Automated Insulin Preparation System Group 22: Brant Cauthorn Jessica Filderman Kellie Stoka.

-

Upload

osborne-montgomery -

Category

Documents

-

view

213 -

download

0

Transcript of Automated Insulin Preparation System Group 22: Brant Cauthorn Jessica Filderman Kellie Stoka.

What is diabetes?

Insulin and Glucagon Type I and Type II Prevalence

366 million people worldwide1

Cost $465 billion a year worldwide1

1 Chang, Maria. The Huffington Post, 13 September 2011.

How is diabetes treated?

Insulin injections Types of insulin

Rapid Short-acting Intermediate Long-acting

Problem: Prepare Injection Wrong

50% of people do it wrong2

How to properly prepare an insulin injection Where can you mess up? Why people do it wrong:

Visual Impairment Peripheral Neuropathy Arthritis

2 Wartburg, Linda. Diabetes Health, 21 March 2009.

Problem: Skip Injections

Insulin is expensive Average insulin user spends $11,476 a year2

Skip injections to save money

2 Wartburg, Linda. Diabetes Health, 21 March 2009.

Problem: Dangerous to take wrong amount of insulin Hyperglycemic

Fatigue, seizures, cardiac arrhythmias Hypoglycemic

Impaired vision, fainting, seizures, comas Health complications:

Blindness, amputation, death3

May result in hospital visit

3 Health Action International. 16 August 2012.

Problem: Expensive Hospital Visits

Emergency Room visit Hospitalization Outpatient Care Cost

Average $31,764 a year2

2 Wartburg, Linda. Diabetes Health, 21 March 2009.

Existing Solution: Insulin Pens

How they work Disposable

Novo Nordisk FlexTouch

Durable Novo Nordisk

NovoPen 3http://www.upmc.com/patients-visitors/education/diabetes/pages/insulin-pens-how-to-give-a-shot.aspx

Campos, Carlos. Expert Opinion on Pharmacotherapy. September 2012

Existing Solution: Insulin Pens Easier to use than syringe

Steadier Easier to read Easier to push down button

Expensive Not for visually impaired Dials are hard to use Possible to not give complete dose Most not sold in US

Existing Solution: Insulin Pump Insulin-filled cartridge

connected to catheter inserted into subcutaneous tissue

Continuously delivers insulin Wear all the time Expensive Major brands:

Disentronic Medical Systems, Minimed Technologies, and Animas

http://www.typefreediabetes.com/Articles.asp?ID=287

Lenhard, James M., Arch Intern Med, 22 October 2001

Apparatus for inserting a syringe needle into a vial (patent #3,853,158)

Helps with insertion of needle

Vial slides toward needle User still has to draw out

liquid themselves

Whitty, Albert J. “Apparatus for inserting a syringe needle into a vial.” Patent 3,853,158. 10 December 1974

Syringe loader and method (patent #4,434,820)

Fill 1 syringe with 2 liquids Dosage gage and dosage

stop indicator User could set gage and stop

indicator wrong

Glass, John P. “Syringe loader and method.” Patent 4.434.820. 6 May 1984

Syringe filling device (patent #4,489,766)

Different size spacers to limit movement of plunger

Spacers may be too small or challenging for some users to set

Montada, Benjamin V. “Syringe filling device.” Patent 4,489,766. 25 December 1984

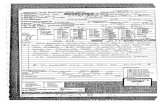

Automated drug preparation apparatus including syringe loading, preparation, and filling (patent #8,209,941)

Syringes banded together with web

Removes and replaces safety cap

Moves plunger Too big and complicated

for at home use For hospital setting

Osborne, Joel A. “Automated drug preparation apparatus including syringe loading, preparation and filling.” Patent 8,209,941. 3 July 2012

Design Requirements General:

Small size Inexpensive Can be used in a home

setting Operation:

Safe Accurate Not limited by user health

conditions

Minimum functions: Hold insulin vial(s) Mix insulin vial(s) Sterilize vial(s) Uncap needles Insert needle into vial(s) Withdraw a specified

amount of insulin

Design Specifications General

Portability: Size: Less than 0.03 m3

Weight: 2-7 kg Can stand alone on a table surface

Cost: < $200 manufacturing cost

Operation: Room temperature: 15-32° C Altitude: 0-6,200 m above sea level

Highest livable altitude in U.S. Aesthetics

Visually appealing Not Bulky

Noise Level: < 30 dB

Power: Provide enough energy to run

components 120V outlet?

Reliability/Safety: ≥ 99.9% Reliable ≥ 99.9% Accurate No exposed sharps No shock hazards Heat: ≤ 49 C

Minimum heat required for a burn Durability:

Sustainable impact force: 19.6-68.6 N Lifespan: 10 – 15 years

Software: Easy to use GUI

Completed By: 03 December 2012

Design Specifications Insulin Vial Storage and mixing

Storage ≥ 2 vials ≥ 1 syringe Insulin vials protected from excess

light Vial Size:

At least standard 10 mg vials Insulin Use

Allows any type of insulin Mixing Function:

Speed: .2-.3 m/s Duration: 20-30 seconds

Safety: ≥ 99.9% sterile Parts not exposed to user while in

use

Syringe Storage and Filling Syringe Size:

At least U-100 size syringes Speed of Filling:

≤ 30 seconds Force on Syringe:

Move plunger: .75-2.25 N Remove caps: .75-2.25 N Push needle into vial: .01- .1 N

Syringe Plunger Movement: Range: 0-0.1 m Speed: 0.003-0.005 m/s

Design Specifications User Interface

Size: .023-.05 m2

Ease of use ≤ 10 user steps Visible GUI Low dependence on motor function, vision, and cognitive function

Transmission speed: ≤ 1 second delay

ScheduleTasks and Milestones 3-Sep 10-Sep 17-Sep 24-Sep 1-Oct 8-Oct 15-Oct 22-Oct 29-Oct 5-Nov 12-Nov 19-Nov 26-Nov 3-Dec 10-Dec

Project Initiation Project Selection & Client Confirmation Project Scope Preliminary Research Define Specifications Preliminary Oral Report Preliminary Written Report Product Design Website Design Risk Analysis Progress Oral Report Progress Written Report Material & Manufacturing Requirements Design Analysis Final Oral Report Final Written Report Poster Competition

Tasks: Milestones:

Team Responsibilities

Brant – Website Design and Maintenance Kellie – Material & Manufacturing

Requirements Jessica – Risk Analysis