Army Aviation Digest - Feb 1989

-

Upload

aviationspace-history-library -

Category

Documents

-

view

219 -

download

0

Transcript of Army Aviation Digest - Feb 1989

-

7/28/2019 Army Aviation Digest - Feb 1989

1/52

. Distribution Restriction: This publication approved for public release. Distribution is unlimited

-

7/28/2019 Army Aviation Digest - Feb 1989

2/52

PROFESSIONAL BULLETIN1-89-2 February 1989

1 Acknowledgment2 We've learned our lessons well , MG Ellis D. Parker3 Sharing some of the good things, BG Marvin E. Mitchiner, Jr .5 The only thing missing in this war is the bullets

10 "We don't use safety as a crutch"13 Somebody's got to make a decision16 "We never compromise the cockpit"19 "Bring everybody home!"23 If it isn 't safe, it doesn't fly27 "One quality required in aviation is honesty"28 You can't have one without the other30 DES checks reveal safety weaknesses33 My, how time flies when you're making progress35 Aviation snapshot36 Flight data recorders are paying off38 Crashfax Videos re-create real accidents39 ATC Focus: Management of Special Use Airspace, LTC(P)James E. Dooley III40 Aviation Personnel Notes

page 12

page 18 page 2242 DES Report to the Field: Aviation Standardization and TrainingSeminar/ Branch Liaison Team Program, CPT Carl Terry Major Ge neral Ellis D. ParkerComm ander44 Aviation Medicine Report: Gastroesophageal Reflux, CPTGilbert R. Teague, M.D.46 RSI Report: Implementation of International Agreements48 PEARL'S49 USAASO Sez: NOTAM Consolidation , Mr . Monroe J. Mitchell

U.S. Army Aviation CenterPatricia S. KitchellEd itor

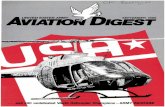

By order of the Secretary of the Army:COVER: This month the Aviation Digest presents a fieldperspective of safety at work . The cover photo shows amodified UH-1 belonging to the opposing force (OPFOR)made up of American soldiers trained to fight as a Sovietmotorized rifle regim ent at the National Training Cent er, FortIrwin , CA.

Carl E. VuonoGeneral, U.S. ArmyChief of StaffOfficial:William J . Meehan IIBrigadier Gene ra l, U.S. Arm yThe Adjutant General

The mission of the U.S. Army Aviation Digest professional bulletin (USPS 415-350)is to provide information of an operational, functional nature concerning safety andai rcraft accident prevention, air traffic control, training and doctrine, maintenance, operations, research and development, aviation medicine and other related data. Information contained in this bulletin does not change or supersede any information presentedin other official Army publications.

The Digest is an official Department of th e Army professional bulletin publishedmonthly under the supervision of the commander, U.S. Army Aviation Center. Viewsexpressed herein are not necessarily those of the Department of the Army nor the u.s.Army Aviation Center. Photos are U.S. Army unless otherwise specified . Use of themasculine pronoun is intended to include both genders unless otherwise stated. Materialmay be reprinted provided credit is given to the Aviation Digest and to the author unlessotherw ise indicated.

Articles , photos and items of interest on Army Aviation are invited. Direct commucation is authorized by writing Editor, U.S. Army Aviation Digest, P.O. Box 699, FRucker, AL 36362-5042, or by calling either AUTOVON 558-3178 or Commerc205-255-3178 . Manuscripts returned only upon request.

Active Army, Army National Guard and U.S. Army Reserve units receive distributias outlined in DA Pamphlet 25-33. To complete DA Form 12-99-R, enter form numb12-05-E, block number 0014, and quantity. Also use DA Form 12-99-R for any chanin distribution requirements . Submit to your publications control officer.

Those not eligible for official distribution or who desire personal copies of the Digcan order the magazine from the Superintendent of Documents, U.S. Government Pring Office, Washington, DC 20402.

POSTMASTER: Send address changes to Superintendent of Documents, UGovernme nt Printing Office , Washington , D.C. 20402, ISSN 0004-2471 .

-

7/28/2019 Army Aviation Digest - Feb 1989

3/52

A FIELD PERSPECTIVE OF SAFETY AT WORK

E < a ~us. ARMY SAfETY CENTERAcknowledgment

We would like to acknowledge the peoplewho directly assisted in setting up visits toaviation units and interviews with peoplewho contributed to this special issue.Fort Campbell, KY. CPT Russell James,Public Affairs Office, IOlst Airborne Division;CW3 Danny Moore, Assistant AviationSafety Officer, IOlst Airborne Division; andCW2 Francisco Cristobal, Aviation SafetyOfficer, 6-101 st Aviation Regiment.Fort Stewart, GA. Mr. James Hardbeck,Aviation Safety Office, Hunter ArmyAirfield.Fort Riley, KS. CW4 Bill King, AviationSafety Officer, 1st Infantry Division (Mech).Fort Bragg, NC. Mr. Ralph Stone, Chief,

Aviation Safety, XVIII Airborne Corps andFort Bragg; CW4 Donnie Ditty,Standardization Officer and CW3 TommieConary, Aviation Safety Officer, 82dAirborne Division.National Training Center, Fort Irwin,CA. CW3 Doyle Wootten, Aviation SafetyOfficer, NTC.We would also like to express appreciationto all the people-commanders, staffofficers, pilots, noncommissioned officers,enlisted personnel, and safety andstandardization people, military andcivilian-in the headquarters, in aviationunits, in the hangars, on the flight line, andin the field, who took time to talk to usabout how they plan their operations and flytheir missions, how they maintain theiraircraft, and above all, how they makesafety a part of everything they do.

FEBRUARY 1989 1

-

7/28/2019 Army Aviation Digest - Feb 1989

4/52

MAJOR GENERAL ELLIS D. PARKERChief, Army Aviation Branch

We've learned ourlessons wellATER MORE THAN 30 years in Armyaviation, I know that our job hasbecome tougher. I know that youreveryday training takes place in high-riskenvironments that are made even morehazardous by the dark of night. Butrecognizing that we can ' t afford to give thenight to our enemy, that 's a fact of life forArmy aviation.It's a fact of life that requires us, morethan ever before, to perform to standard- tostandards that have been developed in manycases from lessons learned the hard way.We've learned our lessons well, and we'reflying safer than ever, even in the face ofincreasing mission demands that have placedtougher requirements on top of already tough

requirements.Many of you share your experiences inthis special issue. And although you havedifferent missions, different aircraft, anddifferent operating environments, thecommon thread tying you together is thatyou operate by the book. You know thestandards. You follow the standards. Youenforce the standards.

2

Our job at the aviation school is toproduce Army aviators who are technicallyand tactically well grounded. We look tounits to make them proficient. This specialissue makes it abundantly clear that you aredoing exactly that. And our record for fiscal88 shows that you're doing it with a highpriority on safety.I acknowledge and applaud youraccomplishments and contributions. But evenwith the safety gains we have made , wecannot afford to rest on our laurels. Thechallenges facing us will grow as ourmission demands continue to increase whilewe train for peak readiness in new aircraftsystems. I ask that you keep up your goodwork so that we may continue to increaseour warfighting capability as we build onour past safety successes.

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

5/52

BRIGADIER GENERAL MARVIN E. MITCHINER, JR.Director of Army Safety andCommander, U.S. Army Safety Center

N THE SAFETY BUSINESS, we spend alot of time and use a lot of ink talkingabout things done wrong. When GeneralParker asked us to do this special safety issueof the Aviation Digest, we decided to turnthat around and look at some of the manythings folks in the field are doing right.To do this , we visited field units. Theunits you ' ll read about in these pages werenot necessarily selected because they havethe best safety records in the Army , or themost hazardous missions, or the highestcaliber maintenance personnel. The majorreason they were selected is that , together ,they represent a cross section of ForcesCommand (FORSCOM) units.We chose to visit FORSCOM units forbasically one reason. They own most of ouraircraft , so they go a long way toward

FEBRUARY 1989

E m ~s. ARMY SAFETY CENTERSharing some ofthe good thingsdetermining not only the Army's aviationsafety record but its aviation readiness .Fiscal 88 was the safest year in the historyof Army aviation. The record-setting rate of1.84 Class A accidents per 100,000 flyinghours is the lowest rate ever recorded. Andour Class A through C rate of 4.82 was alsoa record low.We achieved this record while flyingincreasingly more demanding missions andhigh-risk night tactical operations. Creditmust go to leaders who managed theincreased risks that go along with our moredemanding missions , to aviation personnelwho performed to standard both in thecockpit and on the flight line , and toaviation safety officers who supported theircommanders with strong safety programs.You'll read about some of those programsin this special issue. These are by nomeans all the good units and all the goodprograms in the army. But they are some ofthe best. And it is our hope that sharingtheir programs, their experiences , and theirideas will make other good units and othergood programs even better.

