Art's Process Spec Sheets

-

Upload

said-alauddeen-faisz -

Category

Documents

-

view

230 -

download

0

Transcript of Art's Process Spec Sheets

-

7/27/2019 Art's Process Spec Sheets

1/27

Art Montemayor Process Specification Sheets March 12, 2003

Rev. 0

1

2

3

4

5

6

78

9

10

11

12

13

14

15

16

The accurate and complete preparation of Specification Sheets is one of the most (if not THE most)

important capabilities that a Chemical, Process, or Project Engineer should acquire very early in his/her

career.

does not have the time available to do all that must be done in order to resolve day-to-day problems.

That is why engineers are required to lead and supervise those around them in order to assure an

organized team-effort in resolving problems. To this end, engineers use communications skills (both

oral and written) as well as language, psychology, and interpersonal skills to inform and lead other

team members to a successful resolution.

At the very basic foundation of problem solving is the successful communications of the required

capital equipment required to resolve engineering problems. An engineer is unable to resolve a problem

if he/she is unable to successfully describe it in detail to the "stake holders" in a project. The ability toreceive constructive and cost-effective help and supply from parties involved in the project is directly

related to the timely and accurate description of the supply needed to resolve a problem.

Specification sheets are the indicated tools that are relied upon by engineers to convey an accurate

and detailed description of their needs and expected supply. These Specification sheets not only serve

to identify the required supply, they also serve to organize and structure the knowldege of the owner's

engineers as to the criticality and strategic importance of the supply. They force the Owner to comply

with the classic business rule: Emptor Caveat - buyer beware.

It is a basic business principle and law that the responsibility of defining the specific need for a supply

of goods or materials lies directly with the purchaser (or Owner). If you don't know what you need or don't

know how to describe what you need, you will never resolve your own problems. The Specification Sheetdescribes to others not only what you identify as your specific needs, it also documents them and

communicates this information to all interested parties.

A large part of the problem in preparing accurate Spec Sheets is that the lead engineers (who often are the

most experienced and knowledgeable) are not the ones that prepare the Spec Sheets. It falls upon the

Process and Project engineers to prepare them and many times these individuals have to be trained and

instructed on how to describe and specify equipment that they are only superficially familiar with. Therefore,

good Spec Sheets should be easy and simply to prepare, with a minimum of detail knowledge required.

Art's Centrifugal Blower

Art's Orifice Meter

Art's Coriolis Meter

Art's Ultrasonic Meter

Art's .

Art's Mass Meter

Art's Turbine Meter

Art's Vortex Meter

Art's Magnetic Meter

Specification Sheets Included in This WorkBook

An engineer is a problem solver, pure and simple. However, one cannot simply solve problems by

directly applying ones own efforts and time. In the industrial and competitive world, an engineer simply

Art's API 650 Storage Tank

Art's Centrifugal Pump

Art's Air-Cooled Exchanger

Art's Shell & Tube Exchanger

Art's Plate & Frame Heat Exchanger

Art's Process Vessel

Art's Control Valve

Page 1 of 27FileName: 166794456.xls.ms_office

WorkSheet: Introduction

-

7/27/2019 Art's Process Spec Sheets

2/27

Art Montemayor Process Specification Sheets March 12, 2003

Rev. 0

I have arranged and organized the Spec Sheets found in this WorkBook in a manner that they should be

rather easy and intuitive for young engineers to prepare. A maximum use is made of drop-down list boxes

in order to facilitate the required information to engineers who are unaware of the various feature choices

available or much less how to describe them or spell them correctly. This method also "standardizes"

a variety of choices and does not leave it up to the individual to select whatever he/she thinks is required.

This method also allows the Spec Sheet to impose Corporate standards and pre-selected features without

wasting manpower to check their correct usage.

The utilization of an electronic spreadsheet such as Excel makes it easy for project documentation to be

safely stored, modified, and transmitted with a minimum of manpower. Engineers can generate and process

the documentation without further engineering assistance.

Additionally, the inherent calculation features of a spreadsheet are utilized to the maximum in allowing for

involved calculated information to be self-generated by the spreadsheet automatically. The spreadsheets

can be protected by the used/author for assurance that data will not be revised without prior knowledge.

The need to have calculations and related documentation readily available and filed due to legalities (such

as OSHA requirements on safety relief valve calculations and specifications) makes the spreadsheet a

natural tool for these requirements.

The utilization of Check boxes and Option buttons also give versatility and compactness to these Spec

Sheets, allowing the user to store more details and data in them. I have endeavored to limit the size of the

Spec Sheet to one page and design them around the need for communications of Process data for:

1. Documenting the results of calculations and other equipment details;

2. Preparing data and information for procurement inquiries (RFQs - Request of Quotes);

3. Obtaining Supplier information as related to a specific specification;

4. Preparing information that enters the Operations and Maintenance Manuals of a Unit;

5. Transmitting information regarding Unit equipment to other parties.

These Spec Sheets should be continuously revised and improved as spreadsheet technology improves or

is upgraded.

I will continue to work on and add additional Spec Sheets to this WorkBook in order to achieve as complete

a set of Spec Sheets as I can attain within the framework of available time.

Page 2 of 27FileName: 166794456.xls.ms_office

WorkSheet: Introduction

-

7/27/2019 Art's Process Spec Sheets

3/27

-

7/27/2019 Art's Process Spec Sheets

4/27

Art Montemayor Spec Sheet Log March 12, 2003

Rev: 0Index of Process/Mechanical Data Sheet and Specification Forms

Equipment Type go-by draft* complete* debugged issuable** accepted

Control Valves Pressure Relief Valves

Orifice Plates

Centrifugal Pump Calculation Sheet PSV Selection Criteria

* in Excel spreadsheet format ** write-protected

InstrumentSpecifications

DataSheets,

Calculations(not

specs.)

Page 4 of 27

FileName: 166794456.xls.ms_office

WorkSheet: Spec Sheet Index 2

-

7/27/2019 Art's Process Spec Sheets

5/27

Sheet 1 of 1

ng s n ts

1

2

3

4

5

6

7

8

9

10

11

12

13 Ft14

15 Ft16

17

18

19

2021

22

23

24

25

26

27

28

29

30 F

31

32

33

34 F

35 F

36

37

38

39

40

41

42

43

44

4546

47

48 %

49 lb lb

50

51

52

Rev Date Description By Chk. Rev Date Description By Chk.

