Asq int lss

description

Transcript of Asq int lss

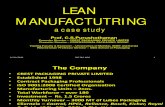

Integrating Lean & Six Sigma

Using Value Stream Mapping and Linked Scorecards to Achieve Breakthrough Improvements in

Quality, Productivity and Competitive Position

Ron Mitchell ASQ, Hamilton, Ontario – 3/10/04

2

Ron MitchellRon Mitchell is Director of Lean & Six Sigma Services at Omnex. He is a trainer and consultant with twenty years experience-helping clients understand and apply Lean Manufacturing and Quality Improvement Technologies. Ron studied the Toyota Production System at NUMMI, the joint General Motors and Toyota Motors Corporation facility in Fremont, California; and, he was part of the team that helped launch Synchronous Manufacturing at General Motors. Ron received his training in Quality Management from Dr. W.E. Deming, Dorian Shainin and through The Crosby Quality College. Ron is a Lean Manufacturing Master Black Belt and a Six Sigma Master Black Belt. Ron holds Bachelor’s and Master’s Degrees in Industrial and Organizational Psychology and a PhD – Abd in Behavioral Systems Analysis.

3

Integration & Alignment

Lean

Six Sigma

ISO/TS 16949

Ne

w P

rod

uc

ts

ISO

14001

Co

st R

edu

ctio

nsM

erg

ers

/Acq

uis

itio

ns

Co

ns

olid

ation

s/La

yoffs

New Technology

4

Cost of Poor Quality and Sigma

COPQ Sigma PPM Position

20-25% of Sales 2.0 308,537 Non Competitive

15-20% of Sales 3.0 66,807 Average Company

10-15% of Sales 4.0 6,210

5-10% of Sales 5.0 233

<5% of Sales 6.0 3.4 World Class

COPQ Sigma PPM Position

20-25% of Sales 2.0 308,537 Non Competitive

15-20% of Sales 3.0 66,807 Average Company

10-15% of Sales 4.0 6,210

5-10% of Sales 5.0 233

<5% of Sales 6.0 3.4 World Class

5

Quality engineeringand administration

Inspection/test (materials,equipment, labor)

Expediting

Scrap

Rework

Rejects Warrantyclaims

Maintenance and service

Cost to customers

Excess inventory

Additionallabor hours

Longer cycle times

Quality auditsVendor control

Improvement program costs

Process control

Opportunity cost if salesgreater than plant

capacity

Cost of Poor Quality (COPQ)

“What about the greatest cost of all… the cost of a lost customer?” Dr. W.E. Deming

6

Cost Savings from Six Sigma

• General Electric reported that Six Sigma produced in excess of $2 Billion in savings in 1999 alone.

• Motorola used Six Sigma to win the first

Malcolm Baldrige National Quality Award and reported cumulative savings in excess of $14 Billion in the first ten years.

• Ford Motor Company reported that Six Sigma projects saved over $385 Million in 2002.

7

The Lean Enterprise*

• Lean companies use less of everything than do mass production companies:

half the human effort in the factory,half the manufacturing space,half the investment in tools, half the engineering hours to develop a

new product in half the time, less than half the inventory

*From Womack, Jones, et.al., “The Machine that Changed the World.”

8

Extra Handling & Storage Costs

Expediting Costs

PremiumFreight

Charges

Late Deliveries

Long Leadtimes

Cost to Customer

Excess Inventory

Excess Scrap & Rework

Cost of Capital

Lost Customer Loyalty

Excess Labor Costs

Opportunity Costs WhenPotential Sales Greater

Than Current Capacity

Cost of Poor Flow (COPF)

Excess Capital Investments

9

Cost of Poor Flow and Inventory Turns

COPF Inventory Turns Competitive Position

20-25% of Sales 8 to 10 Non-Competitive

15-20% of Sales 10 to 20 Average Company

10-15% of Sales 20 to 50

5-10% of Sales 50 to 100

<5% of Sales 100 Plus World Class Company

COPF Inventory Turns Competitive Position

20-25% of Sales 8 to 10 Non-Competitive

15-20% of Sales 10 to 20 Average Company

10-15% of Sales 20 to 50

5-10% of Sales 50 to 100

<5% of Sales 100 Plus World Class Company

10

World Class Processes

• C – Combine

• L – Lean

• A – And

• S – Six

• S – Sigma

Lean Productivity with Six Sigma Quality equals WORLD CLASS Performance.

Better, Faster and Cheaper!

