Asphalt Part 1

-

Upload

louise-luy -

Category

Documents

-

view

222 -

download

1

Transcript of Asphalt Part 1

-

8/16/2019 Asphalt Part 1

1/23

SPH LT

• Mineral filler, bituminous material, and bituminous binde

Dela Rosa, Shechani E,Paz, Patrick Renz Y.

-

8/16/2019 Asphalt Part 1

2/23

sphalt

It is a mixture of bitumen and mineral filler.

Typically composed of 5% bitumen cementand 95% aggregates (stone, sand, andgravel).

It is a composite material commonly used tosurface roads, parking lots, and airports.

-

8/16/2019 Asphalt Part 1

3/23

TYPIC L COMPOSITION OF

SPH LT

SandPetroleum (most widely used asphalt mixture)

Mineral FillerBinder

-

8/16/2019 Asphalt Part 1

4/23

MINER L FILLER

• Dust additives that reduces thevoid content in the mixture

• Classifications:

• Limestone (finely powdered)

• Slag

• Hydrated Lime

• Portland Cement

• Trap Rock Dust

• Fly Ash

-

8/16/2019 Asphalt Part 1

5/23

BINDER PROPERTIES

•

Adhesion Bituminous materials adhere to clean dry surfaces

• Viscosity

All bituminous materials are viscous, i.e. when slong term load they deform continuously.

• Softening point

This is the temperature at which the binder softedetermined point.

-

8/16/2019 Asphalt Part 1

6/23

BITUMENS

• It is an oil based substance.

• It is a semi-solid hydrocarbon product proremoving the lighter fractions (such as liquid petrpetrol and diesel) from heavy crude oil during process.

• Softened by high temperature and solvents

-

8/16/2019 Asphalt Part 1

7/23

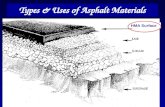

• Used mainly for roadways andparking lots

• Designed to sustain heavy

loads of cars and trucks

BITUMENOUS P VEMENT

Layers: • Base

• Subbase

• Surface Course

-

8/16/2019 Asphalt Part 1

8/23

TYPIC L BITUMENOUS P VEME

-

8/16/2019 Asphalt Part 1

9/23

• Noise reduction

• Surface water dispersal

• Skid resistance

• Easy maintenance reduces traffic disruption• Clearer lane marking with colored asphalts

• Versatile and flexible

BENEFITS OF USING

SPH LT RO D

-

8/16/2019 Asphalt Part 1

10/23

TESTING BINDERS

• Sliding plate viscometer

In this apparatus a thin film of binder is sheared beglass plates and the shearing force is measured.

• Standard tar viscometer

In this test the time taken for a set volume of through an opening at a given temperature is me

-

8/16/2019 Asphalt Part 1

11/23

• Penetration test

For straight bitumens viscosity is normally meas

penetration test. A 1mm diameter needle is loa

weight of 100g and the distance it drops into

sample in 5 seconds is measured (at 25oC). A

referred to as 70 pen if the penetration is 7mm.

TESTING BINDERS

-

8/16/2019 Asphalt Part 1

12/23

• Softening point test

To measure the softening point a small sample is m

in brass ring and cooled and then progressively re-

until it deforms (i.e. "flows") by a given amount.

TESTING BINDERS

-

8/16/2019 Asphalt Part 1

13/23

BINDER MIXTURES

•

Cutbacks

This term is used to describe a mixture of a binder and a lighThey are liquid at low temperatures until the volatile oil evapoto the release of solvents into the atmosphere they are now ra

• Emulsions

When mixed with water binders will generally settle out. An embe added to give a stable solution. Bitumen paints are maThe water evaporates and the bitumen remains on the sucurrent types of cold rolled materials are based on emulsions.

-

8/16/2019 Asphalt Part 1

14/23

FOUR COMPONENTS OF

TYPIC L MIX

• Coarse aggregate (retained on 2.36mm sieve)

• Fine aggregate (passing 2.36mm sieve but reta

• Filler (passing 75), may be cement.

• Binder: Bitumen etc.

-

8/16/2019 Asphalt Part 1

15/23

TESTING BITUMINOUS

MIXTURES

• Penetration test

This test is similar in principle to the penetration testbut on a larger scale. The steel pin is 6.35mm (0.25and the load is 10 N/mm2

• Dissolution of binder

There are a number of BS tests which involve dissolbinder in solvents. The mix proportions and the nabinder may be determined.

