AWG-964 manual opt 2 - cdn3.blocksassets.comcdn3.blocksassets.com/...manuals/.../AWG-964.pdf ·...

Transcript of AWG-964 manual opt 2 - cdn3.blocksassets.comcdn3.blocksassets.com/...manuals/.../AWG-964.pdf ·...

Arc Welder140 AmpFan CooledOperation Manual3 Year Replacement Warranty

AWG-964CAUTION: Read this operation manual before using this tool.

To view the full range visit: www.ozito.com.au1010

SPECIFICATIONS - MODEL NO. AWG-964

1

Input Power: 240V - 50HzMax. No Load Voltage: 48VCurrent Range: 55 - 130 AmpPeak Current: 140 AmpDuty Cycle: 25% @ 80 AmpElectrode Size: 2 - 3.2mm

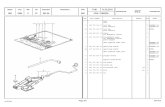

1. Carry Handle2. Current Setting Gauge3. On/Off Switch4. Current Regulating Knob5. Electrode Holder

6. Earth Clamp7. Overload LED8. Internal Cooling Fan (not shown)9. Combination wire brush/chipping hammer10. Welding Mask

1

2

3

4

5

6

7

8

9

10

KNOW YOUR PRODUCT

TABLE OF CONTENTS

2

SPECIFICATIONS………………………………………..

TABLE OF CONTENTS…………………………………

INTRODUCTION…………………………………………

SAFETY INSTRUCTIONS……………………………….

GENERAL SAFETY RULES……………………………..

OPERATION……………………………………………..

MAINTENANCE…………………………………………

DESCRIPTION OF SYMBOLS…………………………

CONTENTS………………………………………………

WARRANTY………………………………………………

Page 1

Page 2

Page 3

Page 3

Page 4

Page 7

Page 11

Page 11

Page 12

Page 13

3

INTRODUCTION

Warning! When using mains-powered equipment, basic safety precautions,including the following, should always be followed to reduce risk of fire, electricshock, personal injury and material damage.

Read and understand the manual prior to operating this product.

Save these instructions and other documents supplied with this product for future reference.

This electrical equipment has been designed for 230V and 240V only.

Always check that the power supply corresponds to the voltage on the rating plate.

Note: The supply of 230V and 240V on Ozito products are interchangeable for Australiaand New Zealand.

If the supply cord is damaged, it must be replaced by an electrician or a power toolrepairer in order to avoid a hazard.

Using an Extension Lead

Always use an approved extension lead suitable for the power input of this electricalequipment. Before use, inspect the extension lead for signs of damage, wear andageing. Replace the extension lead if damaged or defective. When using an extensionlead on a reel, always unwind the lead completely. Use of an extension lead not suitablefor the power input of the equipment or which is damaged or defective may result in arisk of fire and electric shock.

It is recommended that the extension lead is a maximum of 25m in length. Do Not usemultiple extension leads.

Congratulations on purchasing an Ozito Arc Welder. We aim to provide quality products at an affordable price.We hope you will enjoy using this product for many years.

The Ozito Arc Welder AWG-964 has been designed toweld most steel products. Its varying current range,lightweight and portability make it an ideal welder formany jobs.

It is intended for DIY use only.

SAFETY INSTRUCTIONS

ELECTRICAL SAFETY

4

GENERAL SAFETY RULES

1. Keep work areas clean. Cluttered work areas and benches can cause accidents.

2. Consider work area environment. Do not expose your equipment to highhumidity or rain. Do not use your equipment in damp or wet conditions. Keepthe work area well lit. Do not use your tool where there is a risk of causing fireor explosion, e.g. in the presence of flammable liquids and gases.

3. Keep children away. Do not allow children, visitors or animals to come nearthe work area or to touch the equipment or accessories.

4. Dress appropriately. Wear the appropriate protective clothing. Wear a protectivehair covering to keep long hair out of the way.

5. Guard against electric shock. Prevent body contact with earthed or groundedsurfaces. Electrical safety can be further improved by using a high sensitivity (30mA / 30 mS) residual current device (RCD).

6. Do not overreach. Keep proper footing and balance at all times.

7. Stay alert. Watch what you are doing. Use common sense. Do not operate theequipment when tired.

8. Secure work piece. If required, use clamps or a vice to hold the work piece.

9. Extension leads. Before use inspect the extension leads and replace ifdamaged. When using the equipment outdoors, only use extension leadsintended for outdoor use and marked accordingly.

10. Use appropriate equipment. Only use the equipment as outlined within thisinstruction manual. Do not force the equipment to the job of heavier dutyequipment. The equipment will do the job better and safer at the rate forwhich it was intended. Do not force the equipment.

