Asphalt Pro - April / May 2015

-

Upload

asphalt-pro-llc -

Category

Documents

-

view

237 -

download

10

description

Transcript of Asphalt Pro - April / May 2015

April/MAy 2015

Grow with Additives to Terminals

Get ErgonomicDesign to Drain

Add Two For StrengthAvoid Emulsion Overspray

Stay SafeWith Binders

Western Emulsions Adds to Economy

HEATEC,INC. an Astec Industries Company

5200 WILSON RD • CHATTANOOGA, TN 37410 USA 800.235.5200 • FAX 423.821.7673 • heatec.com

®HEATEC

UNMATCHED HEATINGThe 1100 square feet of heating coil surface in our vertical tanks is significantly more heating surface than you will find in vertical asphalt storage tanks built by others.

Coil heating surface area is directly related to how fast you can raise the temperature of asphalt in the tank. So when an asphalt supplier fills the tank with a “cold” load you won’t have long delays while it reaches the required temperature.

We achieve the extraordinary amount of heating surface by using finned pipe. This reduces the number of coils needed and conserves space in the bottom of the tank. Coils without fins would occupy a significantly greater height in the tank and signifi-cantly reduce the usable volume of the tank.

Just for the record the height of the two-layered finned coil above the bottom of our tank is only 11-5/8 inches. But if the same coils had no fins, seven layers with a height of 40-3/8 inches would be needed. The coils in some tanks on the market have

much greater heights, which may severely limit the usability of the tank.

Remember, the asphalt level in the tank needs to always totally cover the heating coils to prevent coking. So you always need to refill the tank before the asphalt level is lower than the topmost coil.

Moreover mixers in tanks filled with PMAC do not work adequately when coils are several feet in height.

To appreciate just how much coil height affects us-ability consider that each inch of height above the coils in a vertical tanks is equal to 58.8 gallons.

So our heating coils are unmatched because they provide an extraordinary amount of heating sur-face while minimizing loss of usable space.

Please call today for more information.

Unmatched heating ad.indd 1 5/22/14 1:58 PM

30

22

28

36

contents

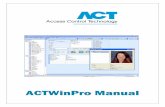

On the CoverAsphalt producers can see big savings when they invest in their own terminal facilities, but the investing continues when new devices hit the market to make operations smoother and more efficient. See related article on page 16.

APRIL/MAY 2015

Grow with Additives to Terminals

Get ErgonomicDesign to Drain

Add Two For StrengthAvoid Emulsion Overspray

Stay SafeWith Binders

Western Emulsions Adds to Economy

DEpArTMEnTS

Editor’s Note5 Arby’s SandwichesBy Sandy Lender

Safety Spotlight6 Handle Binder SafelyBy Jarrett Welch

Around the Globe10

Keep It Up12 Maintain Equipment for Safety’s SakeBy AsphaltPro Staff

Project Management14 Design Drainage from the Base UpBy Hawaii Asphalt Pavement Association (HAPI)

Product Gallery56 Paving and Pavement Maintenance EssentialsBy AsphaltPro Staff

Here’s How It Works62 Roadtec’s Autotracking Package

Resource Directory65

Digital Details66 Apps That Make You More Productive

ArTiclES

16 Control Your A, B, CsBy Michael Maddox and Sandy Lender

20 Imminent Political Decisions in Washington Could Have Major Impacts on Your Livelihood for Years to ComeBy Pete Ruane

22 A Tale of Two AdditivesBy Sandy Lender

28 Slurry Pump Makes Light Work of Drilling MudFrom BJM Pumps

30 How to Avoid Emulsion SoupBy Sandy Lender

30 Innovations Headlined World of Asphalt/AGG1By Sandy Lender

48 Meet the State Exec: Russell SnyderBy AsphaltPro Staff

53 Ergonomics Increases Productivity, SafetyBy Tim Hoffman

48

Rely on CEI

Equipment.Rely on CEI

Parts.Rely on CEI

Service.CEI equipment has a proven

legacy of quality & innovation since 1969.

We stock one of the largest parts inventories in the industry,

for CEI and other brands.

For troubleshooting, repair, maintenance or training, CEI’s service reach is global.

Whatever you need to keep your plant running,

Rely on CEI.

ceienterprises.com • 800.545.4034

CEI ENTERPRISES,INC. an Astec Industries Company

245 WOODWARD RD, SE • ALBUQUERQUE, NM 87102 USA • 800.545.4034 • FAX 505.243.1422 • ceienterprises.com

Arby’s SandwichesThis is not the original editorial column I wrote for this edition of AsphaltPro. You’ll have to check the June/July issue for tips on strengthening asphalt while lengthening your compaction window. No, this month, I needed to modify the content. The asphalt industry has lost a faithful friend, and I want to use this platform to share something lovely about Dr. J. Don Brock.

Any number of trade publications and economist-forecast newspapers will give you a rundown of Dr. Brock’s many achievements, including the 100 patents he owned. One source referenced the fact that Fortune 500 CEOs tune into Astec public quarterly statements to get a bead on the world economy. His nomination to the ARTBA Hall of Fame crossed my email account as I was one of the judges that year, and the list of accom-plishments for the man was mind-boggling.

Of course, the measure of a person isn’t in the num-ber of associations or CEOs who look up to him or her. As Richard Schreck, executive vice president of the Vir-ginia Asphalt Association told NAPA ActionNews in March, “Most people, if they are lucky, will only come to know one or two truly great men in their lifetime. Don Brock was such a man — a quiet genius with a great passion for and com-mitment to the asphalt industry. He was an unassuming man of great personal and profes-sional integrity who throughout his life mentored so many with humility, kindness and re-spect; always willing to listen and encourage.”

I consider myself blessed to have known Dr. Brock. He had been inducted into the Asphalt Pavement Hall of Fame in 1995, three years before I entered the industry, yet he was willing to answer my questions while I worked for an asphalt magazine. It didn’t matter to him that I was new to the industry; he was pleased to help me learn something and understand it.

Dr. Jay Winford, chairman of the NCAT board of directors and president of Prairie Con-tractors Inc. also shared that sentiment with NAPA ActionNews, stating, “Not only was Don Brock a great innovator within the asphalt industry, he was a great friend and mentor. He was certainly a chief engineer to both my personal development and company success. He taught me that the game of life was to create a business, but the meaning of life was to help others and make a difference.”

When the Asphalt Pavement Association of Indiana inducted Dr. Brock into its hall of fame a few years ago, John Ball and I visited with him on the tradeshow floor. He kindly re-sponded to John’s inquiry about his health, letting us know that he was moving forward and continuing to do all he could with each day. That kind of spirit was the man’s hallmark. And then Dr. Brock, who had the weight of the world on his own shoulders, looked John in the eye and asked how he was holding up after the passing of his wife. The men spoke together for a moment, merely sharing what was more important than the business around them.

As for the Arby’s mentioned in the headline this month, the full story is something che-mo/radiation patients can fully appreciate. That craving is pretty strong when it comes on, and I was tickled when I learned that Dr. Brock preferred the fast food to the fancy stuff at one of the conferences we were all attending. He didn’t take me up on my invite to ditch the luncheon for the Arby’s nearby, but I bet there’s time for yummy Arby’s sandwiches by some sort of glorious, golden asphalt roadway with a crew of old friends in Heaven.

Stay Safe,

Sandy Lender

April/May 2015 • Vol. 8 No. 7editor's note

602 W. Morrison, Box 6aFayette, MO 65248

(573) 823-6297www.theasphaltpro.com

GrOup puBlisherChris harrison

chris@ theasphaltpro.com

puBlishersally shoemaker

[email protected](573) 823-6297

editOr

sandy [email protected]

(239) 272-8613

Art direCtOrKristin Branscom

Business MAnAGersusan Campbell

Asphaltpro is published 10 times per year: January, February, March, April/May, June/July,

August, september, October, november and december by Chp holdings, 602 W. Morrison,

Box 6a, Fayette, MO 65248.

Writers expressing views in Asphaltpro Magazine or on the Asphaltpro website are professionals

with sound, professional advice. Views expressed herein are not necessarily the same as the views of Asphaltpro, thus producers/contractors are

still encouraged to use best practices when implementing new advice.

suBsCriptiOn pOliCy: individual subscriptions are available without charge in the united sates,

Canada and Mexico to qualified individuals.

One year subscription to non-qualifying individuals: united states $90, Canada and Mexico $125.00.

For the international digital edition, visit theasphaltpro.com/subscribe-2. single copies available $17 each.

