Banat s Journal of Biotechnology€¦ · devices, industrial or potable water system piping, or...

Transcript of Banat s Journal of Biotechnology€¦ · devices, industrial or potable water system piping, or...

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

REVIEW

NEW SURFACE FOR THE PREVENTION OF BIOFILMS AND BIOFOULING –

A REVIEW

Fei Yang1, Uta Cheruti2, Robert Armon2*

1Institute IWAR, Technische Universität Darmstadt, Petersenstr. 13, 64287 Darmstadt, Germany. (E–mail: [email protected]–darmstadt.de ) and J. Blaustein Institutes for Desert Research, Ben–Gurion University of the

Negev, Kiryat Sde Boker 84990, Israel. (E–mail: [email protected]) 2Faculty of Civil & Environmental Engineering, Division of Environmental, Water & Agricultural Eng.,

Technion–Israel Institute of Technology, Haifa 32000, Israel *Corresponding author (E–mail: [email protected])

Abstract. Since the early 80–s of the last century, biofilm study took off as a discipline on its own. The importance of biofilms in everyday life is beyond any doubt and beside its biotechnological advantages in large processes the hazardous effects are broad with serious financial effects in industry, health and environment. The main process of biofilm formation is its biofouling of almost all surfaces known to human kind (natural and synthetic). To prevent biofouling, new approaches were studied to inhibit surface colonization through development of new hybrid materials, use of biocides and antibiotics, understanding cell–cell communication (quorum sensing) as well physical measures. Hand to hand with advancement in materials chemistry, these new surfaces were developed with variable achievements due to the large diversity of biological systems. The present review describes some major directions in biofouling prevention through surface modifications. Keywords: biofilm, biofouling, surface, colonization, prevention, materials chemistry, adhesion, adsorption

1. Background Generally, biofouling can be defined

as the undesired accumulation of deposits of a biological nature on a surface [VIDELA, 2002]. Such deposits can contain micro–(microfouling) or macro–organisms (macrofouling). The former is defined as the process resulting from the accumulation of microbial biofilms or bacterial adhesion [WATNICK AND KOLTER, 2000; DONLAN, 2002]; and the latter is the attachment of larger organisms, such as barnacles, mussels, polychaete worms, bryozoans, and seaweed [YEBRA et al., 2004].

Biofouling commonly occurs on submerged structures, especially ships' hulls, and also occurs on the surfaces of all living marine organisms, where it is known as epibiosis. Biofilms may form on a large variety of surfaces, including living tissues (teeth, colon, skin etc.), indwelling medical devices, industrial or potable water system piping, or natural aquatic systems. In wastewater treatment field, where organic load is much higher compared to potable water, biofouling takes place in membrane systems, such as membrane bioreactors and reverse osmosis spiral wound membranes, through formation of biofilm.

Biofilms impact many life aspects: they can be essential (in wastewater processes); beneficial (in food digestion); inconvenient (on slippery steps and clogged filters); harmful and unpleasant (as dental plaque); destructive (biocorrosive within water conduits); or can even prove to be lethal (on medical prostheses) [JENKINSON and LAPPIN–

SCOTT, 2001]. Biofilms have been identified as the

primary problem in the biological contamination and economic losses of potable water distribution and industrial process water systems. In membrane technology for advanced wastewater reclamation, fouling of membranes is the most challenging factor with restricted system performance [CHANG et al.,

2002; FLEMMING, 2005]. Biofilms do not only present a

considerable hygiene risk in food industry, but also significant importance in public health through their role in certain infectious diseases and importance in a variety of device–related infections, by growing on implants, venous or urinary catheters and other medical devices [DONLAN, 2002; MEYER, 2003].

Biofouling causes huge material and economic costs in maintenance of mariculture,

9

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

shipping industries, naval vessels, and seawater pipelines. Governments and industry spend more than US$ 5.7 billions annually to prevent and control marine biofouling [Wikipedia–

the free encyclopedia, 2006]. 1.1. Processes of biofilm formation

and bacteria adhesion A biofilm is a surface–associated

accumulation of microbial cells embedded in an Extracellular Polymeric Substance (EPS) self–produced matrix. In most natural environments, a biofilm is the prevailing microbial lifestyle [STICKLER, 1999; WATNICK and

KOLTER, 2000; DONLAN, 2002; BRANDA et al., 2005]. The processes and mechanisms of microorganisms attaching to surfaces and developing biofilms have attracted great attention and have been extensively studied since the 1970's. These can be shown on literatures where many studies and reviews have offered a deep insight into biofilms and biofouling [O’TOOLE et

al., 2000; WATNICK and KOLTER, 2000; JENKINSON and LAPPIN–

SCOTT, 2001; DONLAN, 2002; STOODLEY et. al., 2002; YEBRA et

al., 2004; BRANDA et al., 2005; SMITH, 2005]. The combination of molecular

techniques in conjunction with direct microscopic visualization, has led us to clarify the molecular mechanisms important to control biofilm development [YANG et al., 2000].

Initiation of biofilm formation is characterized by the interaction of cells with a surface or interface as well as with each other [SMITH, 2005]. From the initial adhesion of cells to a surface, their growth and accumulation–through diversification and reorganization–to maturity is a highly dynamic process (Figure 1).

The initial adhesion of bacterial cell to a conditioned surface is considered a random event. If cells adhere then division and accumulation occur and a linking film is produced [WATNICK and KOLTER, 2000; JENKINSON and

LAPPIN–SCOTT, 2001; STOODLEY et al., 2002; BRANDA et al.,

2005], onto which further attachment and accumulation of cells takes place (Figure 1). Once enough cells have aggregated, the biofilm begins to mature through the production of an extracellular matrix (EPS), which contributes greatly to the final architecture of the biofilm community.

The attachment of microorganisms is a very complex process regulated by diverse characteristics of the growth medium, substratum, and cell surface [DAVEY and O’TOOLE,

2000]. In the usual course of events, attachment will occur most readily on surfaces that are rougher, more hydrophobic, nonpolar, and coated with a “conditioning” film (mainly organics from the surrounding fluid.

[Adapted from JENKINSON and LAPPIN–SCOTT, 2001]

Figure 1. Biofilm formation stages on any substrata favoring adhesion of microbial cells in a flow system

10

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

An increase in flow velocity, water temperature, cation presence or nutrient concentration may also be associated to increased properties of the cell surface [specifically the presence of fimbriae, flagella, and surface–associated polysaccharides or proteins (i.e. EPS)], that influence the rate and extent of microbial attachment. [DONLAN, 2002;

STOODLEY et al, 2002; BRANDA et al. 2005; BEECH et al. 2005]. 1.2. Biofilm structure and

communication between bacteria Surface–associated cells (biofilms)

are different from their suspended counterparts (planktonic cells) by generation of an EPS matrix, reduced growth rates, and the up–and down-regulation of specific genes. Microcolonies are the basic structure of any biofilm. The biofilm picture is of interacting, organized, 3–D structures of organisms enveloped by EPS, with networks of intervening water channels and multiple layers of cells [COSTERTON et al., 1999; DONLAN, 2002;

BRANDA et al., 2005]. The physical, chemical, and biological structures of biofilms are subject to multiple intrinsic and environmental influences. A biological fluidity of microbial

cells continually entering into and departing from associations makes biofilm a dynamic entity [WATNICK and KOLTER, 2000; BRANDA et al., 2005]. Simple observation of naturally occurring biofilms, which almost invariably house a mixture of species, reveals that biofilms are as diverse as their constituent microbes. For example, the streaming biofilms formed on submerged rocks in acid mine drainage [EDWARDS et al., 2000] are strikingly different from the plaque formed on air–exposed surfaces of teeth [KOLENBRANDER and LONDON, 1993]. Water system biofilm is highly complex, containing corrosion products, clay material, fresh water diatoms, and filamentous bacteria, while biofilm on medical devices, on the other hand, appears to be composed of a single, coccoid organism and the associated EPS matrix [BRANDA et al., 2005]. Cells' propinquity within a microcolony (or between microcolonies) provides an ideal environment for creation of nutrient gradients, accelerated exchange of genetic material, and quorum sensing, of which protection from environmental insults and assaults is foremost [WATNICK and KOLTER, 2000;

DONLAN, 2002; BRANDA et al., 2005].

Target genesTarget genes

LuxLux RR

LuxLux RR

LuxLux IILuxLux RR

HH

DDPP

PheromonePheromoneprecursorprecursor

Target genes

Target genes

AutoinducerAutoinducer [AHL][AHL]

AutoinducerAutoinducer [peptide][peptide]

GramGram--negativenegativebacteriabacteria

GramGram--positivepositivebacteriabacteria

Vibrio fischeri-light production

Vibrio cholera-When grows on chitin, can acquire DNA from environment.

Requires AHLs to be able to grow on chitin

Pseudomonas aeruginosa-virulence, Fe acquisition, stress response, etc.

