Watch wsbk australia 2015 - wsbk australia - sbk australia 2015 - sbk australia

Australia - swan.wa.gov.au

Transcript of Australia - swan.wa.gov.au

Pollution PreventionStormwater Treatment & Hydrocarbon Capture

Petrol Stations

PURACEPTOR

Australia

Non-Compliant SitesPetrol stations with the following defects.

• Canopy drip line that does not allow for the 10 degree inset

• Fuel hose line that reaches outside the drip line

• Fuel bowsers that have no canopy

• Defective Oil/Water plate separator (Sewer connected)

Unseemly & highly visible hydrocarbons polluting the stormwater. The concentration in the picture is in excess of 100ppm

Picture shows a defective forecourt design with oils and fuels discharging directly to the street drain.

Standards & Guidelines for Petrol Station Stormwater Pollution ControlThere is no Australian Standard for oil/water separators.

There are only guidelines for hydrocarbon discharge limits for stormwater discharge.

All State and territory regulating environmental authorities (or EPA) have guidelines with varying terminology stating that hydrocarbons are not to be visual (10ppm) in stormwater and receiving waters.

European Standard (oil and petrol separators)In the absence of an Australian Standard, the European British Standard 858.1 applies when compliance is the regulating issue.

It is the world’s most stringent standard for hydrocarbons separation for the use of oil/petrol separators in surface water drainage systems. Prevents the emission of petrol odours.

Australian Runoff QualityThe Australian Runoff Quality A Guide to Water Sensitive Urban Design (Engineers Australia) ISBN 0 85825 852 8 Chapter 9 `Hydrocarbon Management` refers to The Standard and the European Agency UK Oil Separator Selection and Design` for petrol stations.

Picture shows a common site at petrol stations - uncovered fuel pumps.

Picture shows an under-sized canopy with fuel pumps outside the canopy dripline

Solution for Non-Compliant Petrol StationsSPEL Puraceptor Class 1 stormwater treatment system is a solution for the treatment, capture and retention of hydrocarbons off petrol stations.

SPEL Puraceptor Class 1 can rationalize the existing use of service stations in conformity with the applicable environmental guidelines and put in place ongoing operational measures to prevent the likelihood of contamination in the case of an unforeseen future event.

SPEL`s Puraceptor Class 1 oil/water separator is connected to the stormwater [provides the site with the highest degree of environmental protection; - a protection that complies with the councils, and the EPA`s guidelines.]

Petrol forecourt and surrounds at a busy metropolitan petrol station rendered compliant. The catchment consists of a grated drain encompassing the complete perimeter of the under-sized canopy. Surface water and forecourt runoff drains to the Puraceptor located under the two trafficable covers in the foreground.

Puraceptor CertificationAustralian Independent Tests

The Puraceptor has been independently tested at Australia`s pre-eminent hydraulics research facility, the University of South Australia (UNISA), and at the UK`s leading hydraulics research faculty HR Wallingford.

• NATA analysis of the tests shows a water quality of `no visible trace` of hydrocarbons from an inflow concentration of 5,000ppm.

In-Situ TestingNATA analysis of Puraceptors operating at similar applications in Australia reveal `no detection` of hydrocarbons from a captured concentration of 8,000ppm.

Council ApprovalsThe increasing awareness by councils of the superior European Standard has prompted many to review their current procedures and in only the past eighteen months over sixty councils have approved SPEL for service stations and similar applications with units’ already operational in excess of forty sites.

Puraceptor Benefits• Full retention Class 1 treatment oil/water separator. It

treats all liquid. There is no bypass.

• Complies with federal and state government regulating environmental guidelines for water quality.

• University tested and certified to independent European Standard EN BS 858.1 for the capture and retention of hydrocarbons with a discharge quality of no visible trace from a tested inflow concentrator of 5,000ppm.

• Capture and contain oil/fuel spillages.

• Can be sized to capture and contain a spill from a refuelling tanker and prevent discharge to stormwater.

• Passive gravity function ensuring treatment is continuous.

• Equipped with an intrinsically safe oil alert probe providing regular detection for oil build-up. Set to alarm when oil hydrocarbons attain 10% of the chamber`s volume.

• Oil alert probe enables `self-monitoring`, suitable for unmanned and remote locations.

• Equipped with a flame trap ensuring fire water is extinguished.

• Equipped with a vapour trap preventing vapours from discharging and preventing the emission of odours.