Astec industries sponsored the high-way Bill character during the co-lo-cated 2015 World of Asphalt and AGG1 tradeshows in Baltimore. As someone who grew up with school-house rock, sandy lender was de-lighted with the marketing concept.

www.theAsphAltpro.coM 5

safety spotlight

Handle Binder SafelyWe all know asphalt binder is a

key component in our mixes. How we handle binder is not

only critical for quality, but also for our safety. Many workers come into contact

with this hot liquid on a daily basis such as employees at the refinery, tanker drivers, plant personnel, and quality control techs to name a few. Over the years I have heard of and been witness to injuries from han-

dling hot liquids, and in most cases the ac-cidents could have been prevented by fol-lowing safety best practices.

An example of this came a few years ago when a plant operator I worked with—

By JArrett WelCh

the safe sampler from Maxam equipment is one example of the strides our industry has made in implementing best practices for the safety of QC/QA techs at the plant. this product is a totally enclosed sampling system. An access door interlock keeps the valve closed while the QC tech places or removes the sampling container. if the safety door isn’t closed, the sampling control valve can’t be opened to let AC flow into the sampling container.

6 April/MAy 2015

Untitled-1 2 7/7/14 2:04 PM

safety spotlight

we’ll call him Louis—was unloading the transport tanker. When Louis went to disconnect the line from the tank, some-thing went wrong with the shut-off valve. The material blew back covering him with hot liquid binder. Fortunately for Louis, he used his safety training and Person-al Protective Equipment (PPE) to come away without injury. Prior to unloading the tanker, Louis put on his PPE, which consisted of a hard hat with a face shield, and a rubber-insulated long cover coat and gloves. These protected him from di-rect contact with the binder. Louis react-ed quickly to the situation and was able to control the blow-back and prevent others from coming into contact with the ma-terial. Management was relieved to hear Louis was not injured, but also wanted to assure this did not happen again. He then became part of the safety team within the company and spoke of his experience at future safety meetings.

As workers, we need to be vigilant when working with this material. We need to be prepared for an equipment failure, but also for human mistakes. The human ele-ment can put us at risk for injury. As hu-mans, we must guard against complacen-cy when performing routine tasks and not relax because we have repeated a task so many times without injury. When this oc-curs, we reduce our preparedness to re-act to the situation. Not only do we want to prepare ourselves with the correct PPE for the task, but we also need to prepare in our minds how we are safely going to per-form the task and what we are going to do should something go wrong.

In the example above, Louis understood the risks involved in the process of per-forming his duties. How we position our bodies when working with hot binders can make a difference in injury prevention. Standing to the side of the hose instead of directly in front of it likely minimized the contact when the valve failed and the hose was released. As a QC technician in the ear-ly days of my career, I had to sample bind-er during production from a nozzle that was directly tied into the feed line entering the drum. These sampling nozzles at times were not in a place that was easy to get to. Regularly, I had to use a ladder to get to the pipe where the nozzle was. I learned quick-ly how hard that was to do safely. Anyone who has sampled liquid AC this way knows that it takes a little bit of time for the bind-er flowing through the pipe to heat the cooler material in the nozzle. There is a de-lay from the time the nozzle is turned to when material begins to flow. Once it does start flowing, it comes in a rush.

Since those days, I have seen where we as an industry have modernized our op-erations for safety. Valves and nozzles are in easy-to-reach locations with stairs and railing to protect workers from falls. Some processes have become automated. Stan-dards and protocols have been developed to inform and guide us. PPE is more read-ily available, and training our employees has become paramount. Yet, it is still up to us as individuals to use these tools for our safety and the safety of those around us. Every day when we perform tasks related to our job we need to evaluate and identify the risks, determine how we will mitigate those risks, and implement the action.

Jarrett Welch is the proprietor of Quali-ty Paving Consultants, Wheat Ridge, Colo. For more information, contact him as (970) 361-1525.

negligible percentages—proceed with common Senseit was brought to our attention that an indus-try publication recently printed an article with an overview of how departments of transporta-tion (dOts) and contractors need to handle the extremely rare scenario where an old pavement constructed with asbestos fibers as an experi-mental additive needs to be removed. the head-line and image garnered attention that the neg-ligible scenario did not deserve. A spokesperson for the national Asphalt pavement Association (nApA) has offered the following statement to set the record straight.

“According to Mundt et al. (2009), only eight states reported having used asbestos in hot-mix asphalt and none did so regularly. "no state re-ported current or historical use of asbestos in hMA for mainline road paving, although eight states (Florida, indiana, iowa, Minnesota, new york, Ohio, pennsylvania, and Washington) re-ported infrequent low-volume use, with earli-est and most recent use dates reported as the 1940s and the 1970s, respectively." the same paper notes some additional testing and use of asbestos fibers in asphalt in those and a few oth-er states, but it was far from a universal prac-tice. [Mundt, d.J.; K.M. Marano; A.p. nunes; & r.C. Adams (2009). A review of Changes in Composition of hot-Mix Asphalt in the unit-ed states.Journal of Occupational and envi-ronmental hygiene, Vol. 6, no. 11, pp. 714-725. dOi:10.1080/15459620903249125]

“ideally, the dOts in each of those states have a good idea of the rare instances when and where asbestos fibers may have been used and it can, as penndOt did in this instance, put in place precautions to make sure workers and the pub-lic are kept safe. Absent dOt acknowledgment or identification, if a company has a reasonable suspicion (based on the location of a job, the pavement structure type, or the date the origi-nal pavement layer was placed) that they might encounter asbestos during milling, core samples could be taken, analyzed, and then appropriate safety measures could be implemented in the very rare case asbestos is actually present.

“As the article noted, only 55 miles of penn-sylvania roads contain asbestos out of more than 100,000 miles of asphalt surfaced roads; that's less than 0.055% of pennsylvania's roads. Gen-erally, these pavements were experimental, may have predominantly included bridgework, and appear to have been documented by penndOt. According the pennsylvania Asphalt pavement Association, the typical process is to only over-lay (and not mill) a pavement layer known to in-clude asbestos.

“Clearly this is an extremely unusual situation and one that only affects a small number of older pavements.”

siNce those dAys, i hAVe seeN where we As AN

iNdustry hAVe ModerNized our operAtioNs for sAfety.

VAlVes ANd Nozzles Are iN eAsy-to-reAch locAtioNs

with stAirs ANd rAiliNg to prOTEcT WOrkErS FrOM

fAlls. soMe processes hAVe becoMe AutoMAted.

8 April/MAy 2015

Untitled-1 1 7/7/14 1:46 PM

Industry News and Happenings from Around the WorldcAnADA• The 2015 International Scrap Recycling In-

dustry Exposition will be held in Vancou-verApril21 through25,2015.Check thesiteat http://travel.state.gov for travel info and http://www.isriconvention.org/ for conven-tion info.

• The Pavement Preservation and RecyclingAlliance (PPRA) also takes its convention northoftheborderwiththe2015FallMeetingat Sheraton on the Falls in Niagara Falls, On-tario this Oct. 13 through 15. Visit ppralliance.org/ppra2015forregistrationinformation.

chiNA• The BeijingMunicipal Government, Beijing

MTR Corporation Ltd. and the three share-holders of Beijing MTR have signed a public-private partnership (P3) concession agree-ment to build and then undertake the op-erations and maintenance of Beijing Metro Line 16, which will run through three major districts and connect to the city’s metro net-work through 13 interchange stations; these are used by 10 million passengers per day. Source: Building.hk

• China’simportofbitumenduringthemonthofJanuarywasup25percentcomparedtoDe-cember’s rate, with 64 percent of its total im-port of bitumen coming from South Korea, according to Petrosil’s Bitumart newsletter. That resource states South Korea exported 298,770megatonnesofbitumenthatmonth.

GErMAnyJudges recognized micronized rubber powder in the Tire Technology International Awards for In-novationandExcellence2015inCologne,Germa-ny,Feb.12.LehighTechnologiesofAtlantaaccept-ed the award for Environmental Achievement.

inDiAAccording to Petrosil’s Bitumart Newsletter, In-diaexported8,200tonsofbitumenduringJanu-ary of this year with the majority going to Malay-sia, Bangladesh and the Maldives. Consider that onemonthofexporttothe12monthsofimport-ing bitumen during 2014when India pulled in495,776MT.

UniTED ArAB EMirATESAttend the Fourth Middle East Base Oil and Lu-bricantsConference,alongwiththe23rdAnnu-alMiddleEastPetroleum&GasConferencethisApril22through24inAbuDhabi.Getalltheinfoat http://www.baseoillubes.com/.