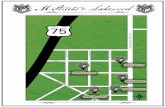

STORAGE TANK SPECIFICATION

Stress Relieve ? Yes

Plot Plan No. :P&ID No.

psig

oz/in.2Set @

Shell Manway

Flush Cleanout MW

CONSTRUCTION/FABRICATION

SumpInternals (attach separate sheet, as req'd):

Design Wind Velocity

Design Specifications:

No

Paint Spec.Fireproofing ? Yes

F. F.

85Radiograph Inspection Req'd ? YesHot

API 650 LATEST EDITION

in.

1

OPERATING/DESIGN DATA

oz/in.2

NOZZLES/CONNECTIONS

0.7900Sp. Gr. : Size RatingQty

4"

8"

3/4"

3/4"

4"

2"

F. F.

F. F.

R. F.

API

48"x48"

1"

10"

150#

8"

30"

Shell & Bottom

Roof L. J.

R. F.

R. F.

F. F.

L. J.

API

L. J.

R. F.

K

Operating Design

P

M

H

Emergency Vacuum Design ?

METALLURGY

Remarks

Service :

Location :

Model :

Unit :

F

G

BarrelsFeet 11,191

Sloped

PID115-EPF-01-112A1

32.00

Bottom Floor Type:

Manufacturer :

1952.000

Fluid Stored : CRUDE OIL

0.50

Flash Point (Closed Cup) :

150#

Mark

A

0

Remarks

Project No.

Service

Cone

50.00

Nominal Volume :

For Inquiry ArtM

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator.

2. Fixed cone roof with internal floating roof.

Appr.

Mixer Manway

Vapor Pressure @ Max. Operating Temperature psia

Two

CA, in.

----Minimum Fluid Temperature

(Hydro)test Pressure expressed in Psig

0.0.3

Fill Nozzle

Sample Tap

Stilling Vent

Temperature Indicator

Outlet Nozzle

Positive Pressure

Yes

Material

200

-25

Component

150#

150#

Maximum Fluid Temperature

Roof Nozzle

N1

N2

Water Draw Nozzle

Top Center Vent

0.1250

0.1250

for:

57370 Normalized

Normalized

APILining/Coating 1Spare

D

Others:

mph100Thickness :

150#

150#

Face

Feet

5.5

Sample Tap

I

J

L

1

1

1

2

2

1

1

1

1

1

Design Engineer : Art Montemayor

T-400 & T-405Equipment No. :

No. Req'd :

Other Ref. Dwg No. :

CRUDE OIL Storage

Galveston, Texas Kirwin

1

1

Mfr Ref. No. :

24"

24"

6"

Roof Manway

E

This Tank Service is considered: Cyclic

Roof Type :

Shell Diameter : 50.00 Shell Height : 32.00

Approvals

125#

125#

125#

150#

150#

150#

150#

150#

Negative Pressure

150#

150#

API

API

16 Grade 5

0.00

1.00 2.00

Appr.

Tank Insulation ?

Insulation Type:

Code (as appl.):

EmptyTank Weight Full of Water

Seismic Zone 3

Montemayor,Inc.

Rev.

No.

48" X 48"FLUSH

CLEANOUT

F

A

MP G

K

D

E

L

E

H

N2N1 J I

-

7/27/2019 Art's Process Spec Sheets

6/27

Sheet 1 of 1

Montemayor Corporation

1

2

3

4 Specification Engr:

5

6

7 %

8 psig (Norm.) psig (Max.) HP HP

9 Disch. Pressure psig (Norm.) psig (Max.) ft ft

10 Differential Pressure psi Diff. Head (TDH) ft gpm Cont. Thermal

11 Temperature, Normal F Max. F fps

12 @ PT @ Max. Temp. CW CCW

13 ft

14 cP cSt SSU Indoors X Outdoors ft ASL

15 F Max. F Min.

16 % psig @ F Max.

17 psig, Min. @ F Max.

18 Liquid is Flammable Toxic Other: v Ph Hz

19 Contains Chlorides H2S Other: II A

2021

22

23 in.

24

25 Case Mount'g CL Foot Brckt Vert. (Type)

26 Split Axial Radial Volute Single Radial Diffuser

27 Case MAWP * psig @ * F Hydrotest @ * psig

28 Connections Vent Drain Gauge Steam Jkt

29 Impeller Open Closed Special

30 Diameter: Rated * in. Max. * in. Min. * in. Case Impeller

31 Mount Betw. Brgs. Overhung Type Diameter in.; Clearance in.

32 Bearings Radial Thrust Int'stge Bush'gs, Diam. * in.; Cl'rnce in.

33 Lube Ring Oil Flood Oil Mist Flinger Pressure

34 Cplg. Mfr Model Approx. Wt., Pump & Base lb

35 Driver Half Mounted By Pump Mfr Driver Mfr Motor Wt. * lb Turbine Wt. lb

36 Seal Mech. Packing Auxiliary Mech. Packing Baseplate Dimensions (in.)

37 Seal Mfr. Type Model Baseplate No. ANSI API

38 Mfr Code API Code

39 Jacketed Box Other API 610

40 Gland Tap Quench Drain Flush Vent ANSI B73.1 B73.2

41 Customer Specs:

42 CW Plan Total CW Req'd No

43 CW Piping Mat'ls : for44 Packing Cooling Injection gpm @ psig Shop Inspection Req'd

45 API Seal Flush Plan SS CS Tubing Pipe Hydrostatic Test Req'd Witness46 SF Fluid : gpm @ psig Box psig Performance Test Req'd Witness

47 Auxiliary Seal Plan SS CS Tubing Pipe NPSH Test Req'd Witness

48 Auxiliary Seal Flush/Quench Fluid Internal Insp'n After Test Req'd Witness

49 Seal Flush Piping Threaded Socket Weld Flanged Other: Req'd Witness

50

51

52

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

Sight FI ?gpm

Corrosion/Erosion Caused By:

Solids Present

16.7

Specific Gravity 0.854 0.839

190120

Vapor Press. @ PT psia6.87Viscosity @ PT

Suction Pressure 14.7NPSH Req'd @ Impeller CL * @ TOC *

Rotation (viewed from Cplg end)

14Location

* Hydr. Eff'y **@ Max. Impeller *

Manufacturer's Proposal Curve No.

Rated Brake Power *

Min. Flow Req'd *Suction Specific Speed *

*RPM No. Stages

Size Distribution

Concentration

Drip Pan

Wear Rings

Sleeve(s)

Ambient Temp. 100 10

Elev. 97

3 60

Wear Rings

Applicable Specifications

Weights and Dimensions

Internal Wear Parts

Epoxy Grout, etc.