11

Toyota Production System

12

Toyota Today

• FY 2003 profit report - $12 Billion in pre-tax operating profits.• More than the Ford, GM & Daimler/Chrysler...

combined.• Toyota has 11% share of the global market

compared with over 60% for The Detroit 3. • Toyota’s current market capitalization is $100

billion…. more than the market caps of the Detroit 3 combined.

13

Show Me the Money!!!

Cost of Poor Flow Cost of Poor Quality

14

Why SO LITTLE Progress?

1. Lack of Commitment/Support From:a. Management b. Supervisionc. Workforced. Unione. Suppliersf. Customers

2. Lack of Direction / Focus.3. Lack of Resources:

a) Timeb) Budgetsc) Skill

15

Managing Change - the Key to Success

16

Change Management

• As Competition Changes:– Technology Must Adapt – Manage the Technology– Organization’s Must Adapt – Manage the Culture– Groups/Teams Must Adapt – Manage the Group Dynamics– Individuals Must Adapt – Manage the Psychology

17

21st Century Management

1. Plan - identify and prioritize improvement projects;

2. Organize – provide the resources to drive improvement;

3. Motivate - manage the change process.

18

Balanced Scorecards

• Performance measures must address the concerns of ALL STAKEHOLDERS.– You don’t want to optimize one measure at the

expense of the others.

•Price•Quality•Delivery•Technology•Service•Profit Margins•Customer Satisfaction•Employee Satisfaction

19

Profits

Products

Process

Projects

People

Scorecard

Scorecard

Scorecard

Scorecard

Scorecard

Linked Scorecards Planning for Improvement

Planning

Improving

20

Profits

Products

Process

Projects

People

Scorecard

Scorecard

Scorecard

Scorecard

Scorecard

Customer Research - Surveys

Value Stream Maps

Continuous Flow Supermarket PullSix Sigma Quality SMED/TPM/FIVE S

StandardsEducationTrainingResourcesFeedback

Planning for Process Improvement

21

Profits

Products

Process

Projects

People

Scorecard

Scorecard

Scorecard

Scorecard

Scorecard

Achieving Process Improvement

New Knowledge, Skill, Attitudes and Behaviors

Improved Methods & Technology

Lean Productivity & Six Sigma Quality(Better, Faster, Cheaper)

Customer Satisfaction Increased Sales Increased Margins

22

Study the Process - Value Stream Mapping

1. To design and communicate the Lean / Six Sigma Vision – the future state.

2. To identify and quantify the process improvement opportunities – the gaps between the current state and the future state.

3. To develop project plans for achieving the future state.

4. To evaluate progress towards the future state.

23

PRODUCTIONCONTROL

MRPWeekly PO fax

90/60/30 DayForecast

90/60/30 DayForecasts

Weekly Order

8400 pcs/mo

Skid = 40 pieces

Distributors& Installers

Weekly

Weekly

ISheets4000

I3000

I1000

I800

I2200

I4800

FS = 600 SQ FS = 800 SQ FS = 300 SQ FS = 4000 SQ

9.5 days 7 days 2.4 days 1.9 days 5.2 days 11.4 days

25 seconds 60 seconds 35 seconds 20 seconds 40 seconds

Lead Time = 37.4 DAYS

Value Added Time = 180 sec

Weekly ShipSchedule

Weekly Schedule2500 Sheets

Michigan Steel Co.

C/T=25 sec.

C/O= 90 sec.

U/T = 95%

QR = 99%

SHEAR PUNCH

C/T=60 sec.

C/O= 0

U/T = 95%

QR = 98%

FORM

C/T=35 sec.

C/O=40 min.

U/T = 90%

QR = 95%

1

C/T = 20

C/O=0

U/T = 99%

10

C/T=40 sec.

C/O=0

U/T = 95%

SHIPPING

Staging 1

FS = 600 SQ

S. WELD

QR = 98% QR = 97%

PAINT/BOX

1 1

24

Process Scorecard

• Process Scorecards provide baseline measures for monitoring and evaluating progress:

• Lean / Six Sigma Process Scorecard Measures:Rolled Throughput Yield (RTY)Process Leadtime (Dock-to-Dock) Process Efficiency (% Value Added) Inventory Days (Raw, WIP & FG Days)Floor Space Used (Square Feet / Square Meters)Direct Labor Productivity (Sales / # of Operators)Process Availability (Process Uptime - %)

25

Measure Current State Future State Improvement

Raw Inventory Days

WIP Inventory Days

F.G. Inventory Days

Process Leadtime

Process Efficiency

Rolled Throughput Yield

Floor Space

Labor Productivity

Process Scorecard for: DSM Cabinet Body Mfg.

