Article 516 FordFocusFCV

-

Upload

bxlmichael8837 -

Category

Documents

-

view

218 -

download

0

Transcript of Article 516 FordFocusFCV

-

7/27/2019 Article 516 FordFocusFCV

1/7

Ford Focus FCEV Hybrid

FUEL CELL TODAY

Opening doors to fuel cell commercialisation

Stefan Geiger, Fuel Cell Today 03 October 2002

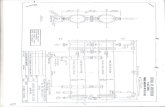

On October 2, Ford presented the first "ready to go into production" version of its

Fuel Cell Car "Focus FCEV Hybrid" in Aachen, Germany. The new car is a hybrid

vehicle, which runs without producing any type of toxic emissions and attains a level

of fuel efficiency that far exceeds any modern internal combustion engine.

Ford Focus Hybridised Fuel Cell Vehicle (Source: Ford Motor Company)

With a maximum efficiency of 90 percent, the Ford Focus FCEV Hybrid offers the

highest specific output (power-from-fuel-ratio) of any known propulsion system. Ford

researchers have achieved this significant increase in fuel efficiency by combining

two previously independent systems into a sophisticated hybrid electric powertrain.

In most driving modes, the new 92-hp (68 kW) Ballard Mk 902 fuel cell stack

provides the sole source of electrical energy for the Ford Focus FCEV powertrain.

However, a new design of battery pack will kick in whenever higher levels of power

are needed. This 216-volt unit serves as the starter battery for the entire system and

also provides additional thrust during acceleration. Whenever the driver requires fast

acceleration, the Ford Focus FCE's energy management system will go into a boost

1 www.fuelcelltoday.com

-

7/27/2019 Article 516 FordFocusFCV

2/7

mode, switching the battery into parallel with the fuel cell to supply an additional 18

kW (25 hp) of propulsion.

This means that the vehicle's energy management system can deliver better

performance than today's fuel cell technology provides on its own because both

systems are operating frequently in or close to their "sweet spot."

This modern hybrid-switching concept offers the benefit of sleek dimensions. Both

the battery and the fuel cell stack are slim components, which have been refined for

optimal efficiency. Additionally, the 96-kilogram, 92-hp (68 kW) Ballard Mk 902 fuel

cell stack is a relatively lightweight unit, though the entire propulsion system,

comprising gas supply, control unit and the fuel cell stack itself, has a total weight of

about 220 kilograms. Engineers are continuing to work on reducing even further the

weight of the entire unit.

The Ford Focus FCEV Hybrid can reach its maximum speed of 128 kph in about 25

seconds. Adding a manual gearbox could attain a higher speed of around 185 kph. In

order to achieve optimal overall efficiency, engineers decided against the use of a

manual gearbox and capped the top speed of the Ford Focus FCEV Hybrid at 128

kph. This limit is set by the electric drive motor, which has a maximum speed of12,500 revolutions per minute.

The fuel cell stack resembles a large gas-powered generator supplying electrical

energy generated in a cold-combustion process to the electric motor. The fuel cell

stack used in the Ford Focus FCEV takes in pure gaseous hydrogen to produce the

electrical energy that powers the electric motor. The fuel cell powertrain of the Focus

FCEV Hybrid comprises the fuel cell stack, its gas and air control system and electric

controls for propulsion power. The entire powertrain has been combined into a 220-

kilogram block assembly, which is flat enough to fit into the vehicle's underbody

structure.

As Ford moves closer to production, for the first time in history, they have assigned a

fuel cell vehicle a development code. The Focus FCV, or C264 to give it its code

name, is an indication of the company's serious commitment to advanced research

and development of this technology. More than 90 years after the launch of its multi-

million selling Model T, Ford is developing the C 264 fuel cell version of the Ford

2 www.fuelcelltoday.com

-

7/27/2019 Article 516 FordFocusFCV

3/7

Focus currently in production and powered by a conventional internal combustion

engine.

More Than Double Efficiency

Fuel cells achieve completely different levels of fuel economy from internal

combustion engines. Whenever a wide range of part load operation, the fuel cell's

thermo-dynamic efficiency is rated at about 60 percent, with temporary peak values

rising to more than 90 percent under low load. Including the electric booster system,

this results in an overall efficiency of clearly more than 60 percent, i.e. three to four

times that of internal combustion engines.

To raise the overall efficiency of the Focus FCEV even further, the small series of FCV

research vehicles features two additional developments geared to achieving a

favourable energy conversion rate, light-weight build and a regenerative braking

system. The FCEV's lightweight construction uses around 150 weight-optimised

parts. The technology for manufacturing these parts is based on a wealth of

experience gained from motor racing and advanced material research. Large

segments of the underbody structure as well as the doors and bonnet are made of

aluminium. Together, with the use of thin high-strength glazing and high-strength

steel plus parts made of titanium, magnesium and composite material this results in

a total weight reduction of 300 kilograms.