3

-

7/28/2019 Army Aviation Digest - Feb 1989

6/52

NATIONAL TRAINING CENTER

Soldiers equipped for combat training at the NTC. If a soldier is "killed," the multiple integrated laser system(MILES) he is wearing sounds an alarm, and he's out of the battle. But on this high-tech battlefield, he learns fromhis mistakes and lives to fight again.

4 u.s. ARMY AVIATION DIGES

-

7/28/2019 Army Aviation Digest - Feb 1989

7/52

Nothing is simulated. If you run out of fuel, you park yourvehicles. If you run out of food, you go hungry . . .The only thing missingn this war is the bullets

ITS ROT A TING to the NationalTraining Center (NTC) find theclosest thing to real war they haveis a real enemy. Theof the opposing force look like,, and fight like the best motorized

in Soviet uniforms use tacticsof captured manuals , and their, vehicles, and aircraft have beenadvantage-in this

of the year ,The only thing missing in this war is theis the real thing- all

of battle are there.line

, NTC aviationno aircraft of their own. They,by its SOPs. " They try to remain in the

background and let people make their ownmistakes as much as po sible; you might saythey ' re very heavy on the observing andlight on the controlling," Wootten adds.

AH-1 belonging to Task Force Falcon on approach toArea Bravo at the NTC.

5

-

7/28/2019 Army Aviation Digest - Feb 1989

8/52

NATIONAL TRAINING CENTERBecause the OCs are with the rotationalunits every day, they are able to spot things

nobody else could. By helping to identify apotential problem early, they can assist theunit in resolving the problem almo t beforeit begins. Large problems, such as thoseinvolving airspace, are taken to the NTCaviation safety officer.Getting readyAs much as 6 months before an aviation unitis scheduled to rotate to the NTC, theyreceive a rotational safety officer packet,which includes NTC Regulation 95-1, thebase document for flying at the NTC, aswell as illumination data, NTC procedures,and other safety information.

NTC and rotationalunits flew nearly25,000 hours last yearunder some of the mostchallenging conditionsanywhere. And they didit without a singleClass A or B accident-and only one Class C.

Before the unit arrive , the NTC aviationsafety officer has analyzed the unit's mishaphistory to identify possible problems or weakspots. As soon as the unit arrives, aviatorsreceive a comprehensive safety briefing

covering uch things a airspace, accidenthistory, weather data and basic procedureswithin the NTC. The briefing also coversenvironmental factor: winds, dust, lack ofvisual cues-all with special empha is onnight flying in the desert.

6

NTC train-upBefore rotating to the NTC,elements of Fort Stewart's 24thInfantry Division undergo anintense 2- to 3-week train-upperiod. During the final 10 dayof this period, the aviation unitstrain even closer than normalwith the infantry brigade,providing support and developingclose working relationships withthe ground units. This providesthe aviation units an opportunityto be in on the planning stagesfor operations as well as givingpilots practice in flying thedifferent types of missions theywill fly at the NTC.While it is impossible tosimulate the environmentalconditions that exist at the

NTC-rugged desert andmountainou terrain- haring ofexperience by aviators who havebeen on previous rotations or whohave experience in mountainflying in Korea and Hondura isan important part of this train-upperiod.This period is also an educationprocess and provides aviationunits an opportunity to let groundcommanders know during theplanning stages of the operationsome of the effects theenvironment can have on thecapabilities and limitations oftheir aircraft. This can help avoidplacing a pilot in a position laterof having to say that a missioncan't be flown afely.

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

9/52

There is no way to adequately prepare anaviator for what he will encounter the firsttime he flies in the desert at night. The totalabsence of light from towns; lack of visualreferences such as trees, automobiles,houses, roads or anything else to provide aclue about relative size; and lack of contrastmake it extremely difficult to fly goggles.When aviators try to fly with pink lightfilters, the goggles are ineffective outside thenarrow beams they get with this filter, andtheir field of vision is narrowed to a fewdegrees. Aviators who come to the NTCmust be proficient in NVGs, not justqualified.Not only does safety begin long before aunit comes to the NTC and continuethroughout the rotation, it is a large part ofwhat happens after the guns are silenced andthe dust has settled.OCs are constantly on the lookout inplayer units for ways to make the operationssafer. For example: What did you noticeabout flying at night or operating in theFARP (forward area refueling point)? This ispart of every briefing, and it almost alwaysbrings out safety tips that other units can use.A commander on a first rotation with hisunit at the NTC faces a real challenge. If hefights his unit better than the enemy, hewins; if he doesn't, he loses. And there's areal psychological impact that goes withlosing. However, there are no real losersat the NTC because of the opportunityto learn from mistakes and live to fightagain.Lessons learnedWithin as little as 4 hours after a battle isfought, a specially equipped van can deliverto commanders in the field a review of thebattle. Through the use of audio, video, andcomputer graphics, participants are able to

FEBRUARY 1989

A UH-60 is almost invisible in the dust from its ownrotorwash as it follows signals from a ground guideduring slingload operations.

see the whole picture of what they weredoing and what the enemy was doing.Leaders can analyze the results of theiractions-both good and bad-and developapproaches to improvements before the nextbattle.In addition, a take-home package isprovided that will allow a commander toreview what his unit did and integrate theNTC training feedback into the training plan

7

-

7/28/2019 Army Aviation Digest - Feb 1989

10/52

NATIONAL TRAINING CENTERhave gotten his people killed.Not only are rotational units provided witha lessons-learned packet from their trainingat the NTC, people at the NTC areconstantly learning how to do their jobsbetter and make the training they providesafer.The outbriefing held after everyone of the14 a n n ~ a l rotations is a lessons-learned, noholds-barred type of meeting chaired by thecommanding general of the NTC. Everybodyfrom the NTC who had anything to do withthe rotation is there, including the aviationsafety officers. They roll up their sleevesand call a spade a spade as they look at anytrends that have been identified and figureout what needs to be changed and how.

.OH-58 appro.aches tactical landing site at the NTC.

For example, in spite of the vast size ofthe NTC and its excellent aviation safetyrecord, airspace is an issue constantly beingworked, particularly NVG airspace. Iseverything covered? Is there enough control?Is there too much control? The program isconstantly being upgraded.

at his home station. Not only can he seewhat he did that caused him to win or losethe battle, he can see what he did that might

8

A few words to the wiseCW3 Doyle Wootten, NTCaviation safety officer, offersthese safety tips to units planningrotations to the NTC: Aviators who come to theNTC must be proficient inNVGs, not just qualified. Virtually every approach atthe NTC is a brownout.Therefore, concentrate on dustlanding type training to preparefor brownout situations. Pair experienced pilots whohave operated in a desert

environment with inexperiencedpilots who have not. Aircrews must understandturbulence and the Venturi effect. Stress the importance ofperformance planning and howquickly information can changeduring the course of a mission. Don't bring sick aircraft tothe NTC; they'll for sure getsicker. Compressor stalls, high oiltemps, and low pressures arecommonplace at the NTC. Fix

everything in your fleet. Keep windscreens clean tohelp reduce glare. Aircrews should review theMarch 1987 PS Magazine article"How to Fight Back at theNTC" for valuable lessonslearned in the areas of preventivemaintenance. Units should train up inaccordance with FORSCOM/TRADOC Supplement 1 to AR385-95 to prepare fordesert/mountain flying.

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

11/52

if a combat pilot could survive his firstmissions, he probably could survive the"Let's get rid of his firstmissions in peacetime, under the mostby creating all

was an accidentn my unit in March of7, but since then we'veover 6,000hours inof the harshestyou can findWe did it byby the standards,nd ever'ybody had ain enforcing those

n a real war in the first 10 missions." Itorked. And that's what the U.S. Army'sNational Training Center is all about.If a soldier gets "killed" 14 times while

ake that succeed, safety has to bentegrated into everything he does from theto his homenit.That is the other part of what the NTC isll about.