Over 200 genes

Yersinia enterocolitica-is activated in foods, possibly involved in enzyme production,

biofilm formation

Salmonella, E. coli, Shigella-do not make AHLs themselves

(have lost the AHL synthase gene)

-detect AHLs produced by other bacteria (have gained a new AHL receptor gene)

Examples of AHL-mediated QS in Gram (–) bacteria

Signals, detection appear more diverse

Streptomyces γ-butyrolactone controls production of aerial hyphae and antibiotics

Myxococcus uses a mixture of amino acids to initiate sporulation

Bacillus and Staphylococus- Peptide signals, control competence, virulence

Examples of peptide-mediated QS in Gram (+) bacteria

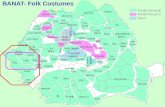

Figure 2. Quorum sensing (QS) systems of Gram negative and positive bacteria

11

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

Recent advances in genomics, proteomics, and analytical chemistry have revealed the importance of cell–cell signaling and global regulatory networks in biofilm development. Biofilm formation is an interactive process affected by local hydrodynamics of the fluid environment, physicochemical properties of the surface, and behavioral responses of bacterial colonizers, which quickly change gene expression and phenotype upon attachment [PRIGENT–COMBARET et

al., 1999; DAVEY and O’TOOLE, 2000; KUCHMA and O’TOOLE,

2000; GEESEY, 2001]. Bacterial products that are able to

diffuse away from one cell and enter another cell are a complex system of intercellular communication between bacteria in surface–attached biofilms (Figure 2).

This method of intercellular signaling seems ideally suited for bacteria in diffusion–limited environment such as the biofilm, rather than that between planktonic bacteria, due to higher concentrations of auto–inducers [WATNICK and KOLTER, 2000]. In Gram–negative bacteria, cell communication can be achieved through the activity of Acylated Homoserine Lactones (AHLs) auto–inducers [STICKLER, 1999]. AHL accumulation in a developing biofilm causes the transformation of individual cells from planktonic to biofilm phenotype by target genes activation and co–ordinates their behavior in some way so that they build the complex structures of the multicellular communities [STICKLER, 1999]. Cells may also communicate via quorum sensing [BALABAN et al.,

2003B]. Extracellular signals, therefore, enforce the zoning laws in single–species biofilms [WATNICK and KOLTER, 2000]. However, precisely how these microbial communities form, and how the genetic switches and cascades are coordinated during surface growth is still unknown.

2. Antifouling systems As reviewed above, depending upon

the unique structure and cell–to–cell communication, microbes enable them to react to changing situations as a population community instead of individually through a cell–to–cell signaling mechanism. Secondly, growth as a biofilm almost always leads to a large increase in resistance to many toxic substances such as antibiotics, chlorine, and detergents, compared with cultures grown in

suspension (planktonic) in conventional liquid media, with up to 1000–fold decreases in susceptibility reported [COSTERTON et al., 1999;

WATNICK and KOLTER, 2000; TAYLOR, 2006]. The general resistance of microbial biofilms is largely phenotypic adaptation and the limited EPS penetration of antibiotics and chemical reaction of biocides with this EPS (“quenching”).

Intriguingly, some antibiotics were found to stimulate EPS production such as the case of Staphylococcus epidermidis exposed to subinhibitory concentrations of tetracycline, quinupristin–dalfopristin and erythromycin. These antibiotics were found to activate expression of genes encoding for polysaccharide intercellular adhesion in S. epidermidis [RACHID et al., 2000]. Thus, the microbes in the deeper layers of the biofilm can survive and multiply. These have brought great challenges against biofilms and biofouling in human’s activities, although many anti–fouling systems have been involved, as demonstrated by many studies and reviews in literatures [VIDELA, 2002; MEYER,

2003; ROBERTS, 2004; TSIBOUKLIS, 2004; YEBRA et al., 2004;

ZHANG, 2005; WANG et al., 2006]. Approaches to prevention, removal and killing of biofilms are therefore sought in almost all fields. The past, present and most likely future steps of the antifouling technology against marine biofouling which is a typical representative of biofouling, have been reviewed thoroughly by Yebra et al. (2004).

Antifouling is the process of removing the accumulation, or preventing its accumulation. Antifouling system means a coating, paint, surface treatment, surface, or device that is used to control or prevent attachment of unwanted organisms. In general, there are two ways to solve the problem of a fouling surface, discriminated by the moment of intervention in the process of adhesion. First of all, it is possible to discourage adhesion of fouling organisms by offering unfavorable conditions. The second solution is removal of adhered foulants from a fouled surface after adhesion has occurred. Basically, there are three different strategies in tackling biofilm problems: − Disinfection “in time”, before a biofilm

develops; − Removal/killing of established biofilms

using harsh disinfectants such as oxidizing

12

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

biocides; − Inhibition of attachment of microbes by

selecting surface materials that do not promote attachment or by supplementation with nutrients.

Electrical enhancement [STEWART et al.,

1999; PICKERING et al., 2003; WAKE et al., 2006], modified surfaces/materials [WOOD et al., 1998; NIE et al., 2004;

XINBO et al., 2009], ultrasound enhancement [REDISKE

et al., 2000; CARMEN et al., 2004a,b] and photodynamic treatment [SOUKOS et al., 2000; O’NEILL et al., 2002;

WAINWRIGHT and CROSSLEY, 2004] have been used to enhance established biofilm removal and to increase the efficacy of biocides against biofilms.

The most effective antifouling paint with a life time up to five years is also the most toxic: the tributyltin self–polishing copolymer paints (TBT–SPC paints). The widespread use of these paints, estimated to cover 70% of the present world fleet [YEBRA et

al., 2004; ZHANG, 2005]. Unfortunately, the TBT–SPC systems impact adversely the environment and are toxic to marine organisms.

Legal restrictions (the AFS Convention, 2001) for the application of organotin based antifouling paints have led to develop alternative technologies to prevent biofilms and biofouling safely. Main research activities focus actually on: natural products, non–stick coatings based on silicones or hydrogels, application of electric currents, and mechanical cleaning. Some authorities have suggested that the way ahead is to produce surface coatings containing antibiotics such as minocycline, rifampicin or fluoroquinolones [MERMEL, 2001], or other biocides such as silver for catheters and other medical devices [MASSÈ

et al., 2000; WOO et al., 2002; PIOZZI et al., 2004; NAMAVAR et al.,

2007]. However, Stickler (1999) pointed out that "this approach is doomed to failure and could even be counter productive in the long–term, adding to the enormous problem of microbial drug resistance". Knowledge gained from experience with a certain type of biofilm cannot be transferred to other types of biofilms. In essence it can be said that each biofilm is different due to its bacterial diversity [STICKLER, 1999; MEYER, 2003]. Therefore, prevention of biofilm formation is still a difficult task.

Since bacterial adhesion is a prerequisite condition for biofilm formation,

and it is mainly in the initial phase when phenotypic adaptation is developed [DAS et al.,

1998; ZHAO and LIU, 2006]. In many application fields, e.g. in the food industry and wastewater treatment systems, it is hardly possible to disinfect frequently enough to avoid this initial step. In another hand, the nature of the substrate, which clearly affects the adhesion mechanisms, also depends on surface properties. Therefore, surface treatment and selecting surface materials may become promising and effective alternatives to prevent or diminish formation and surface colonization of microbes. The goal of this paper is to review new surfaces for the prevention of microbial colonization, and show the recent advance in this filed.

3. New surfaces to prevent biofilms

and biofouling 3.1 New surface materials and

surface modification One approach to prevent biofilm

formation can be achieved by selection of materials that do not support the attachment of microorganisms; due to the type of surface material is one crucial factor in biofilm formation. Several attempts have been made to identify materials that do not promote or even suppress biofilm formation. Rogers et al. (1994) ranked different materials according to biofilm growth of microbes in general and Legionella pneumophila in particular (Table 1). Meanwhile, surface modification contributes another effective way to control biofilms and biofouling. Many researches have been conducted to avoid biofilm formation by incorporation of biocides into surface materials or coat surfaces with biocides, especially in the medical field. Biofilm formation on implanted medical devices is a frequent cause of implant rejection.

The usefulness of phosphorylcholine (PC)–containing polymers with non–fouling properties for improving the properties of medical devices was summarized by Lewis (2000). Gottenbos et al. (2001) demonstrated a reduction in infection rate using silicone rubber implants with covalently coupled quaternary ammonium coatings. Ye et al. (2003) designed a Cellulose Acetate (CA) membrane blended with poly [2–methacryloyloxyethyl phosphorylcholine

13

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

(MPC)–co–n–butyl methacrylate (BMA)] (PMB30) as a blood purification membrane. The CA/PMB30 blend membrane showed good permselectivity and antifouling property during a long time ultrafiltration experiment with protein solutions. Khare et al. (2006) examined the effect of a silver zeolite–impregnated Central Vascular Catheter (CVC) on catheter–related colonization and infection, and showed a superior to non–impregnated catheter in reducing the rate of CVC colonization, although further evaluation is needed.

Table 1. Different materials and their qualitative

potential to support biofilm development

No. Material Biofilm growth support

1 Glass Fair 2 Stainless steel Fair–good 3 Polypropylene Fair–good 4 Chlorinated PVC Fair–good 5 Unplasticised PVC Good 6 Mild steel Good 7 Polyethylene Good 8 Ethylene–propylene Good 9 Latex Very good 10 Rubbers Good 11 Jointing materials Fair–good

12 Glass reinforced plastics Fair

13 Other plastics Poor

14 Paints and protective coatings Fair

15 Packing materials Very good 16 Greases and lubricants Fair [Adapted from: ROGERS et al., 1994; BURMAN and COLBOURNE, 1977].