Impeller

Shaft

Baseplate

Inspection and Tests

Corr. Allow.

GlandInt'l Ctg/Lining

CONSTRUCTION

SITE CONDITIONS

Materials

Electrical Power 220/440

NPSH Available

CW Supply

CW Return

RF

Liquid Pumped Crab JuiceCapacity @ PT, Normal gpm400 Rated gpm500

150#

150#1" Case/Trim (API Class)

Casing

0 For Inquiry

Size Rating

Suction

Discharge 3"

170

2. See Motor Data, Sheet 2 of 2.

1. Items marked with an asterisk (*) to be completed by Vendor.

9-Oct-02

Facing Location

Remarks

Area Classification: Class Div. Group 1

Nozzles

FF

A. Montemayor

Mfr Ref. No. * No. Req'd One

OPERATING CONDITIONS, EACH PUMP PERFORMANCE

Plot Plan No. PLT-03-0000PID-01-0000

Model **Manufacturer

P&ID No.

CENTRIFUGAL PUMP SPECIFICATION(English Units)

Project No.

P-37

1234567

Service

Location P.O. No.

Equipment No.Crab Juice Transfer Pump

Galveston, Texas Unit Balinese Room

*

* *

*

*

*

Auxiliary Piping

Stainless Steel tubing & piping

77.7

63.0

90

XYZDEFABC

Rev.

No.M

-

7/27/2019 Art's Process Spec Sheets

7/27

1 of 1

Corporation

1

2

3 Mfr Ref. No.

4 Draft Type: No. of Bays

5 Btu/h F Surface/Unit, Finned ft2; Bare Tube ft

2

6

7

8

9 Fluid Name

10 Total Fluid Entering lb/h

11

12 Temperature F

13 Vapor lb/h

14 Mol. Wt.

15 Liquid lb/h

16 lb/h

17 Mol. Wt.

18 Steam lb/h

19 Water lb/h

20 Fluid Vaporized or Condensed lb/h Velocity X Max. Min. fps

21 Steam Condensed lb/h

22 Liquid Specific Gravity

23

24 Air Quantity, Total lb/h scfm Plant Altitude ft Above Sea Level

25 Air Quantity per Fan lb/h scfm Temperature In (Design Dry Bulb) F

26 Velocity X Max. Min. Temperature Out F

27 Face Velocity std fps Mass Velocity (Net Free Area) lb/hft2 Min. Design Ambient Temp. F

28

29 F

30

31

32

33 Arrangement: Two in.

34 Bundles in Series Parallel 40 ft

35 Bays in Series Parallel Gasket Material in.36 Bundle Frame:

37 No. Size Rating Facing

38

39

40 in. in.

41 Louvers Auto Manual F

42

43

44

45

46

47 ft

48 HP

49 fps50 % Auto-Variable % v Ph Hz

51 Yes No

52 Air Failure Control Action: Fan Pitch Min. Max. Lockup Louvers Open Close Lockup

53 Vibration Switches Req'd? Yes No Chemical Cleaning, etc.

54 Weight - Bundle lb Shipping Weight lb

55

56

57

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

in.

Code Requirements: ASME Sec. VIII, Para. 1 (1992)

Structural Mounting

Surface Preparation Temperature

**

Length :

Pitch : Rot. Square1.25

Plug Material

Effective MTD

Other Ref. Dwg No.

Viscosity, Liquid

Viscosity, Vapor

Latent Heat

Btu/fthF

Btu/fthF

cP

Forced

PERFORMANCE DATA - TUBE SIDE

Size

Btu/lbF

Btu/lbF

Welded

50

Pattern

Corrosion Allowance

No. of Passes Slope in./ft

0.125

Seamless

OD 1-1/2" 18Gage, B.W.G. :

Material :

Material :

Pressure

Type :Inlet

Outlet

Fins/inch

Transfer Rate, Ext'd Surface :

150

Non-Condensables

PERFORMANCE DATA - AIR SIDE

Bare Tube - Service :

Lethal Service?

Specific Heat, Vapor

Thermal Cond., Liq.

Btu/lb

One

OD

psig psig

Miscellaneous Connections

Size

Location

Process Vapor Condenser

Model

Service

* *

Unit

Manufacturer

250

100,000,000

Type

Heat Duty

Cedar Rapids, Iowa Furfural P.O. No.

1234567Project No.

No. Req'd*

No

Specific Heat, Liquid

cP

Fabrication Type :

Tube Sheet Joint :

No./Bundle :

Tubes

Fins

Low-Finned

316 Stainless SteelType

No. per Bay Material 316 Stainless SteelTube Rows

MECHANICAL EQUIPMENT

Type :TypeMfr/Model No.

Driver Speed Reducer Fan

RPM

Tip SpeedPitch Adj.

No./Bay HP/Fan

Pitch Angle

Blade Mat'l

Enclosure

HP/Driver RPM

ABC DEF27-Nov-020 For Inquiry XYZ

Remarks 1. Items marked with an asterisk (*) to be completed by Vendor.

AIR-COOLED EXCHANGER SPECIFICATION(English Units)

Mfr/Model No.

No./BayNo./Bay

Mfr/Model No.

Btu/ft2hF

Inlet Outlet

Plot Area *

Steam Coil?

AGMA Rating

Power Ratio :Support : Structure

Sheet

Des. Temp.

Stock Thk.

Gear box

Clean :

External - Over SideAir Recirculation Control :

Diameter

Equipment No.

Plot Plan No.P&ID No.

Btu/ft2hF Btu/ft

2hF

DP, Clean (Allow./Calc.)

Pour/Freeze Point

Dew/Bubble Point F

F

psi

Min. Fouling Resistance ft2hF/Btu

Operating Pressure, Inlet psig

In Out

Thermal Cond., Vap.

Section

CONSTRUCTION AND MATERIALS

Test PressureDesign Pressure Design Temperature

Header

Rev.

No.Montemayor

-

7/27/2019 Art's Process Spec Sheets

8/27

Sheet 1 of 1

Corporation

1

2

3

4 Horiz. Vert. Connected in Series Parallel

5 ft2 Gross Eff. Surface/Shell * ft2 Gross Eff.

6

7 PERFORMANCE OF ONE UNIT8

9

10

11

12 Liquid lb/h

13 Steam lb/h

14 Non-Condensables lb/h

15 Fluid Vaporized or Condensed lb/h

16 Steam Condensed lb/h

17 F

18

19 Viscosity

20 Vapor Molecular Weight

21 Specific Heat

22 Thermal Conductivity

23 Latent Heat

24 Operating Pressure, Inlet

25 Velocity Max. Min.

26 psi

27

28

29 Btu/ft2hF . Btu/ft

2hF .

