CHASSIS AA-2D KV-32S42 KV-32S42 KV-32S66 KV-32S66 KV-32V42 K

A.S.T. Power management systems for rail vehicles · A.S.T. Power management systems for rail...

Transcript of A.S.T. Power management systems for rail vehicles · A.S.T. Power management systems for rail...

Gruppe

Angewandte System Technik®

A.S.T. Power management systems for rail vehicles

Power supply for pre-heating and pre-cooling330 VAC, 1000 VAC, 1500 VAC

Depot supply670 VDC

Power supply for auxiliary systems of electric locomotives200 V / 400 V, 16.7 Hz

2

Power supply for pre-heating and pre-cooling Efficient power management for parked rail coaches and

at any track –preheating, airconditioning and freeze protected parkingrailcar trainsets

A.S.T. Power management systems ensure the power supply for preheating, airconditioning and frost protected parking of rail coaches and railcar trainsets.

The systems have been developed in cooperation with the former BZA Munich and the DB Energie in Frankfurt and can save up to 40% of energy compared with manual operated preheating or airconditioning.

In doing so the parked train sets are preheated or airconditioned at a particular time at which the coaches have to be well-temperatured for the entering passengers.

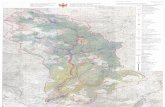

The systems are installed mainly at interchange stations or formation yards. At depots and maintenance workshops the systems supply coaches, traction units or high speed trains with energy.

Due to the unitized setup the system can be easily extended by new branch lines. Switching operations and energy consumption at the specific connection points are captured permanently by the control system and therefore can also be analysed and allocated.

Gruppe

Angewandte System Technik®

3

Operation mode

The supply power is either taken from the overhead contact line (11 kV, 15 kV or 25 kV) or if the track line is not electrified from the public utility (10 kV or 20 kV).

In order to transform the energy to the required supply voltage (330 VAC, 1000 VAC, 1500 VAC) the energy is fed via a medium voltage switch gear with a vaccum circuit breaker to transformers. The distribution switchgear provides the tranformed current via power contactors by cables to the cable connection boxes. From the cable connection boxes with predetermined breaking points the energy is supplied to the coaches and railcar trainsets with a flexible rubber hose cable using a RIC plug connection.

The operation is done at the control pillar next to the track. There the operator choses the designated operation mode and enters the departure time of the trainset at the built-in µP time switch. Depending on the outside temperature the time switch computes the optimal turn-on instant for the power contactor or clocks the power contactor in order to prevent the coaches from frost at temperatures below the freezing point.

The total system is controlled by a process computer-aided control system. There all actions of the system are controlled, monitored and recorded. The current operation states and the activity memory can be read out at any time via modem and analysed by software.

4

Switchgear for heating outlets Include:switchboard for feeding with 1 or 2 transformers switchboard for 2, 4 or 6 heating outlets with steel sheet compartment for auxiliary equipment three-phase system - 400 V, 50 Hzsingle-phase system- 330 V, 16.7 Hz- 1000 V, 16.7 Hz, 50 Hz- 1500 V, 50 Hz

Medium voltage switch gear type tested with vaccum circuit breaker and steel sheet compartment for auxiliary equipment three-phase system- 36 kV, 50 Hz- 24 kV, 50 Hz- 12 kV, 50 Hzsingle-phase system - 25 kV, 50 Hz- 15 kV, 16.7 Hz- 11 kV, 16.7 Hz

