Bangalore Underpass IGC 2006

-

Upload

saritasoham -

Category

Documents

-

view

43 -

download

2

description

Transcript of Bangalore Underpass IGC 2006

-

IGC 2006, 14-16 December 2006, Chennai, INDIA

759

GE

OIN

DE

X

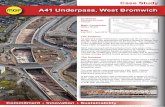

UNDERPASS AT AIR FORCE STATION YELAHANKA, BANGALORE

Sivakumar Babu G. L. Srinivasa Murthy B. R. Amit Srivastava Department of Civil Engineering, Indian Institute of Science, Bangalore [email protected]

ABSTRACT: An underpass was constructed recently in Bangalore using soil nailing, box jacking and the geotechnical aspects and these techniques are reported in this paper. The construction procedure and various aspects of the construction are also discussed. Soil nailing technique has been used extensively throughout the project to improve the stability of excavated vertical cuts. Soil nailing and the underpass are examined by detailed numerical analysis using FLAC3D. A few results of the analysis of excavations stabilized using nailing and the construction of underpass are given in the paper.

1. INTRODUCTION

For the construction of underpasses, soil nailing and box jacking techniques have been used. With the soil nailing, stabilization of excavations was made for approach roads of the underpass and, box jacking was used to push and place the concrete box elements without disturbing the traffic above. The concept of soil nailing consists of placing the closely spaced soil nails to increase the overall shear strength of the in-situ soil and restrain its displacements during and after excavation. The main advantage of the soil nailing lies in its relatively low cost and requires small equipment to drive the nails, as compared to conventional construction of retaining wall system and also in terms of saving of space and time without interrupting the moving traffic on the road above. The adaptability of soil nailing to different site conditions and its capacity to withstand large total and differential settlements than conventional structures, particularly in earthquake prone areas prompts engineers for its use.

1.1 Box jacking / tunneling

It is a non-intrusive method for constructing a new under-bridge, culvert or subway beneath existing surface infrastructure, for example railways and highways. The method enables traffic flows to be maintained through- out the construction period, and maintained with only minor restrictions during the brief period of tunneling. The inconvenience and costs of disruption to infrastructure and traffic flows experienced with traditional construction methods can be avoided. Typically, an open-ended reinforced concrete box is cast on a jacking base adjacent to the road where the underpass

is proposed. A purpose designed tunneling shield is provided sometimes at its leading end, and thrust jacks are provided at its rear end reacting against a jacking beam. The box is then jacked slowly through the ground under the road/railway in a carefully controlled tunneling operation. Excavation and jacking take place alternately in small increments of advance. Measures are taken to ensure stability of the tunnel face and to prevent the ground from being dragged forward by the advancing box. When the box has reached its final position, jacking equipments are removed, and bridge construction is completed with the addition of wing walls and road pavement. The principal benefits of jacked box tunneling are:

A non-intrusive construction method.

Minimal disturbance to surface infrastructure.

Traffic flows maintained throughout the construction period.

An efficient structural and aesthetically elegant form of elements.

1.2 Soil nailing

The in-situ soil has good strength properties and possesses undrained cohesion, which cannot be relied upon under saturated conditions. The stability of vertical cut is analyzed and it was found that the unsupported vertical cut is not safe (FS < 1.5). Hence soil nailing is used to impart stability to the existing vertical cut of 6.8 m high. The design of soil nailing is based on conventional method of resisting the earth pressures of the cut considering the pull out resistance of the soil nail system and the tensile capacity of the nails and a configuration of

-

IGC 2006, 14-16 December 2006, Chennai, INDIA

760

20 mm diameter tor steel bars of 5.0 m length at a spacing of 500 x 500 mm is arrived at. The nails of required length, diameter and spacing were driven using jackhammer. Wire mesh is attached to the soil surface and welded to the nails and the surface is shotcreted with 75 mm lean concrete mix. Figure 1 shows the details of soil-reinforced section. Using similar procedure, two nailed walls were constructed and the performance has been found to be satisfactory (Srinivasa Murthy et al. 2002), Sivakumar Babu et al. 2002) and the technique has been implemented in many excavation projects.

Fig. 1 Soil nailing

For the numerical analysis, FLAC3D is used to examine the response of the vertical cut with soil nailing. The behavior of soil is assumed elastic perfectly plastic Mohr-Coulomb model. Nails were modeled as elastic elements. The material properties of the soil and nails used are shown in Table 1. It was assumed that the interface elements show a minor effect and hence, neglected.