30 CONSTRUCTION AND MATERIALS

31 SHELL SIDE TUBE SIDE Sketch (Bundle, Nozzle Orientation)

32 Design Pressure psig

33 Test Pressure psig

34 Design Temperature F

35 Number of Passes per Shell

36 In37 Out

38 Intermediate

39 Tubes: Type Number OD in. BWG or in. X Min. Av. Wall

40 Tube Length in. Tube Pitch in. Flow Pattern (circle one)

41 Shell: ID in. OD in. Tube-to-Tubesheet Joint :

42 Baffles - Cross: Type Spacing in. % Cut on X Diam. Area

43 Baffles - Long: Perm. Removable Seal Type: Bypass Seal:

44 rv2: Inlet Nozzle * lb/ftsec Bundle Entrance lb/ftsec Bundle Exit lb/ftsec

45 Expansion Joint? Yes X No Type: Impingement Protection? X Yes No

46

47 Tubes

48 Shell

49 Shell Cover

50 Channel51 Channel Cover

52 Fltg Head Cover

53

Stress Relieved (Mark "SR') and/or Radiographed (Mark 'XR') Parts User Spec.:

54 Code Requirements: ASME Sec. VIII, Para. 1 (1992) Stamp? X Yes No TEMA Class:

55 Weights: Shell lb Filled with Water lb Bundle lb

56

57

58

Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

*

* *

**

Carbon Steel

Carbon Steel

Carbon Steel

Carbon SteelCarbon Steel

Stnless Steel

None

0.0625None

NoneNone

16

Rolled and welded

0.062514 BWG Min

* * *

*

*

0.9375

0.75

Btu/lbF

Btu/hftF

Btu/lb

cP

psig

fps

0

Rev

Remarks: 1. Items marked with an asterisk (*) to be completed by Vendor.

Fouling Resistance

Pressure Drop, Clean (Allow./Calc.)

*

Transfer Rate, Service *

Heat Exchanged Btu/h

ft2hF/Btu

Log MTD (Corrected) * FLog MTD (Uncorrected) F

None

None0.125

0.125NoneNone

Cross BafflesLong Baffle

Gaskets

*

**

**

Floating Tubesheet

Fixed Tubesheet

Tube Supports

Site: Km 8, Avda. Venezuela; Lima, PeruMfr Ref. No.

Carbon Steel

(English Units)

Density, Specific Gravity

Temperature

lb/hTotal Fluid Entering

Fluid Allocation

Fluid Circulated

Service:

Manufacturer:

P&ID No.:

Carbon Steel

Carbon Steel

PART MATERIAL THK, in. C.A., in. PART MATERIAL

Carbon Steel

Carbon Steel

Stnless Steel

Vapor (In/Out) lb/h

THK, in. C.A., in.

Transfer Rate, Clean

Equipment No.

SHELL SIDE

Surface/Unit: *Other Ref. Dwg No.Plot Plan No.

Shells/Unit

SHELL & TUBE HEAT EXCHANGER SPECIFICATION

Project No.

*

Unit German Huanuco P.O. No.

Model

TUBE SIDE

*TEMA Size, Type:

No. Req'd

One

Lean MEA Solution Cooler

*

*

For Purchase

ConnectionsSize & Rating

Rev.

No.

Montemayor

-

7/27/2019 Art's Process Spec Sheets

9/27

-

7/27/2019 Art's Process Spec Sheets

10/27

Sheet 1 of 1

Corporation

1

2

3

4

5

6 Position Horizontal X Vertical

7 Shell Diameter ID X OD ft-in. 8'-0" 8'-0"

8 Shell Length TL-TL X S-S ft-in. 9'-6" 9'-6"

9 Internal Pressure psig 0 0

10 Temperature (Min/Norm/Max) F Amb. Amb.

11 Nominal Volume 3,000 gal Total Volume 4,900 gal

12 Fluid Contained Aqueous Amine Sol'ns Specific Gravity 1.0 Note 4

13 Vapor Pressure @ Max. Ambient Temperature 0.95 psia

14 Process Contaminants

15 Service is X Cyclic Lethal Other

16

17

18 Shell & Heads

19 Internals X Weld-in

20 Remov.21 Supports

22

23

24 Des. Press. @ Top psig Ext. Des. Press. psig

25 System PSV Set @ psig; located @

26 Des. Temperature F Minimum Temp. F

27 Vessel Support(s) Skirt X Legs Lugs Saddles

28 Height (Btm of Horiz. or BTL of Vert.) ft Above Grade

29 Fireproofing Other

30 X Insulation X H C PP Thickness in.

31 Design Codes: ASME Section VIII (1992); no stamp req'd

32 Post-Weld Heat Treatment for:

33 X Radiograph 85 % Inspection Req'd? X Yes No34

35 Mark Service Qty Size Rating Facing

36 1

37 1

38 1

39 1

40 1

41 1 Specify Operating Levels Above Btm or BTL

42 1

43 1 LCH

44 1 HLL

45 1 LAH

46 1 NLL

47 1 LAL

48 1 LLL

49 1 LCL

50 1

51 1 Weights: Vessel Only lb Internals lb

52 Operating Weight lb Full of Water lb

53

54

55

Chk. Appr.

DEF XYZ

*

*

N/A5

top of vessel

100 -20

*

PROCESS VESSEL SPECIFICATION(English Units)

RF

Light (Future)

Sight Glass (Future)

Spare 4"

4. Nozzle 'E': Tube Turn 12" T-Bolt hinged closure.

1. Items marked with an asterisk (*) to be completed by Vendor.Remarks:

Chk. Appr.Date Description By

0

Rev

For Inquiry

DescriptionDate

30-Sep-00

1"

2. Ref. set of detail dwgs for existing V - 41 (circa 1969). 3. Agitator supplied by Owner; conn. details on ref. dwgs.

Rev By

ArtM

300 lb

300 lb RF

Liquid Inlet w/Dip Tube

Liquid Inlet w/Dip Tube

N2 Pad

Vent

Fill Connection (Note 4)

Agit'r Opn'g w/Reinf. Pad (Note 3)

Manhole w/Davit

Relief Valve

Level Indicator (DP Cell)

N

O

P

Level Indicator (Equal. Conn.)

Liquid Inlet

Temp. Indicator

Pump Suction

H

Q

J

K

L

M

B

C

D

E

F

G

Unit

Model

Plot Plan No. Other Ref. Dwg No.PLT-03-2049

A

Equipment No.

