Arsenic removal by iron oxide coated sponge: treatment and waste management

-

Upload

trung-kien -

Category

Documents

-

view

214 -

download

1

Transcript of Arsenic removal by iron oxide coated sponge: treatment and waste management

Arsenic removal by iron oxide coated sponge: treatment

and waste management

Tien Vinh Nguyen, Abdur Rahman, Saravanamuthu Vigneswaran,

Huu Hao Ngo, Jaya Kandasamy, Duc Tho Nguyen, Tuan Anh Do

and Trung Kien Nguyen

ABSTRACT

Tien Vinh Nguyen

Abdur Rahman

Saravanamuthu Vigneswaran (corresponding

author)

Huu Hao Ngo

Jaya Kandasamy

Faculty of Engineering,

University of Technology, Sydney (UTS),

PO Box 123, Broadway,

Sydney NSW 2007,

Australia

E-mail: [email protected]

Duc Tho Nguyen

Tuan Anh Do

Trung Kien Nguyen

Institute of Environmental Technology,

18 Hoang Quoc Viet Road,

Cau Giay,

Hanoi,

Vietnam

One of the problems in drinking water that raises concern over the world is that millions of people

still have to use arsenic-contaminated water. There is a worldwide need to develop appropriate

technologies to remove arsenic from water for household and community water supply systems.

In this study, a new material namely iron oxide coated sponge (IOCSp) was developed and used to

remove arsenic (As) from contaminated groundwater in Vietnam. The results indicated that IOCSp

has a high capacity in removing both As (V) and As (III). The adsorption capacity of IOCSp was up

to 4.6mg As/g IOCSp, showing better than many other materials. It was observed from a pilot

study that a small quantity of IOCSp (180g) could reduce As concentration of 480mg/L in 1.5m3 of

contaminated natural water to below 40mg/L. In addition, an exhausted IOCSp, containing a large

amount of arsenic (up to 0.42 wt %) could safely be disposed through the solidification/stabilization

with cement. Addition of fly ash also reduced the amount of arsenic in the leachate.

Key words | arsenic, cement, drinking water, iron oxide coated sponge (IOCSp),

solidification/stabilization, water treatment technology

INTRODUCTION

Arsenic is a toxic element that can be fatal to human health.

It can have a significant adverse impact on the environ-

ment. Arsenic exists in several oxidation states (2III, 0,

þ III and þ V) in the environment. However, in natural

water, arsenic is mostly found in inorganic form as

oxyanions of trivalent arsenite [As(III)] or pentavalent

arsenate [As(V)]. The toxicity of arsenite is 25–60 higher

than that of arsenate. Arsenic occurs in extremely high

concentrations in groundwater in Bangladesh and a number

of other countries (Vietnam, India, Nepal, China, America).

In Bangladesh, 1.2 million tube wells (29%) were found

to be contaminated with arsenic. It is estimated that

85 million people are at risk from arsenic contamination

(Hossain 2006).

Different treatment technologies are reported in the

literature for arsenic removal. USEPA suggested ion

exchange, activated alumina, reverse osmosis, modified

coagulation/filtration and modified softening as best avail-

able technologies (BAT) (USEPA 1999). Other technologies

emphasized are: iron based coagulation assisted microfiltra-

tion, iron oxide coated sand, manganese greensand filtration

and granular ferric hydroxide (GFH). Appropriate treat-

ment depends on many factors, for example, concentration

of arsenic, water composition, pH and cost effectiveness.

Polyurethane is a polymer consisting of a chain of

organic units joined by urethane links. Generally, the chara-

cteristics of polyurethane depend on the manufacturing

method and the starting chemicals used. As a result,

polyurethane sponge can be flexible (for example sponge

used in furniture cushions) or rigid (for example sponge

used in construction panels). Flexible polyurethane are

made from polyols of moderately high molecular

doi: 10.2166/wst.2009.477

1489 Q IWA Publishing 2009 Water Science & Technology—WST | 60.6 | 2009

weight and low degree of branching, whereas rigid

polyurethane are prepared from highly branched resins of

low molecular weight (Braun et al. 1985). Other properties

of polyurethane (PU) such as foam density, cell structure,

rate of wetting, and water retention vary depending on the

ratio of polymer to cross - linking agent, foaming tempera-

ture, pH, and the type and amount of additives (Havens &

Rase 1993).