Table 1. Material properties of soil and nails

Parameter Property

Dry unit weight of soil (dry)

18 kN/m3

Bulk unit weight (bulk)

19 kN/m3

Young's modulus (Es) 20,000 kN/m2

Cohesion (c) 15 kN/m2

Friction angle () 26

Red soil

Poisson's ratio (s) 0.28

Young's modulus (En) 210E06 kN/m2

Nail diameter (d) 0.02 m

Nail

Poisson's ratio (n) 0.30

2. NUMERICAL ANALYSIS WITH FLAC3D

FLAC (Itasca, 2000) is an explicit finite difference code that performs a Lagrangian analysis. It uses explicit time marching method to solve governing field equations in which every derivative in the set of governing equations is replaced directly by algebraic expressions written in terms of field variables (i.e. stress, displacement) at discrete points in space. The general calculation procedure in one time step for every cycle around the loop first evokes the equation of motion to derive new velocities and forces, and then strain rates are calculated from the velocities and new stresses from strain rates. The time step is chosen so small that the information cannot physically pass from one element to another element. The central concept for the explicit method is that the calculational wave speed always keeps ahead of the physical wave speed, so that the equation always operates on known values that are fixed for the duration of the calculation. For the analysis, the medium is divided into a finite difference mesh of polyhedral elements. Internally, it is subdivided into two overlaid set of tetrahedra. The force vector exerted on each node is taken to be the mean of the two force vectors exerted by the two over laid tetrahedra. The convergence criterion is the nodal unbalanced force from the neighboring elements. For the present study, the unbalanced force of each node is normalized by the gravitational force acting on that node. A simulation is considered to have converged when the normalized unbalanced force of every node in the mesh is less than 10-3.

Additionally, it provides an alternative to traditional limit equilibrium programs to determine factor of safety. Limit equilibrium codes use an approximate scheme typically based on the method of slices in which a number of assumptions are made (e.g., the location and angle of interslice forces). Several assumed failure surfaces are tested, and the one giving the lowest factor of safety is chosen. Equilibrium is only satisfied on an idealized set of surfaces. In contrast, the fast Lagrangian analysis continua provide a full solution of the coupled stress/displacement, equilibrium and constitutive equations. Given a set of properties, the system is determined to be stable or unstable. By automatically performing a series of simulations while changing the strength properties strength reduction technique, the factor of safety can be found corresponding to the point of stability, and the critical failure (slip) surface can be located. Although, it does take longer to determine a factor of safety than a limit equilibrium program, yet it provides several advantages over a limit equilibrium solution (e.g.,Dawson and Roth, 1999, and Cala and Flisiak, 2001). Matsui and San (1992) reported a simple method of evaluation of stability termed as strength reduction method using results

-

IGC 2006, 14-16 December 2006, Chennai, INDIA

761

of finite element analysis. In this method, the strength Parameters tan and c of the soil are successfully reduced until failure of the system occurs (equation 1).

0.1c

c

tan

tan

reduced

input

reduced

input ==

--------------------- (1)

The parameters with the subscript 'input' refer to the input properties and parameters with the subscript 'reduced' refer to the reduced properties. Initially the ratio is set to 1.0 at the start of a calculation to set all material strengths to their actual values as shown in equation (1). The strength parameters are successively reduced until failure of the structure occurs. At this point, the factor of safety is given by equation 2.

failureatstrengthstrengthavailableFS = ---------------------------- (2)

Table 2 presents the results obtained from the numerical analysis. Factor of safety using strength reduction method shows that the vertical cut without nails was unsafe with a FS of 0.52 and the same vertical cut has been strengthened using nails (TOR steel bars) of 20 mm diameter and the factor safety improved to 1.48 indicating that the vertical cut is safe and stable with the provision of soil nails.

Table 2. Results of the numerical analysis

Case FS Displacement (mm)

Shear Strain (%)

I 0.52 1600 17.12

II 1.48 13.38 0.20

Placement of nails not only improves the stability but also reduces the deformations. Figure 2(a) and Figure 2(b) show the deformation of the vertical wall without and with soil nails. It is evident that considerable improvement in deformation is achieved with soil nails.