9. 5 Days

16. 5 Days

11. 4 Days37. 4 Days

88%

2300 SQ Ft. *

105 / OP. *

. 02%

* Mfg. Only – excludes paint and assembly operation.

Availability 90%

26

PRODUCTIONCONTROL

MRPDaily PO fax

90/60/30 DayForecast

90/60/30 DayForecasts

Daily Order

8400 pcs/mo

Skid = 40 pieces

Distributors& Installers

Daily

Daily Ship Schedule

500 Sheets

Michigan Steel Co.

SHIPPING

Staging

1 Day 2 Days

10

PAINT/BOX

4040

Body Cell

2 Days

Daily

100

C/T = 59 sec.

C/O = 90 sec.

Uptime = 99%

FTQ = 99.9%

FS = 875

1

FS = 4000 SQ

C/T=40 sec.

C/O=0

U/T = 95%

FTQ = 99.9% Future State MapDSM Cabinet Body CellOctober 7, 2003

TT = 60 sec.

U/T Cell Pull

SupplierDevelop

FTQFTQ

C/O

27

Measure Current State Future State Est. Savings

Raw Inventory Days

WIP Inventory Days

F.G. Inventory Days

Process Leadtime

Process Efficiency

Rolled Throughput Yield

Floor Space

Labor Productivity

Availability

Process Scorecard for: ____________________DSM Cabinet Body Mfg.

9. 5 Days 2 Days

16. 5 Days 1 Day

11. 4 Days 2 Days37. 4 Days 5 Days

88% 99.9%

2300 SQ Ft. * 875 SQ Ft. *

105 / OP. * 420 / OP. *

90% 99.9%

. 02% . 07%

* Mfg. only – excludes paint and assembly operation.

28

Measure Current State Future State Savings

Raw Inventory Days

WIP Inventory Days

F.G. Inventory Days

Process Leadtime

Process Efficiency

Rolled Throughput Yield

Floor Space

Labor Productivity

Availability

TOTAL SAVINGS

Process Scorecard for: ____________________DSM Cabinet Body Mfg.

9. 5 Days 2 Days $147,100*

16. 5 Days 1 Day $313,404*

11. 4 Days 2 Days $185,484* 37. 4 Days 5 Days

88% 99.9% $2,387,045

2300 SQ Ft2 875 SQ Ft2 $28,500

105 / OP. 420 / OP. $270,000

90% 99.9% $1,034,208 $4,365,741

. 02% . 07%

*Fixed cost savings from reduced inventory carrying costs… $3.2 Million in capital savings.

29

AccountingHumanResources

OperationsPurchasing Sales

Strategic Measures – Voice of the Customer/Stakeholder

Process Variation

Process MeasuresVoice of the Process

Leadership TeamObjectives

Organizing for Breakthrough Improvement

Projects

Lean Six Sigma Improvement Organization

Lean Six Sigma Sensei

LSS Project Team

LSS Project Team

LSS Project Team

Lean Six Sigma Project Manager

LSS Project Team

LSS Project Team

LSS Project Team

Lean Six Sigma Project Manager

LSS Project Team

LSS Project Team

LSS Project Team

Lean Six Sigma Project Manager

Lean Champion

30

Lean / Six Sigma Improvement Organization

L e a n S ix S ig m a M as te r B la ck B e lt

L S S P ro je ct T e am

L S S P ro je ct T e am

L S S P ro je ct T e am

L e a n S ix S ig m a B la ck B e lt

L S S P ro je ct T e am

L S S P ro je ct T e am

L S S P ro je ct T e am

L e a n S ix S ig m a B la ck B e lt

L S S P ro je ct T e am

L S S P ro je ct T e am

L S S P ro je ct T e am

L e a n S ix S ig m a B la ck B e lt

L e a n S ix S ig m a C h a m p ion

31

Managing Change - Motivating

• Set High Expectations• Communicate, Communicate, Communicate• Remove the Roadblocks• Accept Failure, Recognize Success• The ONLY CONSTANT is Change

32

Lean / Six Sigma Management Planning

Value Stream Maps

Lean / Six Sigma Project/Change Management

OEE & Quick Pull Continuous T.P.M & Six Sigma 5 S and Changeovers Scheduling Flow (Cells) Error Proofing Quality Process Visual Mgmt.

Design Develop Purchase Produce Assemble Inspect Deliver

Lean Six Sigma Projects

Begin Here

33

Questions & Answers