BASE UNIT - Wren Kitchens · 2019-04-18 · Step 3. Screw back panel in position using 2 x 16mm...

Transcript of BASE UNIT - Wren Kitchens · 2019-04-18 · Step 3. Screw back panel in position using 2 x 16mm...

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.indd

10003 Drawers

8002 Drawers

6002 Drawers

BASE UNIT600 - 1000 Hob

2/3 Drawer

Carcass Assembly

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.inddPage 1

BEFORE YOU START

INSTALLATION SHOULD BE

PERFORMED BY A COMPETENT

PERSON ONLY.

THIS PRODUCT COULDBE DANGEROUSIF INCORRECTLY

INSTALLED

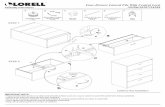

Standard Drawer (Packed Separately)Fitting Pack Contents

REQUIRED TOOLS

NOT to be used with CAM DOWEL

& CAM LOCK

DRAWERCOVER

CAP x2

DRAWERCOVER

CAP x2

METAL BACK PANELx 1

DRAWER SIDEx1 Right Hand

DRAWER SIDEx1 Right Hand

DRAWER SIDEx1 Left Hand

DRAWER SIDEx1 Left Hand

DRAWERFRONT FIXING

x 2

DRAWERFRONT FIXING

x 2

Deep Drawer (Packed Separately)Fitting Pack Contents

(Y) x2 Gallery Head

(J) x16 Drawer Runner16mm Screws

(J) x16 Drawer Runner16mm Screws

(N) x1 Door Buffer

(N) x1 Door Buffer

(Q) x421mmScrew

(Q) x421mmScrew

(L) x215mmScrew

METAL BACK PANELx 1

DRAWERBASE

x 1

DRAWERBASE

x 1

DRAWER RUNNERx 1 Right Hand

DRAWER RUNNERx 1 Right Hand

FRONTAL(Supplied separately)

FRONTAL(Supplied separately)

DRAWER RUNNERx 1 Left Hand

DRAWER RUNNERx 1 Left Hand

GALLERY RAIL

x 2

Fixingclip

& (Q)

BASE UNIT600 - 1000 Hob

2/3 Drawer

Standard Drawer Assembly

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.indd Page 2

Step 2.Clip on metal back panel to drawer base & drawer sides.

Step 3.Screw back panel in positionusing 2 x 16mm screws (J) to drawer base in holes provided.

Step 1.Secure drawer base to drawer side using 4 x 16mm drawer runner screws (J) in holes provided.

Seat the edge of drawer base tight into corner of casing, as shown.

The decorative face of drawer base to be positioned as shown.

View from back

Front of drawer

View on side of drawer side

Decorative face

Drawer base

1

32b

2a

Metal back panel

Metal back panel

Drawer basewhite decorative

face up

J

J

J

JJ

JJ

J

J

J

Step 4.Frontal AttachmentSecure drawer side fixing clips using 2 x 21mm screws (Q) in pilot holes provided as shown.

Step 5.Draw AdjustmentScrew point 1 as shownto adjust drawer frontal right & left.

Drawerbase

Fixing clip& (Q)

Fixingclip

& (Q)

Standard drawer

Step 6.Fit Drawer Cover Caps

over drawer side adjustment.

Screw point 2a as shown to adjust drawer frontal up & down.

Tighten 2b once in position.

Releasing fixing clip. Screw point 3 whilst applying downward pressure as shown to release.

DrawerCover Cap

Fixingclip

Drawer Frontal Adjustment

Drawer frontal

Drawer side

Drawer sidefixing clip

Q

Q

J

Drawer frontal

Repeat step 1 so both drawer sides are attached to drawer base.

99mm67mm

99mm67mm

BASE UNIT600 - 1000 Hob

2/3 Drawer

Deep DrawerAssembly

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.inddPage 3

Step 1.Secure drawer base to drawer side using 4 x 16mm drawer runner screws (J) in holes provided.Seat the edge of drawerbase tight into corner ofcasing, as shown.The decorative face of drawer base to be positioned as shown.

J

J

J

J

J

J

Drawerbase

Fixing clip& (Q)

Fixingclip

& (Q)

Drawer side

Drawer sidefixing clip

Q

Q

2

1

J

J Step 2.Clip on metal back panel to drawer base & drawer sides.

Y & L Y & L

Step 5.Draw AdjustmentScrew point 1 as shown to adjust drawer frontalright & left.

Step 6.Fit Gallery Rail into the top corners of Metal BackPanel.Locate front end of the Gallery Rail into the opening of the gallery Head, which is secured to the frontal as shown

Step 7.Fit Drawer Cover Caps

over drawer side adjustment.Drawer Cover Cap

Drawer Frontal Adjustment

Screw point 2a as shown to adjustdrawer frontal up & down.

Tighten 2b once in position.

Releasing fixing clip. Screw point 3 whilst applying downward pressure as shown to release. View on side of drawer side

Deep drawer

Front of drawer

Decorative face

Drawer base

J

J Metal back panel

Drawer basewhite decorative

face up

Step 3.Screw back panel in position using 2 x 16mm screws (J) to drawer base in holes provided.

Step 4.Frontal AttachmentSecure drawer side fixing clips & Gallery Head (Y) using 2 x 21mm screws (Q) in pilot holes provided as shown.