To increase the effectiveness of sponge, many researchers

have incorporated additives into polyurethane sponge.

Brookes et al. (1987), Hu et al. (1994) have put living

microorganisms into polyurethane foam matrices as a

method of immobilization and used these sponges as

biofilter media to remove phenols from wastewater. Other

researchers (Wood et al. 1982; Havens & Rase 1993)

have immobilized active enzymes in the foam and used

such materials in biological waste-gas treatment system.

Additionally, Lupton & Zupanac (1991) used polyurethane

foam containing PAC and immobilized microorganisms

for the treatment of wastewater containing phenol.

Al-Marzouqi et al. (2003) reported that low density poly-

urethane sponge (13 kg/m3) has the highest capacity for

absorbing oil (0.06 m3 oil/kg sponge after one minute)

in cooperation with palm trunk, pin fish fiber, rice bag,

feathers, and PP pad sponge.

Sponge is an ideal material for adsorption because

it is very porous and its large surface area facilitates

arsenic adsorption. In addition, sponge is cost effective so

it can be applied in small communities as well as in

developing countries. To achieve high arsenic adsorption,

sponge should be coated with metal oxide because arsenite

and arsenate are strongly attracted to iron oxide. Once

adsorption of arsenic onto a sponge matrix is exhausted,

sponge can be directly disposed of or regenerated with

chemical solutions in extreme cases. Sponge can easily be

compressed and incorporated into building materials such

as concrete, making its disposal easier.

A new adsorbent material, iron oxide coated sponge

(IOCSp), exhibited a high capacity to remove arsenic due to

its physical characteristics (high internal porosity and

specific surface) as well as its high iron oxide content

(12%) (Nguyen et al. 2006). However, the waste from this

treatment process (exhausted IOCSp) also needs to be

treated properly.

As a consequence of the toxicity of arsenic, traditional

ways of direct dumping of arsenic waste are no longer

acceptable. For this reason, it has become necessary to

develop a cheap and effective method for processing arsenic

waste accumulated during the water treatment process,

especially from household and community water supply

systems. Different treatment processes such as coagulation,

flocculation, adsorption or membrane processes that are

often used to treat arsenic-contaminated water, cannot

destroy arsenic completely, rather all these processes convert

arsenic into different forms or transform it into- insoluble

compounds in combination with other elements, such as

iron. The safe disposal of arsenic wastes is a problem.

Encapsulation of arsenic through solidification/

stabilization (S/S) techniques is the most attractive solution

for dealing with the arsenic waste. Although solidification/

stabilization do not demolish the toxic but this method could

eliminate the effect of the toxic to nearby environment. In

solidification process, waste is encapsulated to form a solid

material whereas chemical reactions in stabilization process

could reduce the leachability of a waste (USEPA 2000).

A number of researchers have investigated arsenic S/S

processes using different solidifying materials: Portland

cement (Akhter et al. 1990; Buchler et al. 1996), Portland

cement and iron (II) and (III) (Taylor & Fuessle 1994),

Portland cement and lime (Dutre & Vandecasteele 1998),

Portland cement, iron and lime (Palfy et al. 1999), Portland

cement and fly ash (Chu et al. 1991; Akhter et al. 1997),

Portland cement and silicates (Chu et al. 1991).

Akhter et al. (1990) studied different methods for the

immobilization of arsenic in contaminated soil with an

arsenic concentration of 12,200 mg/L. They tested mixtures

of type I Portland cement, type F fly ash, blast furnace slag,

lime and silica fume. Their results showed that the

performance of Portland cement alone is much better

than that of other reagent or combination (The ratio of

soil: cement ¼ 1: 0.44). The arsenic compound in the waste

also has a strong effect on the success of the S/S process

(Buchler et al. 1996). By applying the Toxic Characteristic

Leaching Procedure (TCLP), leachate concentrations was

found to vary between 1.7–510 mg/L. The experimental

results showed that S/S was a better treatment process for

wastes containing either sodium arsenate or sodium

arsenite than the one containing arsenilic acid. The arsenic

1490 T. V. Nguyen et al. | Arsenic removal by iron oxide coated sponge Water Science & Technology—WST | 60.6 | 2009

in leachate concentrations was 1.7–2.1 mg/L for sodium

arsenate and arsenite respectively in comparison with

510 mg/L for arsenilic acid.