• Water tight structure

• Minimum 50 years life span.

• Low frequency and low cost maintenance

• Operations & Maintenance manual with a ledger for accurate recording of maintenance operations.

• Maintenance performed from ground level; no entering of tank is required, satisfying O.H.& S. requirements.

a97% total suspended solids (TSS)

a100% > 5mm gross pollutant

solids (GP)

a99.9% light liquids (TPH)

(certified discharge quality of 5PPM or less,

European standard BSEN 858 .1 2006)

a>45% total phosphorous

a> 45% total nitrogen

a> 90% heavy metals

Independently tested for

reducing the average

annual loads:

Head Office83 – 87 Fennell Street, Parramatta NSW 215002 8838 1036

Stormwater discharge quality is < 1.86 mg/l hydrocarbon content exceeding the Environmental Protection Agency (E.P.A.) requirements of 10mg/l hydrocarbon content.

Test sampling access: Field test discharged samples are taken from sampling point and analysed by NATA accredited laboratories.

SPEL ® PURACEPTOR units are glass reinforced plastic vessels made by the technical advanced chop hoop filament winding process (patented) producing circumferential and longitudinal strength complying with AS 2634-1983 for tank design.

SPEL PURACEPTOR Class 1 separators incorporate coalescer units. They consist of a quality stainless steel mesh container with an adjustable handle and high volume reticulated foam insert.

The coalescer unit is mounted in the second chamber, providing a coalescence process for the separation of smaller globules of light liquid pollutants before final discharge to stormwater.

SPEL® PURACEPTOR tanks contain an immersed inlet dip pipe to extinguish flames and prevent inflammable vapours form passing through to the drainage system. Complies with Section 6.3.4 of BS EN 858.1.2006. SPEL PURACEPTOR can withstand temperatures of up to 140ºC.

Oil Retention Chamber

Secondary Separation Chamber

The probe is freely suspended in the probe protection tube in the separator at the correct level. When the oil-layer or depth of hydrocarbons reaches the predetermined level, the top of the probe will be immersed in the oil, breaking the circuit and activating the alarm. It is intrinsically `fail-safe` system providing complete assurance that is operative. If a fault occurs it will be signaled immediately.

The AUTOMATIC CLOSURE DEVICE (A.C.D.) is a precisely engineered device comprising a water-buoyant ball that is sensitive to any change in the water density as a consequence of light liquids build up, thereby automatically activating a process of depressing the A.C.D. to SHUT OFF the separator, preventing pollutants from discharging to drains and waterways.

MAINTENANCE• Designed for high performance and low maintenance over a long life span• Visible oils (TPH) are skimmed from the surface of the water level• Easy and safe to access and clean, with access shafts positioned on all chambers.• No entering of the unit is required• Not mandatory for the unit to be cleaned every 3 months.• Only oils, sediment and gross pollutants need to be removed. All stormwater does not require removal.• The cylindrical design ensures sediment collects easily on the floor of the chambers effecting easy, quick removal. There are no square corners or unreachable cavities and recesses.• Waste is removed by a vacuum loading truck. (Suction truck)

ACT NT NSW QLD SA VIC WA02 6128 1000 02 8838 1000 02 8838 1000 07 3390 8677 08 8275 8000 03 5274 1336 08 9351 1000

TITLE:

SIZE CODE DWG No: REV

SCALE SHEET

DATE REVISED BY

STORMWATER QUALITYIMPROVEMENT DEVICE

SPEL - PURACEPTOR - 300 SERIESP.040.8.C1.2C.A.300

SP11-15200

0

1 of 1N.T.S

A3N/A

DRAWN BY: P.LEE

DATE: 26/7/2012ALL DIMENSIONS IN MM

83 - 87 FENNELL ST, PARRAMATTANSW. 2150.

PH: + 61 2 8838 1000FAX: + 61 2 9630 0369

EMAIL: [email protected]

SPEL TANK - 300 SERIES

NOTES:-MATERIAL= FIBERGLASS-MATERIAL COLOR = CYAN

34

1850

RIB

S

483

5900OVERALL LENGTH

825

555

3275

86 MAX

145 425 TYPICAL

60

0

60

0

600

900

300 - ALL MANHOLES

1600

INLE

T IN

VER

T

I.D 1800 I.D 1800

700

2150

OVE

RAL

L H

EIG

HT

240 MAX

3921

WINDING 4935

121 MAX

1500

700

VENT/CABLE DUCT HOLESC/W RUBBER RINGS( TO SUIT Ø110 PIPE )

2150

O.D 1875

Certified stormwater solution for fuel

forecourts with contaminated runoff.