Fixing clip

Gallery Head

Repeat step 1 so both drawer sides are attached to drawer base.

Drawer frontal

Drawer frontal

View from back

Metal back panel

J

231mm

99mm67mm

231mm

99mm67mm

BASE UNIT600 - 1000 Hob

2/3 Drawer

Carcass Assembly

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.indd Page 4

Fixing clip& (Q)

Y & L

(F) x8 Wooden Dowel

(G) x6Cam Dowel(Expanding)

(H) x6 Cam Lock

(K) x430mmScrew

(L) x1215mm Screw

(M) x4 Cover Cap

Panel Bx2 End Panel

Panel Ex1 Rail

Panel Cx1 Base Panel

Shelfx1

Sink Railx1

Legsx4 or 5 as req’d

Frontal(Packed separately)

x1 or 2 as Req’d

Panel Ax1 Back Panel

REQUIRED TOOLS

NOT to be used with CAM DOWEL

& CAM LOCK

sink rail + screws

600 - *off800 - *off

1000 - *off

BEFORE YOU START

INSTALLATION SHOULD BE

PERFORMED BY A COMPETENT

PERSON ONLY.

THIS PRODUCT COULDBE DANGEROUSIF INCORRECTLY

INSTALLED

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.inddPage 5

2 drawer

3 drawer

Step 1.To attach drawer runnerscrew into end panels (B) using 2 x 16mm screws (J) per drawer rail, into pilot holes provided,3rd hole from front, as shown.

In the case of a 140 Dummy drawer, utilise secondary drilling (blue) to secure fixing clips.

B

B

37mm 261mm

74mm

646mm

360mm

431mm

74mm

fro

m f

ront

fro

m f

ront

from base

Drawer runner bracket screw position

JJ

J

J

from base

636mm

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.indd Page 6

Step 2.Seat dowel (F) into holes inboth end panels (B) as shown.

Step 3.Seat cam dowel (G) into holes inboth end panels (B) as shown.

Step 5.Join panels (C) to (B).Insert cam lock (H). Do NOT tighten until Step 6.

All Cam Locks (H) are to be positioned facing the outside of the unit carcass, for ease of tightening.

Do NOT use power tools withcam dowel (G) or cam lock (H)

Seat (G) cam dowelinto hole asshown.

B

B

C

BB

View from underside View from underside

H

G

G

H

Sink

Rai

l

Step 4.Attach panels (C) & (E) to panels (B), using dowels (F) (orange) and cam dowel (G) & cam lock (H) (blue) in positions shown. Insert sink rails as shown & secure with 2 x 15mm screws (L) into panels (B).

G G

G

G GF FF F

FF

B B

Sink RailInsert

Sink RailInsert

Dowel (F), Cam Dowel (G) & Sink Rail Screw

Location detail

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.inddPage 7

9mm

Step 6.Slide back panel (A) intogroove of end panels (B).

The back Panel (A) is to be modified accordingly to suit Customer Requirements,prior to inserting into cabinet. for 1000 width cabinets, the Back panel.

Once back panel (A) is in position, ensure the panel is flush & square with bottom of end panels (B).

Step 7.Hand tighten all cam locks (H), this will expand cam dowels (G) and tighten the unit together.

Step 8.Ensure carcass is square. Secure back panel (A) with 3 or 4 x 30mm screws (K) equally spaced at the bottom of back panel (A) into base panel (C), as shown.

Ensure you screw into the centre of the base panels (C) (9mm from the edge).

B

E

C

A

K

B

C A

600 Carcase used for example

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.indd Page 8

Step 9.Secure each of the legs into place with 2 x 15mm screws (L).600-800 Width Cabinets, 4 legs1000 with Cabinets, 5 legs

Step 11.Push leg firmly down into leg base.Adjust legs to 155mm before turning carcass upright. Once in situ level accordingly.

Ensure legs are rotated as shown so that part of it is supporting the end panels (B).

Front legs should have flat edge to the front.

Leg position diagram1000 Carcase used for example

C

C

B

L

L

B

B

BFront

Front

Front

CC

BB Step 10.

Lightly hit centre peg of leg base with hammer until flush.

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.inddPage 9

Securing to adjacent unitsScrew into any side units using the 30mm screws (K) provided to secure to the unit. Screw just to the rear at the top and bottom of both sides of the unit, place a cover cap (M) on the head to conceal it.

WorktopScrew up through the front sink rail (and additional rail where applicable) into worktop to secure it in place.

Screws for attaching to worktop are not supplied as these vary depending on worktop material and thickness. Ensure appropriate fixings for attaching worktop are used. Please refer to the specialist worktop supplier if these are required for solid surface worktops.

K

Securing to WallSecure unit to wall using 2 Screws. Drill 2 pilot holes through the back rail into the wall and insert wall plugs, tighten the screws.

Screws for attaching to walls are not provided as these vary depending on your wall material and construction. Ensure appropriate fixings for wall construction are used.

BASE UNIT600 - 1000 Hob 2/3 Drawer

Assembly Guide

For Internal Use: FI.WR.INS.058_WKIN00112_BASE_600-1000_2-3Drw_Hob_Rev1.indd Page 10