-

8/16/2019 Asphalt Part 1

16/23

• Percentage refusal density

This test is used to measure compaction in road coThe density of a core from the road is comparemaximum density achievable using heat acompaction (the refusal density).

• Marshall test

In this test asphalt mixes are made at several different binCylindrical specimens are loaded in compression on surfaces. The maximum load ( stability) and the deformarecorded.

TESTING BITUMINOUS

MIXTURES

-

8/16/2019 Asphalt Part 1

17/23

SPH LT CONCRETE

P VEMENT

• The term Asphalt Concrete refers to a dense graded road made of hot mineral aggregates, mixed with hot asphalt ahigh temperature of about 275F to 300F.

• Asphalt concrete is the highest type of dense bituminous p

suitable for the most heavily traveled roads.

• The thickness of compacted asphalt concrete ranges fromfor lightly traveled road to 6 inches or more for roads wherconsiderably heavy.

-

8/16/2019 Asphalt Part 1

18/23

SURF CING M TERI LS

•

Hot rolled asphaltCoarse aggregate dispersed in a mortar composefiller and bitumen. This is gap graded.

• Asphaltic concrete

Asphalt in which the aggregate particles are c

graded to form an interlocking structure.

• Surface dressing

Sprayed bitumen binder with stone chippings rolleused for repair work.

-

8/16/2019 Asphalt Part 1

19/23

SURF CING M TERI LS

• Slurry surfacing and micro asphalts

Bitumen emulsions with selected aggregate comAlso used for repair.

•Stone mastic asphalt

gap graded asphalt composed of a coarsaggregate skeleton with mastic mortar.

-

8/16/2019 Asphalt Part 1

20/23

BITUMINOUS P VEMENT F ILUR

1. SurfaceFailure

2. BaseFailure

3. BasementFailure

-

8/16/2019 Asphalt Part 1

21/23

BITUMINOUS P VEMENT

F ILURE

• caused by excessive load. Heavy load creates defon the road surface, with insufficient underlying stre

• Elastic deformations in the sub-grade penetrate to

of 6.00 meters although mostly to a depth from the

-

8/16/2019 Asphalt Part 1

22/23

F ILURE MECH NISMS

• Wearing course• Rutting (shear failure)

• Potholes (bond failure)

• loss of skid resistance (viscous flow)

• Lower courses

• Cracking (Fatigue failure)

• Breakdown due to failure of lower courses (e.gcracking from dry-lean concrete)

-

8/16/2019 Asphalt Part 1

23/23

REFERENCE

• http://www.tpub.com/content/engineering/14071/css/14071_303

• http://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htm

• www.claisse.info/student/Powerpoints/8.%20Bitumens.ppt

• http://www.dykespaving.com/blog/the-origin-and-composition-oconcrete/

• http://www.myasphaltpavingproject.com/design/pavement-des• http://www.eurobitume.eu/bitumen/applications/application-ro

http://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.tpub.com/content/engineering/14071/css/14071_303.htmhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.claisse.info/student/Powerpoints/8.%20Bitumens.ppthttp://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.myasphaltpavingproject.com/design/pavement-design/http://www.eurobitume.eu/bitumen/applications/application-roads/benefitshttp://www.eurobitume.eu/bitumen/applications/application-roads/benefitshttp://www.eurobitume.eu/bitumen/applications/application-roads/benefitshttp://www.eurobitume.eu/bitumen/applications/application-roads/benefitshttp://www.myasphaltpavingproject.com/design/pavement-design/http://www.myasphaltpavingproject.com/design/pavement-design/http://www.myasphaltpavingproject.com/design/pavement-design/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.dykespaving.com/blog/the-origin-and-composition-of-asphalt-concrete/http://www.claisse.info/student/Powerpoints/8.%20Bitumens.ppthttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.aboutcivil.com/Bituminous-Materials-and-Plastics.htmlhttp://www.tpub.com/content/engineering/14071/css/14071_303.htm

![ASPHALT CONCRETE [Types] - KSU Facultyfac.ksu.edu.sa/sites/default/files/AC-1-LabTYPESDISTRESS.pdf · ASPHALT CONCRETE [Types] Introduction ... Sand Asphalt Mix Sand asphalt mixes](https://static.fdocuments.in/doc/165x107/5b72d5437f8b9a674d8d5d0c/asphalt-concrete-types-ksu-asphalt-concrete-types-introduction-sand.jpg)