UniTED STATES• Like us at https://www.facebook.com/

AsphaltPro. Follow us @AsphaltPro.• Time is running short to reach out to your

representatives concerning long-term, fully funded federal highway funding. The current funding for America's highways runs out May 31,2015ifCongressdoesn’ttakeactionfirst.See related article from ARTBA’s Pete Ruane on page xx.

• The Construction & Demolition RecyclingAssociation (CDRA) shared that more than 70 percent of the construction and demoli-tion material generated in the United States is recycled and the C&D recycling industry is responsible for the direct support of 19,000 jobs, with the direct annual revenue of the in-dustrytobeapproximately$7.4billion.

cOlOrADOAtlas Copco, Commerce City, Colo., has launched an employee-led sustainability program called “Blue is theNewGreen” to reduce its resourceconsumption on a global scale. All 3,000+ em-ployees in 65 countries are encouraged to mini-mize their environmental impact by making small changes to consume fewer resources, including electricity, materials and water. The program al-ready inspired employees to submit sustainability ideas, including installing motion-detected light switches that automatically turn on or off over-head lights.

FlOriDAMake sure you’re registered to support the Con-struction Angels and to have a good time with wings, country and rock & roll at the Bergeron Rodeo Grounds in Davie, Fla., this Saturday,April18.TheConstructionAngelshostAlligatorRon’sWingfest2015toraisefundsforthenon-profit entity to turn over to families of construc-tion workers killed while building our nation’s roadways and bridges. Contact [email protected] or [email protected] for more information.

illinOiSDo you have a white paper or presentation that brings new light to asphalt shingle recycling? The 7th Shingle Recycling Forum takes placeOct. 29 through 30, 2015, at the Crowne Pla-za Hotel just outside Chicago’s O’Hare airport. The CDRA has issued a call for papers to anyone who has an innovative and exciting idea for the use of recycled shingles, including beyond use

in hot mix. Submit your abstract to CDRA head-quarters via email at [email protected].

iOWAThe Asphalt Paving Association of Iowa (APAI) celebrates its 60th anniversary this year. The staff spent the first half of April educating its membership along with local city, county and consulting engineers on best pavement main-tenance at a series of six 1-day Regional Road Rehab Clinics. Each 5-hour lunch-n-learn event featured presentations by local engi-neers on local rehabilitation projects, new and innovative methods to rehab failed PCC road-ways, special presentations by experts on HMA rehab, real-life working examples of paving ideas,lunch,anddoorprizesforamere$25perperson. Each person was eligible for 4.5 PDH credits at the end of the day.

lOUiSiAnAJames Construction in Baton Rouge, La., has good things to say about HeavyBid software from HCSS, Sugar Land, Texas. What used to take about120man-hourstoaccomplishforestimat-ing,accountingandbiddingnowtakesabout20to 25man-hours, according to JimRichard, theestimating manager at James Construction.

MArylAnDTheco-locatedWorldofAsphaltandAGG12015exceededexpectationsMarch17through19withmorethan7,000attendeestothetradeshowandconferences. See related article on page xx.

MiSSOUriAsphaltPro Magazine, Fayette, Mo., wishes to rec-ognize and applaud the asphalt professionals who make the industry great. We’re looking for a few good projects. As you work this spring and summer, as you compile your numbers and stats, be sure you take pictures and notes to share with us. You could be featured in the pages of Asphalt-Pro and could be in the running for something special. Stay tuned for details. Stay alert for quali-ty projects that we should brag about. Share them with [email protected].

WiScOnSinNeed to get to the top of the silos or perform maintenance up high? Konecranes Training In-stitute, New Berlin, Wis., offers a short video and a variety of training courses to help keep work-ers safe when renting or using an owned piece of equipment. Contact [email protected] or visit http://www.cranetrainingu.com.

around the globe

10 April/MAy 2015

SaveMyRoad.com is the premier information hub for roadway planning and preservation. Here, you’ll find helpful information ranging from treatment options to preservation strategies that will put your projects in the fast lane.

Click, click, boom.

You’re the smartest guy in the room.

SaveMyRoad.comVisit

keep it up

Maintain Equipment By AsphAltprO stAFF

Copy and use this—or a similar—checklist for pre-shift walk-arounds.

When the mechanic or equipment operator performs the walk-around for a piece of equipment

at the beginning of his shift, he’s not only checking for routine maintenance purpos-es. The daily walk-around serves a safety purpose as well.

Open belts and pulleys, chains, sprock-ets, and other points of operation must be guarded to prevent the operator or ground personnel from accidentally coming into contact with them. If guards are worn, damaged or missing, the pre-shift walk-around will bring the problem to light.

How about propane tanks and acetylene tanks in the shop? If these cylinders are go-ing to be transported to a job site, they must be chained into place for safe transport. Also check their tags to be sure they’ve been inspected within the past year.

You can even discuss the safety as-pect of the mechanic’s job during weekly meetings. The Monday morning toolbox talk or pre-shift toolbox talk serves a very important function in getting all mem-bers of the crew on the same page as far as communication and job responsibili-ties are concerned. This daily or weekly meeting gives the project manager a set time to share any changes in an ongo-ing job with the entire crew at once, and lets everyone become familiar with com-munication signals and guidelines again. This toolbox talk is an important routine in the safety director’s week as well, so why not let the mechanic and equipment operators know how crucial their walk-around is to their safety?

At the end of each week, review all the jobs that were completed that week and

discuss if there were any safety issues on the projects. Clear up miscommuni-cations and share ways workers can be safer in the future. Remind workers of the walk-around safety inspections; this end-of-week time is perfect for complet-ing walk-arounds and performing main-tenance to bring equipment up to per-fection. Evaluate any accident investiga-tions conducted since the last meeting to determine if the cause of the unsafe conditions were properly identified and properly corrected.

Be sure to document attendance at safety meetings and document the sub-jects discussed. Maintain these records for at least one year. Your insurance com-pany will have an interest in these re-cords as your agent works to keep your premiums low.

EQUIPMENT SAFETY INSPECTION CHECKLISTDate: Project:

Equipment Model: OKNeeds Repair

Equipment Model: OKNeeds Repair

All guards and fenders Glass

Brakes Tires

Lights—front, rear, side, dash Electric cords

Back-up alarm—horn Ground fault circuit interrupters

Ladders, stairs, hand holds Electrical hand tools

ROPS (roll-over protection) Power actuated tools

Seat belts Condition of pneumatic hand tools

Fire extinguisher

Other Items Checked: OKNeeds Repair

Add Change

Oil level and leaks

Hydraulic oil level and leaks

Anti-freeze level and leaks

Fuel level and leaks

Emergency Supplies: OKNeeds

Restocking

First-aid kitRepaired by:

Checked by:

12 April/MAy 2015

At GENCOR, we’re always thinking ahead. Two generations ahead, in fact.

We’ve led the industry since 1894. from our development of the first transportable

hot-mix batch plant over 100 years ago, to the clean, quiet, efficient Ultraplant

that’s earned numerous environmental awards. That’s the kind of innovative

thinking you can continue to count on, for generations to come.

Call 407.290.6000 or visit www.gencor.com.

GENCOR_AsphaltPro_V1.indd 1 10/21/14 12:27 PM

project management

Design Drainage from the Base UpBy hAWAii AsphAlt pAVeMent AssOCiAtiOn (hApi)

Figure 1. subsurface drainage example

Proper drainage is important to ensure a high quality, long-lived pavement. Pavement engineers understand that moisture accumulation in any pavement structural layer

can cause problems. In the subgrade and aggregate base layer, it can weaken materials by increasing pore pressure and reducing the materials’ resistance to shear. Additionally, some soils ex-pand when moist, causing differential heaving. We all know what happens when moisture gets into hot mix asphalt (HMA) layers. To prevent moisture such as rainwater, runoff and high ground-water from entering the pavement structure or accumulating in the subgrade, we turn to surface drainage and subsurface drain-age. It is usually more cost-effective to prevent moisture entry and accumulation using surface drainage than to remove it from the subsurface. Let’s look at how to construct both.

Surface DrainageSurface drainage is concerned with removing all water that is present on the pavement surface, shoulder surface or any oth-er surface from which it may flow onto the pavement. If not sys-tematically removed, this water can accumulate underneath and weaken the pavement structure. There are three primary means used to prevent water infiltration and accumulation:• Impermeable HMA. HMA tends to be impermeable below

about8percentairvoids,thereforepropercompactionprac-tices should be followed to ensure an impermeable pavement. Also, minor cracks in the HMA should be sealed.

• Slope.Thepavementsectionshouldbeslopedtoallowrain-water to flow quickly to the edge where it is typically collected in a curb and gutter system or a roadside ditch. A generally ac-ceptedstandardisa2percentcrossslope.