To increase the effectiveness of S/S, a number of

additives were used in the cementation process. Iron

appears to be the favored selection. The research of Taylor

& Fuessle (1994) showed that oxidation states of iron

and arsenic have strong affected on the S/S process.

Solidification investigation of an industrial waste containing

a large amount of arsenic (23–47% arsenic) with cement

and lime was carried out by Dutre & Vandecasteele (1998).

Solidification with cement and lime was found to be

a suitable technique to reduce the leachability of arsenic

from the waste. This process could reduce 99.9% leachate

concentration (from 5 g/L to only 5 mg/L). Palfy et al. (1999)

found the optimum ratios of Ca:As and Fe:As was 8 and 6

respectively for the stabilization of waste arising from the

carbon dioxide scrubbing. The stabilisation process could

help to reduce the leachate concentration from 6,430 mg/L

to 0.823 mg/L.

In this research, detailed experiments were conducted

to evaluate the capacity and effectiveness of the new coated

material IOCSp in removing different forms of arsenic

(As(III) and As(V)) from arsenic-contaminated synthetic

water in the laboratory and natural groundwater in

Vietnam. The encapsulation of exhausted IOCSp through

the S/S technique was also carried out.

EXPERIMENT

Experimental materials

Water

In this study, two kinds of water were used. In the batch

experiments, synthetic water (tap water spiked with the

required concentrations of As(III) and As(V)) was used. In

order to evaluate the effectiveness of IOCSp in practice,

actual groundwater samples from Hanoi, Vietnam were also

employed. The characteristics of the synthetic water and

groundwater used are presented in Table 1. Arsenic

concentration was determined by hydride generation

atomic absorption spectroscopy (HGAAS).

Standards and reagents

All chemicals used in this study were reagent grade, and

were used without any purify cation.

Iron oxide-coated sponge (IOCSp)

Commercial polyurethane (PU) sponge was coated with

iron oxide (IOCSp contains 12% of iron oxide). The method

of preparation is explained elsewhere (Nguyen et al. 2006).

Cement

Common cements, including Type I Portland cement and

Type F fly-ash were used for solidification.

Experimental study

Batch equilibrium study

Equilibrium studies were conducted at a pH of 7 using

IOCSp and synthetic water with As(III) and As(V)

concentrations of 5 mg/L. Equilibrium studies were con-

ducted at the room temperature of 228C. In these

experiments, different amounts of adsorbent (0.018 g

to 1.296 g) was placed into 250 mL Erlenmeyer flasks

containing 100 mL of the arsenic sample, and the samples

were shaken at 130 rpm for 20 hours. After 20 hours of

contact time, samples from each flask were decanted and

analyzed for the residual arsenic in the solution.

Table 1 | Characteristics of the synthetic water and groundwater used in experiments

Parameters Synthetic water Hanoi groundwater

As(III) & As(V) 0.26–5 0.480

pH 7 6.5–7.3

Iron 0.016–0.09 3.6

Manganese 0.004–0.02 0.9

Nitrate 0.74–2 N/A

Copper 0.001–0.049 0.05

Zinc ,0.005 0.01

Phosphate 0.004 1.8

Silicate 0.8 17

Note: All parameters are in mg/L, except pH, N/A: Not available.

1491 T. V. Nguyen et al. | Arsenic removal by iron oxide coated sponge Water Science & Technology—WST | 60.6 | 2009

Pilot study

Pilot scale experiments were conducted to study the

removal of arsenic from groundwater in Hanoi, Vietnam.

