Aviation Depot 101 - SAE International

Transcript of Aviation Depot 101 - SAE International

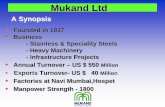

UNCLASSIFED

Naval Aviation Depot Maintenance

November 15, 2011

Aviation Depot Maintenance

• Invests today,

• For service life used yesterday,

• In order to provide readiness tomorrow

UNCLASSIFED

Pratt & Whitney, Bridgeport, WV Engine: JT15D-5C (UC-35C); PT6A25 (T-34C)

PT6A34 (T-44); PT6A41/42 (C-12) PT6A68 (T6); PWC535A (UC-35D)

Public / Private Aviation Depot Sites

ORGANIC INTERSERVICE COMMERCIAL

Rolls Royce, Oakland, CA Engine: T56-A-14/16/425/427

(P-3,C-130, C-2A, E-2C); AE1107C (V-22); AE2100D3 (C-130J)

OC-ALC Tinker AFB, OK Acft: E-6B

Engine:CFM56-2A (E-6B) CFM56-7B (C-40), F135(JSF)

CCAD Corpus Christi, TX Engine: T700 (H-60, AH-1W/Z)

FRC SOUTHEAST Acft: P-3, EA-6B, E-2, C-2, EP-3, F-18, H-60

Engine: J52(EA-6B), F414(F/A-18E/F), F135(JSF)

FRC EAST Acft: AH-1W/Z, AV-8B, F-35, H-46, H-53, H-1, EA-6B, V-22 Engine: T58(H-46), T400(UH-1N), F402(AV-8B), T64(H-53)

Acrohelopro, Richmond, BC Engine: 250C20 (TH-57)

FRC SOUTHWEST Acft: AH-1W/Z, AV-8B, C-2, E-2, F/A-18,

EA-6B, EA-18G, H-1, H-53, H-60 Engine: LM2500 (NAVSEA)

Northrop-Grumman, St Augustine, FL Acft: F-5F/N

OO-ALC Hill AFB, UT Acft: C-130, F-16, F-35

Overseas FRC WestPac-Atsugi

AH-1W/Z, CH-46E, CH-53D/E, E-2C, EA-18G, F/A-18C-F, HH-1N, HH-60H, MH-

60R/S, P-3C, SH-60B/F, UN-1N/Y

Vector Aerospace, Andalusia, AL Acft: TH-57B/C

Helipro, Andalusia, AL Engine: 250-C20J (TH-57)

L-3, Waco TX Acft: P-3C, EP-3E

Dallas Air Motive, Millville, NJ Engine: MK511-8 (C-20D) MK611-8 (C-20G)

Sikorsky, Stratford, CT Acft: VH-3D, VH-60N Exec Helo

Boeing, Seattle, WA Acft: C-40

Sabreliner, Perryville, MO Engine: JT12A8 (CT-39)

J85-21C (F-5E/F)

Boeing, Kent, WA Acft: E-6B

GE Engine Services, Arkansas City, KS Engine: T700 (H-60, AH-1W)

Rolls Royce, Canada Engine: BR710 (C-37)

MK511 (C-20D); MK611 (C-20G)

Allen Aircraft Radio MRO, OK City, OK Acft: C-9

Pratt & Whitney, San Antonio, TX Engine: F100-PW-220 (F-16)

Gulfstream, Savannah, GA Acft: C-20A/D/G

Engine: BR-710 (C-37)

L-3, Richmond, Vancouver Engine: 250C20 (TH-57)

AVMATS, Mascoutah, IL Acft: T-39G/N

Engine: JT12A8 (CT-39)

Aerothrust Corp, Miami, FL Engine: JT8D-9A (C-9)

American Airlines, Tulsa, OK Engine: CFM-56-7B24 (C-40)

Depot Level Maintenance Sites Perform (major repair / overhaul) depot maintenance

Performed at both public and commercial facilities • Fleet Readiness Center (FRC) Sites

• Other Service Sites (Interservice / Intraservice)

• Commercial Sites

L-3, Greenville, TX Acft: P-3C, EP-3E

FRC MID-ATLANTIC Acft: C-2, E-2C, F/A-18, H-60

FRC NORTHWEST Acft: EA-6B, EA-18G,

P-3, EP-3

FRC WEST Acft: F/A-18

Columbus AFB, MS Acft: T-38C

Engine: J85-GE-5

Canada Rolls Royce (Engines)

AE2100D3 (C-130J), MK 511-8 (C-20D), MK 611-8 (C-20G)

Orenda (Engines)

