Batterie Voltabox agli ioni di litio

-

Upload

roberto-rob-barbiani -

Category

Documents

-

view

212 -

download

0

Transcript of Batterie Voltabox agli ioni di litio

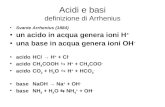

-

8/20/2019 Batterie Voltabox agli ioni di litio

1/2

In an age when the demands on lithium-ion battery

systems are increasing, the need for flexibility, speed

and cost effectiveness cannot be underestimated

Superior batterypack solutions

SUPPLIER INTERVIEW: VOLTABOX

WORDS: KARL VADASZFFY

Offering high-performance batterysystems for local public transportand commercial vehicles, VoltaboxDeutschland and Voltabox of Texasare new, wholly owned subsidiaries

of Paragon AG, which has developed andmanufactured automotive electronic solutionssince 1988.

Formally run under the banner of Paragon’sElectromobilty business unit, new brand Voltabox supplies safe, high-performanceLi-ion batteries for all types of vehicle-basedapplications – in particular hybrid, trolley,and electrical buses. And, with its mostrecent modular battery system for prismaticcells, the company has added the materialhandling market as well as stationaryapplications to its portfolio.

Voltabox, which was launched this year,uses only cells sourced direct from premium,well-known suppliers such as Samsung,Toshiba, K2 Energy and A123. This meansthe company has the direct support of theoriginal equipment supplier, providing costsavings while enabling direct access to thenewest technology to enhance technical datathat won’t be found in common data sheets.

The German company focuses on Li-ion

battery technology, the advantages of whichare explained by Paragon CEO Klaus DieterFrers: “In vehicles, in comparison with leadacid battery systems, lifetime, load time, andusability in combination with lowtemperatures, are superior.

“With trolley buses, for example, arequirement could be to operate purelybattery-driven for 10 or 15 miles on a smallhill. If you consider battery weight, this isonly possible technically and cost-wiseregarding lifetime costs with Li-ion batterysystems. In addition, there’s a weight savingof 50-60%, plus space savings. As a vehicle,

a bus offers lots of physical space, but with

Li-ion, they have more space to transportpeople rather than batteries.”

Branching out

Design, development and production of

Voltabox’s high-performance battery systemsfor its European customers takes place in itsheadquarters in Delbrück, Germany, where ateam of over 30 is based in a recently opened2,000m² production facility.

Frers adds, “Research, development anddesign of our battery modules will be done inGermany. I am keen to be hands-on with theR&D, especially in the case of the BMS, theelectronics, and the software behind thearchitecture, and we provide these for our American colleagues. So Texas will bededicated to sales and production.”

Indeed, for its North American, Canadian

and South American clients, Voltabox will

“We’ve developed battery systems

that will live for nearly as long as

the whole bus – 10 years or longer”Klaus Dieter Frers, CEO, Paragon AG

1. Voltabox nickelmanganese cobaltoxide (NMC) andlithium titanate oxide(LTO) modules

2. A Hess trolley busequipped with ahigh-performance

Voltabox battery system

Electric & Hybrid Vehicle Technology International // July 2014 // 133

2

1

SEE US AT

-

8/20/2019 Batterie Voltabox agli ioni di litio

2/2

possible lifetimes, “so we’ve developed batterysystems that will live for nearly as long as the

whole bus – 10 years or longer, assuming wiseuse” adds Frers. “For these applications, LTO(lithium titanate oxide) cells are the optimalsolution. LTO cells are stable for more than10,000 cycles and, in the right usage, even20,000 cycles.” The LTO cell’s energy densityis 89Wh/kg or 172Wh/l.

As par t of the Ohio project, Voltaboxwill provide a dual-mode trolley bus batterysystem. Its nominal voltage level will be600V, with a total capacity of 61kW/h.Comprising 1,512 LTO cells per system(42 modules, each with 36 cells), theconfiguration will enable up to 24km

battery-driven distance with a 12m bus,with all 43 seats taken. Impressively, in thisapplication, there wil l be up to six load cyclesper day, in up to 18 operating hours per day.

A further applicat ion for which Voltabox’smodular system for prismatic cells is ideal isvehicles used in material handling, such asforklifts. Both 24V and 48V Li-ion batteries,traditionally the standard in theseapplications with the lead acid batteriesthat have been favored until recently, areemployed. Frers says, “Two, four, six, eightand, in some cases, 10 of these modules willbe packed in special containers, combinedwith an external master BMS unit that weproduce, and a display unit will be addedto show the parameters of the battery. Ourmaintenance-free, high-performance batterysystems will ensure the robustness andquality of the vehicles, which are keycomponents of any modern, smooth-runninglogistics operation.”

Frers is also keen to point out that Voltaboxis not limited to the industries on which ithas already made its mark. “With thesenew modules based on prismatic cells,” heconcludes, “we have a ready solution forcar and motorcycle batteries. In fact, we’reworking on exciting projects in these areas

that, for now, will remain confidential.”

open a 2,140m² production facility in CedarPark, a suburb of Austin, Texas, in September.This facility wil l turn out mass-produced Voltabox batteries on assembly l ines identicalto those found in Germany, with the samemaximized degree of automation andend-to-end process monitoring to guaranteeoptimum quality.

Reputed to be the birthplace of lithiumphosphate technology, Austin offers Voltaboxan impressive potential employment base.“Various groundbreaking discoveries in thefield of Li-ion technology originated atuniversities in the region, including theUniversity of Texas and Park University, andthe Southwest Research Institute,” commentsFrers, “which led to the growth of organizationsthat have developed and contributed to someoutstanding infrastructure.

“In the environment of Austin, therefore,there are a lot of very highly skilled people,both from universities as well as rivalcompanies. This means well-qualifiedemployees are always within reach, whichwe intend to take full advantage of.”

Production on projects in Cedar Park willbegin in September, with series batterysystems expected to be delivered from theend of the month onward. In production willbe the company’s new modular systems forprismatic cells. Frers states, “On the onehand, we integrate NMC (nickel manganesecobalt oxide) cells in new 24V Li-ionmodules. Weighing only 18kg, they arevery reliable for up to 6,000 cycles, whilehaving a good energy density (135Wh/kg or316Wh/l) with regard to their size and weight.”

For certain applications, such as its next USproject, which will be for the city of Dayton,

Ohio, batteries are required to have very long

SUPPLIER INTERVIEW: VOLTABOX

1. An example VoltaboxLiFePO4 module, based on

cylindrical cell type 26650

2. A Voltabox batterypack, with LiFePO4 modulesinside, fully integrated activeclimate system and CANcommunications interface

1

2

134 // July 2014 // Electric & Hybrid Vehicle Technology International

“In the environment of

Austin there are a lot

of very highly skilled

people, both from

universities as well as

rival companies. This

means well-qualified

employees are always

within reach, which

we intend to take full

advantage of”Klaus Dieter Frers, CEO, Paragon AG