ASSM Worldwide - Gibdock · PDF filecoamings, hatch covers and gangway. ... especially in...

-

Upload

vuongkhanh -

Category

Documents

-

view

215 -

download

1

Transcript of ASSM Worldwide - Gibdock · PDF filecoamings, hatch covers and gangway. ... especially in...

M A R C H 2 0 1 1

M A G A Z I N E

WorldwideNew Yearbrings newoptimism

ASSMTime to fit aBNWAS

In this Issue...

SpotlightA&P changesownership

DD Mar 11 Cover_v2:Drydock Cover 15/03/2011 12:38 Page 1

DRYDOCK MARCH 201142

Excalibur; the inspection of cargo tanks and

overhaul of cryogenic equipment on LNG Golar

Grand; the repair of the condenser, renewal of

main sea water collector and boiler extraction

line on LNG Port Harcourt; as well as the

renewal of the deck fire fighting line, steel

works in ballast tanks, and installation of new

grey water line as per new regulations on

Princess Naomi.

Work Picking UpFor Niestern Sander Repair, with repair facilities

in the very north of Holland, work picked up in

December. The heavy lift vessel Stellanova of

Rotterdam-based owner Kahn arrived in the yard

in the last month of 2010 for her 3rd Special

Survey. For this new client, the yard executed

steel repairs, renewal of piping, extensive

coating works and, with the assistance of the

vessels experienced crew, testing of cargo gear

and the modification of the bowthruster.

The vessel left the yard after four weeks for

her next heavy lift employment.

Just before the end of the year, the seagoing

tug Typhoon arrived in the yard and was docked

into drydock No1. This vessel, owned by

International Transport Contractors Heemstede,

Holland, was due for her 5th Special Survey.

Both CCP-propulsion unit tailshafts were drawn,

and steel and piping repairs executed as well as

extensive repairs to the towing pins.

The New Year started for the yard with arrival

of the Susanne of Van Dam Shipping. This

vessel sustained considerable ice-damage to

her port and starboard shell plating.

January also saw the Dongeborg drydocked

into dock No2 after the vessel grounded in

Denmark and was towed to Delfzijl for cargo

discharge. About 120-tons of bottom plating

and internals will be renewed and also repairs to

CPP-unit, shafting and rudder-equipment are

required.

As the damage is extending aft from the

forward-engineroom bulkhead, a heavy

supporting frame is being constructed to carry

the load of the aft ship for as long as dock keel

supports are removed. Expected redelivery to

her owner Wagenborg will be in the beginning

of April 2011.

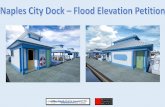

Collision Repairs atGibdockA collision involving the three-year-old

multipurpose general cargo/container vessel

Ems, owned by Werse Schiffahrts of Münster,

Germany, recently brought a new customer to

Gibdock, the Gibraltar-based ship repair yard.

hull cleaning and to carry out the repair and

realignment of its bow azimuth thrusters. A

new radar antenna was also installed and the

corresponding cabling routed to the bridge.

The Federal Yoshino drydocked in the Nº 1

dock at Cadiz towards the end of the month to

carry out, apart from standard drydocking

works, the dismounting of its tail shaft and the

substitution of seals, the polishing of her

propeller, the overhaul of the main engine and

boiler cleaning work.

The Ciudad de Malaga drydocked into the

Nº 4 dock at San Fernando at the start of

January to carry out her standard drydocking

works and hull blasting and painting work, as

well as the withdrawal of her two shaft lines in

order to inspect all of the related elements

and to substitute the respective seals. The

rubber fenders were renewed on both sides

and full overhauls were carried out on the

retractable Schottels and also on the vessel’s

stabilizer fins.

The Martin I Soler drydocked in the Nº 2

dock at Cadiz in the middle of January to

carry out the dismounting, full workshop

overhaul and refitting of the vessel’s starboard

stabilizer fin. The owner took advantage of the

vessel’s stay in drydock in order to carry out

her standard drydocking works (valves, sea

chests, chains, etc.), as well as the painting

of the hull.

The Belle de Cadix drydocked in the Nº 2

dock at San Fernando in the middle of January

to carry out standard drydocking works.

Navantia Shiprepairs Fene-Ferrol started

its 2011 activity with the drydocking and/or

repairs of 10 commercial vessels and five

military units for the Spanish Navy in January.

One again, in line with the trend

established over the past years through the

wORLdwIdE

yard's specialization in the repair and refit of

gas carriers, half of the commercial vessels

repaired this month corresponded to this

sector, with four LNGs and one LPG carrier.

During the month, the centre completed

the repairs of the vessels Charles Darwin and

LPG Eeklo, which had been started earlier, and

the shiprepair centre also started and

completed the repairs of the vessels LNG Port

Harcourt, LNG Golar Grand, LNG Excalibur,

Stolt Kestrel, and Jipro Isis, which were

delivered to their respective owners after the

successful completion of their final tests.

During this same period the yard started

the repair works of LNG Delta, Princess Naomi

and British Kestrel, which will be completed

and delivered in the following months.

The works carried out in January included

the drydocking in Ferrol and Fene of seven of

the commercial vessels repaired this month,

which – except for LNG Port Harcourt, LNG

Excalibur and LNG Delta,, which underwent

alongside repairs – all underwent usual general

docking works, hull surface treatment, etc.