SPEL Puraceptor Class 1Full Retention Automatic separator system for the full retention treatment and capture of

oil/fuels contaminated surface water runoff from fuel forecourts.

Site:

Contents

1. Introduction

2. VICTORIA EPA

Guidelines

3. What is Class 1?

4. Class 1 relevance to

Australia?

5. How does the Class

1 system work?

6. Tank structure

7. How is Class 1

maintenance

performed?

8. Annexure

9. Appendix A: Project

Profile

10. Appendix B:

Selected list of

Victorian

Installations

1. Introduction

The SPEL Puraceptor Class 1 is an integrated oil-spill capture and light liquid treatment separator that provides an

environmentally sustainable and certified solution for the treatment and capture of hydrocarbons in surface water

runoff from high risk sites such as retail fuel forecourts for stormwater discharge.

The Class 1 treatment system surpasses the traditional sewer system for water quality and hydrocarbons capture with

the independently tested and proven design complying with the Department of Environment Climate Change Water of

NSW (DECCW NSW) for stormwater quality.

1. ENVIRONMENT EPA VICTORIA Guidelines

Current guidelines stipulate that hydrocarbons content in stormwater or any receiving waters is to be of `no visible

trace` or <10ppm (It is accepted that hydrocarbons are visible > 10ppm).

EPA VICTORIA are not permitted by legislation to approve or disapprove proprietor`s products They are concerned only

with environmental quality `outcomes`.

http://www.epa.vic.gov.au/water/threats/oil_metals_chemicals.asp

Oil, heavy metals and other chemicals

Oils, heavy metals and other chemicals enter waterways from a variety of potential sources, including urban and

agricultural runoff, industrial and mining operations, landfill leachate, and transportation or industrial spills.

These chemicals can have drastic impacts on freshwater and marine ecosystems. This may vary in severity from reducing

growth and reproduction, to directly killing plants and animals. The effects of many toxic chemicals are increased by their

ability to remain and build up in the environment over a long period of time. The results can be particularly destructive in

wetlands and bays where flushing is limited.

More information about the effects of toxic materials on aquatic ecosystems is available from the Department of

Sustainability

2. What is Class 1?

Class 1 was introduced by the UK Environment Agency (UKEA) www.enviroment-agency.gov.uk over 12 years ago, with

guidelines tailored specifically for the treatment and capture of hydrocarbons from service station forecourts.

Class 1 stipulates a discharge water quality of <5ppm from a tested inflow concentration of 5,000ppm (hydrocarbons

content).

The UKEA has adopted the European Standard BS EN 858.1 Separator systems for light liquids (oil/petrol/diesel). (known

hence in this document as The Standard) for the design, use, selection, installation, operation and maintenance of

prefabricated separators. Separators have to satisfy essential requirements mandated by the Standard`s clauses

including independent testing to the test methodology of Clause 8.3., in order to be certified as a Class 1 separator.

SPEL Class 1 separators have been independently tested by HR Wallingford Research Laboratory UK and the University of

South Australia Hydraulics Research Centre to The Standard with a discharge water quality of :< `no visible trace` from

an inflow concentration of 5,000ppm under test flow conditions.(Attached with this document are the relevant

certificates and the Standard.)

3. Class 1 Full Retention relevance to Australia?

(i) No Australian Standard for Hydrocarbons

There is currently no Australian standard for hydrocarbons and for the management of hydrocarbons

for surface water runoff, and in the absence of such the British European Standard applies when

compliance is a regulating issue.

(ii) Australian Compliance

The Standard and Class 1 system overrides all Australian regulatory requirements pertaining to

hydrocarbons with the exception of South Australia, who have themselves recently adopted the

Class 1 Standard and treatment system for forecourt hydrocarbons management.

(iii) Treatment and Capture Efficacy

Hydrocarbons separation behaves no differently anywhere in the world. The density of oils and fuel

is lighter than water and will always rise, however the Class 1 system requires an efficacy in the

quality of separation that depends upon the right conditions in which to achieve no visibility in the

water column. This includes suitable retention time, low velocity water flow, and enhanced by a

coalescing filter action.