P.O. No.

No. Req'd

Project No.

V - 41

* OneMfr Ref. No.

Site:

Manufacturer

Service:

P&ID No. PID-01-2084

Belle Glade, Florida

Filter Feed Tank

Furfural

**

304SS

304SS Baffles, Dip Tubes,

0.0625

0.0625

NoneNone

Vortex Breaker

Note 2

PROCESS (OPERATING) DATA VESSEL SKETCH

RemarksCA, in.MaterialComponent

NOZZLES/CONNECTIONS

MECHANICAL DESIGN

304SSCarbon Steel

LJ

1" 300 lb RF

Top Bottom

METALLURGY

2" 150 lb RF

1"

1"

1"

1"

1" 300 lb

1"

3"

3"

4"

6"

2"

2"

4"

300 lb

300 lb

300 lb

300 lb

300 lb

300 lb

RF

RF

RF

RF

300 lb

300 lb

300 lb

300 lb

300 lb

300 lb

RF

LJ

RF

RF

LJ

RF

RF

RF

K

Montemayor

Rev.

No.

Standard DisplacerRanges are:

14"24"

32"45"

Special DesignOver 45"

9'-6"S-S

8'-0" OD

1

1

HA

O

PB D

FC E

L

J

M

N

G

6'-11"

Vortex Breaker4Legs(min.)

Baffle(4 req'd)

DipTube(2req'd,

Nozz

les'A'&'B')

Q

-

7/27/2019 Art's Process Spec Sheets

11/27

of

1

2

3

4

5

6

7

8 oF9

10

11

12

13

14

15

16

17

18

19

20 in. in. in.

21

22

23

24 End Connections (Size, Rating, Facing)

25 Bonnet Type Number of Ports

26 Lube

27

28

29

30

31

32

33

34

35 Size

36

37

38

39

40

41

42

43

44

45

46 Type Quantity

47

48

49

50

51 Set Press.

52

53 I 1 II 1 III 2

54

55

56

57

58

Valve Percent Open

Upstream Pressure @ Flow

Downstream Pressure @ Flow

N.A.

200 265 350

500

4.268

psig

350

500

Four

1" 1500# Ring-jointRF 1"

Montemayor Corporation

Fluid Name Phase(s)

psig

F-01-24112" 300AA-5238-457 1" 1500AA-5238-460

N.A.

Unit

InstrumentFormNo.

psi Closed

Packing MaterialPacking Type

VALVE SELECTION, FLOW CHARACTERISTICS

Manufacturer Valtek

Molded V-Ring

cPCritical Press., PC Op'g Viscosity, m

7 psi

lb/ft3

Actual CV @ % Open

Two

psi

Standard Two Cooling Fin

RF 150#

Under

Recycle Gas Vap SCFM

150 180 350

7.0

Over

Bal. in.

Mod. Parabolic

AutomaticValves

300#

316ss

316ss

25%

Fluid Density at Inlet T&P, Flow 0.2708

Maximum Closed DP Fail Position

Trim Characteristic

Closed

Under

100%

LinerBonnet/Body

Lube & Isolating Valve (check)

Extended

2"

Da

te

12-Ma

r-00

Min. Req'd Press.

Spring Action Handwheel Pos., Orient.

Eff. Area, in.2 Service

Max. Allow. Press.

Manufacturer Model

Rev.0

Description By Chk.

SG @ Op. T

Estimate InquiryP.O. No.

PCV G 2ndF-01-2411

Tequila Conmemorativa

350

SCFM2-PhRecycle Gas

C - G - 02 & C - G - 03

150 290

MATERIALS

Molded V-Ring Graphite Impreg.

N.A. psia 0.013

500 500

495 495 495 495

50% 90%

Model Valtek

Rev Date Description By

Cage/Guide Stem

200 265 350 350

N.A.

psia cP0.012

4.268

995 995 995 995

1000 1000

0.6082

Liq. SG @ 60oF Vapor MW

Norm. Max. Capacity

1000 1000

cPpsia

Liq gpm

Open

Flow Units

Temp., Min. Operating Max.

Flow, Min.

Assoc. Equip./Service

Perros Bravos, N. L.

C - G - 02 & C - G - 03

PCV G 1st

Location

Tag Number

P&ID Number

Line Number

INSTRUMENT SPECIFICATION - CONTROL VALVES(English Units)

1Sheet 1

1937Project No.

Valve CV @ Flow (Calculated)

Increases

SWITCHES

Appr.

psig

Rev DateChk.

psig

Double-actingSingle-acting

Appr.

psigpsig

POSITIONER

Diaphragm, pneumatic

Open Top, Left-hand

Modulating Modulating On-off

316ss

316ss

Diaphragm, pneumatic

ACTUATOR

Plug/Ball/Disk Seat/Seat Ring

Type Hydraulic Piston

psigRated Travel @Travel starts @

Avail. Air Supply Press., Max. Min. psig

None

Manufacturer Model

Type

Manufacturer

Check Other By-passGauges

CamSignal incr. output to Actuator

Group B

Filter

Manufacturer Model

SPECIALS/ACCESSORIES/TESTS

Class GroupAGroup Div.Div. Class

Actuation Points

psig Filter Gauge

AIR SET

Model

psig

Square Root

psig

Other (check)

Mechanical

psigpsig

psig

psigpsig

Decreases Square Root

Gauges

ANSI/FCI Leak ClassHydro Pressure

Open

Contacts/Rating

Electrical Area Classification (if appl.) Class

Increases Linear

psig Filter Gauge

Trim Size

Proximity

in.Unbal.

in.

Bal./Unbal. Body Size Port Size

SERVICE CONDITIONS

in.Stroke in.

Linear Equal %

Bal.

Flow Direction

in.

in. in. in.

The Recycle Gas working fluid is a binary mixture of 15% vol NH3 + 85% vol H2 (60 % wt NH3 + 40 % wt H2)

Two control valves are required for each of the two services.

Remarks

Other

psig Class II

psig

psig

Close Top, Right-hand

psig psig

psig

psig

psig Class III

Braided Graphite

Class Ipsig

CDiv.

Graphite Impreg.