A cockpit viewof the NTC

The pilots of C Company, 14th AviationRegiment, Fort Carson, know the NTC well;they go there regularly. In fact, as much as 70percent of their flying is done there, and theyknow how tough it is. According to them, theNTC presents some unique challenges: "The sand and dust cause a lot ofproblems. The sand literally eats up the blades,especially the ones made of fiberglass. You canjust about shave with the trailing edge of aCobra's tail rotor by the end of a rotation." "Another thing is the winds. They come upsuddenly over this rough terrain, and thatcauses a lot of turbulence. We can't fly in somekinds of turbulence." "It's really dark in this place at night, evenwith goggles. And there's no vegetation oranything to show contrast. So you can't tell,especially under goggles, how high you are.You're out there flying around at night, and themountains come up out of nowhere. There's nosloping up and then sloping down; you're in avalley, and then there's a mountain. It'sunpredictable terrain." "The training here at the NTC is asrealistic as we hope most of us will ever see.Somebody can shoot you down, and you're outof the battle-but you don't die. It teaches youthere's an enemy out there, and that plays onyour mind. It's tough at the NTC, but it's goodtraining. "

9

-

7/28/2019 Army Aviation Digest - Feb 1989

12/52

NATIONAL TRAINING CENTER

"We don't use safetyas a crutch", WUSE SAFETY to force us to havetough training. You have to be safe

if you want to train that way."So says LTC Thomas Hayes, commanderof the I-4th Aviation Regiment at FortCarson. His aviation units spend more timeflying at the National Training Center (NTC)at Fort Irwin than they do at Fort Carson.Every time units from the 4th InfantryDivision go to the NTC, these aviators gowith them.They were there with Task Force Falconin November 1988; for some of them, it wasthe third rotation in less than 6 months.Measuring the risksWhen a mission comes down for aviationsupport, the first thing they do is a riskassessment. The result may be, "Yes, wecan accomplish that mission," but LTCHayes makes the final decision, and he maysay, "No, it's not worth the risk."At Carson, CW4 Bob Coder is theaviation safety officer for the I-4th AviationRegiment, but at the NTC he was the safetyofficer for the entire task force. "We don'tlook at safety as a hindrance toaccomplishing the mission. Everybody in theArmy, especially in aviation, is mission10

oriented. If you go out and try to accomplisthe mission regardless of what it takes,regardless of safety considerations, you'llprobably complete the mission for a while.But if you keep doing it, you're going tobreak your equipment and kill your people.If you look at safety as a means toaccomplish the mission, you're going to beable to continue fighting the war day afterday because you'11 have the people andassets to do it."In the heat of battle, with the opposingforce screaming across the desert at you,you want to get in there and kill the badguys. Everybody gets caught up in themission and wants to do as well as theypossibly can, and sometimes somebody hasto say 'Whoa, wait a minute.' It may bethe line pilots, or it may be yourself; it's up

to each individual to be a safety officer. Yohave to look around and see what'shappening with the people you're responsiblfor, and responsible to, and if somebodygets to the point where they're headingtoward being unsafe, it's the responsibilityof every individual to say, 'Wait a minute.Let's look at a better way of doing this.'You're not saying that the mis'sion can't be

U.S. ARMY AVIATION DIGES

-

7/28/2019 Army Aviation Digest - Feb 1989

13/52

done; you're offering alternatives-ways itcan be done without getting anybody hurt.Building in safety, Safety starts months before the unit comesto the NTC. It's part of the planning. Forinstance, crew endurance. As we go throughthe milestones , checking all the things weneed to do-When do we pack the tents?When do we load the trains? When do theaircraft depart?-we're also looking at crewendurance. Days before we depart,everybody is really working hard to get allthe last-minute things done, and no matterhow good you are or how often you do it,something happens-maybe an aircraftbreaks and you've got to get 10 people in towork on it because it's got to launch the

Brownout is a possibility during every takeoff andlanding at the NTC.

FEBRUARY 1989

next day. So those people have beenworking for 5 or 6 days solid by the timeyou get to the NTC, and they need a dayoff."So you start out with one-seventh ofyour people off on Day 1 and another oneseventh on Day 2. You can have l00-percentof your assets in the battle all the time.You'll never have to say, 'We've got thisbig battle right now and we can't launch theaircraft because I didn't give anybody a dayoff this week.' You plan ahead so thatdoesn't happen.Crew rest"You've got to remember your nonflyingcrewmembers too. If I had to choose, ,I'dmuch rather have a rested crew chief than arested copilot. The reason is, the crew chiefis out there by himself repairing the aircraft.Sure the TI (technical inspector) checks it,but he may be just as tired as the crewchief, and if something is missed, people aregoing to die. So, when there's a day thatyou don't have a battle-it may be only thefifth day in the work cycle for the crewchief-you may want to give him the day offso you can start his cycle all over again.You don't go into a battle with yourarmament systems unprepared; for the samereason, you don't want to go into battlewithout a plan for crew rest., Everything we do in the Army is simpleif you think a little bit before you do it, andthat's true of safety too. Take crewselection. If you've got a guy who's got3,000 hours as an Army pilot, but he'snever been to the NTC, you don't put himwith a copilot who has only one rotationhere. Instead, you put him with someonewho has had three rotations at the NTC sohe can learn everything that's different aboutdesert flying. So you think ahead and planwhat you need to do . " .

11

-

7/28/2019 Army Aviation Digest - Feb 1989

14/52

RISK MANAGEMENT

Good aviators know what they and their aircraft can do. If the mission briefed is beyond their capability, they say so.

12 U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

15/52

Go or no-goSomebody's got tomake a decisionAMY A VIA TION is mission-oriented,and Army aviators want to flymissions. The difference betweensuccess and failure is often simply a matterof making smart decisions about missionrisks. Smart commanders don't commit theiraviators to fly missions where the risks aretoo great, and smart aviators don't attemptto fly missions that exceed their abilities ortheir aircraft's capabilities.

"Our commandersensure that we staywithin our ownpersonal operationalenvelope, not just theenvelope of theaircraft. ", Safety starts long before an aircraft everleaves the ground. If you try to put safetyinto it after you've taken off, it won't

work," says COL Dennis Kerr, commanderof the Aviation Brigade of the 82d AirborneDivision at Fort Bragg. He makes the finalgo/no-go decision after all the mission risks

FEBRUARY 1989

All the risks have to be considered before AH-S4s takeof f on missions such as escorting UH-SOs loaded withtroops under blackout conditions.

have been assessed. And if the decision isno-go, he takes the heat-not the pilots inthe cockpit., Safety also starts with the premissionbriefing. Our commanders ensure that westay within our own personal operationalenvelope, not just the envelope of theaircraft. And people aren't afraid to make adecision on whether they or the aircraft havethe capability to do what we want them todo. If they can't do it, for whatever thereason, they'll say so."Key playersIn COL Kerr's brigade, it isn't just thecaptains, the majors, and the colonels that

13

-

7/28/2019 Army Aviation Digest - Feb 1989

16/52

RISK MANAGEMENT

Slingloading is a high-risk operation, particularly atnight, and no two missions are exactly alike. This UH-60is slingloading a HMMWV.

14

are involved in decision making. The seniorwarrant officers and safety officers are keyplayers when a mission is analyzed.Everybody gets a chance to speak his piece,knowing that what he says will beconsidered before a decision is made. Theylook at the pros and cons of the missionwhat it will accomplish as opposed to therisks. The mission gets a high priority, butnot to the extent that they will attempt tocomplete it no matter what the cost.

"Everybody gets achance to speak hispiece, knowing thatwhat he says will beconsidered before adecision is made."The same is true in Fort Campbell's IOlstAirborne Division (Air Assault). "There isnothing we do in peacetime, no Hlission that

is critical enough that we should put acommander, a pilot, a crew chief, or asoldier in a position where he has to make ajudgment about whether it's safe to do it. Ifhe has a doubt that it's safe, then heshouldn't do it-period," says LTC JohnHarris, assistant aviation officer."I think in this division if you had acommander that somebody went to and said,'Sir, this is too high-risk for me. I don't feecomfortable doing it, I think it's unsafe,'and the commander told him to do itanyway, he wouldn't be a commander in theIOlst much longer."Nonrated personnel also have input intothe decision making process. "We've

U.S. ARMY AVIATION DIGES

-

7/28/2019 Army Aviation Digest - Feb 1989

17/52

got some nonrated people here at FortCampbell with a lot of savvy about aviation.It's not uncommon to hear them say, 'Hey,we can't do that; we don't have enoughillumination' or 'That LZ's not big enough.'When you have that kind of understanding,you're not going to have somebody tellingan aviator he will do something he thinks isunsafe. "A tool for doing the missionCOL Robert E. Oakley, Jr., who commandsthe Aviation Brigade at Hunter ArmyAirfield, GA, believes that safety canenhance the way we fly our missions., Safety becomes just another tool you usewhen you analyze the mission to figure outwhat the risks are and determine whether themission is worthwhile in the face of thoserisks. If you do a risk assessment right, itcan help you accomplish the mission betterand more efficiently."He also believes that recognizing ourlimitations is key to smart decision making.."I believe that if we ever get so we thinkwe know how to do it perfectly we'11 havemore problems. When you're not so sure ofyourself, you don't become complacent, andyou end up just being better. When you

recognize there's a lot you don't know andthat there are some problems with theexperience level of some of your aviators

'lIP

Supporting a division involves moving a lot ofequipment. To crews who fly these CH-47s, it's all in aday's work.

and mechanics, and you recognize these aspotential safety hazards, then you can dealwith them effectively. It's when we starttaking things for granted that we start gettinginto trouble."These Army leaders have at least twothings in common: they listen to their peopleand they make smart risk decisions .

