Automated Mercury Monitoring · 2017. 5. 23. · p2h 4.00 25.00 15.91 3.2061 20.12 25.020 2.039...

Transcript of Automated Mercury Monitoring · 2017. 5. 23. · p2h 4.00 25.00 15.91 3.2061 20.12 25.020 2.039...

-

1 www.tekran.com

Karl R. Wilber, PE

Practical Application of Traceability Requirements for Mercury Continuous Emissions Monitoring (HgCEM) Systems

in Response to Recent Regulations in the United States

Presented at the

International Conference on Mercury as a Global Pollutant Edinburgh, Scotland July 28 - August 2, 2013

-

www.tekran.com [email protected] 2

Presentation Outline

• Summary of U.S. Hg emissions regulations

• General description of Tekran HgCEMS

• Drivers for HgCEMS traceability

• Traceability protocol, application and results

• Summary comments

-

www.tekran.com [email protected] 3

Situation Overview – New Regulations • The recently-promulgated U.S. Environmental Protection Agency:

− Portland Cement Maximum Achievable Control Technology (PC MACT) − Electric Generating Unit Mercury and Air Toxics (EGU MATS) − Will result in increased Hg abatement, monitoring and quality assurance. Compliance deadline 2015 for both.

• Targeted parameters added: Mercury, THC, PM, HCl Mercury emissions limits for cement and power processes

• Mercury concentrations will typically run < 1 µg/m3 for coal-fired power plant and range from < 1 to > 500 µg/m3 for cement process

• Some states in U.S. (e.g. MT, NY) less than federal limits for Hg

Process Existing Source Std. New Source Std

Cement 55 lbs/MM tons clinker 21 lbs/MM tons clinker Power 1.2 lbs/ Trillion BTU 0.35 lbs/Trillion BTU

-

www.tekran.com [email protected] 4

HgCEM System Overview

• Stack-mounted dilution probe • Heated probe and umbilical • Instrument modules fit in standard

instrument rack in CEMs shelter

• Wall-mounted conditioner/calibrator (Tekran 3300Xi) now available

• No Hg bottled gas – only Hg generators – Tekran 3300 has:

− Elemental Hg generator/calibrator

− Ionic Hg calibrator (2 approaches)

− Resident permeation source

-

www.tekran.com [email protected] 5

Options for HgCEMS Supply

System at grade (e.g. shelter at base of stack)

• Existing 3300 System – Proven Technology • 3320xi (CCU) with 2537X and hot swap, NIST

traceable 3310 – Can be transitioned from First Generation HgCEMS – Need for all calibrators depends on application

requirements

On stack – at probe/platform level

• 3321 System in environmental cabinet – with “stub” umbilical

• Same as above with dedicated space for small companion rack for analyzer and calibrator

-

www.tekran.com [email protected] 6

All your measurements will be down here!

-

www.tekran.com [email protected] 7

Benefits of Hg CEMS Traceability

• Prepares Hg CEMS for compliance with U.S. EPA regulatory requirements

• Improves confidence in the accuracy of HgCEMS over a range of concentration levels

• Ensures a level playing field for intra and inter-utility mercury emissions compliance

• Provides additional trouble-shooting tools for HgCEMS quality assurance

• Supports improved optimization and economy of Hg abatement strategies

-

www.tekran.com [email protected]

• U.S. EPA released interim1 traceability protocols for Hg generators (July 2, 2009) (http://www.epa.gov/airmarket/emissions/mercury/hgmonitoring.html)

• NIST & EPA preparing for EGU MATS and PC MACT by: − Coordinating needs with anticipated EPA guidelines − Generating lower certified concentrations of Hg (e.g. 0.2 µg/m3) − Providing higher ranges of calibration (30- 300+ µg/m3) − Certifying “Vendor Primes” for HgCEMS suppliers and customers. − Separate protocols for elemental and Ionic Hg generators 1 Even though termed “Interim”, they appear here to stay!

8

What is NIST Traceability for Mercury About?