Warning! The use of any accessory or attachment, or performance of anyoperation with this equipment other than those recommended in thisinstruction manual may present a risk of personal injury.

11. Check for damaged parts. Before use carefully check the equipment andpower lead for damage. Check for misalignment and seizure of moving parts,breakage of parts, damage to guards and switches and any other conditionsthat may affect its operation. Ensure the equipment will operate properly andperform its intended function. Do not use the equipment if any parts aredamaged or defective. Do not use the equipment if the switch does not turn iton and off. Have any damaged or defective parts repaired or replaced by anelectrician or a power tool repairer. Never attempt any repairs yourself.

12. Unplug the equipment. Unplug the equipment when it is not in use, beforechanging any parts, accessories or attachments and before servicing.

13. Do not abuse the cord. Never carry the equipment by its cord or pull it todisconnect from the socket. Keep the cord away from heat, oil and sharp edges.

GENERAL SAFETY RULES (cont.)

5

SAFETY INSTRUCTIONS FOR WELDERS

14. Store equipment. When not in use, equipment should be stored in a dry, lockedup or high place, out of reach of children.

15. Maintain mains equipment with care. Keep the equipment clean and in goodcondition for better and safer performance. Follow the instructions for maintenanceand changing accessories. Keep handles and switches dry, clean and free from oiland grease.

16. Have your tool repaired by an electrician or a power tool repairer. This powertool complies with relevant safety requirements. To avoid danger, electricalequipment must only be repaired by qualified technicians using original spare parts;otherwise this may result in considerable danger to the user.

17. Users. This equipment is not intended for use by young children or infirmedpersons without supervision. Young children should be supervised to ensure thatthey do not play with this equipment.

18. Replacement of the supply cord. If the supply cord is damaged, it must bereplaced by an electrician or a power tool repairer in order to avoid a hazard.

Under no circumstances should the housing of the welder be opened.

Always protect your eyes and face with a welding mask.

Wear appropriate protective clothing such as a welding apron and sleeved gloves etc.

Avoid exposing skin as UV rays are produced by the arc.

Screen off the work place to protect others working nearby from UV rays.

Welding materials with contaminated surfaces may generate toxic fumes. Ensure thesurface is clean before welding. Avoid operating on materials cleaned with chlorinatedsolvents or near such solvents.

Do not weld metal equipment that holds/contains flammable materials, gases or liquid combustibles.

Zinc-plated or galvanized material should not be welded as the fumes created arehighly toxic.

Do not use the welder in damp or wet conditions.

Do not use cables with worn insulation or loose connections.

6

SAFETY INSTRUCTIONS FOR WELDERS (cont.)

Disconnect from the power supply before replacing electrodes.

Avoid direct contact with the welding circuit.

Do not use the welder to defrost piping.

Ensure the welder is placed on a level surface to prevent overturning.

Provide adequate ventilation or a means for removal of the welding fumesproduced (forced circulation using a blower or fan).

FumesToxic gases are given off during the INVENT MIG welding process, which maycollect in the welding area if the ventilation is poor. Be alert at all times to thepossibility of fume build-up. In small or confined areas use a fume extractor.

GlareThe electric arc generated by the INVENT MIG process gives direct heat andultraviolet radiation. It is essential that the eyes of the operator and bystanders areprotected from the glare during welding.

ALWAYS USE A FACESHIELD OR WELDING HELMET FITTED WITH THE CORRECTGLASS FILTER.

HeatIt is desiderable that welding gloves are worn whilst welding. They will protect thehands from ultra-violet radiation and direct heat of the arc.

OVERALLS should also be worn. They should be of type designed to be buttonedat the wrists and the neck.

DressIn addition to face shield, welding gloves and overalls, other types of protectiveclothing should be worn when welding. Additional protective clothing such as aleather apron, sock protectors and a hat will all assist in reducing any injuries due toheat, sparks and slag produced during welding.

7

OPERATION

Remove the welder and contents from the carton. Place the welder in an open areawhere the vents of the housing are not obstructed.

Earth Clamp

Prior to connecting the earth clamp (6) it may be necessary to clean the surface of thework piece using the metal brush. Attach the earth clamp (6) firmly to the work pieceensuring there is good metal to metal contact. Clamp it where it will not be in the way.This clamp provides an earth connection back to the welder.

Always ensure the welder is disconnected for the power supply before attachingelectrodes into the holder (5).