Gauge

By-pass Gauges

Pneumatic

By-pass

Side, Left-hand

M

-

7/27/2019 Art's Process Spec Sheets

12/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

13/27

Sheet 1 of 2

Corporation

1

2

3

4

5

6 Manufacturer's Proposal Curve No.

7 Service is Continuous Intermittent for hrs/day Centrifugal Axial Vane

8 lb/h or SCFM No. Stages 1 Efficiency %

9 Capacity, Design lb/h or SCFM Inlet Size/Rating Top Bottom Side

10 Inlet Pressure in. WC Inlet Temp. F Disch. Size/Rating Top Bottom Side

11 Disch. Pressure in. WC Disch. Temp. F Case Design Press. psig; Design Temp. F

12 Gas Mol. Wt. Compr. (Z) at Inlet Relief Valve No. Located @

13 Cp/Cv at Inlet By Mfr By Customer Set @

14 Corrosion/Erosion Caused By Rotation (viewed from Cplg end) CW CCW

15 Dust Present? No Yes ; Name Packing, Type: No. of Rings

16 Concentration gr/ft3 Size Range m Mech. Seal, Type: Mfr by

17 Solids are Abrasive Explosive Sticky

18 Other (specify)

19 Type: Mfr to Furnish Mount

20 Location Indoors x Outdoors Elev. 97 ft ASL Direct Indirect: V-Belt Gear 21 Ambient Temp. F Max. F Min. Single Variable Speed HP RPM

22 Max. Relative Humidity Other v Ph Hz Enclosure

23 Electrical Area Classification NEMA Service Factor

24

25

26

27 Cast Iron Aluminum Steel Ball Steel V-Belt

28 Steel Alloy Steel 316SS Sleeve Static Conductor

29 Aluminum Cast Steel Roller Guard

30 316SS 316SS Sparkproof

31

32

33 Flexible Oil Stellited Bronze Bronze Seal

34 Fast/Falk Grease 420SS Cast Iron Cast Iron Bearing

35 Guard None Steel Steel None

36 Sparkproof None

37

38 Common Baseplate and Driver by Mfr? Yes No Baseplate Mat'l Cast Iron Fabricated Steel

39 Baseplate Dimensions Approx. Wt., Blower & Base lb lb

40

41

42

43

44

4546

47

48

49

50

51

52

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

0 27-Dec-96 For Inquiry ABC DEF XYZ

CENTRIFUGAL FAN, BLOWER SPECIFICATION(English Units)

Gears V-Belt Drive

No. Req'd One

P.O. No.

Bearing Lubrication Shaft Sleeve Lantern Ring

Driver

SITE CONDITIONS

MECHANICAL DETAILS AND MATERIALS OF CONSTRUCTION

Driver Wt.

Water Cooling

PROCESS CONTROL SKETCH (Incl. Scope of Supply

Coupling(s)

Capacity, Normal

Type

Case Rotor(s) Shaft Bearings

Other Ref. Dwg No.

RPM 3600

Packing Gland

Gas Handled :

Plot Plan No. PLT-03-0000OPERATING CONDITIONS PERFORMANCE

*Manufacturer

P&ID No. PID-01-0000

* Model * Mfr Ref. No.

Project No.

Service Political Hot AirSite: Kingston, Jamaica Unit Alf Newton

CF - 100

1234567

Equipment No.

Montemayor

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

14/27

of

Corporation

1

2

3

4

5

6

7

8

9

10

11

12

13

14 Quality (%) or Superheat (F)

15 N Y N Y N Y

16

17 N Y N Y N Y

18

1920

21

22

23

24

25 in. in. in. in. in. in.

26

27

28

29

30

31

32 Vent (top) Drain (btm) Vent (top) Drain (btm) Vent (top) Drain (btm)

33

34

35

36

37

38

39

40

41 Gr Div Gr Div Gr Div

42

43 Hi Lo Fault Hi Lo Fault Hi Lo Fault

44

45

46

47

48

49

50

51

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

Fluid Density @ STP

Compress. FactorMol. Wt. CP/CV

Date

5-May-99

Plate

F

langes

Sheet

(English Units)FLOWMETER SPECIFICATION, ORIFICE PLATE

MontemayorProject No.

El Gallinero, Nuevo Leon Huevos Rancios *Location Unit P.O. No.

Tag Number

P&ID Number

Line Number

Service or Associated Equipment

cP

psig

gpm lb/min

Fluid Name and Phase (l, v, g or 2 )

Flow, Min. Nominal Max. units

Temp., Min. Nominal Max.

Press., Min. Nominal Max.

Air or Gas Bubbles; Name

SSUViscosity, Min. Nominal

Size Range

Pipe Diameter Schedule

Units

Vent, Drain, Other?

Meter Type

DP @ Max. Flow: Allow./Calc. *

Other:

Manufacturer Model

feet

ClassClass

Other:

feet

Special Requirements:

feet

Min. Range

Area Classification Class

Switches/Alarms

Other:Totalizer (check)

Cable Distance (Transducer to Console)

Units

Housing Requirements

1. Items marked by an asterisk (*) to be completed by Vendor/Mfr.Remarks

Other:

Rev.

0

InstrumentFormNo.

b = d/D

Material

SERVICE CONDITIONS

METER SELECTION, MEASUREMENT PARAMETERS

INSTALLATION, INTERFACE SPECIFICATIONS

Bore Diam., d Thickness

Location

Design Std

Size Range

@ Op'g T&P

Max.

% by volume

% by weight

Flanges & Taps: Supply by

Tap Size

Plate Type Material

Bore Sized for

Rating

Ring Type (if appl.) Material

MaterialFlange Type

Pipe ID, D

Suspended Solids; Name

Manufacturer Model

Liner Material Insulation Thk, Type

ORIFICE PLATE AND FLANGE SPECIFICATIONS

Output Units

UnitsStatic

Chart or Scale Range Chart Multiplier

Range: Diff. (Dry)

Seal Sp. Gr. @ 60F

F F

psig

F

psig

-

7/27/2019 Art's Process Spec Sheets

15/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

16/27

of

Corporation

1

2

3

4

5

6

7

8

9

10

11

12

13 N Y N Y N Y

14

15 N Y N Y N Y

16

17

1819

20

21

22

23 F F F

24

25

26

27

28 % % %

29

30

31

32

33

34 II Gr Div 2 II Gr Div 1 III Gr Div 1

35

36 Hi Lo Fault Hi Lo Fault Hi Lo Fault

37

38

39

40

41

42

43

44

45

46

47

48

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

Op'g T&PSTPFluid Density @

RFConn. Size Type Face WN 125# FF

* psig *

Full Scale% of

% of Full Scale

A

1" 1" SW

Material, Wetted Parts Gaskets, Rings

300# FF

lb/ft

Liq

Material

Max.

% by volume

% by weight

Flow Acc'y @ Min./ Nom.