The green algal genus Ulva (syn.

Enteromorpha) is the most common macroalga contributing to biofouling of man–made surfaces throughout the world. Hoipkemeier–Wilso et al. (2004) showed that incorporation of non–network forming poly (dimethyl siloxane) based oils with poly (dimethyl siloxane) elastomers (PDMSe) significantly reduced settlement density of the green algal Ulva spores.

In general, surfaces to which microorganisms' attachment is impacted can be divided in two main kinds:

− high surface energy materials that

are hydrophilic and often negatively charged and − low energy materials that are relatively hydrophobic (with low surface charge).

For example, boron–doped diamond thin–film electrodes revealed negligible fouling effects in the presence of high levels of surface-active materials (including proteins) due to a relatively lower surface energy and minimal electrostatic characteristics [SHIN et al. 2005].

Wood et al. (1998) devised an ingenious method for the eradication of biofilms from surfaces. Using flow–cells they grew 30 pm thick biofilms on discs of polymers containing copper or cobalt phthalocyanine. These discs were then exposed to dilute solutions of potassium monopersulphate. Here, the polymers act as catalysts and generate short–lived free radicals from the chemical agent at the biofilm–substrate interface. The reactive radicals killed the biofilm from the inside.

Some authors suggested that in oligotrophic environments, leaching of organic material from the surface (plasticizers) or accumulation of organic material on the surface (conditioning film) may promote biofilm formation. This indicated a novel approach to inhibit biofilm by supplementation of systems with nutrients, to inhibit attachment. However, Meyer (2003) pointed out that inhibition of biofilm formation by limitation of the carbon source is virtually impossible. Even ultra–pure water systems have been found to support the formation of biofilms. Membrane separation combined with biological process is a novel and efficient technology for wastewater reclamation. However, system performance often deteriorates because of membrane fouling, mainly biofouling which is induced by interaction between microbial compounds and membrane material. To address the fouling problem, substantial attention has been directed towards membrane surface modification (physical and chemical) [WANG et

al., 2006]. Nie et al. (2004) demonstrated that the antifouling properties and biocompatibility of poly (acrylonitrile–co–maleic acid) (PANCMA) membranes were effectively improved through immobilization of poly (ethylene glycols) (PEG) by an esterification

14

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

reaction on membrane surface. Both the flux recovery by water

cleaning and by chemical cleaning for PANCMA–g–PEG membrane was almost two times of those for original PANCMA membrane. Yu et al. (2005) reported that hydrophobic poly (propylene) hollow fiber microporous membranes (PPHFMMs) with surface modification by nitrogen plasma–induced tethering of α–allyl glucoside (AG) demonstrated a lower fouling property with the flux recovery, the reduction of flux and the relative flux ratio of 17.8% higher, 5.1% lower and 140% higher comparing with those of the nascent one, respectively. Wang et al. (2006) demonstrated that a new random copolymer, which was synthesized by reacting hydrophilic N,N–dimethyl–N–methacryloxyethyl–N–(3–sulfopropyl) (DMMSA) with hydrophobic butyl methacrylate (BMA) through a conventional radical polymerization, was blended with polyethersulphone (PES) to fabricate antifouling ultrafiltration membrane for Bovine Serum Albumin (BSA) separation. For the membrane with 8.0 wt% sulfobetaine copolymer (DMMSA–BMA) concentration, irreversible fouling has been considerably reduced and the flux recovery rate of the blend membrane reached as high as 82.8%, showing sulfobetaine groups at the membrane surfaces endowing the membrane with higher hydrophilicity and better antifouling property.

Furthermore, the blend membrane could effectively resist BSA fouling in a wide pH range from 4.0 to 8.0. Huang et.al. (2006) conducted phospholipid moieties anchoring directly on the poly (acrylonitrile–co–2–hydroxyethyl methacrylate) (PANCHEMA) membrane surface through the reaction of hydroxyl groups and 2–chloro–2–oxo–1,3,2–dioxaphospholane (COP) followed by the ring–opening of COP with trimethylamine. It was shown the antifouling property and biocompatibility of polyacrylonitrile–based asymmetric membrane was enhanced obviously by the introduction of phospholipid moieties on the membrane surface. Liu et al. (2006) examined a novel polyamide–urea reverse osmosis composite membrane (ICIC–MPD) with lower fouling rate and favorable antifouling performance comparing with TMC–MPD and ESPA membranes, due to its favorable hydrophilicity and smoother

surface. Due to the interaction energy between bacteria and membrane surface has a significant influence on the bacterial adhesion onto the membrane surface; Zhao et al. (2004) used a graded electroless Ni–P–polytetrafluoroethylene (PTFE) composite coating technique to tailor the surface free energy of membrane diffusers to the optimum value. Initial experimental results showed that these coatings reduced microbial adhesion by 68–94%.

The studies release the main approach to improve membrane antifouling property by surface modification, e.g. enhancement of membrane hydrophilicity, lowering surface free energy, and smoothing membrane surface, although new membrane materials combined with biocides are also possible.

3.2 New coatings and paints Development of new coatings and

new paints containing biocides or antibiotics are mainly relying on the urgent needs in marine antifouling systems and medical applications.

A variety of coatings and paints were developed since mid 1800s based on the idea of dispersing a toxicant in a polymeric vehicle. Copper oxide, zinc oxide, arsenic, and mercury oxide were popular antifoulants [YEBRA et al., 2004]. The most effective antifouling paints are TBT–based products and their derivates. Due to the ban of organotins and other toxic biocides in marine coatings, safer methods of biofouling control based on environmentally friendly are actively studied. Substitute products are generally based on copper metal oxides and organic biocides [KONSTANTINOU and ALBANIS, 2004]. The most commonly used booster biocides are re–listed by Yebra et al. (2004).

Other chemicals currently used as active compounds in anti–fouling paints are copper pyrithione, benzmethylamide, fluorofolpet, polyphase, pyridone–triphenylborane, and tolyfluanid [THOMAS, 2001]. They can be classified into non–metallic and metal–based compounds. Regarding the metal–based biocides, probably the most interesting products are the polyvalent metal salts of pyrithione, mainly zinc and copper salts [TURLEY et al., 2000; 2005].

These products have gained acceptance for use in marine paints and

15

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

coatings to decrease or minimize soft–fouling. Copper pyrithione offers several advantages over zinc pyrithione for many applications, notably a lower solubility and short half–lives [THOMAS, 2001]. However, copper pyrithione is not as effective as regards the prevention of hard–fouling as might be desired. To overcome this shortcoming, combinations of soft-fouling and hard–fouling agents are necessary.

In addition, Pérez et al. (2006) develop a new antifouling formulation containing cupric tannate but with a large decrease in copper content in the order of 40 times relative to conventional cuprous oxide based paints. Cupric tannate has a narcotic effect on biofouling larvae and therefore has an excellent potential as an environmentally friendly antifouling agent. However, Okamura et al. (2000) pointed out that both Irgarol 1051 which is a newly developed herbicidal additive for use in copper–based antifouling paints and its degradation product M1 may potentially affect and/or damage the primary producer community in aquatic ecosystems. Bellas et al. (2006) and Dahlström et al. (2004) reported that medetomidine seems to be an interesting compound for use as an alternative non–toxic antifouling agent against the most severe fouling organisms (barnacles). Zhao and Liu (2006) showed that stainless steel surfaces coated with Ni–P–PTFE reduced E. coli attachment by 87.7–92.8%, compared with stainless steel 304.

The surface of medical devices is a common site of bacterial and fungal adhesion. In order to prevent biofilms, several physical and chemical modifications of the device surface have been proposed. Some authors reported inhibition of biofilm formation on such devices in vitro by coating with silver [KLUEH et al., 2000; HASHIMOTO, 2001]. Tenke et al. (2004) presented that heparin–coated urethral stents were protected against incrustation and biofilm formation for a longer period of time: 6–12 months, both in vitro and in vivo. Etienne et al. (2005) demonstrated that biofunctionalized polyelectrolyte multilayered films containing antimicrobial peptides of chromogranin A were able to inhibit the growth of yeast Candida albicans by 65% and completely stop the proliferation of filamentous fungus Neurospora crassa, representing an extremely promising method

to achieve protective coatings. However, as a future outlook, the

development of biocompatible surfaces or coatings that allow fibroblast and osteoblast cells to adhere and proliferate, leading to soft– and hard–tissue integration and vascularization, while preventing bacterial adhesion is very much needed [HARRIS and

RICHARDS 2006]. This tissue–covered implant surface then confronts bacteria with an integrated viable tissue layer with a functional host defense mechanism may be the best solution so far to combat bacterial adhesion.

3.3 Disruption of cell–cell

communication by surface technology Any biocide has to interact

chemically with the microbial cell; it can only prevent biofilm formation by leaching out of the materials. Because resistance of biofilm to biocides and antimicrobial agents was acquired through the quorum sensing process, disruption of cell-cell communication can provide a novel approach to prevent biofilm formation and infections associated with antibiotic–resistant strains.

Recently, a peptide termed “RNAIII–inhibiting peptide” (RIP) was described that inhibits biofilm formation and diseases caused by S. aureus [BALABAN et al., 1998, 2000, 2001, 2003a; GOV

et al., 2001]. RIP inhibits cell adhesion and biofilm formation [GOV et al., 2001; BALABAN et al.,

2003a] and inhibits the activity of the gene locus agr, thus preventing the production of a regulatory RNA molecule, RNAIII, that regulates the production of toxins and influences the pathogenesis of S. aureus [GOV et

al., 2001; VIEIRA–DA–MOTTA et al., 2001]. The mechanism through which RIP inhibits quorum–sensing involves inhibition of the phosphorylation of a protein called “target of RNAIII activating protein” (TRAP) [BALABAN et al., 2001]. Balaban et al. (2003b) also demonstrated a RIP inhibition of drug–resistant S. epidermidis biofilm formation through a similar mechanism. RIP is synergistic with antibiotics in eliminating 100% of graft–associated in vivo S. epidermidis infections. These suggest that RIP may be used to coat medical devices to prevent staphylococcal infections.

3.4 Non–toxic technologies In the past years, many investigations

in the medical field, food and marine industry

16

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

have focused on the development of non–stick surfaces within the limitations dictated by each application, resulting in different priorities. One can imagine that toxicity is not allowed in the medical field, whereas costs are more restrictive in the development of a marine coating.

Resistance of bacteria against antibiotics and bactericides urges investigation of other ways to protect implanted biomaterials from infection. Antoci et al. (2007) using a Ti rod (commonly used in implant insertion) covalently derivatized with vancomycin showed colonization prevention of Staphylococcus aureus (involved in periprosthetic infection) even at high levels, extended incubation and repeating challenges.

In food industry, addition of biocides to keep processing units clean is mostly excluded. The non–stick and fouling–release concepts present the most promising non–toxic alternative. The method is to coat surfaces with non–toxic materials onto which the adhesion of microbial colonizers will be greatly lowered. Normally this effect is due to a combination of hydrophobicity, low surface free energy and microroughness [TSIBOUKLIS et al.,

1999; YEBRA et al., 2004; ROOSJEN et al., 2006]. Essentially, to inhibit settlement by manipulating the forces generated by the targeted surface such that they become incompatible with those of bacterial colonizers. For a polymeric material, these are the van der Waals’ forces and sometimes also acid/base interactions [TSIBOUKLIS, 2004].

Non–stick, fouling–release coatings are mainly based upon silicones and fluoropolymers. Many studies (reviewed by Yebra et al., 2004) have been carried out to clarify coat properties to prevent adhesion. Fluoropolymers form non–porous, very low surface-free energy surfaces with good non–stick characteristics [BERRY et al., 2000; BRADY, 2001;

BRADY and ARONSON, 2003]. This low tendency to adhesion on fluoropolymers is optimized by assembling closely packed, oriented perfluoroalkyl groups on the surface, exposing CF3 moieties [BRADY, 2001], and permanently cross–linking them in this arrangement to minimize surface molecular diffusion or rearrangement when exposed to a marine adhesive [BRADY, 2001]. Based on these premises, very low values of surface–free energy are

achieved. However, these materials have limited

mobility due to the stiffness added by the F atoms, which impede the backbone bond rotation [YEBRA et al., 2004]. Silicones, which are applied in thick (6 mm) layers [BRADY, 2001; STEIN

et al., 2003], markedly improved the non–stick efficiency of fluoropolymers. Poly (dimethylsiloxane)–based fouling–release coatings are the most used today due to their low surface energy, low microroughness, and high elastic modulus and low glass transition temperature. Polysiloxanes substituted by fluorine might seem to be attractive candidates for surfaces with low bioadhesion. This could lead to polymers with the main advantages of each type, such as low surface–free energy and the elastic properties of silicones [BRADY, 2001; THÜNEMANN and KUBLICKAS,

2001]. Tsibouklis (2004) observed the resistances of “ultra–low surface energy” fluoropolymer coatings to bacteria and other fouling species use of “ultra–low surface energy” fluoropolymer coatings and showed a possible means of preventing the bacterial colonization of surfaces.

Brady and Aronson (2003) described a new coating which combines the best features of fluorinated and silicone coatings and is non–toxic. It was shown to foul slowly, clean easily, and be durable in the marine environment and organisms bonded to it only weakly.

Kumar et al. (2006) found that silicone/phosphorus modified epoxy coatings prevent the adherence and settling of marine organisms on steel structures, improving their corrosion resistance and their application in marine industry. Zhang et al. (2005) used bismuth dimercaprol to prevent adherence on bile stents by a variety of enteric bacteria (Escherichia coli, Klebsiella pneumoniae, Enterobacter, and Enterococcus,) suggesting future useful uses.

The most effective non–stick coatings possess a self–cleaning mechanism. For example, the loosely attached organisms are easily removed by turbulence experienced when the vessel is underway [YEBRA et al., 2004].

The fouling is peeling itself. On the other hand, non–stick coatings have to fight with some obstacles: high price, difficult application, mechanical frailty and persistence. The latter aspect is important with

17

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

respect to abrasions which enter the sea. This could be improved by Hempel’s

patented idea which incorporates fibers into the paints to enhance the mechanical properties of other binders [YEBRA et al., 2004]. Recent studies aiming at improved coatings used biocides doped elastomeric surfaces. Thus, the joint use of fouling–release systems and fouling deterrent natural biocides could give rise to a wide spectrum of efficient and environmentally friendly anti – fouling system [YEBRA et al., 2004].

3.5 Natural products and their

derived surface materials Marine organisms face similar fouling

problems that can interfere with vital processes such as respiration, nutrient absorption and sensing. In nature some organisms may be heavily fouled on much of their surfaces while others can be totally fouling–free [COWLING et al., 2000; NYS and STEINBERG,

2002]. This has generated interest in identifying the secondary metabolites that might repel or inhibit fouling organisms.

According to Rittschof (2000) these compounds can act enzymatically by dissolving the adhesives, interfering with the metabolism of the fouling organisms (e.g. nervous pathway interference), inhibiting the attachment, metamorphosis or growth, promoting negative chemotaxis, altering the surface of the organisms, as repellents, or finally acting as biocides.

The action of these products may involve mainly a non–toxic interference with a specific component of the signaling pathway of settlement or metabolic processes [YEBRA et

al., 2004], which explains their broad–spectrum activity.

It is well known that mucopolysaccharides in association with sialic acids provide an optimal surface to reduce friction and prevent the attachment of organisms like bacteria in fish skin. Some recent studies focused on the investigation of the surface properties of marine organisms and mimicking the effect of mucous surfaces like fish slime. Hydrophilic hydrogels with approximately 50% water content deterred microfouling for a short period.

After incorporation of active compounds as quaternary ammonium salts a reinforcement of the mechanical stability and

antifouling effectiveness could be achieved. Cowling et al. (2000) presented a successful fouling resistant material composed of Poly–(2–hydroxyethyl methacrylate) (PHEMA) hydrogel and Benzalkonium Chloride (BCl) which acts a dual actions as an antimicrobial agent and a surfactant.

Tests are going on to incorporate a variety of biogenic compounds into hydrogels or hydroviscous layers. Similar to fish slime these coatings smooth the microrough surface, and release sucked water and active compounds when the speed of the ship compresses the layer.

Baum et al. (2002) studied the skin of the pilot whale, which showed a hydrated jelly nano–rough surface characterized by a pattern of nanoridge–enclosed pores, of a pore size below the average value for the skin of most of the marine biofouling organisms.

Similarly, use of microtextured silicones as a way of preventing settlement was proposed by Andersson et al. (1999).

Corals and sponges are known to maintain a foul–free surface as well tunicates, bryozoa and thallophyta were thoroughly screened. Crustacean as lobster and shore crabs, echinoderms as sea stars and sea urchins, as well as eggcases of dog fishes were investigated to elucidate their antifouling strategy [KRUG, 2006]. A passive chemical defense may exist in eggcases of dogfishes and in the shell of the shore crab.

Eggcases appear remarkably clean, with little or no evidence of macrofouling, even after several months in seawater. Extracts of red algae contained halogenated furanones which activities comparable to, or even better than, those obtained with commercial biocides.

Organic extracts from three Mediterranean Sponges of the Genus Ircinia display high but variable level of antifouling activity with toxicity absence, showing their potential to become environmentally friendly antifouling components [TSOUKATOU et al., 2002].

Sjögren et al. (2006) demonstrated six of synthesized peptide analogs of the sponge metabolite barettin with significant inhibition of barnacle larvae settlement, even stronger than barettin. A general problem in the investigation of extracts of aquatic organisms is the origin of the active compounds. In some bryozoans and sponges the active compounds

18

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

originate from epiphytic or symbiotic microorganisms.

Furthermore, the discovered molecules are often very complex and cannot be synthesized. In octocorals there exists a striking similarity between many of the active natural products with respect of their functional groups. The presence of a furan and/or lactone ring is a common feature. However, the effect of these compounds is more based on a repellent mode of action than on a strong toxicity.

In addition, Xu et al. (2005) suggested that both capsaicin and zosteric acid, as natural product antifoulants with substantially less toxicity could be attractive alternatives as new antifouling compounds by incorporating into coatings. Zilberman et al., (2006) used biochemical coatings based on soluble chitin extract to show inhibition of fungal adhesion (C. albicans) to polymeric surfaces. The chitin soluble extract coating of polyurethane revealed 75 % inhibition in fungus adhesion for the chemical binding and 83 % for the physical adsorption, significantly even after 11 weeks.

As Krug (2006) pointed out that "hopefully it may be learnt from the marvelously adapted invertebrates of the benthos and devised environmentally sound antifouling practices, reducing further harm to coastal ecosystems and getting rid of the devilishly persistent propagules of fouling organisms". Once identified which properties of the compound lead to the desired effects, it will be possible to screen products according to their potential applicability to antifouling coatings or even modify them in order to improve their effectiveness.

All these facts, together with the information that it is not clear whether all the attachment mechanisms include chemosensory inputs, leads to the conclusion that attainment of natural metabolites with broad–spectrum activity seems an extremely difficult goal if not unfeasible [YEBRA et al., 2004]. Similar policy may apply to the use of enzymes incorporated into polymeric matrixes or covalently immobilized [MINIER et al., 2005].

Future studies will focus on creating an enzymatic system capable of succeeding against such a complex and adaptable process [Kaplan 2009, 2010].

In contrast, microbial attachment to

mineral surfaces is a selection mechanism for the microbial community. Recent studies have demonstrated that some dissimilatory iron – reducing bacteria use specialized flagella to detect and attach to iron oxide minerals [LOWER

et al., 2001; CACCAVO and DAS, 2002; CHILDERS et al., 2002]. Roberts (2004) demonstrated two

modes of microbial colonization of minerals in pH 6.8, anaerobic groundwater using a native microbial consortium and a variety of Al– and Fe–bearing silicates and oxides. Results showed that microbial colonization on positively charged oxide surfaces regardless of mineral composition is mainly through electrostatic forces.

In contrast, on negatively charged silicate minerals and glasses, the solid phase composition is a factor in determining the extent of microbial colonization, as well as the diversity of the attached community.

Moreover, it was also indicated that microorganisms preferentially colonize those silicate surfaces that offer beneficial nutrients (Fe) and avoid those that contain potentially toxic elements (Al). This suggests that minerals play a fundamental role in subsurface microbial ecology, and may have implications for biofouling control.

3.6 Application of nanotechnology

on fouling prevention Traditionally antifouling paints and

coatings are usually designed by either the chemical or biological nature of these materials. Meanwhile, new advances emerged in the usage of nanotechnology in environmental protection. Recent advances in paints and surface coatings have produced long–term antimicrobial activity through the incorporation of nanomaterials. Zhang (2005) reported a coating based on a polysiloxane, multifunctionalised silanes and the introduction of both in and ex situ silica nanoparticles.

When the coating are immersed in water, air bubbles are entrapped at the liquid–solid interface due to the nature of low surface energy origin and the nano/micro scale roughness on the surface. The air bubble layer creates a barrier for marine pests to land on surface so that it delays the fouling considerably. Lee et al. (2006) presented the fabrication and characterization of antibiofouling polymer–coated superparamag-

19

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

netic iron oxide nanoparticles for magnetic resonance contrast agents.

Commercially, Nanotek® zinc oxide, copper oxide or doped zinc oxides (Nanophase Technologies Corporation, USA) can be fully dispersed into a wide variety of coating formulations including urethanes, acrylics and vinyl acetates, and have a wide variety of potential applications including antimicrobial agents (antifungal, antibacterial and antifouling) for plastics and other surfaces, optoelectronics and tailored UV absorption.

Kim et al. (2003) devised a hybrid Thin–Film–Composite (TFC) membrane consisted of self-assembly of TiO2 nanoparticles (a quantum size around 10 nm or less). The application of the hybrid TFC membrane in Reverse Osmosis (RO) verified a substantial prevention against the microbial fouling by showing less loss of RO permeability, offering a strong potential for possible use as a new type of anti–biofouling TFC membrane.

Cao et al. (2006) examined that smaller nanosized TiO2 particles had much better antifouling effect on the PVDF composite membrane.

Choi et al. (2006) also reported that nanocrystalline TiO2 photocatalytic membranes with a hierarchical mesoporous multilayer structure has great potential in developing highly efficient water treatment and reuse systems, for example, decomposition of organic pollutants, inactivation of pathogenic microorganisms, physical separation of contaminants, and self–antifouling action because of its multifunctional capability.

Sibarani et al. (2006) showed surface modification by highly biocompatible polymers such as 2–methacryloyloxyethyl phosphorylcholine (MPC) by photoirradiation. The modified surfaces revealed excellent protein adsorption prevention (with human plasma protein).

As summarized at the final report by The Royal Society & The Royal Academy of Engineering, UK (2004), recently developed applications of nanomaterials include the self-cleaning window, which is coated in highly activated titanium dioxide, engineered to be highly hydrophobic and antibacterial, and coatings based on nanoparticulate oxides that

catalytically destroy chemical agents. New types of fouling–resistant marine

paint could be developed as alternatives to TBT by incorporating nanoparticles in paints. Antifouling surface treatment by nanotechnology is also valuable in process applications. Applications in the field of medicine are especially promising.

Nanocrystalline zirconium oxide (zirconia) is hard, wear–resistant, biocorrosion resistant and biocompatible, presenting an attractive alternative material for implants. Nanocrystalline silicon carbide is a candidate material for artificial heart valves primarily because of its low weight, high strength and inertness.

Exploit the known antimicrobial properties of silver include wound dressings containing nanocrystalline silver, which release ionic silver over a sustained period of time to provide a claimed extensive antimicrobial spectrum of 150 different pathogens.

Perhaps here is the place to mention of new peptidomimetic polymers against biofouling [STATZ et al., 2005]. Entirely new classes of synthetic antifouling macromolecules that are mimics of polypeptides were described.

The chimeric peptidomimetic polymer consists of a short functional peptide to firmly adsorb to surfaces coupled to a peptoid (of variable length) that prevents fouling. These polymers are specifically designed for robust, water–resistant anchorage to biomaterial surfaces and long–term resistance to fouling in the biological environment.

If nanomaterials can be produced at sufficiently low cost, fouling–resistant coatings could be used in routine duties such as piping for domestic and industrial water systems. However, it remains speculation whether very effective antifouling coatings could reduce the use of biocides, including chlorine.

4. Discussion and conclusions It can be concluded that there is

hardly any material that does not allow biofilm formation. Up to now it is almost impossible to predict, which material will promote biofilm formation least or most under practical conditions. To date no surface modification or coating fully prevents

20

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

bacterial adhesion, however, many of the methods discussed have decreased the numbers of adherent bacteria significantly.

From the short summary given above, the biological basis for the two most promising alternatives to synthetic biocide–based systems (fouling–release and natural biocide–based coatings) can be comprehended.

The broad–spectrum activity of these compounds is still questioned by the huge diversity of organisms, behaviors and attachment mechanisms found in the oceans. Thus, some authors already state that no system entirely based on natural products will ever prevent the fouling of a surface totally. The solution will probably be to use the right strategy, or the right mix of strategies, for each application [YEBRA et al., 2004; LÖSCHAU and

KRÄTKE, 2005]. One alternative is to generate

antifouling coatings with the incorporation of less or no toxic antifoulant compounds, such as natural product antifoulants (NPAs). However, limited knowledge exists about how NPAs act against fouling and about how the incorporation of NPAs affects the adhesion properties of the coatings. In addition, nanotechnology offers another promising and powerful tool for the enhancement of surface property against biofilms and biofouling, as well as modification of membrane properties for advanced wastewater reuse purpose. As Donlan (2002) presented, researchers in the fields of clinical, food and water, and environmental microbiology have begun to investigate microbiologic processes from a biofilm perspective. As the pharmaceutical and health–care industries embrace this approach, novel strategies for biofilm prevention and control will undoubtedly emerge. The key to success may hinge upon a more complete understanding of what makes the biofilm phenotype so different from the planktonic phenotype. Yebra et al. (2004) also pointed out that from the analysis of the factors affecting the biofouling process, the interference with the settlement and attachment mechanisms is the most promising environmentally benign option. This can be accomplished in two main pathways: imitation of the natural antifouling processes and modification of substrate characteristics [STICKLER, 1999]. Blocking the adhesion processes

or interfering with the cell–to–cell communication systems involved in biofilm development are obvious possible approaches.

It was proposed that two aspects were proved to be essential to investigate the action of antifouling coatings: the presence of biocides and the erosion [FAY et al., 2005; LIU et al.,

2006]. Today, Scanning Electron Microscopy (SEM) and Energy–Dispersive X–ray analysis (EDX) offer us two powerful techniques to obtain qualitative and quantitative data about the erosion, the distribution of active molecules in the film, during immersion, for optimization of coatings formulations and producing antifouling paints with reduced toxicants levels.

As already reviewed by Yebra et al. (2004) some substances can control the permeation rate of a polymeric matrix when they are coated with the multiple types of stimuli and responses associated with existing “smart” polymers. Will it some day be possible to create a coating capable of selectively releasing bioactive substances after artificial (electricity, sound etc.) or natural (water temperature, pH, fouling adhesives) stimuli or, in other words, a coating active only when foulants are settled or during stationary periods?

There might be in the next future a self–polishing coating based on natural repellents as a general solution. But it might be as well that a variety of solutions, adequate to each application and service will provide a fouling protection without damage to the environment.

References

1. Andersson, M., K. M. Berntsson, P. R. Jonsson and P. Gatenholm (1999). Microtextured surfaces: towards macrofouling resistant coatings. Biofouling 14 (2), 167–178.

2. Antoci, V., King, S. B., Jose, B., Parvizi, J., Zeiger, A. R.,Wickstrom, E., Freeman, T. A., Composto, R. J., Ducheyne, P., Shapiro, I. M., Hickok, N. J. and Adams, C. S. (2007) Vancomycin covalently bonded to titanium alloy prevents bacterial colonization. J. Orthopaed Res. 25(7), 858–866.

3. Balaban, N., A. Giacometti, O. Cirioni, et al. (2003b). Use of the Quorum–Sensing Inhibitor RNAIII–Inhibiting Peptide to Prevent Biofilm Formation In Vivo by Drug–Resistant Staphylococcus epidermidis. J. Infect. Dis. 187, 625–630.

4. Balaban, N., L. V. Collins, J. S. Cullor, et al.

21

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

(2000). Prevention of diseases caused by Staphylococcus aureus using the peptide RIP. Peptides 21, 1301–11.

5. Balaban, N., T. Goldkorn, R. T. Nhan, et al. (1998). Autoinducer of virulence as a target for vaccine and therapy against Staphylococcus aureus. Science 280, 438–440.

6. Balaban, N., T. Goldkorn, Y. Gov, et al. (2001). Regulation of Staphylococcus aureus pathogenesis via target of RNAIII–activating protein (TRAP). J. Biol. Chem. 276, 2658–67.

7. Balaban, N., Y. Gov, A. Bitler, J. R. Boelaert (2003a). Prevention of Staphylococcus aureus biofilm on dialysis catheters and adherence to human cells. Kidney Int. 63, 340–345.

8. Baum, C., W. Meyer, R. Stelzer, L. G. Fleischer, D. Siebers (2002). Average nanorough skin surface of the pilot whale (Globicephala melas, Delphinidae): considerations on the self–cleaning abilities based on nanoroughness. Marine Biol. 140 (3), 653–657.

9. Beech, I.B., Sunner, J.A. and Hiraoka, K. (2005) Microbe–surface interactions in biofouling and biocorrosion processes. Internat. Microbiol. 8:157–168.

10. Bellas, J., A. Hilvarsson, G. Birgersson, Å. Granmo (2006). Effects of medetomidine, a novel antifouling agent, on the burrowing bivalve Abra nitida (Müller). Chemosphere 65(4), 575–582.

11. Berry, J. A., J. F. Biedlingmaier and P. J. Whelan (2000). In vitro resistance to bacterial biofilm formation on coated fluoroplastic tympanostomy tubes. Otolaryngol. Head Neck Surg. 123, 246–251.

12. Brady, R. F. (2001). A fracture mechanical analysis of fouling release from nontoxic antifouling coatings. Prog. Org. Coatings. 43, 188–192.

13. Brady, R. F. and C. L. Aronson (2003). Elastomeric fluorinated polyurethane coatings for nontoxic fouling control. Biofouling 19 (Supplement 1), 59–62.

14. Branda, S. S., A. Vik, L. Friedman and R. Kolter (2005). Biofilms: the matrix revisited. Trends Microbiol 13 (1), 20–26.

15. Burman, N. P. and Colbourne, J. S. (1977) Techniques for the assessment of growth of micro–organisms on plumbing materials used in contact with potable water supplies. J. Appl. Bacteriol 43(1), 137–144.

16. Caccavo, J. R., A. Das (2002). Adhesion of dissimilatory Fe (III)–reducing bacteria to Fe (III) minerals. Geomicrobiol. J. 19, 161–177.

17. Cao, X. –C. J. Ma, X. –H. Shi, Z. –J. Ren (2006). Effect of TiO2 nanoparticle size on the performance of PVDF membrane. Appl. Surf. Sci. 253(4), 2003–2010.

18. Carmen, J. C., B. L. Roeder, J. L. Nelson, et al. (2004a). Ultrasonically enhanced vancomycin activity against Staphylococcus epidermidis biofilms in vivo. J. Biomater. Appl. 18, 237–245.

19. Carmen, J. C., J. L. Nelson, B. L. Beckstead, et al. (2004b). Ultrasonic–enhanced gentamicin transport through colony biofilms of Pseudomonas aeruginosa and Escherichia coli. J. Infect. Dis. 10, 193–199.

20. Chang, I. S., P. L. Clech, B. Jefferson and S. Judd (2002). Membrane fouling in membrane bioreactors for wastewater treatment. J. Environ. Eng. Nov. 2002, 1018–1029.

21. Childers, S. E., S. Clufo, D. R. Lovely (2002). Geobacter metallireducens accesses insoluble Fe (III) oxide by chemotaxis. Nature 416, 767–769.

22. Choi, H., A. C. Sofranko and D. D. Dionysiou (2006). Nanocrystalline TiO2 Photocatalytic Membranes with a Hierarchical Mesoporous Multilayer Structure: Synthesis, Characterization, and Multifunction. Adv. Funct. Mater. 16, 1067–1074.

23. Costerton, J.W., P. S. Stewart, E. P. Greenberg (1999). Bacterial biofilms: a common cause of persistent infections. Science 284, 1318–1322.

24. Cowling, M. J., T. Hodgkiess, A. C. S. Parr, M. J. Smith, S. J. Marrs (2000). An alternative approach to antifouling based on analogues of natural processes. Science Total Environ. 258, 129–137.

25. Dahlström, M., P. R. Jonsson, J. Lausmaa, et al. (2004). Impact of polymer surface affinity of novel antifouling agents. Biotechnol Bioeng. 86 (1), 1–8.

26. Das, J. R., M. Bhakoo, M. V. Jones, P. Gilbert (1998). Changes in the biocide susceptibility of Staphylococcus epidermidis and Escherichia coli cells associated with rapid attachment to plastic surfaces. J. Appl. Microbiol 84, 852–858.

27. Davey, M. E. and G.A. O’Toole (2000). Microbial biofilms: from ecology to molecular genetics. Microbiol. Mol. Biol. Rev. 64, 847–867.

28. de Nys, R. and P. D. Steinberg (2002). Linking marine biology and biotechnology. Curr. Opinion. Biotechnol. 13, 244–248.

29. Donlan, R. M. (2002). Biofilms: Microbial Life on Surfaces. Emer. Infect. Dis. 8 (9), 881–890.

30. Edwards, K. J., P. L. Bond, T. M. Gihring and J. F. Banfield (2000). An archaeal iron–oxidizing extreme acidophile important in acid mine drainage. Science 287, 1796–1799.

31. Etienne, O., C. Gasnier, C. Taddei, et al. (2005). Antifungal coating by

22

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

biofunctionalized polyelectrolyte multilayered films. Biomaterials 26, 6704–6712.

32. Fay, F., I. Linossier, V. Langlois, D. Haras and K. Vallee–Rehel (2005). SEM and EDX analysis: Two powerful techniques for the study of antifouling paints. Prog Organ Coatings 54, 216–223.

33. Flemming, H. –C. (2005). Membrane fouling: alternative anti–fouling approaches. The Israel Society for Ecology and Environmental Quality Sciences (ISEEQS) 2005 International Conferences, the Weizmann Institute of Science, May 30 to June 1, 2005, Israel.

34. Geesey, G. G. (2001). Bacterial behavior at surfaces. Curr. Opin. Microbiol. 4, 296–300.

35. Gottenbos, B., H. C. van der Mei, F. Klatter, P. Nieuwenhuis, H. J. Busscher (2001). In vitro and in vivo antimicrobial activity of covalently coupled quaternary ammonium silane coatings on silicone rubber. Biomaterials 23, 1417–1423.

36. Gov, Y., A. Bitler, G. Dell’Acqua, J. V. Torres, N. Balaban (2001). RNAIII inhibiting peptide (RIP), a global inhibitor of Staphylococcus aureus pathogenesis: structure and function analysis. Peptides 22, 1609–20.

37. Harris, L. G. and R. G. Richards (2006). Staphylococci and implant surfaces: a review. Injury. Int. J. Care. Injured. 37, S3–S14.

38. Hashimoto, H. (2001). Evaluation of the anti–biofilm effect of a new antibacterial silver citrate/lecithin coating in an in–vitro experimental system using a modified robin’s device. J. Jap. Assoc. Infect. Dis. 75 (9), 678–685.

39. Hoipkemeier–Wilson, L., J. F. Schumacher, M. L. Carman, et al. (2004). Antifouling Potential of Lubricious, Micro–engineered, PDMS Elastomers against Zoospores of the Green Fouling Alga Ulva (Enteromorpha). Biofouling 20 (1), 53–63.

40. Huang, X.–J., Z. –K. Xu, X.–D. Huang, Z. –G. Wang, K. Yao (2006). Biomimetic surface modification on polyacrylonitrile–based asymmetric membranes via direct formation of phospholipid moieties. Polymer. 47, 3141–3149.

