APPROVAL OF UP TO 7 (SEVEN) EXPLORATION WELLS · PDF file• NORSOK R-003: NORSOK Standard...

-

Upload

phungthuan -

Category

Documents

-

view

295 -

download

1

Transcript of APPROVAL OF UP TO 7 (SEVEN) EXPLORATION WELLS · PDF file• NORSOK R-003: NORSOK Standard...

APPROVAL OF UP TO 7 (SEVEN) EXPLORATION

WELLS IN ACCORDANCE WITH

SECTION 15 OF LICENCES

2002/15, 2005/06, 2008/11 AND 2011/16

Public version

Government of Greenland BUREAU OF MINERALS AND PETROLEUM

May 2011

2

ABBREVIATIONS AND DEFINITIONS

Abbreviations

• ALARP: “As low as reasonably practicable”: reducing identified and assessed risks to a

level that is as low as reasonably practicable.

• bbl (Blue barrel) oil barrel containing 42 gallons of oil

• BOP (Blow Out Preventer): Seabed valve system used in connection with the drilling

operation, also known as a secondary barrier.

• Drilling Guidelines: Greenland Bureau of Minerals and Petroleum, Exploration Drilling

Guidelines.

• ERRV (Emergency Response and Rescue Vessel): Vessel which must be available for

the drilling unit as a rescue vessel.

• EEZ (Exclusive Economic Zone) According to the Law of the Sea, an EEZ is a marine

area within which a coastal state has exclusive rights over the exploration of the

resources of the sea, seabed and subsurface.

• GREENPOS (Greenland Positions Reporting system): GREENPOS is a reporting

system and is part of safety at sea.

• HAZID: (Hazardous Identification): A systematic method of identifying risks in

connection with a planned activity. Having identified risks, corrective measures to

reduce the risks to an acceptable level are reviewed. HAZID is primarily used at a high

organisation level in the project phase as part of a company’s control tools.

• HAZOP (Hazardous Operations): A systematic method of identifying risks in

connection with a planned operation or a sub-task. Having identified risks, corrective

measures to reduce the risks to an acceptable level are reviewed. HAZOP is primarily

used at a lower organisational level as part of a company’s control tools in connection

with performance of specific tasks.

•

• NORSOK: Norwegian standards.

• NORSOK D-001: NORSOK Standard D-001, July 1998, Drilling Facilities.

• NORSOK D-010: NORSOK Standard D-010, August 2004, Well Integrity in Drilling

and Well operations.

• NORSOK D-SR-007: NORSOK Standard D-SR-007, Jan 1996, System Requirements -

Well Testing Systems.

• NORSOK R-003: NORSOK Standard R-003, July 2004, Safe use of lifting equipment.

• NORSOK S-001: NORSOK Standard S-001, February 2008, Technical Safety.

• NORSOK S-003: NORSOK Standard S-003, December 2005, Environmental Care.

• NORSOK Z-013: NORSOK Standard Z-013, Oct. 2010, Risk and emergency

preparedness.

• OIM: (Offshore Installation Manager): Senior manager on an offshore platform (drilling

or production rig). The position requires registration in an Offshore Safety Division for

health and safety, and it means responsibility for the health, well-being and safety of

everyone on board.

• OSR: (Oil Spill Response) Oil Spill Response Company

• PVT: (Pressure, Volume, Temperature): Pressure, volume, temperature.

• SAR: Search and rescue services

• SSML: Safety, health, environment and management control systems

• TD: Total Depth.

3

• TVDSS: (True Vertical Depth Sub-sea) vertical depth measured from the sea level

Definitions

• Blowout: Uncontrolled leak of hydrocarbons in the subsurface or over the seabed.

• Fishing Liaison Officer: Fishing Liaison Officer (FLO), fisheries expert, who can

communicate with local fishery operators and the Licensee during the operation.

• Drilling unit: Drilling ships and semi-submersible drilling rigs used in this project.

• By-pass coring: Coring carried out by drilling into the side wall of the well.

• Certificates: Certificates mean the vessel’s classification certificates, national

certificates and other certificates.

• Deadman System: an independent backup BOP control system that automatically shuts

in the wellbore by closing the blind shear ram upon total loss of both hydraulic and

electric communication between the pods and the surface. .

• Fail to Safety: an independent safety system in the BOP where the well is automatically

sealed if hydraulic and electric communication is lost.

• Greenlandic enterprise: An enterprise which is domiciled in Greenland and which

through the exertion of commercial activities has real attachment to Greenland.

