-14-16

-18

-20

-25

-30

-35

-40

0

00

0

0

0

0

0

0

-12

-14-16

-18

-20

-25

-30

-35

-40

0

00

0

0

0

0

0

0

-8

-9-11

-13

-15

-18

-20

-25

-28

0

00

0

0

0

0

0

0

-6

-7-9

-10

-11

-13

-15

-18

-20

12

1416

18

20

25

30

35

40

12

1416

18

20

25

30

35

40

4

44

5

5

5

6

8

10

3

33

3

3

3

4

5

5

9

1112

14

15

19

23

26

30

9

1112

14

15

19

23

26

30

5

56

7

8

9

10

13

14

4

55

5

6

7

8

9

10

3

34

4

4

5

6

6

6

Nominaloutsidediameter

D

mm

Outside diametervariation

V Dp

Mean outsidediameter variation

V Dmp

outer ringaxial runout

Sea

Mean outside diameter deviation

∆ Dmp

Class

K

Class

N

Class

C

Class

B

Note: Please consult NTN Engineering for Class A bearings.

Class

K

over incl. high low

Class

N

high low

Class

C

high low

Class

B

high low max

Class

K

Class

N

Class

C

Class

B

Class

B

max max

80

120

180

250

10

80

120

180

0

-100

-150

-150

+100

+100

+150

+150

0

0

0

0

+50

+50

+50

+50

-100

-100

-100

-150

+100

+100

+100

+100

***

*

Note 1: "*" mark are to be manufactured only for combined bearings.

2: Please consultNTN

Engineering for Class A bearings.

Unitμm

0

-100

-100

-100

+100

+100

+200

+200

0

0

0

0

+50

+50

+100

+100

-100

-100

-150

-150

+100

+100

+100

+100

***

*

Nominalbore

diameter

d

mm

over incl. high low high low high low high low high low high low high low high low

Class

K

Class

N

Class

C

Class

B

Class

N

Class

K

Class

C

Class

B

***

*

***

*

Effective width deviation of roller and inner ringassembly of tapered roller bearing

∆T 1s

Tapered roller bearing outer ringeffective width deviation

∆T 2s

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 9/14

Unitμm

18

20

25

35

40

45

50

60

70

18

20

25

35

40

45

50

60

70

5

6

6

6

7

8

10

11

13

3

3

4

4

4

4

5

5

5

Inner ring radial runout K iaand

Outer ring radial runout K ea

max

Class

K

Class

N

Class

C

Class

B

18

30

50

80

120

150

180

250

315

30

50

80

120

150

180

250

315

400

Note: Please consult NTN Engineering for Class A bearings.

Nominaloutside

diameter

D

mm

over incl.

●Bearing Tolerances

A-43

Table 6.6 (4) Radial runout of inner and outer rings

3

4

4

4

5

7

8

+200

+200

+200

+200

+200

+350

+350

0

0

0

0

-200

-250

-250

+100

+100

+100

+100

+100

+150

+150

0

0

0

0

0

0

0

+200

+200

+200

+200

+200

+350

+350

-200

-200

-200

-200

-200

-250

-300

+200

+200

+200

+200

+200

+200

+200

-200

-200

-200

-200

-200

-250

-300

Inner ring

axial runout

Sia

Class

B

max sup inf sup inf sup inf sup inf

Class

K

Class

N

Class

C

Class

B

Overall width deviation of assembled

tapered roller bearing

∆T s

Unitμm

Master conesub-unit

Master cupsub-unitT 1 T 2

φd φd

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 10/14

Nominaloutsidediameter

D

mm

over incl.

Mean outside diameter deviation

∆ Dmp

0

0

0

0

0

0

0

0

0

0

0

0

-11

-13

-16

-19

-22

-25

-30

-35

-40

-45

-50

-75

Outside diametervariation

V Dp

0

0

0

0

0

0

0

0

0

0

0

0

-7

-8

-9

-11

-13

-15

-20

-25

-28

-33

-38

-45

10

18

30

50

80

120

180

250

315

400

500

630

18

30

50

80

120

180

250

315

400

500

630

800

8

10

12

14

17

19

23

26

30

34

38

55

5

6

7

8

10

11

15

19

21

25

29

34

According to the tolerance

of S1 against "d" of the same

bearings

Raceway thickness variation

Se

Unitμm

Class

0,6,5

high low

Class

4

high low

Class

0,6,5

Class

4

max

Class

0

Class

6

Class

5

Class

4

max

Nominal

borediameter

d

mm

over incl.

0

0

0

0

0

0

0

00

0

0

-8

-10

-12

-15

-20

-25

-30

-35-40

-45

-50

Bore diameter

variation

V dp

0

0

0

0

0

0

0

00

0

0

-7

-8

-10

-12

-15

-18

-22

-25-30

-35

-40

―18

30

50

80

120

180

250315

400

500

18

30

50

80

120

180

250

315400

500

630

6

8

9

11

15

19

23

2630

34

38

5

6

8

9

11

14

17

1923

26

30

10

10

10

10

15

15

20

2530

30

35

5

5

6

7

8

9

10

1315

18

21

3

3

3

4

4

5

5

77

9

11

2

2

2

3

3

4

4

55

6

7

Raceway thickness variation

Si

Unitμm

Class

0,6,5

high low

Class

4

high low

Class

0,6,5

Class

4

max

Class

0

Class

6

Class

5

Class

4

max

Mean bore diameter deviation

∆dmp

●Bearing Tolerances

A-44

Table 6.7 (2) Housing raceway washer

Table 6.7 (3) Bearing height

Table 6.7 Tolerance of thrust ball bearings

Table 6.7 (1) Shaft raceway washer

Nominalbore

diameter

d

mm

over incl. high low

0

0

0

0

0

0

0

0

0

0

-75

-100

-125

-150

-175

-200

-225

-300

-350

-400

―30

50

80

120

180

250

315

400

500

30

50

80

120

180

250

315

400

500

630

Unitμm

Single direction

Bearing heightdeviation

∆T s

1 This standard is applied for flat back face bearing of class 0.

1

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 11/14

●Bearing Tolerances

A-45

Table 6.8 Tolerance of spherical thrust roller bearing

Table 6.8 (1) Shaft raceway washer

Table 6.8 (2) Housing raceway washer

50 80 0 -15 11 25 +150 -150

120 180 0 -25 19 30 +250 -250

180 250 0 -30 23 30 +300 -300

250 315 0 -35 26 35 +350 -350

315 400 0 -40 30 40 +400 -400

400 500 0 -45 34 45 +450 -450

80 120 0 -20 15 25 +200 -200

Unitμm

Nominalbore diameter

d

mm

over incl. high low high lowmax max

Borediametervariation

V dp

Siderunout

with bore

Sd

Bearing heightdeviation

∆T s

Mean borediameter deviation

∆dmp

120

180

250

315

400

500

630

800

180

250

315

400

500

630

800

1,000

0

0

0

0

0

0

0

0

-25

-30

-35

-40

-45

-50

-75

-100

Unitμm

Nominaloutside diameter

D

mm

Single plane meanoutside diameter

deviation

∆ Dmp

over incl. high low

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 12/14

●Bearing Tolerances

A-46

Unit mm

r s min1

orr 1s min

Nominalbore diameter

d over incl.

r s max or r 1s max

Radialdirection

Axialdirection

0.05

0.08

0.1

0.15

0.2

0.3

0.6

1

1.1

1.5

2.1

3

2.5

4

5

6

7.5

9.5

12

15

19

2

―

―

―

―

―

―

40

―

40

―

50

―

120

―

120

―

80

220

―

280

―

100

280

―

280

―

―

―

―

―

―

―

―

―

―

―

―

―

40

―

40

―

50

―

120

―

120

―

80

220

―

280

―100

280

―

280

―

―

―

―

―

―

―

―

―

0.1

0.16

0.2

0.3

0.5

0.6

0.8

1

1.3

1.5

1.9

2

2.5

2.3

3

3

3.5

3.8

4

4.5

3.8

4.5

5

5

5.5

6.5

8

10

12.5

15

18

21

25

0.2

0.3

0.4

0.6

0.8

1

1

2

2

3

3

3.5

4

4

5

4.5

5

6

6.5

7

6

6

7

8

8

9

10

13

17

19

24

30

38

1 These are the allowable minimum dimensions of the chamfer dimension

"r " or "r 1" and are described in the dimensional table.

Table 6.9 Allowable critical-value of bearing chamfer

Table 6.9 (1) Radial bearing (Except tapered roller bearing) Table 6.9 (2) Tapered roller bearings of metric series

Unit mm

r s min2

orr 1s min

r s max or r 1s max

0.3

0.6

1

5

3

―

40

―

40

―

50

―

120

250

―

120

250

―

120

250

―

120

250

400

―120

250

400

―

180

―

180

40

―

40

―

50

―

120

250

―

120

250

―

120

250

―

120

250

400

―

120

250

400

―

180

―

180

―

0.7

0.9

1.1

1.3

1.6

1.9

2.3

2.8

3.5

2.8

3.5

4

3.5

4

4.5

4

4.5

5

5.5

5

5.5

6

6.5

6.5

7.5

7.5

9

1.4

1.6

1.7

2

2.5

3

3

3.5

4

4

4.5

5

5

5.5

6

5.5

6.5

7

7.5

7

7.5

8

8.5

8

9

10

11

2 These are the allowable minimum dimensions of the chamfer dimension

"r " or "r 1" and are described in the dimensional table.

3 Inner rings shall be in accordance with the division of "d" and outer rings

with that of " D".

Note: This standard will be applied to the bearings whose dimensional series

(refer to the dimensional table) are specified in the standard of ISO 355

or JIS B 1512. For further information concerning bearings outside of

these standards or tapered roller bearings using US customary unit,

please contact NTN Engineering.

1.5

2

2.5

4

6

Radialdirection

Axialdirection

Nominal bore3

diameter of bearing"d" or nominal

outside diameter " D"over incl.

6.2 Chamfer measurements and tolerance orallowable values of tapered bore Side face of inner

ring or center

washer, or side face

of outer ring

Bore diameter face

of bearing or outer

diameter face of

bearing (Axial direction)

r s minor r 1s min ( R a d i a l d i r e c t i o n )

r s max or r 1s max

r s m i n o r r 1 s m i n

r s m a x o r r 1 s m a x

r s minor r 1s min

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 13/14

A-47

●Bearing Tolerances

Table 6.9 (3) Thrust bearingsTable 6.10 (1) Tolerance of and tolerance values for tapered bore of

radial bearingsStandard taper ratio 1:12 tapared hole (class 0)

Table 6.10 (2) Tolerance of and tolerance values for tapered bore ofradial bearingsStandard taper ratio 1:30 tapered bore (class 0)

d mm

over incl. high low high low max

V dp∆dmp

10

18

30

50

80

120

180

250

315

400

500

630

8001,000

1,250

1,600

10

18

30

50

80

120

180

250

315

400

500

630800

1,000

1,250

0

0

0

22

27

33

+

+

+

0

0

0

39

46

54

+

+

+

0

0

0

63

72

81

+

+

+

0

0

0

89

97

110

+

+

+

00

0

0

125140

165

195

++

+

+

0

0

0

15

18

21

+

+

+

0

0

0

25

30

35

+

+

+

0

0

0

40

46

52

+

+

+

0

0

0

57

63

70

+

+

+

00

0

0

8090

105

125

++

+

+

9

11

13

16

19

22

40

46

52

57

63

70

――――

Unitμm

1 2-∆d1mp ∆dmp

d mm

over incl.

low

V dp

max

∆dmp

high low

high

80

120

180

250315

400

500

630

50

80

120

180250

315

400

500

0

0

0

+15

+20

+25

00

0

+30+35

+40

0

0

+45

+50

0

0

0

+30

+35

+40

00

0

+46+52

+57

0

0

+63

+70

19

22

40

4652

57

63

70

1 Applies to all radial flat planes of inner ring tapered bore.

2 Does not apply to diameter series 7 and 8.

Note: Quantifiers

For a standard taper ratio of 1:12 d1=d+ B

For a standard taper ratio of 1:30 d1=d+ B

∆dmp :Dimensional difference of the average borediameter within the flat surface at the theoreticalsmall end of the tapered bore.

∆d1mp :Dimensional difference of the average bore

diameter within the flat surface at the theoreticallarge end of the tapered bore.

V dp:Unevenness of the bore diameter with the flat surface B :Nominal width of inner ring α :Half of the tapered bore’s nominal taper angle

For a standard taper ratio of 1:12 α=2°23′9.4″For a standard taper ratio of 1:30 α=0°57′7.4″

Units μm

112

1 2

130

-∆d1mp ∆dmp

0.05

0.08

0.1

0.15

0.2

0.3

0.6

1

1.1

1.5

2

2.1

4

3

5

6

7.5

9.5

19

12

15

0.1

0.16

0.2

0.3

0.5

0.8

1.5

2.2

2.7

3.5

4

4.5

5.5

6.5

21

15

25

10

8

12.5

18

4 These are the allowable minimum dimensions of the chamfer

dimension "r " or "r 1" and are described in the dimensional table.

r s max or r 1s max

Radial and axial direcitionr s min or r 1 min

4

Unit mm

α

φ ( d + ∆ d m p )

φ ( d 1 + ∆ d

1 m p )

∆ d 1 m p − ∆ d m p

B B

φ

d 1

φ

d

Theoretical tapered bore Tapered bore having dimensionaldifference of the average borediameter within the flat surface

α

2

7/28/2019 Bearing en a035-048

http://slidepdf.com/reader/full/bearing-en-a035-048 14/14

●Bearing Tolerances

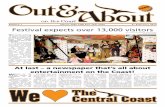

6.3 Bearing tolerance measurement methods

For reference, measurement methods for rolling bearing

tolerances are in JIS B 1515.

Table 6.11 shows some of the major methods of

measuring rotation tolerances.

Table 6.11 Rotation tolerance measurement methods

Inner ring radial runout

( K ia)

Outer ring radial runout

( K ea)

Inner ring axial runout

( Sia)

Outer ring axial runout

( Sea)

Inner ring side

runout with bore

( Sd)

Outer ring outside

surface inclination

( SD)

Characteristic tolerance Measurement method

Measuring load Measuring load

Measuring loadMeasuring load

Measuring load Measuring load

Measuring loadMeasuring load

Reinforcingplate

1.2r s max

1.2r s max

Radial runout of the inner ring isthe difference between themaximum and minimum readingof the measuring device whenthe inner ring is turned onerevolution.

Radial runout of the outer ring isthe difference between themaximum and minimum readingof the measuring device whenthe outer ring is turned onerevolution.

Axial runout of the inner ring isthe difference between themaximum and minimum readingof the measuring device whenthe inner ring is turned onerevolution.

Axial runout of the outer ring isthe difference between themaximum and minimum readingof the measuring device whenthe outer ring is turned onerevolution.

Inner ring side runout with boreis the difference between themaximum and minimum readingof the measuring device whenthe inner ring is turned onerevolution together with the

tapered mandrel.

Outer ring outside surfaceinclination is the differencebetween the maximum andminimum reading of the measuringdevice when the outside ring isturned one revolution along thereinforcing plate.