41. Jenkinson, H. F. and H. M. Lappin–Scott (2001). Biofilms adhere to stay. Trends Microbiol. 9 (1), 9–10.

42. Kaplan, J. B. (2009) Therapeutic potential of biofilm–dispersing enzymes. Internat. J. Artific. Organs. 32 (9), 545–554.

43. Kaplan, J.B. (2010) Biofilm dispersal: mechanisms, clinical implications, and potential therapeutic uses. J. Dent. Res. 89 (3):205–218.

44. Khare, M. D., S. S. Bukhari, A. Swann, P.

Spiers, I. McLaren, J. Myers (2006). Reduction of catheter–related colonization by the use of a silver zeolite–impregnated central vascular catheter in adult critical care. J. Infection. 54(2), 146–150.

45. Kim, S. H., S.–Y. Kwak, B.–H. Sohn, T. H. Park (2003). Design of TiO2 nanoparticle self–assembled aromatic polyamide thin–film–composite (TFC) membrane as an approach to solve biofouling problem. J. Membr. Sci. 211, 157–165.

46. Klueh, U., V. Wagner, S. Kelly, A. Johnson, J. D. Bryers (2000). Efficacy of silver–coated fabric to prevent bacterial colonization and subsequent device–based biofilm formation. J. Biomedic. Mat. Res. 53, 621–631.

47. Kolenbrander, P. E. and J. London (1993). Adhere today, here tomorrow: oral bacterial adherence. J. Bacteriol. 175, 3247–3252.

48. Konstantinou, I. K. and T. A. Albanis (2004). Worldwide occurrence and effects of antifouling paint booster biocides in the aquatic environment: a review. Environ. Internat. 30 235–248.

49. Krug, P. J. (2006). Defense of benthic invertebrates against surface colonization by larvae: a chemical arms race. Progress in Molecular and Subcellular Biology, Subseries Marine Molecular Biotechnology. Springer–Verlag Berlin Heidelberg 2006.

50. Kuchma, S. L. and G. A. O’Toole (2000). Surface–induced and biofilm–induced changes in gene expression. Curr. Opinion. Biotechnol. 11, 429–433.

51. Kumar, S. A., T. Balakrishnan, M. Alagar, Z. Denchev (2006). Development and characterization of silicone/phosphorus modified epoxy materials and their application as anticorrosion and antifouling coatings. Progr. Org. Coatings. 55, 207–217.

52. Lee, H., E. Lee, D. K. Kim, N. K. Jang, Y. Y. Jeong and S. Jon (2006). Antibiofouling Polymer–Coated Superparamagnetic Iron Oxide Nanoparticles as Potential Magnetic Resonance Contrast Agents for in Vivo Cancer Imaging. J. Am. Chem. Soc. 128, 7383–7389.

53. Lewis, A. L. (2000). Phosphorylcholine–based polymers and their use in the prevention of biofouling. Coll. Surf. B: Biointerfaces 18, 261–275.

54. Liu, L. –F., S.–C. Yu, L.–G. Wu, C.–J. Gao (2006). Study on a novel polyamide–urea reverse osmosis composite membrane (ICIC–MPD): (II) Analysis of membrane antifouling performance. J. Membr. Sci., 83(1+2), 133–146.

55. Löschau, M. and R. Krätke (2005). Efficacy and toxicity of self-polishing biocide–free

23

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

antifouling paints. Environ. Pollut. 138, 260–267.

56. Lower, S. K., M. F. Hochella, T. J. Beveridge (2001). Bacterial recognition of mineral surfaces: nanoscale interactions between Shewanella and α–FeOOH. Science. 292, 1360–1363.

57. Massè, A., A. Bruno, M. Bosetti, A. Biasibetti, M. Cannas, P. Gallinaro (2000). Prevention of Pin Track Infection in External Fixation with Silver Coated Pins: Clinical and Microbiological Results. J. Biomed. Mater Res. (Appl. Biomater) 53, 600–604.

58. Mermel, L. A. (2001). New Technologies to Prevent Intravascular Catheter–Related Bloodstream Infections. Emerg. Infect. Dis. 7 (2), 197–199.

59. Meyer, B. (2003). Approaches to prevention, removal and killing of biofilms. International Biodeter & Biodegrad 51, 249–253.

60. Minier, M., Salmain, M., Yacoubi, N., Barbes, L., Méthivier, C., Zanna, S. and Pradier, C–M. (2005) Covalent immobilization of lysozyme on stainless steel, interface spectroscopic characterization and measurement of enzymatic activity. Langmuir, 21, 5957–5965.

61. Namavar, F., Jackson, J. D., Sharp, J. G., Mann, E. E., Bayles, K., Cheung, B. C. L., Feschuk, C. A., Varma, S., Haider, H. and Garvin, K. L. (2007) Searching for Smart Durable Coatings to Promote Bone Marrow Stromal Cell Growth While Preventing Biofilm Formation. Materials Research Society Symposium Proceedings (2007), Volume Date 2006, 954E (Biofilm–Material Interactions), Paper #: 0954–H04–04.

62. Nie, F.–Q., Z.–K. Xu, Q. Yang, J. Wu, L.–S. Wan (2004). Surface modification of poly (acrylonitrile–co–maleic acid) membranes by the immobilization of poly (ethylene glycol). J. Membr. Sci. 235, 147–155.

63. O’Neill, J. F., C. K. Hope, M. Wilson (2002). Oral bacteria in multispecies biofilms can be killed by red light in the presence of toluidine blue. Lasers. Surg. Med. 31, 86–90.

64. O’Toole, G., H. B. Kaplan and R. Kolter (2000). Biofilm formation as microbial development. Ann. Rev. Microbiol. 54, 49–79.

65. Okamura, H., I. Aoyama, D. Liu, R. J. Maguire, G. J. Pacepavicius and Y. L. Lau (2000). Fate and ecotoxicity of the new antifouling compound Irgarol 1051 in the aquatic environment. Water Res. 34 (14), 3523–3530.

66. Pérez, M., G. Blustein, M. García, B. del Amo, M. Stupak (2006). Cupric tannate: A low copper content antifouling pigment. Progr. Organic Coatings 55, 311–315.

67. Pickering, S. A. W., R. Bayston, T. F. Scanlin

(2003). Electromagnetic augmentation of antibiotic efficacy in infection of orthopaedic implants. J. Bone Jt. Surg., BR 85B, 588– 593.

68. Piozzi, A., I. Francolini, L. Occhiaperti, M. Venditti, W. Marconi (2004). Antimicrobial activity of polyurethanes coated with antibiotics: a new approach to the realization of medical devices exempt from microbial colonization. Int. J. Pharmacol. 280, 173–183.

69. Prigent–Combaret, C., O. Vidal, C. Dorel and P. Lejeune (1999). Abiotic Surface Sensing and Biofilm–Dependent Regulation of Gene Expression in Escherichia coli. J. Bacteriol. 181 (19), 5993–6002.

70. Rachid, S, Ohlsen, k., Witte, W., Hacker, J., Ziebuhr, W. (2000). Effect of subinhibitory antibiotic concentrations on polysaccharide intercellular adhesin expression in biofilm–forming Staphylococcus epidermidis. Antimicrob Agents Chemother 44:3357–3363.

71. Rediske, A. M., B. L. Roeder, J. L. Nelson, R. L. Robison, G. B. Schaalje, R. A. Robison (2000). Pulsed ultrasound enhances the killing of Escherichia coli biofilms by aminoglycoside antibiotics in vivo. Antimicrob Agents Chemother 44, 771–772.

72. Rittschof, D. (2000). Natural product antifoulants: one perspective on the challenges related to coatings development. Biofouling. 15 (1–3), 119–127.

73. Roberts, J. A. (2004). Inhibition and enhancement of microbial surface colonization: the role of silicate composition. Chem. Geol. 212, 313–327.

74. Rogers, J., A. B. Dowsett, P. J. Dennis, J.V. Lee, C. W. Keevil (1994). Influence of plumbing materials on biofilm formation and growth of Legionella pneumophila in potable water systems. Appl. Environ. Microbiol. 60(6), 1842–1851.

75. Roosjen, A., Norde, W., van der Mei, H.C. and Busscher, H.J. (2006) The use of positively charged or low surface free energy coatings versus polymer brushes in controlling biofilm formation. Progr. Colloid Polym. Sci. 132: 138–144.

76. Shin, D., D. A. Tryk, A. Fujishima, A. Merkoçi, J. Wang (2005). Resistance to Surfactant and Protein Fouling Effects at Conducting Diamond Electrodes. Electroanalysis 17 (4), 305–311.

77. Sibarani, J.,Konno, T., Takai, M. and Ishihara, K. (2006) Non–biofouling surface prepared by living radical graft polymerization of 2–methacryloyloxyethyl phosphorylcholine for micro–biochip. Trans. Mater. Res. Soc. Japan 31 (3), 641–644.