A bucket of 200 mm in diameter and 350 mm in height

was used in the study. The bucket was packed with 180 g

of IOCSp. The test was conducted at a normal pH of

water of between 6.5–7.3. The water was allowed to

flow through the packed bucket at a filtration velocity

of 50 mL/min (which corresponds to 0.1 m/h).

Solidification

The exhausted IOCSp was obtained by mixing IOCSp with

synthetic water for 20 hours. The amount of As(III) and

As(V) in the exhausted IOCSp were calculated by following

equation:

Q ¼ ðCo 2 C1Þ*V =M

in which: Co: initial As(III) and As(V) concentrations of

synthetic water, C1: As(III) and As(V) concentration of

synthetic water after 20 hours contact with IOCSp, V:

Volume of synthetic water, M: Amount of IOCSp.

The exhausted IOCSp were solidified in different

concrete samples with different ratios of cement: sand:

binders and cured for various times. Leachate tests were

conducted by agitating 10 g of the concrete with 100 mL of

aceticacid (10%) for24 h.Hereexhausted IOCSprefers to the

IOCSp which has attained maximum adsorption of arsenic.

RESULTS AND DISCUSSION

Equilibrium adsorption experiments

Adsorption equilibrium experiments were conducted

to evaluate the adsorption capacity of IOCSp. The

equilibrium results were then fitted with Langmuir,

Freundlich, and Sips isotherm equations. The adsorption

curves simulated by all of these models fitted well with

the observed values. The simulated and the experimental

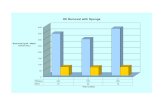

Figure 1 | Prediction of equilibrium adsorption of As by different adsorption models (contact time ¼ 20 hours, mixing rate ¼ 130 rpm, temperature ¼ 228C).

Table 2 | Isotherm equations for arsenic removal using IOCSp (for synthetic water

spiked with arsenic)

Arsenic species

Parameters As(III) As(V)

Langmuir qm 3.85 4.5

b 0.95 0.7

r 0.966 0.974

Equation qe ¼ 3.66C/(1 þ 0.95C)

qe ¼ 3.15C/(1 þ 0.7C)

Freudlich kF 1.97 1.9

n 3.5 2.8

r 0.985 0.990

Equation qe ¼ 1.97C 0.29 qe ¼ 1.9C 0.36

Sips qm 4.2 4.6

b 0.91 0.74

n 1.27 1.22

r 0.965 0.972

Equation qe ¼ 4.18 (0.91C)0.79/(1 þ (0.91C)0.79)

qe ¼ 4.6 (0.74C )0.82/(1 þ (0.74C )0.82)

1492 T. V. Nguyen et al. | Arsenic removal by iron oxide coated sponge Water Science & Technology—WST | 60.6 | 2009

concentrations of the remaining As(III) and As(V) are

shown in Figure 1. The model equations and the isotherm

parameters are shown in Table 2.

Where Ce: the equilibrium concentration (mg/L),

Langmuir model qe ¼ ðqmbCe=1 þ bCeÞ, b: Langmuir

constant related to the binding energy of adsorption

(L/mg), qm: the saturated maximum monolayer adsorption

capacity (mg/g), Freundlich isotherm qe ¼ KF·C1=ne , KF:

a Freundlich constant indicative of the adsorption

capacity of the adsorbent, n: an experimental constant

indicative of the adsorption intensity of the adsorbent,

Sips model qe ¼ qmðbCeÞ1=n=1 þ ðbCeÞ

1=n has the features

of both the Langmuir and Freundlich isotherm models.

It can be seen that the Langmuir and Sips models

yielded the same values for arsenic adsorption capacity

(qm). The values were 3.85–4.2 mg As(III)/g IOCSp and

4.5–4.6 mg/g IOCSp respectively. The values of b for

both models were almost same. It was in the range of

0.91–0.95 for As(III) and 0.7–0.74 for As(V). This predic-

tion shows that there is not much difference between these

two models in describing the adsorption of a single

component system. The low value of 1/n (,0.36) in the

Freundlich isotherm suggests that any large change in the

equilibrium concentration of soluble arsenic would not

result in a significant change in the amount of arsenic

sorbed by the IOCSp. The correlation coefficient (r) for all

the isotherms ranged from 0.965 to 0.99, representing a

good fit of the observed data.