• Grade.Thecurbandgutterorroadsideditchmustbeproperlygraded to allow flow to central collection points such as catch basins or detention ponds. A generally accepted standard is a grade of 0.5 percent or more although lesser grades have been used effectively.

Subsurface DrainageSubsurface drainage is concerned with removing water that per-colates through to, or is contained in, the underlying subgrade. This water, typically the result of a high water table or exception-ally wet weather, can accumulate under the pavement structure by two chief means:• Gravityflow.Waterfromsurroundingareascanbeabsorbed

by the soil, and then flow by gravity to areas underneath the pavement structure. In pavement with high are voids—above 8to9percent—watercanpercolatedownthroughthepave-ment structure itself.

• Capillaryrise.Capillaryriseistheriseinaliquidabovethelev-el of zero pressure due to a net upward force produced by the attraction of the water molecules to a solid surface, such as the soil.Capillaryrisecanbesubstantial—upto20feetormore.

In general, the smaller the soil grain size, the greater the po-tential for capillary rise. Often, capillary rise is a problem in ar-eas of high groundwater tables.

prevent problemsMost pavements have performed adequately without considering these effects; however, HMA pavements can fail if the subgrade deteriorates as a result of excessive moisture or other water-relat-ed problems. These issues can be addressed in two manners:1. Minimize water infiltration into the pavement structure. In

most cases, the accumulated water in the underlying subgrade that causes the damage comes from surface infiltration. This infiltration can be minimized by providing proper roadside drainage and minimizing air voids within the HMA.

2.Providesubsurfacedrainage.Thisneedstobedonejudicious-ly, because it may be somewhat akin to treating the symptom rather than the problem. Subsurface drainage consists of three basic elements (see Figure 1). Those elements appear below.

Element 1. A permeable base to provide for rapid removal of water that enters the pavement structure. Based on research from California, permeable base layers may strip and become clogged with fines thus weakening the overall pavement struc-ture. If unbound, they may also be less stable than a dense-grad-ed aggregate.

Element 2.Amethodof conveying the removedwater awayfrom the pavement structure. At the least, this may consist of a base sloped toward a drainage ditch. At the most, this may con-sist of a pipe collector system.

Element 3. A filter layer (such as a geotextile, graded aggregate layer or ACB*) to prevent the migration of fines into the perme-able base from the subgrade, subbase or shoulder base material. Excess fines in the permeable base will clog its drainage routes and render it ineffective. Depending upon the subgrade and pavement structure a filter layer may not be used.

Article from the HAPI Asphalt Pavement Guide used with permission.

*ACB = Hot mix asphalt base course of dense-graded HMA primarily used for binder and base courses in Hawaii. The nominal maximum aggregate size is 1 inch; compacted lift thicknesses should be between 2.5 and 6 inches. AC content ranges from 3.8 to 5.7 percent by total weight of mix.

14 April/MAy 2015

®

16 April/MAy 2015

Producers in and around Coolidge, Ariz., know that Western Emul-sions, Inc., in Pinal County began

operationof a$17millionasphalt storageand distribution terminal about five years ago. The company uses the facility to man-age its supply of raw asphalt base stocks for its own emulsion products and has part-nered with paving grade asphalt manufac-turers to manage product distribution.

The effect on Pinal’s economy has been positive. The new terminal provides 50,000 tons of asphalt storage capacity. Western Emulsions footed the $3 million invoice to construct supporting rail spur and switch-ing infrastructure to facilitate the long haul shipment of asphalt via commercial rail. That rail infrastructure has led to addition-al development in Coolidge surrounding the new terminal. Money magazine took noteandrankedPinal#1among25countiesfor job growth and one of the fastest grow-ing in the nation. Employment growth con-tinues there, but let’s zero in on Western Emulsions and what that company is doing for its air quality and bottom line now that capacity is climbing.

To provide heat for the terminal’s as-phalt storage capacity, Western Emulsions installed a terminal heating system that was designed and built by CEI Enterpris-es, Albuquerque, N.M. The system is com-

prised of two 6.3 million BTU/hour hot oil heaters, a 3,000-gallon expansion tank that is shared between them, and the asso-ciated piping, pumps and controls.

The burners on the heaters are designed to use either LP or natural gas fuels. This provides Western Emulsions the flexibil-ity to alternate between fuels to adapt to fluctuating prices and to reduce expenses overall.

John Miller is the terminal manager at Western Emulsions, and said, “Five years into our terminal operation, we’ve found the heating system to be very reliable, and have had no major operational issues with the heaters. We’ve been pleased with the fuel efficiency of the system. The hot oil system works in conjunction with two steam boilers. Fuel costs are spread out among all the units.”

Another factor in reducing fuel expense is to reduce fuel use. That means getting as much efficiency out of the heating sys-tem as you can. With that in mind, CEI engineers designed the Jacketed Firebox hot oil heater with a two-stage heat trans-fer system. In the system, heat transfer oil gains heat from the burner flame as the oil circulates around the firebox and from the burner’s hot exhaust gases via the shell-and-tube heat exchanger that is part of the exhaust system.

Air quality, Bottom line and Capacity overall drive decisions for Western emulsions

By MiChAel MAddOx And sAndy lender

Upgrade YoUr a, B, Cs

Upgrade YoUr a, B, Cs

www.theAsphAltpro.coM 17

Western Emulsions also chose the bolt-in stack heat exchanger for both of their heaters. This places a second heat ex-changer in the exhaust flow of each heat-er, boosting thermal efficiency by another 5 percent. This arrangement transfers as much heat as possible to the heat trans-fer oil, thus reducing the workload on the burner, which in turn reduces fuel use.

According to CEI’s parts and service manager, Stuart Baker, heater emissions are directly affected by burner tuning. This is part of regular maintenance, and involves a qualified technician adjust-ing the burner’s fuel-to-air ratio based on flue gas analysis and ambient temper-ature. Baker describes it like this: “The service technician will insert a flue gas

analyzer into the heater’s exhaust stack. This analyzer will show the precise com-position of the exhaust gas…and in how many parts per million. This information allows the technician to adjust the burner for optimal combustion and the cleanest possible emissions.

“The variable in all this analysis and ad-justment is ambient temperature,” Bak-er added. “Ambient temperature affects

the combustion air going into the burner. That, in turn, affects the content of the emissions. In other words, a burner that is properly tuned on an afternoon when it’s 80 degrees outsidewill performdif-ferently when the ambient temperature drops at night.

“Obviously, it would be cost-prohibitive for a technician to remain onsite and con-tinuously tune the burner day and night, all year long. However, new technology is available that essentially does that very thing.” The new technology Baker refers to is the Fireye Nexus PPC 4000 system, which uses an O2 sensor in the exhauststack to feed flue gas analysis informa-tion in real time to a digital controller.

“obViously, it would be cost-prohibitiVe for A

techNiciAN to reMAiN oNsite ANd coNtiNuously tuNe the

burNer dAy ANd Night, All yeAr loNg.”—stuArt bAker

Management at Western emulsions installed the terminal about five years ago. since then they have seen economic benefits for themselves and the surrounding pinal County.

18 April/MAy 2015

When Astec parts salesman GREG PAINTER is not calling on customers to support their parts needs, you can find him on the water fishing or in the woods hunting. But when you call, he’ll trade that fishing hat for a hard hat, because he is always your parts man.

THE FACES OF ASTEC PARTS

An ASTEC parts salesman knows that being successful in his job means that you count on him to deliver when needed. So when you need a part, he will take the call because no matter what else he is, he is always your parts man.

Anyone can stock parts and ASTEC stocks the world’s largest inventory of parts for asphalt plants. But ASTEC doesn’t just stock parts. ASTEC delivers the industry’s best customer service. That is what sets us apart.

Any part, any brand. We can help.

Greg Parts Ad AP_copy rev.indd 1 10/10/14 11:02 AM

As the owners, operators and key management personnel of the nation’s asphalt plants and facilities,

you might be wondering why a Washington, D.C.-based advocacy trade association executive is writing a column in AsphaltPro and if it’s even relevant to the work you do.

Considering$85billionisinvestedan-nually in highway and bridge construc-tion by all levels of government, it rep-resents a huge market for the asphalt in-dustry. This fact alone should tell you why spending decisions in the Nation’s Capital have an impact on the livelihood of all employees working in asphalt plant operations.

The federal Highway Trust Fund (HTF) is thesourceof52percentofallhighway and bridge capital investments

made annually by state governments. Unless Congress acts to replenish the fund by May 31, America’s surface trans-portation investment programs will come to a grinding halt. Such a scenario would have a devastating impact on the U.S. economy, the motoring public and everyone involved in the transportation infrastructure community.