The most remarkable works in this period

included the complete overhaul of the main

engine and tank coating in all cargo tanks of

the vessel British Kestrel; the overhaul of

steam system valves, repair of main condenser

and installation of new funnel on LNG

DD Mar 11 interior_double spreads_v7_single pages:DD 15/03/2011 13:32 Page 42

DRYDOCK MARCH 2011 43

The 94m long, 5500dwt Ems (formerly the

Buluklu and Rhone) - delivered in 2007 by the

Torgem yard in Turkey - was alongside in the

port of Montril, near Almeria, Spain, when the

vessel was struck by the bulbous bow of the

ferry Ace 2, formerly Euroferry Atlantica, which

had broken free from its moorings. Ems was

effectively sandwiched between the Ace 2 and

the quay wall, and in the process suffered

significant damage to both her port and

starboard sides.

The rogue vessel’s bulbous bow punctured

the Ems’ hull, causing a large 5m x 4m hole,

while significant damage was also caused to

the fuel tanks, main deck, cargo hatches,

coamings, hatch covers and gangway. One of

the fuel tanks was in fact punctured and

caused damage to a pipe inside the fuel tank

which in turn contaminated the ballast tank.

Although not holed on impact against the

quay, the port hull shell plating actually

incurred a larger area of damage than was

caused to the starboard side.

The Ems arrived in Gibraltar in early

December and a thorough inspection of the

vessel was undertaken by the yard together

with the owner. This revealed the full extent of

the damage sustained in the incident, after

which the process of repairing the stricken

vessel commenced. In all, some 22 tonnes of

steel was used to repair the hole in the

vessel’s side and other work during a 14 day

period in Gibdock’s No. 3 drydock. The ship

was redelivered on time to the owner, in line

with the original specification. On leaving the

drydock the Ems remained at the yard for a

further period of alongside repairs and

maintenance to hatch cover hydraulic systems.

John Taylor of Gibdock says the project

highlights the capacity of the yard to carry out

intensive repair jobs of this type, allowing the

vessel to re-enter service without undue delay.

He adds, “Our covered Number 3 dock was

particularly well suited for this task as it

ensured the work could go ahead regardless of

the weather conditions.”

The ship owner and manager, Werse

Bereederungs, has expressed itself highly

satisfied with the work carried out, and has

indicated that it plans to bring further vessels

to the yard in future. Superintendent, Captain

Peter Lodygowski, says, “We recognised that

this period before Christmas was a very busy

one for everybody but Gibdock promised to

get the extensive steel work done before the

holiday time and they were true to their word.

I can say that the quality of the steel work

repairs was excellent, leaving me pleasantly

surprised.”

Gibdock has a strong track record

repairing vessels of this type trading in the

Mediterranean. In 2010, some 125 multi-

purpose and container vessels were serviced

at the yard.

AsiaST MarineBreakthroughST Marine scored a breakthrough by securing

its first contract with The Royal Australian Navy

(RAN) to convert its 157.2m long combat

logistics vessel, HMAS Success, to be double

hulled to meet the International Maritime

Organisation standards for environmental

protection against oil spills. As a testament to

ST Marine’s strong track record in ship repair,

especially in upgrading and conversion, the

company secured several upgrading and

modification contracts from both its naval and

commercial customers.

The HMAS Success is designed to supply

naval combat units with fuel, ammunition,

food and stores whilst underway at sea.

Capable of day and night Replenishment at

Sea to ships alongside and concurrently by

her embarked helicopter to other ships in

company, the HMAS Success weighs 18,000

tonnes when fully loaded. Commissioned in

1986, HMAS Success is the largest ship built

in Australia for the RAN. Work was scheduled

to commence before the end of last year when

the tanker was deployed in the region and will

be re-delivered by the first half of 2011.

On the commercial front, ST Marine

secured two significant repair and conversion

jobs from Saipem (Portugal) Comercio

Maritimo (Saipem) and Coastline Group of

Companies (Coastline). Saipem’s 31,901

tonnes (GRT) SEMAC 1, a semi submersible

pipe lay vessel measuring 188.1m long

including truss and 54.8m wide, will undergo

upgrading and modification works including:

stern winches upgrade, installation of new

pipe tensioners, modification of Abandonment

and Recovery winch, maintenance activities

and Australisation of the vessel. As SEMAC 1

will be deployed in Australia, the vessel

needs to undergo Australisation to meet

requirements such as having each cabin

accommodating up to maximum two persons

and equipped with a private toilet unit as well

as ensuring that the entire vessel is Asbestos

free. Some of the major Australisation work

include: removing existing accommodation

(98 cabins with galley and offices) to rebuild

168 new cabins with galley and offices,

building a new helideck and an extra

accommodation block. The project has

commenced and is expected to be completed

by end July in 2011.

Caballo Maya, a 143.5m long and 22m

wide offshore diving support construction

vessel will be undergoing fabrication and

installation of sponsons, crane foundation and

modification of the stern section. The

sponsons fabrication will widen the vessel

WORLDWIDE

DD Mar 11 interior_double spreads_v7_single pages:DD 15/03/2011 13:32 Page 43