Quotable quote"Every night when otherpeople are in bed, there'san aviator flying withNVGs with a maximumgross slingload or 12infantry soldiers on board,flying at treetop level at 80

FEBRUARY 1989

or 100 knots, in a veryhigh-risk environment.And he's doing \t safely.Nobody's supervising himafter the briefing; it 's himdoing it. That's absoluteprofessionalism."

15

-

7/28/2019 Army Aviation Digest - Feb 1989

18/52

THE IMPORTANCE OF LISTENING

"We never compromisethe cockpit"C

T MICHELLE SKOMAS is a platoonleader and line pilot in Delta Company,Aviation Brigade, Hunter Army Airfield,GA. This unit has deployed to Hondurasthree times, and CPT Skomas was with themon two of those deployments. She takespride in her platoon's crew integration.Some of the older pilots are good at trainingnew pilots even though they may not be IPs;others aren't, so she keeps that in mindwhen she assigns missions.

"Once you're in the cockpit, rank isn'timportant. What matters is who has the mostexperience. For example, when a pilot getsinto weather, he can get pretty rattled in thefirst few minutes. When you're transitioning,your whole frame of reference has suddenlygone topsy-turvy, and it takes another pairof eyes and another mind to help you out.That's one reason good crew coordination isso important, and that's what we have in thisplatoon. "People make it happenWhen asked why D Company has a goodsafety record, CPT Skomas replied, "It's thepeople. The commander can influence it, butit's individuals who make it happen. It's thesame in my platoon. It wouldn't matter howgood I was if I didn't have good people. I'mat a low level, right down where it getsdone or doesn't get done. When I look aguy in the eye and say, 'Can you fly this?'

16

and he says 'No,' I'll turn to the guy aboveme and say 'No.' I'm not afraid to say noand I know my pilots aren't afraid to tell methe truth.

"That's what I expect from my pilots.When you're flying an aircraft, every livingsoul on board is your responsibility. If apilot thinks he can't do it-maybe he'stired- I expect him to speak up and I'll getsomebody else.

"Once you're in thecockpit, rank isn'timportant. Whatmatters is who has themost experience."

"That's my personal philosophy, and Ithink it goes for everyone in this company.Quite a few of us are right at the 1,OOO-hourmark now, and at some time during those1,000 hours we've been in situations wherewe thought we weren't going to make it.This changes your attitude. You stop beingso gung-ho and you think, 'Now, I reallydon't need to do that.' I think we have a lotof people with that kind of common sensewho'll say, 'How can we make sure we dothis safely?' And they'll do it that way."

u.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

19/52

-

7/28/2019 Army Aviation Digest - Feb 1989

20/52

-

7/28/2019 Army Aviation Digest - Feb 1989

21/52

REFORGER op order"Bring everybody home!"T A T WAS THE op order from thevery first planning meeting for FortRiley troops going to REFORGER 88."Bring everybody home" was the order asthey went from the plains of Kansas toTexas to Belgium to Germany and backagain on a grueling mission that tested bothmen and materiel to the limit. And theycarried out the op order; they returned withall their people and all their aircraft withouta single fatality and without seriouslydamaging any of their equipment.COL Lon E. Maggart, Fort Riley's Chiefof Staff, attributes this success to threefactors: a good plan, good leadership, andgood execution.The planPlanning for REFORGER 88 began at least18 months before deployment. A specialREFORGER Planning Group focusedattention and emphasis on the dangerousenvironment, not just for aviators but for allthe participants. According to COL Maggart,"The plan focused on safety and thosethings you have to do to be safe."The leadership"Obviously, no number of safety officers orslogans or coffee cups or all of those things

FEBRUARY 1989

take the place of a concerned chain ofcommand. Individual commanders were theguys in charge of making things safe overthere. They were the safety officers for theoutfit. They took responsibility for makingsure their units operated safely, and theymade sure their subordinates did the same."They carried out the oporder; they returnedwith all their peopleand all their aircraftwithout a singlefatality and withoutseriously damaging anyof their aircraft.The execution"We executed our plan in. a very focused,precise way. We took little pieces of thepie-we looked at the deployment over asone little piece; the equipment draw wasanother little piece; deployment to thetactical area was another little piece;and so on."

19

-

7/28/2019 Army Aviation Digest - Feb 1989

22/52

REFORGERDoing that made a very long exercisemanageable. "Command focus and breakingthat long period into little pieces allow you .to be safe on a day-to-day basis. And thenbefore you know it, you have safety throughthe whole period. And I think: that's whathappened . We took each piece at a time, andwe talked about how we were going toexecute that piece. And included in thatwere some very specific things about safety.Then we finished that, did a little wrap-up, alittle after action review, and then 'we wenton to the next one."

Command and controlCOL Billy G. Murphy, commander of theAviation Brigade, 1st Infantry Division,believes in the importance of command andcontrol. "When someone is in absolutecommand and control, it is extremely seldomthat we have mishaps," said COL Murphy."It 's when nobody's in command or

When soldiers areasking who's incommand, mishaps willprobably occur.nobody's in control that accidents happen."When the unit, which supports the 1st ID,is at home, command and control is veryhigh. The commander is where he needs tobe and all the soldiers are where theybelong. The organization is totally together.In an exercise as large as REFORGER,soldiers and equipment are deployed in manydifferent areas at once. Cohesion decreases.Absolute command and control begins towaver; commanders are spread thin.According to COL Murphy, whencommand appears fuzzy and soldiers are

With a UH-60 in the foreground, tracked vehicles move across the German countryside during REFORGER 88.

20 u.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

23/52

asking who's in command, mishaps willprobably occur. That applies right down theranks.

at a given time. There's a logic associatedwith that., Hope is not an alternative to safeoperations. You do not 'hope' soldiers are inposition. You don't 'hope' 60 aircraft getsafely to Belgium and Germany and back.You cause that to happen. If you're incommand and control of every situation, youdon't have to 'hope' anything's in place.".

"I say, 'First sergeants, there's a place foryou to be that is righter than all otherplaces. You evaluate. You make the riskassessment. ' We talk about it a great deal.We make leaders go through the thoughtprocess of determining where they should be

Building a better mousetrapAviation people in the fieldfrequently come up with a way tobuild a better mousetrap. Hereare some examples that haveproved to be better than "the waywe've always done it."Slingloading operationsArtillery pieces were designed tobe towed on the ground. Riggingan artillery piece to be moved bya CH-47 is challenging at anytime. Trying to rig one at nightunder NVGs is like "taking acourse in advanced basketweaving with a blindfold on,"says CW4 Earle Irwin, assistantaviation safety officer for the101st Airborne Division. "In thefirst place, there is a lot ofapprehension when a gun crewhears a 50,OOO-pound helicopterhovering over their heads in thedark."

In the 101st, they have comeup with a 5-foot-Iong pendantmade of Kevlar that has a plasticsleeve on it. Now, instead of arigger trying to hold a 40- to50-pound chain rig to do ahookup, he has a lightweightplastic pintle that he puts rightover the hook. Because of theplastic, the danger from static

FEBRUARY 1989

electricity has also beeneliminated. Not only are theriggers safer, the aircrew is saferbecause of the lessened exposuretime that the aircraft has to hoverin an LZ at night with thepossibility of blowing dust andthe hover becoming unstable.

in its UH-60s, was formerlyorganized as two companies,leaving a gaping hole incommand and control between thecaptain company commanders andthe brigade.COL Kerr restructured theseunits into a provisional battalionwith a lieutenant colonel incommand, providing theexperience of a battalion-level

staff for planning and conductingoperations.UH-60 crew requirementsAll the UH-60s in the AviationBrigade at Fort Bragg carry a:,., .: , / fourth crew member And all the

! . ! ", ' ."1" / crewrnembers, including the.. .. .. ~ /. I: ,. enlisted personnel, are trained in:/i -': . "":.,; < , . .... . : ~ ~ g ~ ~ . i p p e d with night vision

t '. . Individual skills trainingBetter command and controlCOL Dennis Kerr, commander ofthe Aviation Brigade, 82dAirborne Division, Fort Bragg,made an important organizationalchange in the 2-82d Brigade thatimpacts on the safety of everysoldier in the Division. Thisassault battalion, which isresponsible for transporting troops .

At Fort Riley, the AviationBrigade devotes Wednesdaymornings to focusing on theindividual skills ofcrewmembers-mechanics andpilots. According to LTC AlbertPatterson, XO of the AviationBrigade, "It's taking it out of ourhide to provide that period oftime, but it's well worth it."