The American Road & Transporta-tion Builders Association (ARTBA) and our coalition allies like the National As-phalt Pavement Association are working aggressively to help ensure that Con-gress fixes the ailing HTF and passes a robustly-financed, multi-year highway and transit investment bill. However, in order to create the necessary political pressure, members of Congress need to

hear from the grassroots back home—that means you! As a constituent, you have a power no Washington lobbyist or organization has. You vote…so they will listen to what you have to say.

In the near future, invite your con-gressmen and senators to come to your plant headquarters. When they get there, tell them your story in personal terms. Explain how critical strong feder-al transportation investment is to your ability to keep workers and hire new ones. Share the many economic bene-fits to your community that come from building transportation systems.

More immediately, however, we en-courage you to use the toll-free ART-BAActionHotlineat (888)448-2782 toconnect directly with your members of Congress. Deliver this simple message: “Congressman/Senator, it’s time to find a permanent funding solution for the Highway Trust Fund so we can continue to build a better America.”

If you want to stay on top of oth-er transportation developments from Washington that impact your business operations, download the TransCon Ad-vocate™ app to your mobile phone. It contains state-specific transportation information and talking points. You, your co-workers, colleagues and friends are facing an imperative where you can make a real difference. Act now, so we can grow and protect your market for the future.

Pete Ruane is the president and CEO of the American Road & Transportation Builders Association. For more information or assistance, contact a member of ART-BA’s government relations team at (202) 289-4434.

By pete ruAne

imminent political Decisions in washington could have Major impacts on your livelihood for years to come

We can’t keep putting Band-Aids™ on bridges and roadways, or on the nation’s highway infrastructure funding. We must all tell our representatives: “it’s time to find a permanent funding solution for the highway trust Fund so we can continue to build a better America.”

20 April/MAy 2015

a Tale of Two additives By sAndy lender

22 April/MAy 2015

Let’s start with the obvious: not all additives do the same thing. Even when injected mid-stream to an asphalt pavement mix to create warm-

mix asphalt (WMA), different additives do different things. They’re not necessarily bringing temperatures down. That’s not what they’re created to do; that’s not what they’re doing. Various additives used to create WMA bind elements or foam asphalt cement, or per-form another chemical or mechanical reaction to effect a change on the behavior of the binder with the aggre-gate. The end result means your plant operator can run the procedure at a lower temperature, and you can real-ize all the benefits thereof.

Focus on two additives in particular. I’ve selected these two based completely on the kind availability of the two companies represented. In alphabetical order:

Evotherm 3GEvotherm® WMA technology from MeadWestvaco Corporation, North Charleston, S.C., is manufactured in Charleston and available around the world to pro-mote adhesion of mix elements. In simple terms, the Evotherm WMA is a liquid that you inject into the binder stream. The Evotherm then creates a chemical reaction between the aggregate and the binder in the asphalt mix. Think of this chemical reaction as forever, all-over attraction that the manufacturer calls “com-paction insurance.”

Ben Bredenkamp explained that Evotherm creates its own chemical reaction in place of the thermal reaction that happens in the typical HMA process. Once Evo-therm is mixed into the binder, either at the terminal or asphalt plant, the plant operator can lower the produc-tion temperature and still see full coating of aggregate because of this chemical reaction.

Among the low-temperature benefits of WMA that plant operators have read repeatedly in this and oth-er publications, Bredenkamp discussed the compac-tion benefits this additive offers. “Evotherm lengthens the compaction window,” he explained. What happens with the liquid additive is a chemical reaction that al-lows the asphalt binder to adhere to the aggregate ful-ly at lower production temperatures than previously used. The lower production temperature equates to a lower paving temperature in the field, which gives the roller operators a longer window to achieve density behind the screed.

FOrTA-FiFORTA-FI represents three fiber reinforcement blends thatForta®Corporation,GroveCity,Pa.,formulatedtoreinforce HMA, WMA and hot/cold patch, respectively. Each of the three products is a proprietary blend that contains aramid and polyolefin fibers of ¾-inch length and other inert materials to provide reinforcement to the asphalt mix. Their purpose is to enhance the cur-rent mix designs.

the first load of asphalt binder with evotherm 3G left the terminal in Owensboro headed for scotty’s Contracting asphalt plant. the 70-Corvette escort made an impressive scene traveling William t. hatcher pkwy to the plant in Bowling Green.a Tale of Two

additives By sAndy lender

www.theAsphAltpro.coM 23

At this time, Lane Construction Corpo-ration in Bridgeville, Pa., is a certified pro-ducer of the fiber blends. The fibers have been used on projects in 14 states and 5 other countries. In the test of the fibers at Evergreen Drive at Arizona State Uni-versity, researchers found, “The flexural strength and corrected flexural strength areincreasedby14%and25%respectivelywith the addition of the 1 lb/Ton dosage of the FORTA-FI blend. While various ratios of materials in the FORTA-FI blend were tested to determine the optimum mixture across a wide range of applications, it was determined that the 1 lb/Ton dosage of

the FORTA-FI blend would be best, or op-timum, in terms of flexural properties.”

Another parameter that proved the fi-bers’ mettle in the ASU study was the per-manent deformation testing. From the study’s authors: “Two important char-acteristics were observed for the FOR-TA-FI mixture when compared to the control mixture. One was the endurance of the secondary stage, and the second was gradual/less accumulation of per-manent strain. Both were attributed to the presence of the reinforcing fibers in the mixture, as this behavior is not typi-cally observed in conventional mixtures. The fiber-reinforced mixture had higher

Flow Time values than the control mix-ture(over900%higher),and700%low-er slope values. These indicate that the FORTA-FI mixture has a much higher po-tential to resist permanent deformation than the control mixture.”

This study with other information For-ta Corp has gathered in the field shows a family of fiber-based additives that offer a strengthening property to asphalt mix design. Regional salesman Scott Nazar shared that this property is an ideal offer-ing for those breaking into the Thinlay® market. “It’s a no-brainer,” Nazar said. “The thinner lifts that asphalt profes-sionals are being asked to put down can

herink s.r.o. produced an ACO 11 s 50/70 mix with FOrtA-Fi hMA fibers introduced at a rate of 0.5 kg per ton for the wearing course of the Vaclav havel Airport project in prague. they placed 40 mm on 7,000 square meters for taxiway e and 50 mm on 1,500 square meters of taxiway A. the mix with FOrtA-Fi was also used for repairs on the side of the strips. riGht: scotty’s Contracting created a pG92-28 mix with evotherm 3G to pave the nation-al Corvette Musuem performance track. the racing industry requires a 165 softening point. it’s a highly polymer-modified material.

Crack propagation test is represented by Where du* equals the change in energy rate for a load p and a crack extension dC, and B equals thickness

1du* BdC

C* =

24 April/MAy 2015

have this added strength to hold up lon-ger and resist reflective cracking if the let-ting agency doesn’t allow a mill, profile or crack-stabilizing process for the underly-ing pavement beforehand.”

The resistance to cracking that Na-zar mentions was also proved in the ASU study with crack propagation testing. From the study’s authors: “After the re-lationships between crack growth rates as well as slopes of crack growth rates for the 1 lb/Ton dosage of FORTA-FI mixture and the control mixture were developed, it was noted that the fiber-reinforced mixture had higher C* and slope values than the control mixture. This means that

the fiber-reinforced asphalt mixture has a higher potential to resist crack propaga-tion because of the reinforcement effect provided by the reinforcing fibers.”

it’s All About that FWhether we’re discussing cracking po-tential or strength, temperature plays a role in the evaluation of an additive’s ben-efits. How high does a temperature have to go to melt recycled material or how low can a temperature go and still get all the rocks coated with bitumen?

The ASU study authors wrote: “The vis-cosity-temperature susceptibility rela-

tionship at lower temperatures showed no changes from virgin binder, which is positive and desirable, but at high tem-peratures, improved properties were observed to have higher viscosities. The modified binder is far less suscep-tible to viscosity change with increased temperatures...”

With the liquid additive Evotherm functioning as an anti-strip and adhe-sion-promoter, it allows lower produc-tion temperatures for asphalt mixes. That in turn allows longer cooling time behind the screed during which the rolling team can achieve bonus-worthy densities.

www.theAsphAltpro.coM 25

By MiKe BJOrKMAn

Air quality, Bottom line and Capacity overall drive decisions for Western emulsions

Slurry PumP makeS light Work of Drilling muD

“Mud” serves a number of important functions during drilling: it lubricates and cools the drill bit, thereby extending its life; it transports rock fragments, known as cuttings, to the surface; it prevents the wellbore from caving in before the casing is inserted; and it prevents the oil or gas from entering the well before it’s complete. ideally and increasingly, the fluid creating the mud is recycled during drilling. some of the clients of West texas premix pits (Wtpp) needed to recirculate and reuse their drilling mud and tried out the KZn series pumps to do it.