Rev.

Date

SERVICE CONDITIONS

InstrumentFormNo.

Special Requirements:

Area Classification Class

Output Units Housing Requirements

Other:

4 to 20 mA

Switches/AlarmsOther:

feet

Other:

NEMA-4X

Remarks

Totalizer (check)

Cable Distance (Transducer to Console) feet

UnitsMin. Range

feet

1. Items marked by an asterisk (*) to be completed by Vendor/Mfr.

Class C

% of Reading

INSTALLATION, INTERFACE SPECIFICATIONS

Class B

* g/cc *

% of Full Scale

* * *

* * * %

*

*

* * *

150#2" SO

% of Reading

psi

psig *

* * * fps*

* * * %

% of Reading

* g/cc *

** * psi

fps

* * *

* *

* g/cc *

* * * %

* * * fps

* * *

psi

psig **

* * *

Density Accuracy

Velocity @ Min. Nominal Max. Flow

NRe @ Min. Nominal Max. Flow

Max. Flow

Model

Meter MAWP Max. Allow. Temp.

DP @ Min. Nominal Max. Flow

Rating

Liner Material Insulation Type, Thk None None

Manufacturer

FLOWMETER SELECTION, MEASUREMENT PARAMETERS

* *

Air or Gas Bubbles; Name

Size Range

Suspended Solids; Name

Size Range

Pipe Diameter Schedule

A-Swt " Hot

Viscosity, Min. Nominal

1"

Temp., Min. Nominal Max.

Press., Min. Nominal Max.

Fluid Name (l, v, g or 2 )

Flow, Min. Nominal Max. units

cSt

lb/gal

lb/min

F

psig

SSU

Gas

g/cc

F

cP

psig

gph

Vap

psig

gpm

F

Tag Number

P&ID Number

Line Number

Service or Associated Equipment

Project No.

Chiclayo, Peru Cayalti *Location Unit P.O. No.

Pulse NEMA-7 Digital NEMA-12

Sheet

(English Units)FLOWMETER SPECIFICATION, CORIOLIS

Montemayor

0

5-May-

99

Required Accuracy

Required RepeatabilityOther:

-

7/27/2019 Art's Process Spec Sheets

17/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

18/27

-

7/27/2019 Art's Process Spec Sheets

19/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

20/27

of

Corporation

1

2

3

4

5

6

7

8

9

10

11

12

13 N Y N Y N Y

14

15 N Y N Y N Y

16

17

1819

20

21

22

23 F F F

24

25

26

27

28 % % %

29

30

31

32

33 I Gr Div 2 II Gr Div 1 III Gr Div 1

34

35

36 Hi Lo Fault Hi Lo Fault Hi Lo Fault

37

38

39

40

41

42

43

44

45

46

47

48

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

Material

@ Op'g T&P

Max.

% by volume

% by weight

FLOWMETER SELECTION, MEASUREMENT PARAMETERS

SERVICE CONDITIONS

Date

5-May-9

9

Rev.

0

InstrumentFormNo.

Special Requirements:

1. Items marked by an asterisk (*) to be completed by Vendor/Mfr.Remarks

NEMA-4

Digital

Other:

feet

NEMA-7

Pulse

Other:

feet

Totalizer (check)

Cable Distance (Transducer to Console)

UnitsMin. Range

feet

AlarmsOther:

Class CArea Classification Class

NEMA-4X

4 to 20 mA

Housing Requirements

Output Units

% of

BA

% of

%

g/cc

fps

psi

psig

% of

%

g/cc

% of

fps

psi

psig

Full Scale% of

% of Reading

INSTALLATION, INTERFACE SPECIFICATIONS

Class

* g/cc *

* * * %

* * fps

* * *

psig **

Density Accuracy

Required Accuracy

Required Repeatability

Other:

psi* * *

*

NRe @ Min. Nominal Max. Flow

Flow Acc'y @ Min./ Nom. Max. Flow

Velocity @ Min. Nominal Max. Flow

Liner Material Insulation Type, Thk

Manufacturer Model

Max. Allow. Temp.

* *

None Hot

Size Range

Pipe Diameter Schedule

Air or Gas Bubbles; Name

Size Range

Suspended Solids; Name

None None

Nominal Max.

A-Swt

Fluid Density @ STP

Viscosity, Min. Nominal

Fluid Name (l, v, g or 2 )

Flow, Min. Nominal Max. units

1"

Temp., Min. Nominal Max.

Press., Min.

lb/ft3

cP

psig

gpmoF

lb/ft3

cP

psig

gpmoF

cP

psig

lb/ft3

gpmoF

Tag Number

P&ID Number

Line Number

Assoc. Equip./Service

Caracas, Venezuela Rbt. Humphries *Location Unit P.O. No.

FLOWMETER SPECIFICATION, MASS(English Units)Montemayor

Project No.

Sheet

-

7/27/2019 Art's Process Spec Sheets

21/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

22/27

of

Corporation

1

2

3

4

5

6

7

8

9

10

11

12

13 N Y N Y N Y

14

15 N Y N Y N Y

16

17

18

19

20

21

22

23 F F F

24

25

26

27

28 % % %

29

30

31

32

33 II Gr Div 2 I Gr Div 1 I Gr Div 1

34

35

36 Hi Lo Fault Hi Lo Fault Hi Lo Fault

37

38

39

40

41

42

43

44

45

46

47

48

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

FLOWMETER SPECIFICATION, TURBINE(English Units)Montemayor

Project No.

Sheet

Arica, Chile Air Products *Location Unit P.O. No.

Tag Number

P&ID Number

Line Number

Assoc. Equip./Service

oF

gpm

cP

psig

gpm

lb/ft3

psig

lb/ft3

cP

gpmoF

cP

oF

psig

lb/ft3

Fluid Name (l, v, g or 2 )

Flow, Min. Nominal Max. units

Temp., Min. Nominal Max.

Press., Min. Nominal Max.

Fluid Density @ STP

Viscosity, Min. Nominal

Air or Gas Bubbles; Name

Size Range

Suspended Solids; Name

Size Range

Pipe Diameter Schedule

* *

Liner Material Insulation Type, Thk

Manufacturer Model

Nominal Max. Flow

NRe @ Min. Nominal Max. Flow

Max. Allow. Temp.