Transformers

three-phase transformerssingle-phase transformers

standard configuration:- oil-filled transformers

Special transformer models:- cast resin tranformers- dry type transformers

with built-on rollers with monitoring unit

Accessible concrete building

- type tested

- accidental arcing security tested

- reinforced concrete C35/45 according DIN 1045-2

- outside walls in dispersion coating

- aluminium pierce-proof door fans and roof hoodsfor air ventilation

- maintainance free doors made of anodized aluminium with panic lock

- separating walls between tranformer rooms, basement oil-proof

- flat roof or in the style of the landscape architecture e.g. span roof

- cable entrances

Transformer outputs

three-phase system 50 Hz- 315 kVA, 630 kVA, 800 kVA, 1250 kVA, 1500 kVA

single-phase system 25 kV, 50 Hz- 1250 kVA, 1600 kVA

single-phase system 15 kV, 16.7 Hz • 800 kVA, 1000 kVA, 1250 kVA

single-phase system 11 kV, 16.7 Hz • 630 kVA, 1000 kVA

special sizes on demand

System components

Gruppe

Angewandte System Technik®

5

Low voltage switch gear

- fully electronic µP control

- control signal input 230 VAC

- voltage measuring input 100 VAC

- current measuring input 1 AAC

- 15” touchscreen data display formonitoring and operationing

- evaluation software

- data logger to capture all switching operations andmeasuring values

- data can be readout via modem

- DCF 77 time synchronizing

Control pillar- single or double control pillar - housing and screws in A2 - height 1025mm, 750mm- outside temperature

controlled µP-time switchwith DCF 77-synchronisation

- frost protection at outside temperatures below 1,5°C

- for ground mountingoptional:- for wall mounting- with digital amperemeter or

voltmeter

Cable connection boxwith predetermined breaking point- post hot zinc dipped - with cut-off point- with monitoring switch

a) one-way pull-off height 720mm

b) both-way pull-off with kink height 1080 mm / 750 mm

- for ground mountingoptional:- for wall mounting

Plug holder with dummysocket - holder hot zinc dipped - with monitoring switch- height 860 mm / 750 mm- for ground mountingoptional:- for wall mounting- for mounting at rail pillars- with cable storage

Integrated control pillarsingle control pillar- housing and screws in A2 - height 1045mm- width 200mm- integrated predetermined

breaking point with turn rollers for both-way pull-off

- with monitoring switch- for ground mounting

Concrete fundamentfastening of the outdoor components

- screw sockets in A2 steel - openings for cable entry

at all sides

Connecting cableto feed in the energy into the coach socket- flexible rubber

hose cable185/25 qmm

- connection plug800A

- optional: with pilot contact

6

Power supply for auxiliary systems of electric locomotives For testing of auxiliary systems at the depot

Feeding voltage15 kV, 16.7 HzSupply voltages: 200 V, 16.7 Hz; 40 kVA per branch400 V, 16.7 Hz; 160 kVA per branch

670VDC - Depot supplyExternal power supply for ICE-3 and ICE-TPower supply for ICE-3 and ICE-T at the depot, if operations at the high voltage section are required. The systems fullfil the high supply voltage demands concerning static and dynamic variations- with preload device - galvanically isolated - with isolation monitoring- with decoupling inductor at the output

Feeding voltage: 24 kV, 12 kV or 400 V, 50 HzSupply voltage: 670 VDC, 250 kVA

Gruppe

Angewandte System Technik®

7

Our scope of supply and services

References

+ Planning and realization

Our scope of work includes planning, development, delivery and ready to operate assembling of the system. The system is set in operation and handover to the customer. In cooperation with selected, rail experienced partners we serve underground construction, cabling and sounding.

+ Experience

A.S.T. Power management systems for rail vehicles are on duty for more than 35 years. We installed already over 215 systems with a nominal total power of 320 MVA and about 2050 power outlets.

Concering the system built before 1984 another 2000 power outlets have been equipped with our energy saving outside temperature depending control pillars.

+ Service

Using modules and standard subassemblies a cost-effective storage can be realized both at the customer’s depot and our company.

+ Maintenance

Of course we can carry out the necessary maintenance work, including inspection and adjustment of the protection relays and inspection of the safety precaution.

Our systems are on duty effective and reliable at the following railways:

+ Deutsche Bahn AG DB (German National Railways)+ Osthannoversche Eisenbahnen AG OHE+ Nord-Ostsee-Bahn NOB+ Schweizerische Bundesbahnen SBB (Swiss Federal Railways)+ Luxembourg State Railways CFL + Matterhorn Gotthard Bahn MGB+ Österreichische Bundesbahnen ÖBB+ Norwegian State Railways NSB+ Iraqi State Railways IRR

Gruppe

Angewandte System Technik®

A.S.T. Angewandte Systemtechnik GmbH Energie & UmwelttechnikHagertshausen 785283 WolnzachDeutschlandFon +49 (0) 84 42 67 200Fax +49 (0) 84 42 67 [email protected] www.ast.de