28 April/MAy 2015

According to the U.S. Energy Information Administration (EIA), oil and gas produc-tionintheUnitedStatesinAugust2014was

at its highest volume since 1986. Oilfield rigs areoften located in remote areas. Although the rug-ged terrain may be barren, the site still has to be prepared to accommodate the rig and all of the re-quired equipment, hundreds of feet of pipe, and one or more pits for drilling mud and other fluids. Before drilling can begin, the site must be cleared and leveled and in some cases access roads need to be built. A source of water is also required, which may mean drilling a water well, and one or more pits are dug and lined.

Fluids play an integral role in oil and gas explo-ration and production. When a new well is drilled, some form of fluid is needed. The base of this drill-ing fluid, or mud, can be freshwater or saltwater (brine) or it may be an oil- or synthetic-based liq-uid. The type of fluid and the additives used are de-termined in part based on the composition of the rock being drilled into. Cost and environmental impact are also considerations. The mud may also be modified as drilling progresses and the under-ground environment changes.

Ideally and increasingly, this fluid is recycled during drilling. To facilitate reuse, cuttings are al-lowed to settle out in a pit and the resulting liquid is pumped back to the wellbore.

Water is often a natural byproduct of the drilling and production process. Water may be trapped un-derground along with the oil and gas. Sometimes this produced water is incorporated and used in the drilling process.

This simple overview illustrates the fact that drill-ing a new well is a complicated process with many moving parts. A variety of providers are necessary at different times to deliver their unique services until a well is completed. Not surprisingly, moving all of this liquid requires pumps. United Rentals – Pump Solutions is a large equipment rental provider that helped West Texas Premix Pits (WTPP) of Midland, Texas, with those moving parts.

WTPP manufactures and sells premix pits, trash pumps and safety showers to oil and gas drillers in the Midland-Odessa area. Some of its clients need-ed to pump and recirculate spent drilling mud. Ian Walker, sales representative for United Rentals, rec-ommended BJM Pumps’ KZN series heavy duty sub-mersible pump.

Among other things, WTPP installs and maintains the reserve pits used during oil exploration. The pits areroughly1-acrepondsthatholdfrom2to10feetof drilling fluid that can be from brine or freshwater. The mud coming up out of the hole with the cuttings is deposited into one side of the pit and allowed to settle out, and the fluid that’s reused is pumped out of the other side of the pit. Although using a conven-tional pit configuration, WTPP is trying something new with its pumps. It’s floating the pumps on top of the liquid in the pit. WTPP builds specialized bas-kets to hold the pumps so they’re sitting in just 6 to 8inchesofwater.

“It helps the drilling rig pick up cleaner fluid be-cause the pumps are taking fluid off the top,” Danny Freeman, owner of WTPP said. “As the stuff settles out they have cleaner drilling fluid, and that results in faster drilling.”

WTPP initially rented BJM’s KZN series pumps from United Rental, but after the pumps proved their worth, Freeman decided to buy. “They were great pumps so we stuck with them,” Freeman said.

Although WTPP’s floating configuration has min-imized the pumps’ exposure to solids, the oilfield environment still presents challenges, particularly if the water is brine. “Saltwater is hard on anything,” Freeman said. “I have customers flush the pump on a regular basis to keep it from getting corroded.”

As a result of the success they’ve had with the KZN pumps over the past two years, WTPP now oper-ates 11 of the pumps in various oilfield installations across West Texas.

Mike Bjorkman is the vice president of BJM Corp., Old Saybrook, Conn. For more information, contact him at (860) 399-5937.

tough puMpsAlthough not maintenance-free, KZn series pumps are rugged enough to provide long-term operation in harsh drilling environments, including those where the pumps have to handle a great percentage of solids, according to the manufacturer. some of the characteristics that set the KZn series apart from other pumps include:• weAr resistANce: All wetted parts are constructed

of abrasive-resistant 28 percent chrome iron (600 Brinell, 71 rockwell C). in addition, a replaceable hardened wear plate is located on the suction side.

• solids hANdliNg cApAbility: An integral agitator fluidizes settled solids into a slurry, making them easier

to pump with less chance of clogging. the semi-open impeller handles abrasive solid concentrations as high as 70 percent by weight.the KZn series pumps feature Class h motor insulation

and built in amperage ( FlA ) and temperature overload protection; double silicon carbide mechanical seals in a separate oil filled seal chamber; a heavy duty lip seal to provide additional protection for the mechanical seals; stainless steel shaft and shaft sleeve; pump volutes cast from hardened ductile iron (300 Brinell hardness), which is twice as abrasive-resistant as standard ductile iron with walls that are extra thick at the point where pumped slurry enters the discharge.

www.theAsphAltpro.coM 29

How to avoid emulsion SoupBy sAndy lender

30 April/MAy 2015

WWith the success of five test sections incorporating comparison tack ma-terials and rates for bonding research

at the National Center for Asphalt Technology (NCAT) Pavement Test Track in Auburn, Ala., contractors are likely to see an uptick in the call for tack between pavement layers. From emulsion-based products you’ll ideally want to spray during daylight hours for best chance of break to trackless tacks that incorporate low penetration asphalt binder, the products available perform their best when shot with best practices. We’ve covered the routine care and maintenance of the tack truck in the Keep It Up department recently; now let’s take a look at the truck’s use in different situations to avoid a tacky mess.

The National Cooperative Highway Research Program (NCHRP) Report 712: Optimization of Tack Coat for HMA Placement suggests that if you have an older, highly oxidized pavement, the sur-face may require a higher rate of tack application. This makes sense. Consider what happens to a 15-year-old asphalt road that’s never seen pre-ventive maintenance. If a community decides to add a protective sealcoat to the pavement, de-pending on the level of oxidation the roadway sucks in that first coat of sealer. A second coat is vital to providing a good seal of microscopic voids. The same holds true when shooting tack for a good bond. You’re not out to make emulsion soup, but you want a coat of material that doesn’t immediately get absorbed, leaving only traces of adhesiveness behind.

The Florida Department of Transportation (FDOT) specifies tack will be sprayed only when ambient temperatures are at 40 degrees F and ris-ing, but it has different rates of application de-pending on the age/oxidation and type of pave-ment to be sprayed. In the state of Florida, you’re more apt to find a pavement made of an open-graded friction course (OGFC) than you are inMinnesota. When the underlying pavement sur-faceisanewlyconstructedOGFC,thetargettackrate is 0.05 gallons per square yard (gal/yd2), give or take 0.01 gal/yd2.Whenit’samilledOGFC,thetargettackrateis0.07gal/yd2.

Not every pavement in Florida is open-graded, so the DOT has other application rate guidelines. For example, if the underlying pavement surface is newly constructed base course, structural course or dense-graded friction course, the target tack rate is 0.03 gal/yd2. If the underlying pavement surface is a milled surface or oxidized and cracked, the target tack rate is 0.06 gal/yd2. The state also recommends a target tack rate of 0.08 gal/yd2 when shooting on a concrete pavement, but this editor’s opinion is that gray mess probably needs to be milled off and replaced.*1

Next look at Michigan (MDOT) specs for tack shooting. Ambient temperatures there must be 60 degrees F and rising, and the rate of application is fairly uniform at 0.05 to 0.15 gal/yd2 for the prod-ucts it approves. The differentiation comes in the guidance for product temperature. For example, MDOTSpecP-603requiresaproducttempof75to 130 degrees for Emulsified Asphalt SS-1h and Emulsified Asphalt CSS-1h; and a product temp of 120to160degreesforCutbackAsphaltRC-70.*2

“Each state has its own spec,” John Ball said. He’s the proprietor of Top Quality Paving, Man-chester, N.H., and regularly consults with contrac-tors to help them get tack coverage right. What he pointed out is not every contractor is follow-ing a state spec for a state job. When you’re work-ing on a commercial or county project, you have to do your own homework and quality control. “You follow the tack manufacturer’s guidelines for am-bient and product temperatures. If the ambient temperature is too cold, the tack coating will cool too fast and the emulsion won’t break. The ground temperature matters.”

What Ball’s referencing is the second law of thermodynamics. The hot tack will transfer its heat to the relatively cooler surface pavement—and to the air above—because it must. It’s the law.