21

-

7/28/2019 Army Aviation Digest - Feb 1989

24/52

MAINTENANCE

Today's sophisticated aircraft and demanding missions make maintenance more critical than ever before. By-thebook maintenance performed by disciplined, professional mechanics and a system of checks and balances thatinvolves mechanics, inspectors, crew chiefs and aviators I"elp ensure safety and mission completion.

22 u.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

25/52

If it isn't safe, itdoesn't flyCL DENNIS KERR, commander of theaviation brigade of the 82d AirborneDivision at Fort Bragg, believes safetystarts with the crew chiefs and technicalinspectors. "If the aircraft isn' t mechanicallysafe to fly, we don't fly."In 2-82d Aviation Brigade, SFC KenGregory, a technical inspector in the DCompany quality control office, is often theguy who makes that decision. "In aviationyou must work as a team. You can't workas individuals. The only exception is me,quality control. I can make the commandermad, I can make the PIC mad, and I canmake the crew chief mad. Why? Because Ihave to make sure the aircraft is safe. If Idon't feel it's safe, it ain't going anywhere.

"People have to understand that if anairplane's going to take 5 hours to fix, it'sgoing to take 5 hours to fix. We can't cut itto 3 112 hours because doing that may meanit will make it only half way through themission. "Another thing SFC Gregory stresses is theimportance of quality rest for maintenancepeople. "Rest is just as important for theguys on the flightline as it is for the guys inthe cockpit. But mechanics may work until10 o'clock at night and then have to be back

FEBRUARY 1989

in there at 6 0 'clock the next morning. After4 or 5 days, the mechanic gets in a forgetfulmode. Instead of putting the O-ring in, hejust slaps the piece together and tightens itdown and forgets to tell so-and-so that heneeds to come check it."

Maintenance crews andcrewchiefs work longhours under toughconditions, but from allindications, they do itwillingly. Why?Because they arerespected members ofthe team . . . and theyknow it.

LTC Albert Brocious is commander of the6-101st Aviation Regiment, 101st AirborneDivision at Fort Campbell. His emphasis onindividual and collective self-discipline andsafety extends to the quality control program

23

-

7/28/2019 Army Aviation Digest - Feb 1989

26/52

MAINTENANCE

Boresighting weapons system on an AH-64.

24

and the maintenance people in the hangars.It includes how they take care of aircraft bymonitoring time change of aircraftcomponents, how they do phasemaintenance, and how they account for theirtools. It so permeates what they do thatwhen soldiers in Delta Company, themaintenance company, were asked how thebattalion could better accomplish theirmission, maintain aircraft, and other ways toensure safety, they decided one way was toextend their workday. They felt they couldbe more productive during nonduty hourswhen there would be fewer interruptions."Interruptions will kill you, because that'swhen a tool gets lost somewhere in theaircraft, ' , LTC Brocious said. "Soldiershave good ideas, and if you can just let themknow they're important and their ideas aregoing to be listened to, they'll come up withsome good suggestions.

"It's the soldiers and NCOs who aredoing it. It was their idea to work until 2100at night. It's not me, and it's not theircompany commander telling them to do it. Ifan aircraft part comes in on a Friday, theymay work on the weekend, but it's their ideato do that. They know we'll take care ofthem with time off, but they're taking careof their company, their aircraft. They'redemonstrating their pride by trying to makeit a better unit by being available when theparts are available.". CPT Douglas Noble, who commandsDelta Company, is proud of the fact that hismechanics have shortened the time it takesto do a l50-hour phase inspection on anaircraft from the 14 days required by thebrigade to 4 days. These are the soldierswho decided on their own that by extendingtheir workday into the evening hours whenthere are fewer distractions they could

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

27/52

produce safer aircraft. The fact that they aresafety oriented is apparent in the way theirwork areas look. The ramp and hangar floorare clean, and there are no tools lyingaround or overflowing FOD cans. Firepoints are well marked, and safety posterscall attention to possible hazards.In Delta Company, quality control isseparated from production, which makes iteasier for technical inspectors to makeunbiased determinations on whether anaircraft is safe and flyable. The operationalreadiness rate in the company averages morethan 85 percent over a 12-month period, 10percent above the Army standard.

Company, 6-101 st Aviation Regiment, says,"Safety is something we have to deal withevery day. One way we've done it is byhaving crew chiefs help each other. Anotherthing is the checks and rechecks we dobefore an aircraft takes off. A mechanicworks on the aircraft, the quality controlpeople check it and sign it off, then the crewchief does the daily, and the pilotpreflights the aircraft. These checks andbalances are what makes sure the aircraft isall right when it takes off."

SSG Robert Wall, safety NCO for BYou never know where the safety officerfor B Company is going to turn up with hiscamera. CW2 Steven Murphy carries hiscamera with him. If he sees people doing

The aviation version of the CPARecords. Confused yet? Here's anPaperwork. example.You wouldn't believe just how E ~ ~ h ~ ~ ~ S "Say you- pull an engine; that's

much of it is involved in keeping a 2410. The components that goArmy aircraft in the sky. Listen with it will be listed on ato SFC Ken Gregory, a technical dash-16, so you take that dash-16inspector in the quality control out and make out a 2410 for that;office of D Company, 2-82d engine. A copy of that is sent toAviation Brigade at Fort Bragg. St. Louis and a copy goes with"When you change a the engine-the new engine-thencomponent, you've got to make you also have to log' it on yourout a whole new set of records to 2410 log. Then you have to goreinstall that component. Once back through and refigure allyou've taken it off, you 've got to these times for Vte internalfill out all those forms, and when components in this engine for the

you put it back in you've got to ~ ~ ; ~ ~ ~ ~ ~ ~ ! : ~ ~ ~ n e w one.figure out the replacement time." "You're looking at about 21/2Sound easy enough? Read on. to 3 hours of paperwork-just"Now, if that component has know how many hours since it paperwork-for changing out analready had time put on it from was new, how many hours since engine. "another aircraft , and they 've it was overhauled, and figure out Records.pulled it off and fixed it-not when that item has to be pulled Paperwork.repaired it, jus t fixed it so they off that aircraft again. Attention to detail.could use it on another aircraft- "And that's for each internal All in aday's work for the

or overhauled it, you 've got to item and the component." guys that keep 'em flying.

FEBRUARY 1989 25

-

7/28/2019 Army Aviation Digest - Feb 1989

28/52

MAINTENANCEsomething wrong or tools scattered around,he snaps a picture. That picture will appearon the wall. It points a finger straight at theperson who did it.At Fort Campbell, when an aircraft comesin from a mission, the pilots stay with thecrew chief while he takes care of theaircraft. This is a big safety factor. Forinstance, if a crew chief slipped and fellwhile working on an aircraft on the flightline in the winter, he could die of exposurebefore anybody found him.In the Aviation Brigade at Hunter ArmyAirfield, GA, a great deal of the credit for

UH-60 undergoes 100-hour phase maintenance.accomplishing their missions safely is givento the maintenance crews and crew chiefs. Itisn't a them-us relationship, particularlywhen the units are deployed or out in thefield. They become close-knit into almost afamily relationship, and some of theformalities go out the window.Aircrewmembers know their safety-in fact,their very lives-depend on each other. Thatputs everything into perspective.

26

Maintenance andground supportsafety

The following safety areas are singled out foremphasis in the aviation brigade of the 82dAirborne Division: Simplified procedures. Because of thecomplexities of using different manuals for ajob such as cleaning the inside of an engine,one of the unit maintenance officers and abattalion safety officer came up with a checklistfor mechanics to follow. A recommendedchange to the manual has been submittedthrough official channels. Quality control. Because of the importanceof quality control, the unit has begun providingclasses for new maintenance personnel on thepurpose of the QDR (quality deficiency report)and how it should be filled out and submitted. Refueling. Refuelers are reminded of theimportance of venting fuel tanks on the Apacheto avoid the danger of being sprayed by fuelfrom the pressurized tank when the flappervalve is opened for open-port refueling. Theyare also cautioned that hangups in the stopvalves and failure of switches to close can resultin overpressurization of the AH-64 s fuel tanks.

U.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

29/52

"One quality required inaviation is honesty", ou HAVE TO BE willing toadmit there is human error, thatwe all make rnistakes," saysSFC Ken Gregory, technical inspector atFort Bragg. "The command environment hasto be such that we don't burn a kid fordoing that. If he made an honest mistake andhe was trying his best and he had a humanshortcoming, we have to account for that.We have to repair whatever he damages andgo on.