In this study, the value of the adsorption capacity of

IOCSp (qm) is much higher than that with a number of

other adsorbents (Table 3). This indicates that IOCSp has

a superior arsenic adsorption capacity.

Pilot experiments

Following the success of the IOCSp system in removing

arsenic at the University of Technology, Sydney (UTS),

Australia, the IOCSp pilot system was tested with ground-

water contaminated with arsenic in Vietnam. To evaluate

the effectiveness of IOCSp under actual conditions,

pilot experiments were carried out using groundwater

with an arsenic concentration of 480mg/L from a well

in Hanoi, Vietnam. The filter was run at a filtration rate

of 0.1 m/h. The column (bucket) was packed with 180 g

of IOCSp. These experiments were conducted using

a small bucket of 200 mm in diameter and 350 mm in

height (Table 4).

During the initial stage of the experiment, the effluent

arsenic concentration was less than 10mg/L (up to a

throughput volume of 330 L). After this, the arsenic in the

effluent increased slowly but the effluent concentration was

Table 3 | Comparison of arsenic adsorption capacity of IOCSp with other adsorbents

Name of adsorbent Adsorption capacity (mg/g) References

Iron oxide coated sand 0.029 Gupta et al. (2005)

Granular ferric hydroxide 0.11 Thirunavukkarasu et al. (2003)

Activated alumina 0.180 Singh & Pant (2004)

Red mud 0.66 Altundogan et al. (2000)

Ferruginous manganese ore 0.680 Chakravarty et al. (2002)

Iron oxide impregnated activated alumina 0.734 Kuriakose et al. (2004)

Activated red mud 0.87 Altundogan et al. (2002)

Nanoscale zero valent iron 3.5 Kanel et al. (2005)

Iron oxide coated sponge 3.85–4.6 This study

Table 4 | Arsenic removal from groundwater by IOCSp bucket

No Throughput volume (L) Effluent conc. (mg /L) Bed volume

1 75 4 11

2 330 10 47

3 1,120 20 160

4 1,410 31 201

5 1,550 40 222

1493 T. V. Nguyen et al. | Arsenic removal by iron oxide coated sponge Water Science & Technology—WST | 60.6 | 2009

still lower than 40mg/L even when the bed volume was

about 222 (which correspond to a throughput volume of

about 1,550 L).

Solidification experiments

The safe disposal of IOCSp after the adsorption process

is very important to prevent the spreading of toxicants

into the environment. In this study, the fully exhausted

IOCSp (containing up to 0.42% of arsenic) were solidified

in different concrete samples with different ratios of

cement: sand: binders and cured for various times. The

As(III) and As(V) concentrations in the effluent after

leaching test are presented in Table 5.

The results showed that arsenic concentration in the

leachate of the concrete samples was very low, from 1 to

35mg/L. The percentage of arsenic leached in term of

quantitative was only from 0.1 to 1.1%. The low leachability

of arsenic in the samples is attributed to the high affinity of

arsenic to the iron oxide coated in sponge. The arsenic

concentration in the leachate increases with decreasing

ratios of cement. However, this decrease was very small.

The results also showed that fly ash can help in reducing

arsenic concentration in the leachate, especially with As(V)

through the formation of insoluble fly ash–arsenic com-

pound in the leachate. Arsenic concentration in the

leachate of samples added by fly ash was at least three

times lower than the samples without adding fly ash

(Table 5). The addition of lime also increased the capture

of arsenic but the effect of lime addition was smaller than

that of fly ash.

The batch extraction results indicate that the exhausted

IOCSp have no adverse effect on the environment if it is

properly encapsulated in cement. Only a small amount of

arsenic is released from the concrete. The concrete can be

used as road base or safely disposed directly in the landfill.

The ratio of cement: sand in the first 3 samples were based

on the Vietnamese standard for concrete. If the ratio of

cement: sand and cement: IOCSp increased (more than 3.5

and 50 respectively), the hardness of concrete decreases

significantly although arsenic is still captured in the

concrete. In this case, the concrete should be disposed

directly to landfill as it is not suitable for road base.