*

Required Accuracy

Required Repeatability

Other:

Flow Acc'y @ Min./ Nom. Max. Flow

Density Accuracy

Velocity @ Min.

psig **

fps

* * *

*

* * *

psi*

INSTALLATION, INTERFACE SPECIFICATIONS

Class

* g/cc *

* * * %

Reading% of

% of Full Scale

psig **

fps

psi

* * * %

* g/cc *

% of

*

fps

psi

psig *

* * * %

% of

g/cc *

% of

% of

Area Classification Class

NEMA-4X

4 to 20 mA

AA

Housing Requirements

Output Units

Totalizer (check)

Cable Distance (Transducer to Console)

AlarmsOther:

Class C

UnitsMin. Range

feet

lb

Special Requirements:

NEMA-4

Pulse

Other:

NEMA-7

Pulse

Other:

US gal

feet

kg

feet

1. Items marked by an asterisk (*) to be completed by Vendor/Mfr.Remarks

Date

5-May-9

9

Rev.

0

InstrumentFormNo.

Material

@ Op'g T&P

Max.

% by volume

% by weight

FLOWMETER SELECTION, MEASUREMENT PARAMETERS

SERVICE CONDITIONS

*

-

7/27/2019 Art's Process Spec Sheets

23/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

24/27

of

Corporation

1

2

3

4

5

6

7

8

9

10

11

12

13 N Y N Y N Y

14

15 N Y N Y N Y

16

17

18

19

20

21

22

23 F F F

24

25

26

27

28 % % %

29

30

31

32

33 I Gr Div 1 II Gr Div 2 III Gr Div 2

34

35

36 Hi Lo Fault Hi Lo Fault Hi Lo Fault

37

38

39

40

41

42

43

44

45

46

47

48

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

Material

@ Op'g T&P

Max.

% by volume

% by weight

FLOWMETER SELECTION, MEASUREMENT PARAMETERS

SERVICE CONDITIONS

Date

5-May-9

9

Rev.

0

InstrumentFormNo.

Special Requirements:

1. Items marked by an asterisk (*) to be completed by Vendor/Mfr.Remarks

NEMA-7

Digital

Other:

US gal

feet

NEMA-4

Pulse

Other:

kg

feet

Totalizer (check)

Cable Distance (Transducer to Console)

UnitsMin. Range

feet

lb

AlarmsOther:

Class CArea Classification Class

NEMA-12

4 to 20 mA

Housing Requirements

Output Units

% of

BA

% of

%

g/cc

fps

psi

psig

% of

%

g/cc

% of

fps

psi

psig

% of

% of

INSTALLATION, INTERFACE SPECIFICATIONS

Class

* g/cc *

* * * %

* * fps

* * *

psig **

Density Accuracy

Required Accuracy

Required Repeatability

Other:

psi* * *

*

NRe @ Min. Nominal Max. Flow

Flow Acc'y @ Min./ Nom. Max. Flow

Velocity @ Min. Nominal Max. Flow

Liner Material Insulation Type, Thk

Manufacturer Model

Max. Allow. Temp.

* *

Size Range

Pipe Diameter Schedule

Air or Gas Bubbles; Name

Size Range

Suspended Solids; Name

Nominal Max.

Fluid Density @ STP

Viscosity, Min. Nominal

Fluid Name (l, v, g or 2 )

Flow, Min. Nominal Max. units

Temp., Min. Nominal Max.

Press., Min.

lb/ft3

cP

psig

gpmoF

lb/ft3

cP

psig

gpmoF

cP

psig

lb/ft3

gpmoF

Tag Number

P&ID Number

Line Number

Assoc. Equip./Service

La Paz, Bolivia Pepe Mendietta *Location Unit P.O. No.

FLOWMETER SPECIFICATION, VORTEX(English Units)Montemayor

Project No.

Sheet

-

7/27/2019 Art's Process Spec Sheets

25/27

Rev.

No.

-

7/27/2019 Art's Process Spec Sheets

26/27

1 of

Corporation

1

2

3

4

5

6

7

8

9

10

11

12

13 N Y N Y N Y

14

15 N Y N Y N Y

16

17

1819

20

21

22

23 F F F

24

25

26

27

28 % % %

29

30

31

32

33 I Gr Div 1 II Gr Div 1 III Gr Div 2

34

35

36 Hi Lo Fault Hi Lo Fault Hi Lo Fault

37

38

39

40

41

42

43

44

45

46

47

48

Rev Date Description By Chk. Appr. Rev Date Description By Chk. Appr.

Sheet

*Location Unit P.O. No.

FLOWMETER SPECIFICATION, MAGNETIC(English Units)Montemayor

Project No.

Tag Number

P&ID Number

Line Number

Assoc. Equip./Service

Victoria, TX DuPont Nitric Acid

gpm

kPa

Liq

oC

lb/ft

cP

lb/min

oC

psia

lb/ft

SSU

lb/min

cSt

2-Ph

oC

atm

lb/ft

Fluid Name (l, v, g or 2 )

Flow, Min. Nominal Max. units

Gas

Temp., Min. Nominal Max.

Press., Min. Nominal Max.

Fluid Density @ STP

Viscosity, Min. Nominal

Air or Gas Bubbles; Name

Size Range

Suspended Solids; Name

Size Range

Pipe Diameter Schedule

* *

Liner Material Insulation Type, Thk

Manufacturer Model

Nominal Max. Flow

NRe @ Min. Nominal Max. Flow

Max. Allow. Temp.

*

Required Accuracy

Required Repeatability

Other:

Flow Acc'y @ Min./ Nom. Max. Flow

Density Accuracy

Velocity @ Min.

psig **

fps

* * *

*

* * *

psi*

INSTALLATION, INTERFACE SPECIFICATIONS

Class

* g/cc *

* * * %

Full Scale% of

% of Reading

psig **

Reading

fps

psi

Full Scale

%

g/cc

% of

*

fps

psi

psig *

%

% of

g/cc

% of Full Scale

% of

Area Classification Class

NEMA-4X

4 to 20 mA

BA

Housing Requirements

Output Units

Totalizer (check)

Cable Distance (Transducer to Console)

Reading

AlarmsOther:

Class C

UnitsMin. Range

feet

lb

Special Requirements:

NEMA-4

Digital

Other:

NEMA-7

Pulse

Other:

US gal

feet

kg

feet

1. Items marked by an asterisk (*) to be completed by Vendor/Mfr.Remarks

Date

5-May-99

Rev.

0

InstrumentFormNo.

Material

@ Op'g T&P

Max.

% by volume

% by weight

FLOWMETER SELECTION, MEASUREMENT PARAMETERS

SERVICE CONDITIONS

-

7/27/2019 Art's Process Spec Sheets

27/27

Rev.

No.