" I f a guy makes a mistake and he's honestenough to say, 'Hey, Sarge, I broke this. Ididn't mean to, but it happened,' weshouldn't give him an Article 15 or makehim pay for it. In the first place the kiddoesn't have enough money to pay for it, sowhy take his paycheck. If you do, he'sgoing to say, 'I'm not going to tell nobodynothing no more.'"Maybe he just bent a tail stinger, which

is no biggy. He was moving the aircraftback and bent it to the side a little bit. Thenext thing you know he hides where a nutfell down inside the engine. He doesn't tellme. I do my FaD engine inspection, but it'shidden up underneath the blade. I can't seeit. We go out, punch the trigger, the nut iswedged in there, and everything goes goodon the ground. We take it to 1,000 feet andthat nut comes loose and goes through theengine. The engine just lost all itsperformance. It still runs, but it's not givingyou any power.

FEBRUARY 1989

Maintenance crew checks out main rotor and flightcontrols on a Black HaWk.

"Here you are. The kid has now caused amajor accident because he didn't tell anyonehe dropped a nut. The bottom line is, he hasto be honest."Instead of burning the guy, make himthe safety guy that day. After you teach him,have him sit there and overwatch the otherguys. He sits out there and he makes a list

of how many things go wrong. That buildssafety-mindedness. It will build integrity andhonesty, and I' d say honesty and safetywork hand in hand."The kids need to be taught when theyfirst come that it's okay to let somebodyknow when they screw up, that nobody's outto burn them because they make a mistake.

That's human error, but as long as it'scaught on the ground before we get in theair, we're okay. We can fix that. We can'tfix an acc ident. ' ,

27

-

7/28/2019 Army Aviation Digest - Feb 1989

30/52

STANDARDIZATION

Safety and standardization

You can't haveone without the other

, ' SOMETIMES we talk aboutsafety and standardization likethey're two separate entities,"says CW4 Joel Warhurst, an SIP in 6thBattalion, IOlst Airborne Division."Actually, if I'm doing something safely,I'm doing it in a standardizedmanner. If I do it to our standards, thenwe have already determined that is the safeway to do it. I don't think you can everseparate the two."This battalion's mission is probably morediverse than some of the other units in theIOlst. We might be flying an IFR mission inFAA airspace one day and a tactical missionthe next. We might be doing a paradrop or arappelling mission for the air assault school.So you get a wide range of ATM tasks, butyou don't get them every week. That meansyou have to be selective to train andmaintain your aviators' qualifications."I don't think a day goes by that our IPs,IFEs, and UTs are not just talking safety butapplying safe practices to everything we do.And we do that by teaching standardization.That goes back to the fact that the two areinseparable."Flying a mission is complex. If youlooked at every regulation, manual, or bookthat tells you how to do a certain mission,

28

you might find as many as 400 of them havesomething to say about how to do it. It takesspecial people-the safety officer, thestandardization officer, and IPs-gettingtogether to pull all that information togetherinto an SOP so that an aviator has onedocument instead of 400 to tell him what heneeds to know about flying the mission. And99.99 percent of the time, he does themission safely and in a standardized manner., Another important aspect ofstandardization is teaching. No matter howdetailed an SOP is, there is always the littlebit that isn't there and the 'reasonable man'concept takes effect. Because of a pilot'sknowledge, what he does in such cases isalmost always the right thing to do. That is

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

31/52

why we continually teach aviators to beindependent thinkers and to never stopreading and studying.IPs are teachers first"In some units an IP is only an evaluator.That isn't true in this unit, and it should notbe in any unit. The IP is a teacher firstsomewhere down the line he becomes anevaluator. If we can make this the way aunit thinks, it will spill over more and moreand PICs will be teachers. They won't goout and try to do it all themselves. They willteach new aviators because they know more.It goes back to being standardized. I havethe knowledge, and if I know it, I can applyit. If I don't know it, I'm certainly not goingto apply it very well. If you take away theapprehension about 'How do I do thismission?' by giving the pilot knowledge, hecan concentrate on actually manipulating thecontrols and executing the mission, and hewill do it safely.

"There's probably not an aviator in theArmy who has not done one dumb thing. Ifhe's honest with himself, every aviatorknows he has done at least one dumb thing.An aviator wants to know his aircraft andSoldiers with combat equipment perform static lineparachute drop from UH-60.

FEBRUARY 1989

what its limitations are. What I try to tellthem is that it's a lot more difficult to, forexample, do a VMC approach properly, byA TM standards, which might say plus orminus 10 degrees on heading, and notchange the heading even 1 degree-to notjust meet the standard but to exceed thestandard-than it is to go out and fly under abridge. So if you want to try somethingreally difficult, something unusual, try to notjust meet the standard, but maximize thestandard. So we challenge them to use theirenergy trying to do something that is 100percent by the standard."Enforcing standardsCW3 Doyle Wootten, aviation safetyofficer at the National Training Center, alsobelieves that safety and standardization aresynonymous. "If you get out of the habit ofthinking of safety as an add -on thing, if youperform to the standard, safety's there."CPT(P) Fred Edwards, commander of CCompany, 3/159th Assault HelicopterBattalion, NTC, modifies standards to meethis mission. Then he enforces the standards."I ensure the standards are enforced bythose people involved. If the standards aren'tenforced, then that's where you getinvolved. And I very rarely have to getinvolved in that respect."Standards and safety have got to worktogether. And that comes down to discipline,crew discipline. We have to practice that.Enforce it. If you have the standards butdon't enforce them, then there's going to beno safety."If you perform any task in the Army tostandard, safety is inherently built into thattask. When we do our missions to standard,safety falls into place. I can't see anythingeasier or simpler than that. If you don't dosomething to standard, then you've increasedyour risk of having an accident.".

29

-

7/28/2019 Army Aviation Digest - Feb 1989

32/52

STANDARDIZATION

Check your unit

DES checks revealsafety weaknessesAN ARMY POST on a growing spreebegan hav ing airspace a c c i d e ~ t s .duringnight vision goggle (NVG) mISSIons.Pilots weren't seeing each other, but theairspace hadn't changed in years. Inspectorsfrom the Directorate of Evaluation andStandardization (DES) at Fort Rucker foundwhat had changed was the ground space;specifically, what was on the ground.

Army housing had sprung up, lightingpreviously dark areas. Somehow , during thegrowth spurt, limitations regarding the useof NVGs in lighted areas had beenoverlooked. The lights from the housing areawere degrading the goggles' effectiveness orcausing them to malfunction. Aircraft met inmidair collisions because their pilots couldn'tsee each other.Since the new quarters couldn't be moved

Any aviator in theArmy should be able towear any goggles a tany post or installation.

30

easily, the fix DES recommended was rerouting the flight corridors.Recent Armywide standardizationinspections have revealed deficiencies inseveral safety-critical areas. NVGs are being modified improperly.For a period of time there was no strictstandardization of modifications for pilotsand maintenance personnel to follow.Modifications were different from post topost and even from aviator to aviator. In onemidair collision, four NVGs were in use,and they were modified three different ways.Although the modifications did not cause thatparticular accident, it was an indication of aproblem in standardization. M o ~ i f i c a t i o ~ shad gotten so diverse that an aVIator mIghtnot be able to wear goggles on his helmeteven though they had been modified in his

own unit. The actual modification kits arevery specific on the approved modification.Once night vision goggles are modifiedappropriately, any aviator in the Armyshould be able to wear any goggles at anypost or installation. Airframe modifications are also beingmade inappropriately. Some units have no

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

33/52

written standards, so their aviators end uptaping over lights and removingmodifications that are already in place. Ittakes a lot of hours to modify an aircraftproperly. The Black Hawk, for instance,requires more than a thousand man-hours ifit has not been modified for NVGs at thefactory. But there is a standard formodifying the airframes for flying NVGmissions. If this standard cannot be metbecause of time versus mission requirements,commanders are authorized to allow interimmodifications. However, these measuresmust be in writing. This provides every pilotin the unit with a written standard for flyingnight vision missions.

Unwritten standards affect training aswell. DES inspectors found an exceptionalprogram where the entire training doctrinewas a product of institutional knowledgeshared by three aviators. A move, seriousillness or death of one of the participantswould have seriously handicapped a verygood program. With the help of a DES teammember, they were able to create a writtenstanding operating procedure (SOP)immediately, and flying hours were neveraffected.