CONCLUSIONS

IOCSp exhibited a high arsenic removal capacity in both

batch and column experiments. The high removal capacity

of IOCSp was due to its physical characteristics (high

internal porosity and specific surface) as well as its high iron

oxide content (12%). The IOCSp adsorption equilibrium

results with synthetic water were successfully simulated by

Langmuir, and Sips models. The adsorption capacity of

IOCSp (up to 4.2 and 4.6 mg of As(III) and As(V) per gram

of IOCSp respectively) was much higher than that of a

number of adsorbents such as ferruginous manganese

ore (0.680 mg/g), iron oxide coated sand (0.029 mg/g),

activated alumina (0.180 mg/g), red mud (0.66 mg/g), iron

oxide impregnated activated alumina (0.734 mg/g),

and activated red mud (0.87 mg/g) (Altundogan et al.

2000, 2002; Chakravarty et al. 2002; Kuriakose et al. 2004;

Table 5 | Effect of additives on leachate concentration

Weight of additives per 2g of exhausted IOCSp material (g) Leachate concentration (mg/L)

No Cement Sand Lime Fly ash

1 day 1 week 1 month

As(III) As(V) As(III) As(V) As(III) As(V)

1 150 230 0 0 24 21 23 18 16 14

2 150 320 0 0 27 28 26 23 21 15

3 150 320 75 0 16 9 17 12 13 6

4 50 125 0 0 32 19 35 25 27 22

5 50 190 0 10 20 12 5 2 13 1

6 100 350 0 50 12 6 3 3 8 2

7 150 525 0 75 5 3 2 2 8 1

1494 T. V. Nguyen et al. | Arsenic removal by iron oxide coated sponge Water Science & Technology—WST | 60.6 | 2009

Singh & Pant 2004). The IOCSp filter yielded consistent

arsenic removal efficiency for a long period. A bucket

(20 cm diameter and 35 cm height) packed with 180 g of

IOCSp reduced As from 480mg/L to less than 40mg/L. The

bed volume was 222. Once adsorption of arsenic onto a

sponge matrix is exhausted, IOCSp can easily be com-

pressed and incorporated into building materials such as

concrete, making its disposal easier. The results showed that

solidification process with cement is suitable to encapsulate

arsenic into the cement. This simple method can help in

managing the disposal of waste in an inexpensive and safe

way. This simple method can be applied in small commu-

nities as well as in developing countries.

ACKNOWLEDGEMENTS

This research was funded by the Australian Research

Council (ARC) Discovery Grant (DP0450037: Healthier

Water: Innovative Processes for Arsenic Removal and

Sludge Management) and ARC International Linkage

Grant (LX0345566: A better way to remove arsenic from

drinking water).

REFERENCES

Akhter, H., Butler, L., Branz, S., Cartledge, F. & Tittlebaum, M.

1990 Immobilization of As, Cd, Cr and Pb containing soils by

using cement or pozzolanic fixing agents. J. Hazard. Mater. 24,

145–155.

Akhter, H., Cartledge, F., Roy, A. & Tittlebaum, M. 1997

Solidification/stabilization of arsenic salts: effects of long cure

times. J. Hazard. Mater. 52, 247–264.

Al-Marzouqi, A. H., Busamra, A. A., Mohammed, F., Al-Shehhi, S.

& Abdulwahab, W. 2003 An absorbent-skimmer method

to clean-up oil spills. The fourth annual U.A.E. University

Research Conference. Glance, The United Arab Emirates.

Altundogan, H. S., Altundogan, S., Tumen, F. & Bildik, M. 2000

Arsenic removal from aqueous solutions by adsorption on red

mud. Waste Manage. 20, 761–767.

Altundogan, H. S., Altundogan, S., Tumen, F. & Bildik, M. 2002

Arsenic adsorption from aqueous solution by activated red

mud. Waste Manage. 22, 357–363.

Braun, T., Nauratil, J. D. & Farag, A. B. 1985 Polyurethane Foam

Sorbents in Separation Science. CRC Press, Boca Raton, Florida.