Electrodes

Attach the electrode to the holder (5). Retract the holders clamp by squeezing thelever on the electrode holder. Once retracted, guide the thin (unsheathed) end of theelectrode into the slot in the holder (5). Release the lever and ensure the electrode issecurely clamped.

Warning! Do not touch the electrode while the welder is turned on.

Always store the electrodes in a dry place protecting them from moisture. Shouldelectrodes become damp or moist, bake them in an oven at 200 - 250˚C for 2 hours.Unless the electrodes are vacuum packed, basic coated electrodes will always requiresuch baking prior to use.

8

OPERATION (cont.)

ARC WELDERS DO NOT OPERATE CONTINOUSLY FOREXTENDED PERIODS WITHOUT BEING ALLOWED TO COOL.

DO NOT TURN YOUR WELDER OFF AS THE FAN WILLASSIST IN REDUCING THE COOLING TIME.

All Welders have a feature called a duty cycle.

Duty cycle on a welder refers to the time in which the welderoperates during normal welding.

A welder can only weld for a certain continuos period of timebefore it requires to cool down.

If the internal components of the welder should become hotthe welder could overheat. If the welder overheats theThermal Overload Protection feature will automaticly shutdown the welder.

The Welder will cease to weld and the Thermal Overload LEDlight will turn on. This LED indication light is just to inform youthat your welder is becoming too hot and requires to cooldown to protect the internal components of the welder. DoNot turn your welder Off as the welder has an internal coolingfan and this will assist your welder to cool down quicker.Reducing the cooling time will enable you to get back to yourwelding job quicker.

Depending on how many Amps or how heavy the welding youare doing the cooling time may take up to 10 Minutes for yourwelder cool down so you can return to your welding job.

9

Electricity

The electricity flows through the electrode cable to the attached electrode. Theelectricity will not leave the electrode unless it touches an earthed object.

Electricity always finds the fastest path to the earth. When the earth cable clamp isconnected to the metal work piece a direct earth connection is created back to thewelder. When the electrode makes contact with the earthed work piece an arc iscreated. The electricity flows through the electrode, the metal work piece and thenthrough the earth cable straight back to the welder.

Setting the Welding Current

The welding current must be regulated in accordance with the diameter of theelectrode and the thickness of the metal being used. Below is a table suggestingsuitable ratios.

On the front of the welder is the current regulating knob. Rotate this knob clockwise toincrease, and anti clockwise to decrease the current supplied. Observe the gauge ontop of the welder for the current setting.

Prior to performing any welding the surfaces to be welded may need to be cleaned ofdust, rust, grease, paint and also slags from previous welding work performed.

Starting to weld

BEFORE WELDING ENSURE THAT:

You have read the safety section of this manual.

All oil. Petrol and flammable containers have been removed from the area.

There is good all round ventilation. Particularly at the front and rear of the unit.

You have an adequate fire-fighting appliance on hand.

Welding Procedure

1. Attach the earth clamp to the work piece as previously described.

2. Insert an electrode into the electrode holder (5) as previously described.

3. Connect the arc welder power cord to a live mains outlet.

4. Turn the welder on by depressing the on/off switch (3) to the “On” position.

5. Adjust the welding current (4) to suit the diameter of the electrode and also thethickness of the metal being welded.

Electrode Diameter Welding Current Amps) Thickness of Metal

2mm 55 - 75 1.5 - 2mm

2.5mm 80 - 105 3 - 5mm

3.2mm 105 - 130 4 - 6mm

OPERATION (cont.)

SPECIFICATIONS - MODEL NO. MSH-115

10

6. Position the two pieces of metal you wish to join.

7. Hold the electrode approximately 2 cm away from the desired join area. Loweror hold the welding mask over your face. Lower the electrode slowly andproceed to strike the electrode tip against the desired join area on the workpiece as if you are striking a match. This is the correct strike up method.

Note: Hitting the electrode on the work piece can damage the electrode fluxcoating and make strike up difficult.

8. The end of the electrode should ignite. Theignition of electrode end is called the “arc”. Assoon as you have the arc, try to maintain a distancefrom the work piece equal to the diameter of theelectrode being used. Weld along your desiredjoin from left to right. Try to keep this distanceconsistent for the duration of the weld. The angleof the electrode as it is advanced should bebetween 70 to 80˚ to the welding direction (Fig. 1). When you have reachedthe end of the weld bead bring the end of the electrode backwards and quicklylift the electrode from the weld. By removing the electrode from the metal youhave broken the electrical path and the arc will extinguish.

Warning! Failure to use a welding mask can result in “eye flashing” where yournaked eye sees the arc. Eye flashing is harmful and can damage your eyes.Always look through the tinted glass of the welding mask when observing the arc.