Another problem inspectors find is incommand knowledge and management andimplementation of the aircrew trainingprogram (A TP), to include enlisted A TP.Each unit must have a Flight CrewQualification and Selection Program. Thisprogram must include qualification, selectionand evaluation methods for all crewmemberpositions for which an aircrew trainingmanual (A TM) exists. If a crewmemberposition, such as a crew cruef or medic, doesnot have an ATM, development of a crewqualification and selection program is highlyencouraged.FEBRUARY 1989

"We includesafety where itbelongs"~ - .CW4 Donnie Ditty, standardization officer forthe Aviation Brigade, 82d Airborne Division,sums up the necessity for safety and standards:

"We've taken the vertical dimension away.We're all down about 5 to 20 feet off theground doing what we have to do. There'salways the chance that somebody might nailyou, or that you might cut right through themiddle of a UH-60 that's flying around with itslights off. The chance always exists that it canhappen."It is because of the reality that what they dois inherently dangerous that members of the 82dAirborne Division have integrated safety intoevery operation and every mission, before anaircraft ever leaves the ground.

"We integrate safety into everything we do,"says safety officer CW4 Jim Crow of the 1-82d,the attack battalion. "We include safety whereit belongs-in our SOPs, not hidden awaysomewhere in a safety annex. Safety andstandards get involved up front, in the planningstages of our op plan, before it goes out to thecompanies and some line pilot says, 'Wait aminute. What about VHIRP, or what about theconversion routes?' I f you let things get too fardown the road toward execution and then try tomake changes, you create confusion, and thataffects the safety of the whole operation."

31

-

7/28/2019 Army Aviation Digest - Feb 1989

34/52

FLASHBACK

Army aviation has come a long way since the days of the H-23. The Army is training tougher and safer than everbefore while operating sophisticated aircraft in a high-risk environment.

32 u.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

35/52

During the early days of Army aviation, everyone knewthere were accidents, but no one really knew how many,what kind, or what to do about them.My, how time flies whenyou're making progressIN A LITTLE MORE than 3 years, wewill celebrate the 50th birthday of Armyaviation. While the Army owned and flewaircraft from 1909 through the early days ofWorld War II, it was not until June 6, 1942,that Army aviation was born at Fort Sill,Oklahoma. This was the date the WarDepartment approved organic aviationfor the Field Artillery-the date nowofficially recognized as the birthday of Armyaviation.

Army aviation has come a long way inthis almost half-century-from flying L-2s,-3s, and -4s to flying UH-60s and AH-64stoday.The flight safety program has also come along way since those early days of Armyaviation. In 1955, when the Army AviationCenter was established and Camp Ruckerwas designated Fort Rucker, the Departmentof the Army learned of Army aircraftaccidents through the newspapers. Everyoneknew there were accidents, but no one reallyknew how many, what kind, or what to doabout them.During those early days of Army aviation,accident reports were usually only brief

FEBRUARY 1989

descriptions of what happened, with little orno thought given to why pilots erred.Arbitrary punitive measures applied in manycases failed to correct accident causes, butthey were successful in restrictingoperations.

In 1958, the Army'saircraft accident ratewas 54.3 majoraccidents per 100,000flying hours. In FY1988, that rate was1.84-the lowest rate inthe history of Armyaviation.

In 1956, the University of SouthernCalifornia began its first Army course inaviation safety for key staff officers, aviationunit commanders, and installation safety

33

-

7/28/2019 Army Aviation Digest - Feb 1989

36/52

FLASHBACK

Before installation of the crash resistant fuel system, firewas the biggest killer in Army helicopter accidents.

directors. As graduates of the course tooktheir places in the field, a constantimprovement in aircraft accidentinvestigation and reporting was noted, aswell as a magnified interest in aircraftaccident prevention.A three-man accident review board thathad been at Fort Sill was moved to FortRucker with the Aviation School in 1954.The Review Board was renamed the U. S.Army Board for Aviation Accident Research(USABAAR) in 1957. That first year, theBoard produced nine design criteria forapplication to future aircraft and initiatedactions on several engineering changes inaircraft. Board studies also evolved manychanges in operating techniques andpractices.

34

Over the years, USABAAR (redesignatedthe U.S. Army Safety Center in 1978)initiated and sponsored numerous projects,including fire retardant flight clothing andprotective helmets, survival kits, chipdetector warning lights, spectrometric oilanalysis, crashworthy fuel cells, crashworthyseats for gunners, wire strike protectionsystems, and flight data recorders.Before installation of the crash resistantfuel system and the conscientious wearing ofNomex flight suits and gloves, leather boots,and helmets, fire was the biggest killer inArmy helicopter accidents. Studies coveringthe period July 1957 through June 1963showed that fire accounted for nearly twothirds of all aircraft accident fatalities.Another study reported 123 fatalities due toburns in FYs 1967 through 1969. By FYs1973 and 1974-after installation of thecrash resistant fuel systems-thermal injurieshad declined to zero.In 1958, the Army's aircraft accident ratewas 54.3 major accidents per 100,000 flyinghours. Thirty years later, the Class Aaccident rate was 1.84-the lowest rate in thehistory of Army aviation-quite animprovement. And nobody has to tell youthere are a lot more risks involved in flyingtoday than there were in 1958-moredemanding missions and high-risk nighttactical operations, where a singleperformance error greatly increases theprobability of a major accident.

Today, safety does not restrict missionaccomplishment but, rather, enhances it.Accident research continues to determinecause factors and recommend actions thatwill increase the reliability and warfightingcapability of Army "aviation. Commandersare training tougher than ever before anddoing it safer than ever before.

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

37/52

Aviation snapshotA look at statistics that tell a storyClass A Accident Rate Average Cost of Class AI I2.7($ Millions)

2.94

1.84IFY84 FY88 FY84 FY88Class A-C Accident Rate Aircraft Accident CostI I8.58 8.75

FY84

I 104.4($ Millions)

4.76IFY88 FY84

58.3

FY88Data as of 20 Dec 88

FEBRUARY 1989 35

-

7/28/2019 Army Aviation Digest - Feb 1989

38/52

FLIGHT DATA RECORDER

Flight data recorders arepaying offLKE R2D2 AND 3CPO, the friendlyStar Wars robots, flight data recorders(FDRs) provide electronic assistanceto their human cohorts. FD Rs, however, goone step further. They have unmeasuredpotential for making the skies safer.It's a fact that, in the last 15 years,unsolved mysteries cost the Army nearly$208 million for aircraft accidents where acause could not be determined. The adventof sophisticated, high-tech equipment-helicopters with hybrid flight controls andflight control computers-brought with it theneed for more than traditional investigativetechniques.Chief of Staff directedSeveral unsolved Class A Black Hawkaccidents were cause for concern and, inMarch 1986, the Army Chief of Staffdirected the immediate installation of FDRsin UH-60s flying high-risk missions. Theprogram has seen about 200 FDRs installedin high-risk-mission UH-60s at Fort Rucker,Fort Bragg, and Fort Campbell.Development and procurement of animproved solid state FDR for the AH-64 andUH-60 was also directed. This program isongoing, with installation to begin in mid 1989.

36

In the beginning, the FDR was seen onlyas a tool for improved accident investigation.But while it has proved to be just that, theFDR can also be a valuable diagnostic toolfor pilots as well. If a pilot perceives aproblem such as stabilator failure, the datain the FDR can be unloaded and analyzed totell the pilot whether the problem was in theaircraft or in his flying technique.To date, information has been receivedand analyzed from three accidents and oneincident involving aircraft equipped with

Information from a fight data recorder Is being convertedInto computer-generated Imagery to recreate the fli ghtprofile of an accident aircraft.

U.S. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

39/52

FORs. The data has been invaluable.A good example is the case of the UH -60involved in a midair collision with anotherArmy aircraft. There were no survivors toprovide clues to the cause. However, theBlack Hawk's FOR had withstood the impactforces of the crash and the ll00-degree heatof the postcrash fire. Information from therecorder was converted into computergenerated imagery that recreated in real timethe flight profile of the accident aircraft. Thedata showed that no maneuver had beenmade to avoid the collision, indicating thatthe UH-60 pilot never saw the other aircraft.After plotting the flight paths of the twoaircraft and studying the relative angles ofeach aircraft, investigators determined thatthe crews could not have seen each other.In another recent accident involving anaircraft equipped with an FOR, data wasanalyzed and converted to computergenerated imagery within 15 minutes of thetime it was received. The FOR functionedduring the entire accident sequence, and itclearly depicted the cockpit instrumentdisplays.More than an investigation toolFuture use of FORs involves fullyexploiting the potential of the FOR in areasother than investigation. For example, in thearea of maintenance, the FOR can provideinformation on system malfunctions. TheFOR can give duration, speeds, temperaturesand other information needed to improveaircraft maintenance.

The future FOR will also capture aircraftsystem "exceedances" and provide awarning flag that a malfunction hasoccurred. The aircraft would then begrounded until corrective action is taken.FORs will also provide "predictive"maintenance capabilities by warning whenmajor components need to be replaced.