The results are also examined in-terms of shear strains; maximum shear strain in the case of un-reinforced vertical cut is 17.12% that reduced to 0.2% indicating that the shear strains have been transferred to the reinforcement. The maximum mobilized tensile force is 42.67 kN, this value is less than the maximum tensile capacity of the reinforcement bar and hence safe under tensile failure/pullout failure. In addition the analysis was carried out with facing element and different fixities to the facing

element and not much difference were observed in both the cases (less than 20 mm).

Detailed investigations on the behavior of reinforced soil structures indicate that maximum/limiting displacements at the crest in the range of 1% of the excavation depth and hence satisfactory as the value is less than the reported values from literature.

FLAC3D 2.10

amit

Step 4743 Model Perspective17:00:06 Fri Jul 14 2006

Center: X: 5.000e+000 Y: 5.000e+000 Z: 4.998e+000

Rotation: X: 10.000 Y: 0.000 Z: 0.000

Dist: 3.265e+001 Mag.: 1Ang.: 22.500

Contour of Displacement Mag. Magfac = 1.000e+000

0.0000e+000 to 0.0000e+000 0.0000e+000 to 2.0000e-001 2.0000e-001 to 4.0000e-001 4.0000e-001 to 6.0000e-001 6.0000e-001 to 8.0000e-001 8.0000e-001 to 1.0000e+000 1.0000e+000 to 1.2000e+000 1.2000e+000 to 1.4000e+000 1.4000e+000 to 1.6000e+000 1.6000e+000 to 1.6807e+000

Interval = 2.0e-001

Fig. 2(a) vertical wall without soil nail

FLAC3D 2.10

amit

Step 4743 Model Perspective16:55:37 Fri Jul 14 2006

Center: X: 5.000e+000 Y: 5.000e+000 Z: 4.998e+000

Rotation: X: 20.000 Y: 0.000 Z: 10.000

Dist: 3.434e+001 Mag.: 1Ang.: 22.500

Contour of Displacement Mag. Magfac = 1.000e+000

0.0000e+000 to 0.0000e+000 0.0000e+000 to 1.0000e-002 1.0000e-002 to 2.0000e-002 2.0000e-002 to 3.0000e-002 3.0000e-002 to 4.0000e-002 4.0000e-002 to 5.0000e-002 5.0000e-002 to 6.0000e-002 6.0000e-002 to 7.0000e-002 7.0000e-002 to 8.0000e-002 8.0000e-002 to 9.0000e-002 9.0000e-002 to 1.0000e-001 1.0000e-001 to 1.1000e-001 1.1000e-001 to 1.2000e-001 1.2000e-001 to 1.3000e-001 1.3000e-001 to 1.3388e-001

Interval = 1.0e-002

cable Axial Force Magfac = 1.000e+000

Fig. 2(b) Vertical cut with soil nailing

3. BOX JACKING TECHNIQUE

Box jacking technique is used to place the elements in position and six elements of 6 m length each and a width of 11.4m having two vents for vehicular traffic and a third vent at the center for pedestrian traffic is provided.

-

IGC 2006, 14-16 December 2006, Chennai, INDIA

762

Carriageway

Pathway

Carriageway

Fig. (3) Typical element section

Figure 3 shows the typical section of underpass and box element pushing / jacking. The RCC element of length 6m is pushed using high power hydraulic jacks of four numbers located at the wall and base slab junctions. These jacks are of capacity of 5000 kN (500 tons) each. Header beam and reaction beams are cast at the top and bottom of the RCC element. Further reinforcing the soil above the RCC element and a pushing gap of 0.20 m was left for scooping. Nailing has been carried-out in the section ahead of pushing to avoid soil collapse. Generation of lateral stresses during jacking, affects the capacity of jack if frictional force is more. Hence, geogrid is placed between element and soil to reduce the frictional force. This geogrid was attached to front part of element using mild steel pipes and plates. A canopy was made to avoid loose soil to fall from top. The project was completed in a span of about 150 days successfully and is being used.

Fig. 4 Jacking of element

4. CONCLUSION

The construction of underpasses using soil nailing and box jacking technologies presented as a case study are very useful in infrastructure development. The numerical

analysis shows that use of nailed retaining structures helps considerably in the stability of excavations and limits the deformation to a great extent. Box pushing is an effective method of constructing underpasses without disturbing the traffic above. The soil nailed retaining wall occupies much lesser space than ordinary retaining walls and also it is cost effective and less time consuming from construction point of view. The techniques can be adopted effectively depending on the site conditions.