(iv) Proven Record in Australia

Class 1 is not solely a design theory but has indeed a proven record in the UK, one of the world`s

most industrialized and urban environments, and for the past 2 years in Australia. A list of selected

sites in NSW can be found in Appendix A.

(v) Independent Standard and Validation

The Standard and the independent validation that applies to the SPEL Class 1™ separators provides

the council and the authority the appropriate latitude to assess the product and the catchment

design unencumbered by commercial partiality.

(vi) Current Guidelines and Practices Pollute the Environment

Existing ` traditional` guidelines are, and have proved to be, totally unsatisfactory in protecting the

environment from hydrocarbon pollution, both for egress to receiving waters and soil absorption.

- Sewer systems cannot receive stormwater meaning there is a significant portion of the

forecourt catchment that egresses to stormwater or to soil (on sites where there is no

stormwater). The majority of service stations within the council`s and the territories precinct

are marked by these defects and consequently are non-compliant. Attached with this document

is SPEL Petrol Stations brochure highlighting the defects and the Class 1 solution.

- Most sites either existing or new have no provision for the capture of a tanker compartment

spill (8,000L).

(vii) Early Alert Monitor Probe: Maintenance and Spill Alert and Monitoring of Unmanned Sites

The Class 1 system with its integrated oil/fuel monitoring probe system (SPEL Class 1™ Oil Alert

Probe) can be connected to a central service centre, by a SKADA type arrangement or telemetrically

for automatic monitoring. The probe is set at 10% of the SPEL Puraceptor`s primary chamber spill

capacity providing an early automatic alert for any abnormal accumulation of hydrocarbons that may

happen between maintenance frequencies and provides an early alert warning alarm in the event of

a major spill. This makes the Class 1 system essential for unmanned sites. Refer within for technical

explanation of the SPEL Class 1™ Oil Alert Probe. The technical manual is attached with this proposal.

- Traditional sewer systems arrangements require manual monitoring and therefore are subject

to human error.

(viii) Render Existing Non-compliant Sites Compliant: Suitable for Retro-fitting.

The SPEL Puraceptor Class 1™ system remedies environmental defects and can rationalize the

existing use of service stations in conformity with the applicable environmental guidelines and put in

place ongoing operational measures to prevent the likelihood of contamination in the case of an

unforeseen future spill event.

4. How does the Class 1 Full Retention work?

Dynamics and basic working operation.

a. Hydrocarbon treatment/separation operation.

The Puraceptor Class 1 is a gravity-type, passive, full retention flow process that treats all flows through two chambers.

Low velocity laminar flow provides quiescent conditions in the separator enabling the light liquid content of the water to

separate and rise to the surface due to the difference in density of the oil and water. Contaminated water cannot flow

directly across the surface before effective separation has taken place. Treatment process involves the `cleaner` water

passing from the primary chamber by underflow into the secondary chamber and finally through a coalescing filter

mounted in the secondary chamber to `collect` smaller droplets of hydrocarbons and encourage larger droplets to form

enabling better removal by gravity to the collecting area in the sealed secondary chamber.

b. Spills capture operation.

The primary chamber is over- sized to retain the maximum spillage legally required at the service station. The spill is

contained in the primary chamber, with all flow from the primary chamber stopped by the sealing action of the Auto

Closure Device (A.C.D.) The spill cannot scour from the separator and is contained in the chamber until the time the

emergency recovery response team removes it by eduction.Refer below for more details on the ACD.

Full Retention ( Closed System) Flow Treatment

The SPEL Puraceptor Class 1 is sized to treat and capture all flows. There is no bypass facility, meaning all pollutants are

captured and retained between maintenance cycles.

Coalescing filter

The coalescer is a high- reticulated and high-contact surface filter with a minimum life span of eight years.

It is mounted into the secondary chamber, providing a coalescing process for the separation of smaller oil droplets.

Incorporated in the secondary chamber prevents the coalescer from being blocked in the event of major spillages and

large amounts of accumulated hydrocarbon or heavy silt content in the surface water.

It can be simply lifted out for cleaning during routine maintenance.

Auto Closure Device

A precisely engineered device comprising a water-buoyant ball that is sensitive to any change in the water density as a

consequence of light liquids build up, thereby automatically activating a process of depressing the A.C.D. to shut off the

separator, thereby providing maximum protection to receiving waters in the unlikely event of a major emergency.