Brookes, I. K., Lilly, M. D. & Drozd, J. M. 1987 Use of immobilized

subtillus for the stereospecific hydrolysis of d,1-methyl acetate.

Enzyme Microb. Technol. 9(4), 217–220.

Buchler, P., Abdala, H. R., Akhter, H., Cartledge, F. K. & Tittleaum,

M. E. 1996 Solidification/stabilization of arsenic: effects

of arsenic speciation. J. Environ. Sci. Health 31(4), 747–754.

Chakravarty, S., Dureja, V., Bhattacharyya, S., Maity, S. &

Bhattacharjee, S. 2002 Removal of arsenic from groundwater

using low cost ferruginous manganese ore. Water Res. 36,

625–632.

Chu, P., Rafferty, M., Delfino, T. & Gitschlag, R. 1991 Comparison

of Fixation Techniques for Soil Containing Arsenic. American

Chemical Society, Washington.

Dutre, V. & Vandecasteele, C. 1998 Immobilization mechanism of

arsenic in waste solidified using cement and lime. Environ. Sci.

Technol. 32(18), 2782–2787.

Gupta, V. K., Saini, V. K. & Jain, N. 2005 Adsorption of As(III)

from aqueous solution by iron oxide coated sand. J. Colloid

Interface Sci. 288, 55–60.

Havens, P. L. & Rase, H. F. 1993 Reusable immobilized enzyme/

polyurethane for removal and detoxification of localized

organophosphate pesticide spill. Ind. Eng. Chem. Res. 32,

2254–2258.

Hossain, M. F. 2006 Arsenic contamination in Bangladesh—an

overview. Agric. Ecosyst. Environ. 113, 1–16.

Hu, Z. C., Korus, R. A., Levinson, W. S. & Crawford, R. L. 1994

Adsorption and biodegradation of pentachlorophenol by

polyurethane immobilized flavobacterium. Environ. Sci.

Technol. 28(3), 491–496.

Kanel, S. R., Manning, B., Charlet, L. & Choi, H. 2005 Removal of

Arsenic(III) from groundwater by nanoscale zero valent iron.

Environ. Sci. Technol. 39(5), 1291–1298.

Kuriakose, S., Singh, T. S. & Pant, K. K. 2004 Adsorption of As(III)

from aqueous solution on to iron oxide impregnated activated

aluminia. Water Qual. Res. J. Can. 39, 258–266.

Lupton, F. S. & Zupanac, D. M. 1991 Removal of phenols from

waste water by a fixed bed reactor. U.S. Patent no. 4983299.

Nguyen, T. V., Vigneswaran, S., Ngo, H. H., Pokhrel, D. &

Viraraghavan, T. 2006 Iron-coated sponge as effective media to

remove arsenic from drinking water. Water Qual. Res. J. Can.

41(2), 164–170.

Palfy, P., Vircikova, E. & Molnar, L. 1999 Processing of arsenic waste

by precipitation and solidification. Waste Manage. 19, 55–59.

Singh, T. S. & Pant, K. K. 2004 Equilibrium, kinetics and

thermodyanamic studies for adsorption of As(III) on activated

aluminia. Sep. Purif. Technol. 36, 139–147.

Taylor, M. & Fuessle, R. 1994 Stabilization of Arsenic Wastes.

HWRIC, Illinois.

Thirunavukkarasu, O. S., Viraraghavan, T. & Subramanian, K. S.

2003 Arsenic removal from drinking water using granular

ferric hydroxide. Water SA 29, 161–170.

USEPA 1999 Technologies and costs for removal of arsenic from

drinking water, EPA 815-R-00-012, Washington, DC.

USEPA 2000 Solidification/stabilization use at superfund sites. EPA

542-R-00-010, Cincinnati.

Wood, L. L., Hartdegen, F. J. & Hahn, P. A. 1982 Enzymes bound

to polyurethane. U.S. Patent no. 4342834.

1495 T. V. Nguyen et al. | Arsenic removal by iron oxide coated sponge Water Science & Technology—WST | 60.6 | 2009