78. Sjögren, M., A.–L. Johnson, E. Hedner, M.

24

Available on-line at www.dse.usab-tm.ro/en/bjb.html

Banat′s Journal of Biotechnology

2010, I(1),

Dahlström, U. Göransson, H. Shirani, J. Bergman, P. R. Jonsson, L. Bohlin (2006). Antifouling activity of synthesized peptide analogs of the sponge metabolite barettin. Peptides 27(9), 2058–2064.

79. Smith, A. W. (2005). Biofilms and antibiotic therapy: Is there a role for combating bacterial resistance by the use of novel drug delivery systems? Adv. Drug. Delivery. Rev. 57, 1539–1550.

80. Soukos, N. S., S. S. Socransky, S. E. Mulholland, S. Lee, A. G. Doukas (2000). Photomechanical drug delivery into bacterial biofilms. Pharmacol Res. 17, 405–409.

81. Statz, A. R., Meagher, R.J., Barron, A.E. and Messersmith, P.B. (2005) New Peptidomimetic Polymers for Antifouling Surfaces J. Am. Chem. Soc., 127, 7972–7973.

82. Stein, J., K. Truby, C. D. Wood, M. Takemori, M. Vallance, G. Swain, C. Kavanagh, B. Kovach, M. Schultz, D. Wiebe, E. Holm, J. Montemarano, D. Wendt, C. Smith, A. Meyer (2003). Structure–Property Relationships of Silicone Biofouling–Release Coatings: Effect of Silicone Network Architecture on Pseudobarnacle Attachment Strengths. Biofouling 19 (2), 87–94.

83. Stewart, P. S., W. Wattanakaroon, L. Goodrum, S. M. Fortun, B. R. McLeod (1999). Electrolytic generation of oxygen partially explains electrical enhancement of tobramycin efficacy against Pseudomonas aeruginosa biofilm. Antimicrob Agents Chemother 43, 292–296.

84. Stickler, D. (1999). Biofilms. Ecology and industrial microbiology: Curr. Opinion Microbiol 2, 270–275.

85. Stoodley, P., K. Sauer, D. G. Davies and J.W. Costerton (2002). Biofilms as complex differentiated communities. Annu. Rev. Microbiol. 56, 187–209.

86. Taylor, C. J. L. (2006). The effects of biological fouling control at coastal and estuarine power stations. Marine Pollut. Bull. 53, 30–48.

87. Tenke, P., C. R. Riedl, G. L. Jones, G. J. Williams, D. Stickler, E. Nagyd (2004). Bacterial biofilm formation on urologic devices and heparin coating as preventive strategy. Intern J. Antimicrob. Agents. 23 (S1), S67–S74.

88. Thomas, K. V. (2001). The Environmental Fate and Behaviour of antifouling Paint Booster Biocides: A Review. Biofouling 17 (1), 73–86.

89. Thünemann, A. F. and R. H. Kublickas (2001). Low surface energy polysiloxane complexes. J. Mat. Chem. 11 (2), 381–384.

90. Tsibouklis, J. (2004). Preventing the bacterial

colonisation of surfaces: the “ultra–low surface energy” approach. Presented at Fourth International Symposium on Contact Angle, Wettability and Adhesion, June 14–16, 2004, Philadelphia, USA.

91. Tsibouklis, J., M. Stone, A. A. Thorpe, et al. (1999). Preventing bacterial adhesion onto surfaces: the low–surface–energy approach. Biomaterials 20, 1229–1235.

92. Tsoukatou, M., C. Hellio, C. Vagias, C. Harvala and V. Roussis (2002). Chemical Defense and Antifouling Activity of Three Mediterranean Sponges of the Genus Ircinia. Z Naturforsch 57c, 161–171.

93. Turley, P. A., R. J. Fenn, J. C. Ritter (2000). Pyrithiones as antifoulants: Environmental chemistry and preliminary risk assessment. Biofouling 15 (1–3), 175–182.

94. Turley, P. A., R. J. Fenn, J. C. Ritter, M. E. Callow (2005). Pyrithiones as antifoulants: environmental fate and loss of toxicity. Biofouling 21 (1), 31–40.

95. Videla, H. A. (2002). Prevention and control of biocorrosion. Internat. Biodeter & Biodegrad 49, 259–270.

96. Vieira–da–Motta, O., P. D. Ribeiro, W. Dias da Silva, E. Medina–Acosta (2001). RIP inhibits agr–regulated toxin production. Peptides 22, 1621–27.

97. Wainwright, M., K. B. Crossley (2004). Photosensitising agents–circumventing resistance and breaking down biofilms: a review. Int. Biodeterior Biodegrad 53, 119–126.

98. Wake, H., H. Takahashi, T. Takimoto, K. Takayanagi, K. Ozawa, H. Kado, M. Okochi, T. Matsunaga (2006). Development of an electrochemical antifouling system for seawater cooling pipelines of power plants using titanium. Biotechnol. Bioeng., 95(3), 468–473.

99. Wang, T., Y.–Q. Wang, Y.–L. Su, Z.–Y. Jiang (2006). Antifouling ultrafiltration membrane composed of polyethersulfone and sulfobetaine copolymer. J. Memb. Sci. 280(1+2), 343–350.

100. Warscheid, T. and J. Braams (2000). Biodeterioration of stone: a review. Internat. Biodeterior & Biodegrad 46, 343–368.

101. Watnick, P. and R. Kolter (2000). Biofilm, City of Microbes. J Bacteriol 182 (10), 2675–2679.

102. Woo, G. L. Y., M. L. Yang, H. Q. Yin, F. Jaffer, M. W. Mittleman, J. P. Santerre (2002). Biological characterization of a novel biodegradable antimicrobial polymer synthesized with fluoroquinolones. J. Biomed. Mater. Res. 59, 35–45.

103. Wood, P., D. E. Caldwell, E. Evans, M. Jones,

25

Banat’s University of Agricultural Sciences and Veterinary Medicine from Timisoara,

Department of Exact Sciences, Contact: web: www.dse.usab-tm.ro, e-mail: [email protected]

D. R. Korber, G. M. Wolfhaardt, M. Wrlson, P. Gilbert (1998). Surface–catalysed disinfection of thick Pseudomonas aeruginosa biofilms. J. Appl. Microbial 84, 1092–l098.

104. Xinbo S., Zhengbing C. and Yuyu, S. (2009) N–chloro–alkoxy–s–triazine–based antimicrobial additives: preparation, characterization, and antimicrobial and biofilm–controlling functions. Ind. Eng. Chem. Res 48, 607–612.

105. Xu, Q. W., C. A. Barrios, T. Cutright, B. Z. Newby (2005). Evaluation of Toxicity of Capsaicin and Zosteric Acid and Their Potential Application as Antifoulants. Environ. Toxicol. 20(5), 467–474.

106. Yang, X.M., H. Beyenal, G. Harkin, Z. Lewandowski (2000). Quantifying biofilm structure using image analysis. J. Microbiol. Methods 39, 109–119.

107. Ye, S. H., J. Watanabe, Y. Iwasaki, K. Ishihara (2003). Antifouling blood purification membrane composed of cellulose acetate and phospholipid polymer. Biomaterials 24, 4143–4152.

108. Yebra, D. M., S. Kiil, K. Dam–Johansen (2004). Antifouling technology–past, present and future steps towards efficient and environmentally friendly antifouling coatings. Progr. Organic. Coatings 50, 75–104.

109. Yu, H.–Y., M.–X. Hu, Z.–K. Xu (2005). Improvement of Surface Properties of Poly (propylene) Hollow Fiber Microporous Membranes by Plasma–Induced Tethering of Sugar Moieties. Plasma Process. Polym. 2, 627–632.

110. Zhang, H. (2005). Marine Biofouling Control through Engineering Nanoscale Roughness on Surface. Presented at ISNEPP 2005, International Symposium on Nanotechnology in Environmental Protection and Pollution, January 12–14, 2005, Bangkok, Thailand.

111. Zhang, H., Tang, J., Meng, X., Tsang, J. and Tsang, T–K. (2005) Inhibition of bacterial

adherence on the surface of stents and bacterial growth in bile by bismuth dimercaprol. Digestive Dis. Sci. 50(6), 1046–1051.

112. Zhao, Q. and Y. Liu (2006). Modification of stainless steel surfaces by electroless Ni–P and small amount of PTFE to minimize bacterial adhesion. J. Food Eng. 72, 266–272.

113. Zhao, Q., S. Wang, H. Müller–Steinhagen (2004). Tailored surface free energy of membrane diffusers to minimize microbial adhesion. Appl. Surf. Sci. 230, 371–378.

114. Zilberman, M., Navon, A., Sandovsky–Losica, H. and Segal, E. (2007), Biomedical coatings based on chitin soluble extract for inhibition of fungal adhesion to polymeric surfaces. J. Biomed. Mat. Res., Part A, 81 A (2), 392–398.

115. ***Wikipedia–the free encyclopedia, 2006. http://64.233.183. 104/search?q=cache: VBp9ip4op_8J: en.wikipedia.org/wiki/Biofouling+Governments+and+industry+spend+than+US%24+5.7+billion+annually+to+prevent+and+control+marine+biofouling&hl=en&ct=clnk&cd=1.

116. ***The AFS Convention (International Convention on the Control of Harmful Anti–fouling Systems on Ships), done at London on 18 October, 2001. Report 52: Treaties Tabled in March 2003.