“When we talk about heat transfer, the hotter mass is giving some of its heat to the cooler mass,” Bruce Wilson, O’Fallon, Mo., explained. He’s on the board of the American National Standards In-stitute and wrote the book on Design Dimension-ing and Tolerancing used in college engineering courses around the United States. “We say that the hotter mass is becoming cooler by transferring some of its heat. In a perfect world, the two materi-als would eventually reach the same temperature and be in a state of equilibrium.”

“When it comes to the product temperature, typically you’re looking at 120degrees for emul-sion-based products,” Ball said. “There’s water in these products that has to evaporate off so it be-comes adhesive. For asphalt-based products in a statelikeGeorgia,you’relookingattemperaturesof 400 degrees.”

Your tack truck driver doesn’t have to under-stand the laws of thermodynamics, but he does have to know when his product is ready to spray. Depending on the equipment you use, there will be a number of thermometers located in differ-ent places on the truck and tank. “There’s a dial on the outside of the tank that measures from zero to 300 to give the reading of the inside of the tank,” Ball said. “A glass stick thermometer goes inside through the manhole on top or through a port on the side to measure the material temperature.”

The Etnyre Centennial II tack truck pictured at right gives temperature readings in the control

the thermometer on the driv-er’s side of the tank of the et-nyre Centennial ii tack truck can unscrew and come out. product must be half-way up the tank for the thermometer to get a reading on the actual material temperature.

www.theAsphAltpro.coM 31

panel on the driver’s side, back of the tank. Brian Horner shared that the Centennial II has a temperature sensor located between the jacketing and the tank. It sends the tem-perature information to the control pan-el where the operator can read it, but what seems more important is the burner con-trols “sense” off the thermometer on the belly. The instructions posted right on the equipment state the operator is not to light the lower burner if the material within the

tank is less than 650 gallons and not to light the upper burner if the material in the tank is less than 900 gallons, no matter what the temperature sensor is reading. Just a quick glance to the large dial on the left side of the back end of the tank will let the operator see how much product he has—it has a range of 64to2,000U.S.gallons.

With temperatures and application rates in mind, there are some basic best practic-es that the authors of the NCHRP Report

712discoveredduringtheirexperiments.Atthis time, many state DOTs have adopted these practices/ideas. Here are some tips to make these ideas work for you.*3

1. Dusty conditions will negatively af-fect your tack adhesion. Clean and sweep the existing pavement surface. The Michigan DOT directs contrac-tors, “Immediately before applying the tack coat, the full width of sur-face to be treated shall be swept with a power broom and/or airblast to re-move all loose dirt and other objec-tionable material.”

2.Water will negatively affect the bond-ing interface. Clean and dry the exist-ing pavement surface. For materials that require dilution with water, Mich-igan DOT spells out its expected prac-tice. “Emulsified asphalt shall be dilut-ed by the addition of water when direct-ed by the Engineer and shall be applied a sufficient time in advance of the pav-er to ensure that all water has evaporat-ed before any of the overlying mixture is placed on the tacked surface.” Buzz Powell of NCAT reminds readers that many states have put a stop to the dilu-tion of emulsified tack.

3. A milled surface provides a better/stron-ger interface than a smooth surface. Con-sider mill-and-fills rather than merely tacking and paving a thin layer on exist-ing surfaces.

4. For the tack products tested in the NCHRP research, each one reached its optimum ISS at a peak temperature, and then began to lose efficiency as the temperature continued to increase. Watch your product’s recommended temperature range(s) and stay within that range during application.

*1 Source: dot.state.fl.us*2 Source: Michigan.gov*3 Ideas 1 through 4 sourced from: Button, Joe;

Elseifi, Mostafa A; Scherocman, James A; Mohammad, Louay N; Bae, Abraham; Pa-tel, Nachiketa. Transportation Research Board "Summary ." NCHRP Report 712: Optimization of Tack Coat for HMA Place-ment. Washington, DC: The National Academies Press, 2012.

For more information, contact Libra Systems via email ([email protected]) or phone (215.256.1700)

Are your ticket delivery methods stuck in the past?Consider the efficiencies of keeping the driver in the truck and delivering tickets electronically!

LIBRA REMOTE PRINTER TERMINALS

Printer• Document presenter holds

ticket for driver and retracts it into an internal box if not taken

• Loop print presenter ensures jam-free operation by

eliminating user access to the document while it is printing

• Best reliability of print head, cutter and presenter (2x to 10x over other thermal printers)

• Handles 3” or 4” wide paper and various paper thicknesses

• Highest-speed printing

• Exceptional print quality

Enclosure• Industrial enclosure designed to house

printer and paper roll

• Heat shield keeps printer cool in direct sun

• Internal heater keeps printer warm in freezing climate

• Motion-activated light illuminates when enclosure is opened

Experience the Advantages:

be AwAre of the differeNce:Tack coat = adhesive bond between layersprime coat = a protective layer on top

32 April/MAy 2015

R

C

M

Y

CM

MY

CY

CMY

K

Cat_Com_Paving_Site_2012326154819.pdf 1 3/26/12 6:02 PM

facebook.com/CATPaving

youtube.com/CATPaving

QEXC1879© 2015 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow,” the “Power Edge” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

70 kW integrated generator saves time and fuel.

• 15minutescreedplateheating• 15,000hourservicelife• Systemmonitoringkeepsoperatorinformed

Learn more at www.cat.com/paving

THE NEW STANDARD

CAT® F-SERiES pAvERS

QEXC1879 New Standard F-Series Generator.indd 1 2/16/15 9:49 AM

LISTEN TO OUR CUSTOMERS NOT OUR COMPETITORS

For 40 years and counting, ADM has been committed to producing quality, high-production asphalt plants. On top of that, we take great pride in delivering an unmatched level of service before, during and after the sale.

At the end of the day, our plants speak for themselves. But we certainly appreciate that our customers have so many good things to say. They’re the ones we listen to, and we think you should, too.

VISIT WWW.ADMASPHALTPLANTS.COM

“I had an ADM plant in my former business and had tremendous success with it. I really saw no reason to look elsewhere. That’s why we went with the new EX plant. We knew we could depend on ADM’s engineering expertise to help make our project a success.”

- Steve Bevilacqua President/Owner Bevilacqua Asphalt

Scan to read more about Bevilacqua’s

experience.

BEVILACQUA ASPHALT EX SERIES PLANT Uxbridge, MA Commissioned: 2013 Production: 300 TPH

LISTEN TO OUR CUSTOMERS NOT OUR COMPETITORS

For 40 years and counting, ADM has been committed to producing quality, high-production asphalt plants. On top of that, we take great pride in delivering an unmatched level of service before, during and after the sale.

At the end of the day, our plants speak for themselves. But we certainly appreciate that our customers have so many good things to say. They’re the ones we listen to, and we think you should, too.

VISIT WWW.ADMASPHALTPLANTS.COM

“I had an ADM plant in my former business and had tremendous success with it. I really saw no reason to look elsewhere. That’s why we went with the new EX plant. We knew we could depend on ADM’s engineering expertise to help make our project a success.”

- Steve Bevilacqua President/Owner Bevilacqua Asphalt

Scan to read more about Bevilacqua’s

experience.

BEVILACQUA ASPHALT EX SERIES PLANT Uxbridge, MA Commissioned: 2013 Production: 300 TPH

36 April/MAy 2015

Innovations Headlined World of Asphalt/AGG1Given the record-breaking number

of exhibitors and amount of ex-hibit space sold for the 2015 co-

locatedWorldofAsphaltandAGG1trade-shows, it’s hard to imagine anyone giving a realistic wrap-up of the event(s). The good news is AsphaltPro staff had three people walking the floor, taking notes and gathering information for the folks who couldn’t get to BaltimoreMarch 17through 19. Here’s what you missed if you

didn’t get to the show, and some things you might have missed even if you did get to the show.

the stats:Record registered attendance totaled more than 7,600. Registrants came from all 50states, 9 of the 10 Canadian provinces and more than 50 other countries.

Both shows set exhibitor and exhibit space records for a total 450 vendors taking

more than 135,000 net square feet to show off the latest technologies and products.

Attendees purchased 10,000-plus ed-ucation session tickets for the shows’ learning programs.

Nearly 30 industry-related associations and groups worldwide were official show supporters.