FEBRUARY 1989

Improved pilot trainingThe FOR will also be valuable inimproving pilot training. With factualemergency profiles provided by the FOR,the effectiveness of training and emergencyprocedures can be evaluated. The FOR candrive a motion simulator, making it possibleto "fly" through the accident sequence inorder to refine emergency procedures andprovide countermeasures against futuresimilar accidents.The payoff from FDRsis not only moreaccurate accidentinvestigations, butbetter training andprocedures, improvedmaintenance, andgreater safety.

When fully developed, FORs can alsoprovide the information needed to improveindividual aviator skills and unit training.Using information provided by the FOR,postflight evaluation and desk-side debriefswill be possible immediately. A systembeing developed is personal-computer-basedand fully transportable down to the unitlevel. A pilot will be able to plan themission, fly the mission, then return to adesk and re-fly the mission and do apersonal evaluation. The postflight analysiscan be used in future preflight briefings aswell.The payoff from FORs will not only bemore accurate accident investigations, butbetter training and procedures, improvedmaintenance, and greater safety. And greatersafety means more warfighting capability.

37

-

7/28/2019 Army Aviation Digest - Feb 1989

40/52

SAFETY VIDEOS

Crashfax Videosre-create real accidentsATENTION commanders and ASOs!Need something new for your unitsafety meetings? Something to stimulatediscussion? Have we got a tool for you!Videos. "Crashfax Videos." Twoavailable now at your local audiovisuallibrary and more in the works.Crashfax Videos are not your typicalsafety films. They're short. To the point.They don't just tell what happened, theyshow what happened. And seeing isbelieving.Crashfax Videos re-create real accidents.Recent accidents. Accidents that killed Army

38

people and destroyed Army aircraft.Accidents that resulted from human errors,errors that could kill again if not avoided.The visual accounts of Army aviationaccidents in Crashfax Videos complementthe written accounts in Flightfax. They showthe circumstances that led up to the errorsthat caused the accident. They open the doorto self-examination, not only by individualaviators but by the unit as a whole. Theyprompt folks-commanders, ASOs, andaviators alike-to ask, "Could that happen inmy unit? Do those conditions exist here?Could that be me?"Following are synopses of the twoCrashfax Videos that are available now.A vailabili ty of future videos will beannounced in Flightfax. "UH-60 Midair" (CFV 46-1, PIN707996). This video re-creates the midaircollision of two Black Hawks during a nightvision goggle training mission. All sevencrewmembers and ten soldiers on board theaircraft were killed. The absence of evasiveaction by either crew indicates they neversaw each other.

"High-Risk Aviator" (CFV 46-2, PIN707997). This video re-creates the eventsleading up to the crash of an OH-58 into alake. The warning signs were there that thepilot was a high-risk aviator, but he wasallowed to continue to fly until the inevitablehappened. He was killed in the crash.

u.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

41/52

-

7/28/2019 Army Aviation Digest - Feb 1989

42/52

-

7/28/2019 Army Aviation Digest - Feb 1989

43/52

Military Intelligence (MI) Corps Associationfor Aviation Personnel

MI Corps association certificates are used to recognizenot only 15C35 (tactical intelligence) commissionedaviators but warrant officers who possess MOS 156A(OV-lIRV-l pilot), 155E2V (RC-12 pilot), 155DC(RU-21 pilot) , 153D 1V (EH-60 pilot) and enlisted soldierswho possess MOS 66H (technical inspector) or 67H(airplane observation repairer) and who have served inaerial exploitation battalions.

The certificates of association are to recognize the aviation personnel who support and contribute to the vital roleof the MI mission. They do not , however, authorize

individuals to wear the MI regimental crest on their uniforms nor does it imply regimental affiliation with the MICorps. This would violate Army Regulation 600-82, TheUnited States Army Regimental System.

For more information write or call the Office of theChief, Military Intelligence (Captain Kitson), Ft. Huachuca, AZ 85635-7000, AUTOVON 821-118211183.Enlistment Contract and Bonus Changes

Changes to initial enlistment contracts have been in effect since 11 June 1988. Since 15 November 1988, thefollowing MOS-incentive bonus program changes havebeen in effect:

MOS INCENTIVE BONUS PROGRAM CHANGES *EB - enlistment bonus,' paid aftergraduating from advancedindividual training.PREVIOUS NEWMOS BONUS BONUS

3SK (68N) *EB $1 ,SOO/6 years3SL (68L) EB $1 ,SOO/6 years3SM (680) EB $1 ,SOO/6 years3SR (68R) **SRB 2A-E3/S EB $1 ,SOO/6 yearsSRB 1A-E4/6

67H EB $1 ,SOO/6 years66R SRB 3A/2B-ES/667R SRB 3A-E3/4 EB $1 ,SOO/6 yearsSRB 3A/2B-ES/7 SRB 3A-E3/7SRB 2B-ES/767S EB $1 ,SOO/6 years67T EB $1 ,SOO/6 years66Y EB NoneSRB 1A/1 B-ES/667Y SRB 1A-E3/8 EB $1 ,SOO/6 yearsSRB 1A-E3/7

SRB 1B-ES/793B SRB 3A-E3/4 EB $2,SOO/4 yearsSRB 3A/3B-ES/8 EB $1,SOO/eachadditional yearSRB 3A-E3/4SRB 3A/3B-ES/693C SRB 3A-E3/4 EB $2,SOO/4 yearsSRB 3A/2B-ES/8 EB $1 ,SOO/eachadditional yearSRB 3A-E3/4SRB 3A/2B-ES/7

PREVIOUS NEWENLISTMENT ENLISTMENT4 years Syears4 years Syears4 years Syears4 years Syears

all CMF 67MOSs requireas-yearenlistment

CMF 93contracts requirea 4-yearenlistment

**The Selective ReenlistmentBonus (SRB) is denoted by zonesas follows:

A = initial-term soldiers lessthan 10 years of total activeservice.B = midterm soldiers with aminimum of 10 but less than 15years of service.

C = all soldiers with 15 ormore years of service.The numbers positioned next to

the letters (denoting zones)indicate the multiplier used todetermine bonus payment. Forexample: 2A equals two times themonthly base pay , which is thenmultiplied by the number of yearsthe reenlistment is for . 2A = 2 xbase pay x years reenlisting =total bonus.Note: Those enlisted aviationMOSs not shown have no changeto incenti ves.

41

-

7/28/2019 Army Aviation Digest - Feb 1989

44/52

USAlMY

Directorate ofEvaluation/Standardization.. ~

REPORT TO THE FIELD AVIATIONSTANDAIDIlAfI. . .

AVIATION STANDARDIZATION ANDTRAINING SEMINAR/BRANCHLIAISON TEAM PROGRAMCaptain Carl TerryEvaluation DivisionDirectorate of Evaluation and StandardizationFort Rucker, AL

THE DIRECTORATE of Evaluation and Standardization (DES), U.S. Army Aviation Center, Ft. Rucker, AL,has realigned the scope of its Aviation Standardization andTraining Seminar (ASTS)/Branch Liaison Team (BL T)Program. For the past 6 years, the ASTS/BLT has playeda major role in the Aviation Center's efforts to provideAviation Branch information and assistance in standardization matters to all aviation units throughout the world.Concurrently, the ASTS/BLT Program is the primary vehicle by which the Aviation Center evaluates the proficiency of its products.

In recent years, budget constraints have severely limitedASTS/BLT visits to requesting units. Occasionally, unitshave funded ASTS/BLT visits; but, for most units, theexpense involved was often prohibited. With a forecastof continued budget constraints, DES was faced with adifficult challenge-How do we maximize our assistanceand evaluate ASTS/BLT visits with available resources?

The DES plans to realign the ASTS/BLT by sendingsmaller teams, limiting the onstation period to 2 days, andconcentrating on brigade-sized, continental United Statesbased aviation units.

42

The DES will select and visit five installations a yeain concert with the U.S. Army Forces Command Umbrella Week and special visitation programs as describein U.S. Army Training and Doctrine (TRADOC) Regulation (Reg) 350-15, TRADOC Training Evaluation anQuality Assurance Program. Units may still request aASTS/BLT visit if they are not scheduled for the upcoming year. The ASTS/BLT visits may be requested by caling DES , Evaluation Division at AUTOVON 558-6571As outlined in TRADOC Reg 350-15, the ASTS/BLvisits will focus on the following key areas:

Assess/evaluate the adequacy of the school produc(competency of graduates, doctrine and training suppormaterials) through surveys, interviews, record checksperformance evaluations and other means. This is aassessment of the school product only and not of thvisited unit.

Provide information to unit on school products, processes and concepts.

Provide instructor pilot/standardization instructopilot (SP) seminars, classes, assistance and training as requested by the unit.

u.s. ARMY AVIATION DIGEST

-

7/28/2019 Army Aviation Digest - Feb 1989

45/52

The DES will provide assistance as funding allows andmay include the following areas: