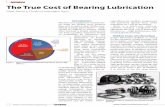

Bearing and Motor Lubrication

-

Upload

jade-limbago -

Category

Documents

-

view

131 -

download

4

Transcript of Bearing and Motor Lubrication

BEARING AND MOTOR LUBRICATION

BY: Albert Abijay and Michael James Piagola

TOPIC OUTLINE

WHAT IS BEARING AND ITS PURPOSE BASIC TYPES OF BEARING BEARING CONSTRUCTION BEARING SELECTION CONSIDERATIONS BASED ON ITS

APPLICATION COMMON BEARING APPLICATION INSPECTION & INSPECTION CHECKLIST MOTOR BEARING LUBRICATION

- Types & Purpose of Lubrication- Consideration- Common Bearing Failures

TROUBLES AND REMEDIES SAFETY INSTRUCTIONS

WHAT IS BEARING AND ITS PURPOSE1. BEARING – IS A INTEGRAL PART OF

ROTATING EQUIPMENTS TO REDUCE FRICTION AND CONSEQUENTLY REDUCE POWER REQUIREMENT OF A DRIVE SYSTEM.

TYPICAL BEARING @ PLANTSITE Ore Prep. Area

HPAL AreaCam Shaft Bearing Pillow Block & Thrust

BearingPillow Block Bearing

Motor & Pump Assy. Bearing Motor & Agitator Assy. Bearing

TYPICAL BEARING @ PLANTSITE CCD & NTRL Area

Motor & Pump Bearing Assy. CCD & NTRL Slew Ring Bearing Assy. Zinc, MS, FNTRL, LIMESTONE & CHEMICAL Area

Motor &Agitator Bearing Assy.

Motor & Pump Bearing Assy.

BASIC TYPES OF BEARINGBALL BEARINGROLLER BEARING 1. CYLINDRICAL BEARING 2. TAPERED ROLLER BEARING 3. SPHERICAL ROLLER BEARINGJOURNAL BEARING- Travagrate, engine’s

main bearing, shake-out machines and camshaft bearings.

BEARING CONSTRUCTION

BEARING CONSTRUCTION

BEARING SELECTION CONSIDERATIONS BASED ON ITS APPLICATIONINTERNAL CLEARANCE – LOAD,

TEMPERATURE, SPEED, ALLOWABLE MISALIGNMENT

CAGE AND MATERIALSLUBRICANT, SEALING AND LUBRICATION

METHOD

COMMON BEARING APPLICATIONPILLOW BLOCK BEARING – CONVEYOR

SYSTEM (HEAD PULLEY, TAIL PULLEY, TAKE-UP PULLEY AND IDLER PULLEY)

PLUMMER’S BLOCK BEARING – CONVEYOR SYSTEM

ROTATING EQUIPMENTSBEARING ASSEMBLY – FOR WARMAN

PUMPS, AGITATORS, ETC

INSPECTIONMETHOD OF INSPECTION 1. BY SENSES A. VISUAL (EYES) – LEAKS, DRY,LOOSE, DAMAGED B. TOUCH – ABNORMAL VIBRATION AND HEAT GENERATION C. HEAR – ABNORMAL SOUND D. SMELL – BURNT OIL OR GREASE 2. BY INSTRUMENT A. THERMOMETER (INFRARED) B. VIBROMETER C. STETHOSCOPE

INSPECTION CHECKLIST

Abnormalities Drive End Bearing

(DE)

Non-Drive End Bearing (NDE)

Remarks

Yes No Yes No

Abnormal Sound

Excessive Heat Generation

Excessive Vibration

MOTOR BEARING CONDITION

Criteria for Inspection using an instruments (Vibrometer & Infrared Thermometer).

1. Criteria for vibration readings depend on the motor size and capacity.

2. Bearing housing normal operating temperature depend on motor specifications

LUBRICATIONPurpose of LubricationReduction of friction and wear.Dissipation of friction heat.Prolonged bearing life.Prevention of rustProtection against harmful element

LUBRICATIONTYPES OF LUBRICATION 1. OIL LUBRICATION A. OIL-BATH LUBRICATION B. DRIP LUBRICATION C. CIRCULATING LUBRICATION D. SPRAY LUBRICATION, ETC 2. GREASE LUBRICATION A. MANUAL APPLICATION OF GREASE B. AUTOMATIC GREASE PUMP LUBRICATION

LUBRICATIONCONSIDERATIONS: 1. OIL/GREASE GRADE 2. INTERVAL 3. QUANTITY 4. CRITERIA A. TEMPERATURE B. CONDITION (VISUAL) C. VIBRATION D. SOUND

LUBRICATIONNDE Grease Fitting DE Grease Fitting

Non-Drive End Bearing Drive End

Bearing

TROUBLES AND REMEDIESAbnormalities Possible Causes Action to be taken Inspection Method Countermeasures

Senses Instrument

Excessive/Abnormal Heat Generation

- Over Greasing - Close monitoring and check running hours after the last greasing

Touch Infrared Thermometer

Monitor greasing interval and running hours (Every one month or 750 Hrs interval.

- Lack of greasing -hours after the last greasing.- Apply grease

SoundTouch Visual

StethoscopeInfrared ThermometerVibrometer

Monitor greasing interval and running hours

- Failure/Damaged -Close monitoring SoundTouch

StethoscopeInfrared ThermometerVibrometer

Replace

Abnormal Sound Lack of lubrication Apply grease SoundTouch

StethoscopeInfrared ThermometerVibrometer

Apply grease gradually and monitor the changes of temperature and vibration

Failure/Damaged Close monitor SoundTouch

StethoscopeInfrared ThermometerVibrometer

Replace

Misalignment Check alignment VisualSoundTouch

Using straight edge

Stop and isolate and check the alignment

TROUBLE AND REMEDIESAbnormalities Possible Causes Action to be taken Inspection Method Countermeasures

Senses Instrument

Excessive Vibration - Failure/Damaged -Close monitoring SoundTouch

StethoscopeInfrared ThermometerVibrometer

Replace

- Lack of greasing -hours after the last greasing.- Apply grease

SoundTouch Visual

StethoscopeInfrared ThermometerVibrometer

Monitor greasing interval and running hours

Misalignment/loose mounting

Check alignment and mounting VisualSoundTouch

Using straight edge

Stop and isolate and check the alignment

Excessive Vibration and abnormal sound after motor start-up and abnormal temperature

- Over Greasing (Greasing was done in shorter interval)

- Monitor and check running hours after the last greasing

Touch Infrared ThermometerVibrometer

Necessary to monitor the motor’s running hours for greasing interval.

Failure and damaged due to long time standby. Flaking due to metal to metal contact

Close monitor SoundTouch

StethoscopeInfrared ThermometerVibrometer

Implement proper equipment utilization and manual turning

MOTOR BEARING LUBRICATION MOTOR GREASING CONSIDERATIONS

1. INTERVAL – CONDITIONED BASED OR TIME-BASED (ONCE A MONTH AND RUNNING HOURS OR DEPEND ON

MANUFACTURER’S RECOMMENDATION. 2. QUANTITY – DEPEND ON THE BEARING SIZE, SHOTS PER

MANUFACTURER’S RECOMMENDATION. BEARING RANGE FROM 40 TO 60 SHOTS WITH AVERAGE 1.5 GRAMS PER SHOT (STANDARD MANUAL GREASE GUN). RECOMMENDED GREASING QUANTITY IS 30%TO 40% OF THE BEARING SPACE AND 30% TO 60% FOR HOUSING.

3. GREASE GRADE – USUAL GRADE FOR MOTOR BEARING IS RL-3.

4. AS REQUIRED BASED ON EXISTING CONDITION.

COMMON MOTOR BEARING FAILURES (Lubrication)OVER GREASINGLACK OF LUBRICATIONBEARING NOT SUITABLE FOR

APPLICATIONMISALIGNMENTCONTAMINATIONLEAKSWRONG GREASE

Safety Instructions Always wear the minimum PPE requirements during the inspection. Be aware of excessive noise while conducting an inspection. Always wear

ear plugs. Be aware of possibly splashing of solution due to leak at the working area. Hands off from the rotating parts. Keep a safe distance from rotating equipments. Be aware of loose clothing and belonging’s that might caught by rotating

elements. Be aware of slipping and tripping hazards at the working area. Always

watch your steps. Be aware of sharp edges and always wear leather gloves. Low head room. Conduct finger pointing and calling and always wear hard

hat.

TEST I:MULTIPLE CHOICEItem Questions Select Answer Answer

(Letter)A B C D E

1 Most common type of bearing Needle Bearing

Tapered Roller Bearing

Ball Bearing Cylindrical Bearing

Spherical Bearing

2 What is not the possible cause of abnormal heat generation

Lack of greasing

Over greasing Dirty motor housing

Wrong grease Exposed to the heat of the sun

3 The tools use for applying grease for motor

Degreaser Greaser Jack Grease Nipple

Grease Gun Grease Fitting

4 Motor re-greasing interval must be based on _________

Monthly Bi-monthly Running Hours

Weekly Existing condition

5 What is the average amount of grease per shot

1.0 gram per shot

1.25 grams per shot

1.5 grams per shot

1.75 grams per shot

2.0 grams per shot

6 Bearing failure can not be detected and observed by

Touching Visual Inspection

Hearing Vibrometer Infrared Thermometer

TEST 2: IDENTIFICATION7.

8.

9.

10.

PILLOW BLOCK

THERMOMETER Use to measure temperature profile of bearing

VIBROMETER Use for reading of acceleration & velocity profile of bearing

STETHOSCOPE Use for manual listening of abnormal sound within the bearing

BEARING ASSEMBLYPump Bearing

Pump Bearing Assy.

ROTATING EQUIPMENT Fan Bearing @ Utility Area

OVERGREASING Damage of oil seal & winding

LACK/POOR LUBRICATION Damage cage, inner ring, & rolling elements

DAMAGED BEARING

CAGE

CONTAMINATION Contamination that result to corrosion & damage winding

MISALIGNMENT Damage rolling elements, inner ring, cage & abrasion of shaft

BALL BEARING

TAPERED ROLLER BEARING

SPHERICAL ROLLER BEARING

CYLINDRICAL ROLLER BEARING