ACKNOWLEDGEMENTS

The authors thank Indian Institute of Science and SID, Bangalore; National Highway Authority of India, New Delhi; Ministry of Defence, New Delhi; BBR Constructions, Bangalore.

REFERENCES

Cala, M., and J. Flisiak. Slope Stability Analysis with FLAC and Limit Equilibrium Methods, in FLAC and Numerical Modeling in Geomechanics2001 (Proceedings of the 2nd International FLAC Symposium on Numerical Modeling in Geomechanics, Ecully-Lyon, France, October 2001) D. Billaux, X. Rachez, C. Detournay and R. Hart, Eds., Rotterdam: A. A. Balkema, 2001. pp. 113-114.

Dawson, E. M., and W. H. Roth. Slope Stability Analysis with FLAC, in FLAC and Numerical Modeling in Geomechanics (Proceedings of the International FLAC Symposium on Numerical Modeling in Geomechanics, Minneapolis, Minnesota, September 1999),. Detournay and R. Hart, Eds. Rotterdam: A. A. Balkema, 1999. pp. 3-9.

FLAC 4.0. 2000. Reference Manual, Itasca Consulting Group Inc. Minneapolis

Matsui, T. and San, K-C. (1992) Finite element slope stability analysis by shear strength reduction technique, Soils and Foundations, Vol. 32, No. 1, pp. 59-70.

Sivakumar Babu, G. L., Srinivasa Murthy, B.R. and Srinivas, A. (2002) Analysis of construction factors influencing the behavior of soil-nailed earth retaining walls, Ground Improvement, Vol. 6, No.3, pp. 137-143.

Srinivasa Murthy, B.R., Sivakumar Babu, G. L. and Srinivas, A. (2002) Analysis of prototype soil-nailed retaining wall, Ground Improvement, Vol. 6, No.3, pp. 129-136.

/ColorImageDict > /JPEG2000ColorACSImageDict > /JPEG2000ColorImageDict > /AntiAliasGrayImages false /CropGrayImages true /GrayImageMinResolution 300 /GrayImageMinResolutionPolicy /OK /DownsampleGrayImages false /GrayImageDownsampleType /Bicubic /GrayImageResolution 300 /GrayImageDepth -1 /GrayImageMinDownsampleDepth 2 /GrayImageDownsampleThreshold 1.50000 /EncodeGrayImages false /GrayImageFilter /DCTEncode /AutoFilterGrayImages true /GrayImageAutoFilterStrategy /JPEG /GrayACSImageDict > /GrayImageDict > /JPEG2000GrayACSImageDict > /JPEG2000GrayImageDict > /AntiAliasMonoImages false /CropMonoImages true /MonoImageMinResolution 1200 /MonoImageMinResolutionPolicy /OK /DownsampleMonoImages false /MonoImageDownsampleType /Bicubic /MonoImageResolution 1200 /MonoImageDepth -1 /MonoImageDownsampleThreshold 1.50000 /EncodeMonoImages false /MonoImageFilter /CCITTFaxEncode /MonoImageDict > /AllowPSXObjects false /CheckCompliance [ /None ] /PDFX1aCheck false /PDFX3Check false /PDFXCompliantPDFOnly false /PDFXNoTrimBoxError true /PDFXTrimBoxToMediaBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXSetBleedBoxToMediaBox true /PDFXBleedBoxToTrimBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXOutputIntentProfile (None) /PDFXOutputConditionIdentifier () /PDFXOutputCondition () /PDFXRegistryName () /PDFXTrapped /False

/Description > /Namespace [ (Adobe) (Common) (1.0) ] /OtherNamespaces [ > /FormElements false /GenerateStructure false /IncludeBookmarks false /IncludeHyperlinks false /IncludeInteractive false /IncludeLayers false /IncludeProfiles false /MultimediaHandling /UseObjectSettings /Namespace [ (Adobe) (CreativeSuite) (2.0) ] /PDFXOutputIntentProfileSelector /DocumentCMYK /PreserveEditing true /UntaggedCMYKHandling /LeaveUntagged /UntaggedRGBHandling /UseDocumentProfile /UseDocumentBleed false >> ]>> setdistillerparams> setpagedevice