J85-GE-4A/5/5M/21C (T-2, F-5)

Standard Aero (Engines)

PT6A-25 (T-34C), PT6A-34 (T-44)

Hawker Beech, Wichita, KS Acft: TC-12B, UC-12B/F/M/W

Jetworks Air, Denton, TX Acft: U/C-35C/D

Lockheed Martin, Greenville, SC Acft: EP-3C, P-3C

Stevens Aviation, Greenville, SC Acft: T-34C, T-44A/C

Hamilton Sundstrand, Windsor Locks, CT Engine: T62T-11/27/46-2

Honeywell Aerospace, Phoenix, AZ Engine: TPE331-2 (C-26D)

Allen Aircraft Radio MRO, Indianapolis, IN

Acft: C-9

Delta, Atlanta,, GA Acft: C-40

Engine: CFM-56 (C-40)

UNCLASSIFED

Resourcing Overview • Aviation Depot Maintenance (ADM)

• Operations and Maintenance Navy (O&M,N/NR) funded

• Funds all Naval Aircraft and Engine Organic, Intra-Service

and Commercial depot workload

•Also fund directly some unique weapon system components

• 58 Unique Type/Model/Series (TMS) Aircraft

•~3900 aircraft in the Navy inventory

•Generate ~750 Airframe and ~2600 Engine/Module

maintenance events per year

•$1.1B Baseline budget / $1.3B w/OCO in PB12

•Engine repairs/overhauls driven by reliability and hours

operated

•Distributed airframe maintenance uses Planned Maintenance

Intervals based on Fixed Inductions Dates (FID)

•~40% of Airframe events performed in/near flight line by

depot field teams

3

UNCLASSIFED 4

29%

20% 23%

9%

7%

12%

Airframes USN

Airframes USMC

Engines USN

Engines USMC

Other USN

Other USMC

Aviation Depot Maintenance ($1.6B FY11)

FY11

1A5A AF/EN/OT O&MN / O&MN,R

UNCLASSIFED

Issues

• Forecasted budget constraints across the FYDP risk

unfunded aircraft maintenance (backlog)

• Aviation Depot Maintenance has relied on Overseas

Contingency Funding to execute full requirement

• Current modeling approaches have focused on risk

as a function of depot recovery • Maximum one year recoverable backlog of 100 Airframes / 340 Engines

• Difficult to map backlog impact to future readiness

• Configuration details within a TMS not currently tracked

for PPBE purposes

• Developing impact of specific aircraft inventories against

future schedule demands to show impact

5

UNCLASSIFED

INTEGRATED MAINTENANCE PROGRAM Notional

PMI 1 180 Days PMI 2 56 Days 4 Years Operational

Fixed

Scheduled Induction

Date

4 Years Operational

Fixed

End Date

Repeat Cycle

• Fundamental shift by the Navy

• Moved away from conditional inspections (ASPA) and

SDLM for all major TMS

• Maintains more consistent level of material condition

• Improved ability to forecast future workload and stabilize

requirements within the PPBE process

Heavy Industrial

Induction Field Event

Requirement

Review

Process

Primary Aircraft

Authorization

(PAA)

Aircraft Inventory

Integrated Maintenance

Work Load Standards

AIR 6.0

Minimize

Inventory Risk

With Available

Funding

Funded

/Backlog

Maintenance

Forecasted

Workload

w/Unit Cost

by Depot

Depot Core

Minimums

Source of Requirement

ADM Pricing

Model

Title 10 CNO

Fleet SYSCOM

Flight Line

Entitlement

Requirements Collections and Modeling Process

TMS PMI

Schedules/Engine

Demands

Wide Variance in Unit Cost

Slide 8

$0

$1,000,000

$2,000,000

$3,000,000

$4,000,000

$5,000,000

$6,000,000

$7,000,000

$8,000,000

$9,000,000

$10,000,000

0

2,500

5,000

7,500

10,000

12,500

15,000

17,500

20,000

22,500

25,000

27,500

30,000

EA-6

B PM

I 2 (

3)

EA-6

B PM

I 3 (

6)

EA-6

B PM

I 4 (

13)

C-2

A PM

I 1 (

4)

C-2

A PM

I 2 (

4)

FA-1

8C PM

I 2 (

37)

FA-1

8F PM

I 2 (

1)

FA-1

8A PM

I 2 (

6)

FA-1

8D

PM

I 2 (

14)

MV-2

2B PM

I 1 (

7)

MV-2

2B PM

I 2M

( 2

)

E-2

C P

MI 1 (

5)

AV-8

B PM

I 3 (

6)