-

www.tekran.com [email protected]

Vendor Prime

Field Reference Generator

User or Field Generator

Unbroken Chain of Comparisons1

NIST Prime

1Slide courtesy of Jeff Ryan, U.S. EPA Clean Air Markets

9

-

www.tekran.com [email protected] 10

Terminology and Definitions

NIST Traceability Unbroken and certified chain of comparison between candidate generators and the National Institute of Standards and Technology

Vendor Prime NIST mercury generator resident at vendor facility

Reference Generator Typically mobile NIST traceable generator used for in-field verification of mercury generators used in HgCEMS

End-User Generator Mercury generator resident in operating HgCEMS used in regular calibrations of the system

Perm-Source A proven mercury generator source which is uniquely employed for regular calibration checks of Tekran HgCEMS

Bracketing Procedure Direct calibration comparison between a NIST-Traceable source (e.g. Vendor Prime) and candidate (e.g. reference generator) via multiple pre-determined Hg concentrations.

-

www.tekran.com [email protected] 11

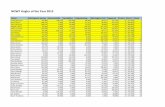

Standard Certification Points – Hg0 Span Adjusted SI Calculated EPA Percent

Range Point Temp MFC2 MFC1 Vapor conc MFC1 Output Flow Output Conc Output Conc Target ofug/m3 ID Setting Setting Setting ug/aL Setting SLPM ug/m3 ug/m3 Conc Span

(20/760) dC slpm sccm (Lindberg) sccm (0/760) (0/760) (20/760) (20/760) (EPA) Min % Max %

2.0 P2Z 4.00 25.00 0.00 3.2061 0.00 25.000 0.000 0.000 0.00 0.00%P2L 4.00 25.00 4.19 3.2061 5.30 25.005 0.537 0.501 0.50 25.0% 20% 30%P2M 4.00 25.00 9.21 3.2061 11.65 25.012 1.181 1.100 1.10 55.0% 50% 60%P2H 4.00 25.00 15.91 3.2061 20.12 25.020 2.039 1.900 1.90 95.0% 80% 100%

5.0 P5Z 7.00 20.00 0.00 4.2316 0.00 20.000 0.000 0.000 0.0 0.0%P5L 7.00 20.00 6.59 4.2316 8.24 20.008 1.394 1.299 1.3 26.0% 20% 30%P5M 7.00 20.00 14.21 4.2316 17.78 20.018 3.004 2.799 2.8 56.0% 50% 60%P5H 7.00 20.00 23.87 4.2316 29.86 20.030 5.043 4.699 4.7 94.0% 80% 100%

10.0 P10Z 15.00 20.00 0.00 8.6186 0.00 20.000 0.000 0.000 0.0 0.0%P10L 15.00 20.00 6.73 8.6186 8.19 20.008 2.899 2.701 2.7 27.0% 20% 30%P10M 15.00 20.00 14.21 8.6186 17.28 20.017 6.118 5.701 5.7 57.0% 50% 60%P10H 15.00 20.00 23.69 8.6186 28.81 20.029 10.194 9.499 9.5 95.0% 80% 100%

20.0 P20Z 20.00 20.00 0.00 13.1760 0.00 20.000 0.000 0.000 0.0 0.0%P20L 20.00 20.00 8.96 13.1760 10.71 20.011 5.900 5.497 5.5 27.5% 20% 30%P20M 20.00 20.00 18.75 13.1760 22.42 20.022 12.339 11.497 11.5 57.5% 50% 60%P20H 20.00 20.00 31.01 13.1760 37.07 20.037 20.392 19.000 19.0 95.0% 80% 100%

30.0 P30Z 25.00 20.00 0.00 19.8530 0.00 20.000 0.000 0.000 0.0 0.0%P30L 25.00 20.00 8.76 19.8530 10.30 20.010 8.691 8.098 8.1 27.0% 20% 30%P30M 25.00 20.00 18.51 19.8530 21.76 20.022 18.354 17.102 17.1 57.0% 50% 60%P30H 25.00 20.00 30.33 19.8530 35.65 20.036 30.053 28.003 28.0 93.3% 80% 100%

40.0 P40Z 25.00 15.00 0.00 19.8530 0.00 15.000 0.000 0.000 0.0 0.0%P40L 25.00 15.00 8.93 19.8530 10.50 15.010 11.811 11.005 11.0 27.5% 20% 30%P40M 25.00 15.00 18.68 19.8530 21.96 15.022 24.687 23.003 23.0 57.5% 50% 60%P40H 25.00 15.00 30.89 19.8530 36.31 15.036 40.785 38.003 38.0 95.0% 80% 100%

