Background to Mako -Lube Lubricants

description

Transcript of Background to Mako -Lube Lubricants

Introduction to Specialist Lubricants Mako-Lube Lubricants Limited

Presentation by:Gavin Armitage

Mako-Lube Lubrication Ltd Managing Director

Background to Mako-Lube Lubricants

Mako-Lube Lubricants is an independent specialty lubricant manufacturer based in Manchester, United Kingdom.

Mako-Lube Lubricants is the sister Company of Brit-Lube who were formed in year 2000. Mako-Lube formed in 2011 as the export division. “ An exciting new brand for Distribution only !”

Current Distributors in UK, Ireland, China, Thailand, Canada, South Africa, Brazil, Norway, Sweden, Ecuador……..

Mako-Lube Lubricants have purpose built modern production facilities in the UK.All product are manufactured & packaged in the UK.

Background to Mako-Lube Lubricants Group

Mako-Lube Lubricants offers a world class range of products.

Mako-Lube Lubricants has affiliate companies & distributors.

Mako-Lube Lubricants are represented worldwide.

Mako-Lube Lubricants specialise in high performance lubricants and lubrication including a complete range of synthetic oils, high performance, high and low temperature greases, fluid and dry film coatings.

Product Range

Unrivalled Product Portfolio Food-Tek Indu-Tek Ultra-Tek Xtreme-Tek

Manufactured to a quality, not a costHigh performanceApplication SpecificBespoke to customers specification

Access on www.mako-lube.com - Members Area !

Mako-Lube Lubricants service many sectors….

Automotive

Aerospace

Conveyors & Chains

Corrugating Machines

Food Industry

Electrical Industry

Textile Machinery

Faucets, Valves & Fittings

Moulding

Casting Metalworking

Oxygen

BASIC LUBRICANT TRAINING

The Refining Process

KEC Atmos tower

Vacuumtower

desulphuri-ser units

WSR

Kerosine

GasoilKerosine

Diesel

Base Oils

Naphtha

Sulphurplant Sulphur

Lube Oil Unit

pda Bitumen

Heavy Oils

Light Oils

Crude Oil Distillation

CNG

LPG

gasoline

heavier fuels:

bigger molecules

aromatics

CH3

alkenes(olefins)

CH3 CH3

cycloalkanes(naphthenes)

CH3

alkanes(paraffins)

CH4CH3 CH3

CH3

CH3

CH3 CH3

CH3CH3

CH3

CH3 CH3

CH3

CH3 CH3 CH3

CH3

CH3

CH3

Distillation is fluid separation on boiling point

INTRODUCTION

Lubrication has been practiced for centuries. Early lubrication involved the use of water or animal fat to improve free running and reduce wear. Chariot wheels were lubricated with rendered animal fat. Modern lubricants are more sophisticated, but similar principles are involved.

Reduction of friction & wear.

BASIC LUBRICATION THEORY

At a microscopic scale, even apparently smooth surfaces are actually quite rough. Friction and wear result when these rough surfaces move across each other. *

BASIC LUBRICATION THEORY

Lubricants act between the opposing surfaces, reducing friction and wear. Maintenance of the lubricant film is paramount; loss of lubrication leads to huge increases in friction; hence wear, seizure and component failure.

FRICTION REGIMES

HYDRODYNAMIC ‘Aquaplaning’

BOUNDARY ‘Last ditch’

MIXED EHD (lowest friction)

SLA - Solid Lubricating Additives Explained

PTFEOil

Graphite

MoS2

*

SOLID LUBRICANTSSOLIDS WITH SPECIAL PROPERTIES

LOW INTERNAL FRICTION, SOFTNESS

EXTREME TEMPERATURE RESISTANCE, CAN BE USED ALONE OR AS ADDITIVES…

GRAPHITE, MOLYBDENUM DISULPHIDE (MOLY or MoS2), PTFE (TEFLON), MINERALS, SOFT METALS…

MOLY & GRAPHITE: The crystals are arranged in layers which slide easily over one another, GRAPHITE…up to 600°C, MoS2…up to 450°C DECK OF CARDS

Other solids include Talc, Mica, Boron Nitride, Zinc sulphide and Tungsten disulphide, similar layer structure.

PTFE/ TEFLON: Very low friction solid “Described as the Slipperiest Substance in the World!” Struggles under very high load.

PTFE SAMLPLES, GRAPHITE & MOLY

COEFFICIENT OF FRICTIONThis is a measure of the ‘slipperiness or lubricity of a system. For a simple bearing, it varies with rotational speed, loading and viscosity of any lubricant.

An Inclined plane

BASIC TYPES OF LUBRICANTS

OILS

GREASES

SOLID LUBRICANTS

DRY FILM COATINGS

OTHER FLUIDS

OILS

LUBRICATING OILS are made from a blend of base oils and additives

BASE OILS may be of many different types

ADDITIVES are included to improve the performance of the base oil

TYPES OF BASE OIL

VEGETABLE (OR ANIMAL)

MINERAL OIL

SYNTHETIC HYDROCARBON

SYNTHETIC NON-HYDROCARBON

*

TYPES OF ADDITIVES

• VI IMPROVERS• CORROSION INHIBITORS• ANTI-WEAR AGENTS• ANTI-OXIDANTS• EP ADDITIVES• DETERGENTS• ANTI-FOAMS

VEGETABLE OILS

CHEAP

BIODEGRADABLENATURALLY VARIABLE QUALITYLIMITED RANGEUNSUITABLE FOR EXTREME TEMPERATURESCHEMICALLY UNSTABLE

MINERAL OILS

CHEAP

MODERATE CHEMICAL STABILITYWIDE RANGE OF GRADESNATURALLY VARIABLE QUALITYUNSUITABLE FOR EXTREME TEMPERATURESNON-BIODEGRADABLE

SYNTHETIC HYDROCARBONS

PURE MOLECULES

HIGHER CHEMICAL STABILITY

RELATIVELY EXPENSIVE

MAY BE BIODEGRADABLE

TYPES OF SYNTHETIC HYDROCARBONS

POLY ALPHA OLEFINS (PAOs) Synthetic mineral oil without

the impurities. Higher temperature resistance, less lacquer, same additives.

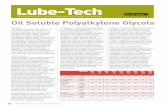

POLY ALKYLENE GLYCOLS (PAGs) Can be oil soluble, water

soluble or neither. Very low lacquer, higher temperature resistance. PAG additives are generally less effective.

ESTERS DIESTERS. Better temperature

resistance than PAGs. More expensive.

TRIESTERS. Better temperature resistance than diesters. Still more expensive

POLYOL ESTERS. Best temperature resistance of the esters. Unlike the previous synthetic oils these are biodegradable. Yet more expensive.

NON-HYDROCARBON OILS

SILICONES Wide temperature range, high price

FLUOROSILICONES Wider temperature range, higher price

FLUOROCARBONS, PFPEs Widest temperature range, highest price

*

BENEFITS OF NON-HYDROCARBONS

COMPATIBLE WITH SEALSVERY HIGH CHEMICAL STABILITYCHEMICAL INCOMPATIBILITYEXPENSIVE TO EXTREMELY EXPENSIVE

VISCOSITY & VIViscosity is an important parameter. Film thickness increases with viscosity, but so does friction. At low speeds, a viscous oil is best, at high speeds a light mobile fluid is preferred, as long as it is viscous enough to keep the surfaces separate!

The standard temperatures of measurement are 40°C & 100°C. The unit of measurement is the ‘centistoke’ cSt.

The viscosity also determines the ‘grade’ of oil. For example, ISO VG 220 oils are around 220 cSt @ 40°C

The property of viscosity varying with temperature is measured by the Viscosity Index, or VI – different oils have different Viscosity indexes. The VI is calculated from the difference in the viscosity at 40 & 100°C,Less change in Viscosity with temperature = a higher VI

Oil Viscosities - Explained

High Speed, Low Load

High Load, Low Speed

*

Conclusion :- Oils

All oils are not the sameFinished products are basically a blendFinished products of the same nature i.e. Esters, Mineral Oils etc. may perform differently as performance is due to specific “Additive Packages” used.Rule of Thumb – Higher the Viscosity – Lower the speed, higher the loadSome Mako-Lube products have SLA’s Solid Lubricating Additives added for improved performance & friction reduction. i.e. MOS2 & Teflon/PTFE

GREASES

Greases are thickened oils.

Formulated greases therefore contain:- BASE OIL

ADDITIVES

THICKENER

GREASE = 100 %

More Common

Less Common

BASE OIL +(70 – 95%)

SYNTHETIC OILS

Dialkylbenzène

Polyalphaolefins

Esters

Polyglycols

Silicones

Perfluoropolyethers

Polyphenylethers

THICKENER +

(3 – 20%)SIMPLE SOAPS

Lithium

Calcium

Sodium

Aluminium

Barium (rare)

INORGANIC

Bentone

Silica

Polyurea

PTFE & other solids

ADDITIVES

Corrosion inhibitors

Anti wear

Extreme pressure

Antioxidant

Polymers

Anti copper

Solid Lubricants

Colourings

Friction Modifiers

Metal powders

ADDITIVES (0 – 10%)

COMPLEX SOAPS

Calcium

Lithium

Aluminium

Barium (rare)

MINERAL OILS

Paraffinic

Naphthenic

COMPOSITION OF GREASES

What is a Grease?A grease is a mixture of a base lubricating fluid (usually a mineral or a synthetic oil) and a thickener (usually a soap) dispersed in the oil.

Designed to provide extended lubrication intervals by gradually allowing the base fluid to provide lubrication between working surfaces.

More specialised greases contain additional additives to enhance high temperature and anti-wear performance and to provide corrosion protection.

31

Grease Composition

SOAPS & COMPLEXES These are the most common greases. They contain no solid matter

and are suitable for general purpose applications

SOAPS are simpler cheaper formulations. Limited by melting point

Most common Lithium i.e. Lithium EP 2 Grease

COMPLEXES have greater resistance to high temperatures, water & steam “Act Like a Sponge” to draw the oil film back into the grease. Sponge Demo

Lithium Complex, Calcium Complex, Aluminum Complex, Barium Complex etc.

Properties depend upon the chemical attributes of the thickener

Note: Lithium Grease & Lithium Complex have completely different performance characteristics but “Sound” the same

What goes into a specialised grease?• Base Oil• Thickener• EP / Anti-wear Additives• Solid Lubricants• Oxidation Inhibitors• Corrosion Inhibitors

33

Grease Composition

Base OilProvides hydrodynamic lubrication

Types of Base OilMineral Oil (-30ºC to 150ºC)Synthetic Oil (-70ºC to 300ºC)Vegetable Oil (-10ºC to 130ºC)

34

Grease Composition

ThickenerActs as a sponge and releases small quantities of oil when worked

Types of ThickenerSoaps: Lithium, Calcium, Aluminum, SodiumPowders: Silica, Clay (Bentone), PTFE – Teflon

WHEN CHANGING FROM ONE TYPE OF GREASE TO ANOTHER, ALWAYS CHECK COMPATIBILITY!

35

Grease Composition

EP AdditivesChlorine, Sulphur, Phosphorus. EP Additives react with the metal surface when friction generates momentary high temperatures

Solid LubricantsMolybdenum Disulphide (MoS2)GraphitePTFEWhite Solids

36

Grease Composition

*

Anti-oxidantsProtects base oil by delaying the onset of oxidation caused by high temperatures. This is one of the key ingredients in extending grease life.

Anti-corrosion agentsProvide protection of metal surfaces operating in wet, corrosive conditions.

37

Grease Composition

38

Cone Penetration – NLGI Grading – National Lubricating grease Institute

Cone is set so that it just touches surface of grease. Temp 25ºCCone is released and allowed to sink into the grease for 5 secs.Depth of Penetration measured in 0.1mm

NLGI 6

NLGI 5

NLGI 4

NLGI 3

NLGI 2

NLGI 1

NLGI 0

NLGI 00

NLGI 000

HOW IS GREASE THICKNESS MEASURED?

Synfood EP 1Synfood EP 2 Synfood EP 000

NLGI No. (National Lubricating Grease Institute)

No. Penetration Consistency Food Comparison

6 85 – 115 Block grease Cheddar Cheese 5 130 - 160 Extremely stiff grease Smooth Pate 4 175 - 205 Very stiff grease Frozen Yogurt 3 220 - 250 Stiff grease Lard 2 265 - 295 Standard grease (85% of grease market) Peanut Butter 1 310 - 340 Soft grease (for centralised lube systems) Tomato Paste 0 355 - 385 Very soft grease ( “ “ “ ) Mustard 00 400 - 430 Semi fluid grease Apple Sauce000 445 - 475 Fluid ‘slumping’ grease Cooking oil

40

Cone released onto a flattened surface of a worked sample of grease, left for 5 seconds, depth of penetration measured in 0.1mm

Consistency - NLGI

*

41

Penetration - Grease Worker

To establish “Worked Penetration”, the grease is subjected to 60 strokes in a grease worker, where the grease is forced backwards and forwards through a perforated disc.

42

Shell 4 Ball

No lubricant satisfies all working conditions68% of bearings fail prematurely• Half of this due to incorrect lubricationCauses:

Initial over-lubrication Over-lubrication at frequent lube intervals Infrequent lubrication Mixing greases of different types Incorrect lubricant

43

Selection of the correct lubricant is key

So often grease is applied until it is seen to extrude through the bearing housing.

44

Over-lubrication

Recommended lubrication 60%

Over-Lubrication

Why the wrong lubricant?

Misjudgment of operating conditions:• Temperature• Water• Speed• Dust• Load• Chemicals• Bearing Type• Method of application

Wrong recommendation by supplier

45

Selection of the correct lubricant is key

Recommending an equivalent or alternative:

How often does the lubricant supplier ask about the application and working conditions?

How sure is the lubricant supplier that the product put forward is the best one for the job? Never match a current grease always Specifiy what “YOU” determine is best for the application !

46

Selection of the correct lubricant is key

Non – Grease CompoundsANTI SEIZES-SOFT

METALSSoft metals can be used as anti-seize materials (e.g. Anti-Seize 1100 ) at extreme temperatures. (i.e. over 600°C) Sacrificial layer of soft metal allows release from seizure.Nickel & Lead are toxicCopper is an environmental hazardAluminium is not as effective at high temperatures.They are NOT greases and should not be used for bearing lubricationUsed for bolts, threaded fittings, slides, sleeves etc. Protection against seizure of threads caused by high temperature or corrosive conditions, dismantled parts can be re-used *

Other ProductsDRY FILM COATINGS

Dry film lubricants are used in many areas as a thin film of a low friction ‘paint’ or coating to provide lubrication and corrosion protection:

1. SOLVENT / WATER DISPERSIONS – solid particles of lubricant held in a carrier solution or dispersion – Mako-Cote Range

2. BONDED COATINGS –They contain solvent, resin (to bond to the surface) & lubricant. The dried film is resin + lubricant:- a compromise. Dry Moly & PTFE Sprays *

Conclusion :-

Oils & Greases are Blends!

Performance is defined by base fluid properties & additives packages etc

SLA’s Reduce friction & improve performance

Oils & Greases come in many different forms, Fluid, Semi-Fluid, Compounds, Greases, Water-Based, Aerosols, Trigger Sprays, Solvent Based, Resins etc

Thank you for your time!Any questions?

Mako-Lube LtdUnits 2&3 Mayfield Industrial Estate

Liverpool Road Irlam

Manchester M44 6GD

+44(0)161 777 [email protected]