AV-8

B PM

I 2 (

11)

MV-2

2B PM

I 2 (

8)

AH

-1W

PM

I 1N

( 2

0)

AH

-1W

PM

I 2N

( 1

0)

UH

-1Y

PM

I 1 (

8)

MH

-60S PM

I 1N

( 2

4)

UH

-1N

PM

I 1N

( 8

)

MH

-60R PM

I 1N

( 1

)

UH

-1N

PM

I 2N

( 1

)

MH

-60S PM

I 2N

( 1

1)

MH

-60R PM

I 2N

( 2

)

FA-1

8D

PM

I 2M

( 2

)

FA-1

8C PM

I 2M

( 3

)

SH

-60B PM

I 1N

( 7

)

SH

-60B PM

I 2N

( 3

)

FA-1

8D

PM

I 1 (

3)

FA-1

8A PM

I 1 (

4)

FA-1

8C PM

I 1 (

12)

AV-8

B PM

I 1 (

6)

FA-1

8D

PM

I 1M

( 7

)

FA-1

8C PM

I 1M

( 1

0)

CH

-53E PM

I D

( 2

5)

MH

-53E

PM

I D

( 5

)

E-2

C PM

I 2 (

2)

E-2

C P

MI 2H

( 2

)

P-3

C PM

I 1 (

4)

C-2

A PM

I 3 (

4)

P-3

C

PM

I 2 (

2)

EA-6

B PM

I 1 (

2)

FRC-CHP/JAX/NIS Airframe Events by Workload Standard

$.108M avg

1,322 avg mhrs

$.278M avg

3,688 avg mhrs

$.50M avg

5,703 avg mhrs

$1.33M avg

9,002 avg mhrs

$1.44M avg

11,092 avg mhrs

$1.22M avg

13,717 avg mhrs

$6.4M avg

19,554 avg mhrs

$3.1M avg

21,821 avg mhrs

$4.2M avg

27,652 avg mhrs

Work

load S

tandard

-

H

ours

Unit

Cost

per

Event

Determining which TMS

can take risk may cause

large shifts in

cost or backlog

DLHs

Cost

UNCLASSIFED

Understanding Funding Shortfall Impact?

• Developing new thinking on how to take and reflect

risk when funding is constrained

• Currently report unfunded depot workload as a function of number of

airframes and engines not funded (backlog)

• Backlog is an easier understood metric for those outside the

maintenance community

• A Direct Labor Hours (DLHs) metric would be more reflective of depot

production risk but not tied to readiness impact

• New modeling efforts are being developed to better link

aircraft production to readiness demand • Will link necessary production to future inventory demands necessary to

meet readiness goals

• Will emphasize meeting Flight Line Entitlement required for tiered

readiness

9

UNCLASSIFED

Conclusions

• Requirements process is well defined and uses

accredited pricing models to balance funding risk

• Planned Maintenance Intervals with Fixed Period End

Dates has been an effective tool to establish and

manage depot requirements

• Next evolution of modeling fidelity will add stronger

tie to future demand to show impact if funding is

constrained

10

UNCLASSIFED

Questions?

11

UNCLASSIFED

Backup Slides

12

Backlog – 500K DLH Combinations

| Brief Title Slide 13

0

20

40

60

80

100

120

140

160

180

200

1.3K 3.7K 5.7K 9.0K 11.0K 13.7K 20K

Manhours

(K

)

ManHours per Unit

500K Manhours Lines

55 19

12

8 7

5

3

150

units

2

33

4

2 1

1

69

110

30

16

7

4

83

25

13 22

18

4

6

4

33 Units *3.7K manhours/unit

Example

150 @ 1.3K = 195K

33 @ 3.7K = 122K

16 @ 5.7K = 91K

4 @9.0K = 36K

2 @11.0K = 22K

1 @13.7K = 14K

1 @20.0K = 20K

= ~500K manhours

Flightline Entitlement Aircraft for a

representative 12 aircraft squadron

32 month Deployment Cycle

Maintenance Basic Intermediate Sustain Deploy Sustain

R+1 R+2 R+3 R+4 R+5 R+6 R+7 R+8 R+9 R+10 R+11 R+12 R+13 R+14 R+15 POM PDL R+24 R+25 R+26 R+27 D+1 D+2 D+3 D+4 D+5 D+6

Navy Flight Line Entitlement Total FLETMS = Navy Tac Air by FRTP Phase+ Training and Support PAA

3 2 1

Basic Integrated Deployment Sustain Sustain Maintenance

CDR Pete Morrison, OPNAV N32 FHP RO