The welding mask protects your face from the welding sprays and ultra violet raysproduced by the arc. The tinted glass is essential for protecting your eyes whileobserving the arc.

Warning! During and immediately after welding the weld will be extremelyhot. Ensure it has cooled before touching with your hands. If it needs to bemoved while still hot use a clamping device.

9. Once the weld has been completed turn the welders on/off switch to the “Off”position and disconnect the welder from the power supply.

10. Slag is refuse left around the weld after welding, this should only be removedafter the weld has cooled down and is no longer glowing. To remove this slaguse the combination wire brush and chipping hammer (9) provided in the kit.Use the chipping hammer (9) side of the wire brush and strike or chip off theslag from the weld just performed. The slag will chip or break away from yourweld producing a clean looking weld. Use the wire Brush (9) to finish cleaningup the weld and workpiece ready for a protective coating or paint.

MAINTENANCE

Never splash or clean the welder with water.

Store the welder in a dry place.

If necessary, clean the welder using a damp/moist rag, disconnect from the powersupply prior to cleaning.

Keep the ventilation slots of the welder clear at all times and prevent foreign matterfrom entering the housing.

Note: Ozito Industries will not be responsible for any damage or injuries caused by therepair of the welder by an unauthorised person or by mishandling of the welder.

11

DESCRIPTION OF SYMBOLS

V Volts Hz Hertz

~ Alternating current W Watts

U0 Non-load voltage I 2 Current rating

t W Load time t r Reset time

ø Diameter

U1 Rated AV input voltage (with tolerance ±10%)

IP Protection class

Suitable for welding in an environment which has high risk of electric shock

MAG welding

Warning

Symbol of single-phase AV power and rated frequency

I1max Rated maximum input current I1eff Maximum effective input current

Vmax Max. wire feeding speed

Double insulated Regulator compliance mark

A Amperes

Single-phase transformer- Rectifier

Do not operate in the rain

Read operator’s manual

CARING FOR THE ENVIRONMENT

12

1 x Arc Welder AWG-9641 x Combination wire brush

and chipping hammer

1 x Welding Mask1 x Instruction Manual

AUSTRALIA (Head Office)1 - 23 Letcon Drive, Bangholme, Victoria, Australia 3175Telephone: 1800 069 486Facsimile: +61 3 9238 5588Website: www.ozito.com.auEmail: [email protected]

Power tools that are no longer usable should not bedisposed of with household waste but in an environmentallyfriendly way. Please recycle where facilities exist. Check withyour local council authority for recycling advice.

Recycling packaging reduces the need for landfill and rawmaterials. Reuse of recycled material decreases pollution in theenvironment. Please recycle packaging where facilities exist.Check with your local council authority for recycling advice.

CONTENTS

OZITO INDUSTRIES PTY LTD

WARRANTYTHIS WARRANTY FORM AND CONFIRMED BUNNINGS REGISTER RECEIPT SHOULDBE RETAINED BY THE CUSTOMER AT ALL TIMES

The warranty is only made available by returning the product to your nearestBunnings Warehouse with a confirmed Bunnings register receipt.

PURCHASED FROM:________________________________________________

DATE PURCHASED: ________________________________________________

3 YEAR REPLACEMENT WARRANTYYour Ozito product is guaranteed for a period of 36 months from the original dateof purchase and is intended for DIY (Do it yourself) use only.

WARNING

The following actions will result in the warranty being void.

• Professional, Industrial, trade or high frequency use.

• If the product has been operated on a supply voltage other than that specifiedon the product.

• If the product shows signs of damage or defects caused by or resulting fromabuse, accidents or alterations.

• If the product is disassembled or tampered with in any way.

Note: Warranty excludes accessories and consumable parts such as welding masksand combination wire brush and chipping hammers.

YOUR WARRANTY FORM SHOULD BE RETAINEDBY YOU AT ALL TIMES.

SHOULD YOU HAVE ANY QUESTIONS PRIOR TORETURNING YOUR PRODUCT FOR WARRANTY OR

REPAIR PLEASE TELEPHONE OUR CUSTOMERSERVICE HELPLINE:

Australia 1800 069 486New Zealand 0508 069 486

TO ENSURE A SPEEDY RESPONSE PLEASE HAVE THE MODEL NUMBERAND DATE OF PURCHASE AVAILABLE. AN OZITO CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL AND ANSWER ANY QUESTIONSYOU MAY HAVE RELATING TO THE WARRANTY POLICY OR PROCEDURE.