Detail of the Engine Compartment of Ford's hybridized version of the

Focus Fuel Cell Vehicle (Source: Ford Motor Company)

3 www.fuelcelltoday.com

-

7/27/2019 Article 516 FordFocusFCV

4/7

Low consumption without an overfuel effect

Achieving a significant improvement in the fuel economy of the latest generation fuel

cell was of particular importance to the development team - and the Ballard Mk 902

fuel cell stack produces a new level correlation between gas flow and efficiency.

The Ballard 902 shows a novel degree of ingenuity in terms of reducing the size of

the fuel cell stack to efficient dimensions. Moreover, an electronically controlled

powertrain management avoids the effect of over-fuelling. In previous fuel cell

prototypes, the accelerator pedal position under full load (strong acceleration)

spontaneously opened the throttle valve, causing a strong influx of hydrogen and air

into the two separate channel systems of the fuel cell stack. This resulted in

relatively high amounts of unburned hydrogen fuel (an overfuel effect). This wasted

hydrogen together with warm air, had to be fed back into the exhaust air

recirculation system behind the fuel cell stack. In extensive tests, Ford researchers

were able to confirm that smooth transitions between different power levels, versus

sudden leaps, improve the fuel cell's performance. The Ford Focus FCV Hybrid can

still supply the additional power required by sudden acceleration immediately using

the 216-volt battery pack to a maximum of 25 hp.

Combined with the electric booster, which adds 25 hp of battery power to fuel cell

system power in the lower part load range, the new intelligently controlled hybrid

powertrain of the Ford Focus FCEV achieves around 20 percent better fuel economy

compared to the predecessor generation (Ballard Mark 900).

Impressive performance: the efficiency of the fuel cell

In addition to emission-free operation, the other main advantage of propelling a

vehicle by PEM fuel cells is, thanks to the fact that the concept is simply controlled,

by using pure hydrogen as a fuel, the supply of more hydrogen and air to the cells

via a simple gas valve is all it takes to spontaneously generate a higher output of

power to propel the vehicle.

Installing a fan and a simple hydrogen-dosing valve can easily control driving power.

In the Focus FCEV Hybrid, both the fan and valve are electronically connected to the

"accelerator pedal." Spontaneity is extremely important in this regard, because

drivers will only experience a genuine feeling of driving dynamics if the vehicle's

4 www.fuelcelltoday.com

-

7/27/2019 Article 516 FordFocusFCV

5/7

-

7/27/2019 Article 516 FordFocusFCV

6/7

Fuel cell vehicle development timeline

Fuel cell technology development aims to make emission-free vehicles available to

the customer within the foreseeable future. Moreover, fuel cell technology could be

used as an emission-free primary or secondary source of energy for homes in remote

locations. Ford is projecting the following timeline for its fuel cell developments:

Starting in 2003:

The first production vehicles of a Focus FCV fleet will be taking to the roads in the

United States for testing purposes. Part of this fleet testing programme will be a type

of "customer clinic" involving various Ford partner organisations. Future customers

will be invited to initial drive tests in order to obtain constructive feedback on

handling and other specific characteristics of fuel cell vehicles early on.

Starting in 2007:

The testing fleet is expected to incorporate a second-generation fuel cell system and

see a further expansion within certain cities in the United States, Europe and Japan.

After 2010:

Marketing of a commercially viable FC fleet will be targeted. The objective is to offer

FC vehicles to customers at affordable prices. At that point, Ford FC vehicles will be

marking the first stage of a development that will ultimately see the successive

replacement of conventional Ford models powered by internal combustion engines.

Technical Specifications

Fuel Cell System

Fuel cell stack Ballard Mk 902 (PEM Fuel Cell)

Max. Power 68 kW / 92 hp

Fuel Gaseous hydrogen / air

Weight 96 kg

Max. Operating temperature 85 C

Operating pressure 2 bar

Battery Sanyo high-performance battery (NiMH 216

volts, 1.14 kWh)

6 www.fuelcelltoday.com

-

7/27/2019 Article 516 FordFocusFCV

7/7

7 www.fuelcelltoday.com

Powertrain

Electric motor, type Ecostar alternating three-phase current motor

Max. perm. power 65 kW / 88 hp

Max. torque 230 Nm

Max. efficiency 91 %

Transaxle integrated single-speed planetoid

Motor management / traction inverter module

Type 3-phase direct-current

Max. current 330 A

Min./max. / nominal voltage 250 / 420 / 315 V

Weight 16 kg

Focus FC Vehicle

Wheelbase 2615 mm

Total length 4338 mm

Width 1758 mm

Curb weight 1600 kg

Weight distribution front/rear 51 / 49 %

Fuel tank capacity 178 l; hydrogen at 350 bar

Performance/ fuel economy

Acceleration 0 to 100 kph 13.5 s

Max. speed 128 kph / 80 mph

Fuel economy (petrol equivalent) 5.35 l/100 km (urban),

3.88 l/100 km (extra urban)

4.58 l/100 km (combined)

Range 320 km

Emissions zero

About the author

Stefan Geiger is working for Fuel Cell Today, the global Internet portal for companies

and individuals with an interest in the commercialisation of fuel cells. It is your single

free source for comprehensive and authoritative fuel cell news, commentary,

resources and business opportunities. To contact the author, please send an email

to: . Fuel Cell Today, 2002