Oil Alert Probe

The Puraceptor Class 1 is fitted with an SPEL oil alert probe Model: OILSET 1000 in the primary chamber for oil spill

detection and maintenance monitoring which includes an alarm panel for remote mounting. The alarm is triggered when

hydrocarbon build-up accumulates to 10% of the primary chamber`s volume.

Fire Trap

SPEL Puraceptor Class 1 tanks contain an immersed inlet dip pipe to extinguish flames and prevent inflammable vapours

from passing through to the drainage system. It is also prevents mosquito breeding.

No Scouring: Suitable for Flood & Tidal Conditions

The horizontal configuration, internally sealed treatment chambers and its coalescing function ensures no risk of

scouring including when the separator is submerged in flood or tidal events.

5. Tank Structure-Certification & Manufacture

SPEL Puraceptor Class 1 units are glass reinforced plastic vessels made by the technical advanced chop hoop filament

winding process (patented) producing circumferential and longitudinal strength complying with BS4994 FRP Pressure

Vessel code and AS 2634FRP Chemical Equipment to ensure the construction meets the necessary strength and stability

requirements. The tank is designed to accept ground conditions with low stiffness down to 4.8MPa, water tables are set

to ground level as standard with a minimum depth of cover, based on a standard soil density.

6. Maintenance Operation

Maintenance is performed at a minimum of every six months or if the probe alarm is activated, by eduction method

(suction).

Coalescer:

Suspend the coalescer above the secondary chamber and flush contaminants into the chamber using only garden hose

pressure. This will ensure no release of pollutants into the surrounding environment.

Sediment:

Sediment is removed by a vacuum loading truck from the base of the primary chamber. The cylindrical shape ensures

sediment collects at the base of the chamber.

Hydrocarbons:

Oil/fuel is skimmed from the surface of the water in both chambers, by suction from a vacuum loading truck. The

internal `gel-coat` ensures hydrocarbons do not `stick` to the sides of the tank.

Floatables:

Gross pollutants and litter are removed by the same process described above.

Operation & Maintenance Manual:

The Maintenance Programme will be kept on the premises at all times, with a ledger recoding all maintenance and

inspection activities. This will provide a useful and efficient record for Council Inspection officers to facilitate random

verification.

7. Annexure

a. Certification: HR Wallingford

b. Certification: UNISA

c. SPEL Class 1™Oil Probe Manual

d. SPEL Puraceptor Class 1™ O&M Manual with Maintenance Manifest

e. SPEL Class 1™ Petrol Station Brochure

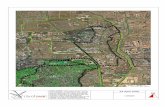

8. APPENDIX A: Project Profile

Petrol forecourt and surrounds at a busy metropolitan petrol station rendered compliant. The catchment consists of a

grated drain encompassing the complete perimeter of the under-sized canopy. Surface water and forecourt runoff

drains to the Puraceptor located under the two trafficable covers in the foreground.

SPEL Puraceptor Class 1 was sized to meet the council`s Q20 flow rate requirements.

Water quality testing of discharge flows six months following operation has revealed levels of no-detectable

concentration of hydrocarbons from an inflow concentration of >1,000ppm.

The full retention (closed system) treatment process of the Class 1 system ensures all pollutants are retained between

maintenance cycles.

9. APPENDIX B

Selected list of Victorian & Other selected Installations

CLIENT LOCATION COUNCIL

Caltex Tullamarine Hume

Caltex Kilsyth Maroondah

Caltex Gisborne Macedon Ranges

Caltex Mt Waverly Monash

Caltex Shepparton Shepparton

Caltex Chelsea Kingston

Shell Footscray Maribynong

Shell Eltham Nillumbik

Shell Warrnambool Warrnambool

Shell Wodonga Wodonga

Shell Spotswood Hobsons Bay

Shell Sunshine Brimbank

Coles Packenham Cardinia

Coles Taylors Hill Melton

Reliance Epsom Bendigo

Seven Eleven Point Cook Wyndham

Independent BP Yering Yarra Ranges

Shell Randwick Randwick

Shell Tumut Tumut

Shell Heathcote Sutherland Shire

Shell Oyster Bay Sutherland Shire

Baileys Marine Fuels White Bay Sydney Harbour National Park

Kosciusko-Thredbo Authority Thredbo Snowy Mountains National Park