Co-located events included the Mary-land Asphalt Association annual confer-ence, Northeast Asphalt User/Producer

leFt: Ben Brock (at left) and norm smith (at right) of Astec industries, inc., Chattanooga, posed with the giant highway Bill character that Astec sponsored for the show. the char-acter walked the aisles of the show to remind attendees and exhibitors alike that we have a responsibility to contact our elected representatives about long-term transportation legis-lation. photo courtesy Astec industries. ABOVe: nick howell of t&n Asphalt services, inc., salt lake City, utah, shared his knowledge of the Crafco crack filling machine.

By sAndy lender

www.theAsphAltpro.coM 37

Groupexecutiveboardandsteeringcom-mittee meetings, and the American Road & Transportation Builders Association Safety in the Work Zone conference.

plantsBefore the shows opened, producers could attend the Beyond Compliance: Environ-mental, Health & Safety Conference. It is designed to give companies some help in developing a safety culture in their compa-nies. Asphalt plants and paving crews have unique requirements. The EH&S confer-ence’s purpose each year is to highlight is-sues of concern for the asphalt industry, at both plants and paving sites.

“This is the only conference to focus exclusively on issues related to environ-ment, health, and safety at asphalt plants and paving sites,” Howard Marks said. He’s the vice president for environment, health and safety at the National Asphalt Pavement Association (NAPA). One of the topics discussed at the conference this year was that of safety data sheets for asphalt pavement mix, which will be re-quiredasofJune1,2015.

In the March issue of AsphaltPro, we re-ported that NAPA would provide an SDS template; however, NAPA recently con-cluded that having asphalt pavement mix producers contract with a third party SDS vendor directly would be most credible. NAPA has identified Experien Health Sci-ences, which you can visit at www.expe-rienhealthsciences.com, as one SDS au-thoring vendor that is already familiar with the industry and able to provide an appro-priate SDS for asphalt pavement mix. In addition, NAPA will work with other SDS authoring vendors that your company may already have a relationship with to ensure an accurate and valid product hazard state-ment on the SDS. The cost and time com-mitment to develop an SDS for typical as-phalt pavement mix is negligible, accord-ing to NAPA, and most of the safety sheets will be “warning” of the potential for hot mix to cause burns, etc.

At the Tarmac booth, Ron Heap shared that he’s seen a sort of consolidation of ideas and technologies in the plant side of the industry. From the options for turn-ing the drum to the types of drums, he sees a lot of “consistency” throughout the marketplace.

roadtec’s rx-600e

Wirtgen’s capture bag

38 April/MAy 2015

Caterpillar’s pM200

Bomag’s rear rotor machine

www.theAsphAltpro.coM 39

At the Stansteel booth, a representa-tive shared one of the consistent trends in the industry: adding goodies to the mix. The Stansteel/Hotmix Parts & Service team offers the Accu-Shear® multi-pur-pose blending system to foam liquid as-phalt cement (AC), and can send a vari-ety of additives through. For example, the company offers the AC Modifier Package, which is a skid containing a custom-de-signed injection additive pump with vari-able speed motor, a mass flow meter with a multi-variable transmitter to calculate flow rate, valving arranged for latex injec-tion and calibration, in-line strainer/filter with screen, and electrical starter panel with a variable frequency drive to control the shear/mill speed and variable speed motor controller for the additive pump. Once this AC modifier system completes its job, the modified AC goes through the Accu-Shear. The company also offers Ad-ditive Metering Assemblies to add Evo-therm, antistrip, chemical additives or other items before sending the modified AC to the Accu-Shear.

These and other innovations dotted the tradeshow floor for asphalt and aggre-gate producers, but paving and pavement maintenance contractors had plenty to check out as well.

paving, compactionBomag Americas, Kewanee, Ill., had the TanGO “oszillation” compaction tech-nology with Economizer intelligent compaction (IC) monitoring on display alongside theCR662RMRoadMixpaver/material transfer vehicle (MTV). You’ll be

seeing more of the RoadMix paver and its technology in months to come. Other re-mixing machines were on the tradeshow floor. At the Roadtec booth, the Shuttle Buggy had a new element that you can learn more about in this month’s Here’s How it Works department. It’s the Road-tec Autotracking Package, which helps the paving crew keep the paver and MTV moving at matching speeds.

One of the big focuses at World of As-phalt this year was behind the paver. Both Volvo Equipment and Atlas Copco intro-duced their IC technologies. The two are similar in that they offer readings to the roller operator to help him or her achieve a smooth finished asphalt surface. They differ in the reading that they give and in the way in which they achieve the read-ings, among some other science. Let’s take a look, alphabetically.

Atlas Copco: The new version of the in-telligent compaction system from Atlas Copco uses a global navigation satellite system to track the number of complet-ed passes and a drum-mounted acceler-ometer to measure the surface’s relative

correctioN: iN the MArch iSSUE OF AsphAltpro,

we reported thAt NApA would proVide AN sds

teMplAte; howeVer, NApA receNtly coNcluded thAt hAViNg AsphAlt pAVeMeNt Mix prODUcErS cOnTrAcT

with A third pArty sds VeNdor directly would be

Most credible.

Members of the successful silica/Asphalt Milling Machine partnership celebrated the decade-long work developing real-world guidance for safest worker environments. photo courtesy Jay hansen, nApA.

40 April/MAy 2015

While you’d never let this contraption near your stockpiles, dust control around other areas of the asphalt plant could become a little more automated with a hi-pressure Air Water Cannon (hAWC) from CW environmental, Carroll, Ohio.

www.theAsphAltpro.coM 41

material stiffness. The system gives op-erators immediate materials stiffness re-sults from within the cab to help mini-mize the number of passes. When using the system on asphalt, it also detects the temperature of asphalt to provide con-sistent, relative stiffness readings. In ad-dition, Atlas Copco’s intelligent compac-tion system helps contractors detect any

loose materials so they can perform addi-tional passes to reach the right compaction. Contractors can use the intuitive system on a tablet to set project parameters and view compaction data. Once they achieve the optimal level of compaction, the program alerts the operator. The data storage also means contractors have the results readily available to print off or display for inspec-

tors. The system is available on Atlas Cop-coCC2200throughCC6200asphaltrollersandCA2500throughCA6500soilrollers.

Volvo: Starting in the fourth quarter of2015,VolvoConstructionEquipmentwill offer the Volvo Intelligent Compac-tion (IC) for select Volvo asphalt com-pactors in two packages—Volvo IC and Volvo IC with Density Direct. In addition

CMi roadbuilding had a small stand with just a couple signs way back at COnexpO-COn/AGG 2014. the company came to World of Asphalt with a life-size asphalt drum that booth visitors could look into from either end.

42 April/MAy 2015

800-826-0223 contact us today! STANSTEEL

Asphalt Plant Productswww.stansteel.com

Interested in used equipment? Go online to find hundreds of listings with photos at: www.stansteelused.com

• Mounted Exhaust Fan on Gooseneck equipped with Twin 150 HP motors & exhaust damper • Stack testing platform and access ladder • 1,008 total Bags & Cages • Inertial Dust Collector • Hopper mounted, twin dust collection augers with cross auger • Triple Axle Chassis with installation support legs to grade • Full perimeter safety handrails around top.

• Nominal 9’-6” Diameter x 45’ long Counterflow • Slinger Belt type material feed conveyor • Later model Hauck Model ESII combination Oil/Gas Burner • Heavy duty stationary frame and legs to grade • RAP entry Collar • Heavy duty twin drive motors and reducers • Trunnion type drive assembly in excellent condition • Later model knockout type primary collector with interconnecting ductwork between Drum and knockout box is included.

Gencor® is a trademark of Gencor® Industries, Inc. and Stansteel is not related to or licensed by Gencor®.

Skid mounted Gencor® transfer oil heat exchanger. The heater’s Power Flame dual fuel burner is designed for operation on #2 Diesel & Natural Gas. The burner is a nominal 2.0 million BTU output and the Oil Circulation Pump is powered by a 10 HP Motor. This Gencor® heater also features an On-Board, Operator Friendly control panel and a “Stackpack” BTU Recovery unit.

GTB-5034 AWS Custom Built Stationary Counter�ow Drum

GTB-5034 HWS Gencor® Transfer Oil Heat Exchanger

GTB-5035 IWS CMI 85,000 ACFM Portable Baghouse

GTB-5035 JWS Burke Stationary Liquid Asphalt Storage TanksTwo Burke 30,000 gallon stationary coiled liquid asphalt storage tanks. These Tanks are mounted on heavy duty full length extended frames. Both tanks are empty, fully insulated, wrapped with a metal skin and in very good condition. Additional features include:• Insulated and Jacketed piping • Ladder to top and catwalk to Interior Inspection Ports • (2) Pre-installed ports with covers for future agitators in each tank • Vent Condenser on each tank