Allowable Percentof Span Range

-

www.tekran.com [email protected] 12

NIST Traceability Hg Generator Results

• Tekran’s 3310 Hg0 calibration results – largest deviation (2-40 ug/m3) < 1% • Tekran’s 3315 Hg2+ solutions traceable to NIST, mass flow controllers • Calibrated to standard reference – concentrations from 100 ug/m3)

NIST CALIBRATION & TRACEABILITY PROGRAMTekran 3310 Elemental Mercury Source

y = 1.0084x - 0.0529R2 = 0.9999

0

10

20

30

40

50

0 10 20 30 40 50

NIST Concentration (ug/m3)

TEK

RA

N

Con

cent

ratio

n (u

g/m

3)

-

www.tekran.com [email protected] 13

Periodic QA/QC Checks – Hg0

• Once per quarter, calibrator must be checked against an independent mercury standard at a single concentration (1x3x1)

• As a reference, user may use either: 1. Independent “Field Reference” calibrator

2. Method 30B sorbent cartridges

3. Hg gas cylinder (if certified)

4. Internal permeation source (Tekran Only)

• 1, 2 and 3, above will require on-site testing

• Successful QA/QC tests will defer the requirement to recertify an elemental calibrator for up to 24 months

-

www.tekran.com [email protected] 14

Compliance Assurance

• Follow EPA/NIST traceability protocol starting with the Vendor Primes (need multiple for ongoing intercomparison)

• Provide customers with “Hot-Swap” program for Tekran 3310 Hg0 Generators (see next slide)

• Take advantage of resident permeation source in Tekran 2537 • Conduct regular Relative Accuracy Test Audits (RATAs) • Provide non-Tekran users with Model 1360 permeation source

Tekran 1360 Mobile Permeation

Source

-

www.tekran.com [email protected] 15

Mercury Generator Traceability “Hot-Swap Program”

• There are no economical and accurate “gas bottle” standards for gaseous mercury calibration-Hg Generators are used for this purpose

• Hg Generators must be traceable to the National Institute of Standards and Technology

• An ongoing traceability program is required for HgCEMS operations.

• Figure on right shows “Vendor Prime” referenced against “Field Standards” as part of Tekran “Hot-Swap Program”

-

www.tekran.com [email protected] 16

Tekran HgCEMS RATA Results

• Data taken as part of State- mandated mercury monitoring and reduction program

• Third-party test agent using 30B test methodology

• Each data point in table is average of minimum of nine (9) sorbent trap tests

• Data reveals common bias of sorbent traps higher than electronic CEMS measuring total mercury vapor – per regulations

Midwestern Utility RATA Results

Site Date Sorbent Trap HgCEMS Difference %ug/m3 ug/m3

1 Aug-10 1.400 1.122 0.278 19.9%2 Aug-11 0.611 0.456 0.155 25.4%3 Oct-12 0.578 0.400 0.178 30.8%4 Oct-11 0.290 0.290 0.000 0.0%5 Nov-11 2.911 2.622 0.289 9.9%6 Mar-10 0.489 0.489 0.000 0.0%7 Aug-10 3.156 3.122 0.034 1.1%8 Aug-11 1.670 1.670 0.000 0.0%9 Mar-11 1.140 1.140 0.000 0.0%

10 Jun-11 0.809 0.611 0.198 24.5%11 Jun-10 2.567 2.798 -0.231 -9.0%

AVERAGE 0.1 9.3%

y = x

0.000

0.500

1.000

1.500

2.000

2.500

3.000

3.500

4.000

0.000 0.500 1.000 1.500 2.000 2.500 3.000 3.500 4.000

CMM

Res

ults

(u

g/m

3)

Appendix K Results (ug/m3)

Series1

ST=CMM

Linear (ST=CMM)

-

www.tekran.com [email protected] 17

Economics of Mercury Removal - 500 MWe Plant Accurate Measurement and Traceability are Critical

Reduction in Hg emissions from 80 – 90% using ACI costs an additional $500K! (reduction from 1.0 to 0.6 µg/m3)

-

www.tekran.com [email protected] 18

Conclusions

• Traceability protocol have been developed, are in practice, and are being refined for new mercury emissions regulations in the United States.

• HgCEMS traceability protocol must embrace a wide range of anticipated flue-gas concentrations from anthropogenic sources (viz. cement and power) of mercury (i.e.