• HAZID/HAZOP: Review meeting with all of the most important technical operators and

Licensees, at which risks are identified for all planned operations. Mitigating initiatives are

implemented to reduce or eliminate the risks identified.

• Hot bedding: Hot bedding means that more than one person takes turns to sleep in the

same bunk/bed.

• Onhire vessel: Vessels which are under contract with the Licensee for a given period.

• Pilot hole: Drilling a small-diameter well before main drilling operations, to identify

any risks in the top section.

• Pre-spud: Pre drilling preparations

• Actual drilling programme: drilling programme excluding the top hole section.

• Clean certificates: Clean certificates means that the ship’s certificates are valid and not

encumbered with conditions/recommendations from the classification society or

relevant authority at the time the ship is navigating the Greenland Exclusive Economic

Zone (EEZ).

• Licensee: “The Licensee” is the group of companies described in section 1.2.

• Riser: A common term used in the oil industry for a conduit/a drilling fluid pipe that

provides a temporary extension to a subsea oil well to a surface drilling facility.

• Spot-hire: Supply vessels hired for a single navigation and a limited period; for

transport solely between international and Greenlandic ports.

• Technical operator: A technical operator is defined as an enterprise which, on behalf of

the Licensee, conducts exploration (Ocean Rig) and the enterprises which are

responsible for the daily operation of an offshore installation, or a ship etc. (support

ship, chartered aircraft to carry personnel and equipment etc.).

• Sub-supplier: A sub-supplier is defined as an enterprise which supplies goods and

services to the project (hotels, suppliers of fuel and food, port operators etc.)

4

Table of Contents

1 The Application 6 1.1 Application documents .................................................................................................... 6

1.2 Operator and Licensees .................................................................................................... 6

1.3 Project description............................................................................................................ 8

1.4 The legal foundation for approval.................................................................................. 13

2 Drilling programme 16 2.1 Offshore activities .......................................................................................................... 16

2.2 Ports and onshore activities............................................................................................ 19

2.3 Other activities ............................................................................................................... 21

2.4 Personnel conditions and working hours ....................................................................... 21

3 Authorisation terms for mobile drilling units, vessels and aircraft 23 3.1 Vessels in general........................................................................................................... 24

3.2 Drilling units and vessels ............................................................................................... 24

3.3 Mobile drilling units....................................................................................................... 25

3.4 Ships............................................................................................................................... 26

3.5 Aircraft and helicopter operations................................................................................. 26

4 Drilling locations 27 4.1 Site survey evaluation regarding geohazards................................................................. 27

4.2 Requirements to data acquisition ................................................................................... 28

5 Drilling and well operations 28 5.1 Requirements for drilling and well operations............................................................... 29

5.2 Primary and secondary well barriers.............................................................................. 30

5.3 Handling and use of chemicals ...................................................................................... 33

5.4 Storage, handling and use of explosives ........................................................................ 34

5.5 Storage, handling and use of radioactive materials........................................................ 36

5.6 Abandonment/suspension plans..................................................................................... 37

6 Licensee’s environmental and management systems, including safety, health and contingency plans 40

6.1 Safety and health plans .................................................................................................. 40

6.2 Emergency response and contingency plans.................................................................. 43

6.3 The roles of the authorities in the Licensee’s emergency response............................... 43

6.4 Emergency response for drilling units and other units .................................................. 45

6.5 Emergency response for major accidents....................................................................... 46

6.6 Emergency response for H2S ......................................................................................... 46

6.7 Emergency response for blow-out and relief well ......................................................... 47

6.8 Ice management ............................................................................................................. 49

6.9 Emergency response for oil spill.................................................................................... 54

6.10 SAR emergency response .............................................................................................. 56

7 Competencies, qualifications, training and drills 56

8 Socially sustainable development 58

9 Environment 60 9.1 Environmental background studies................................................................................ 60

9.2 Discharges and emissions .............................................................................................. 60

9.3 Waste management ........................................................................................................ 62

9.4 Chemicals....................................................................................................................... 63

9.5 Discharge of drilling mud, drill cuttings and cement..................................................... 65

5

9.6 Helicopter transportation................................................................................................ 67

9.7 Environmental monitoring ............................................................................................. 67

10 Registration, verification, checks and reporting 69 10.1 Special tax reporting requirements for the Licensee, technical operators and sub-

suppliers with no residence in Greenland ................................................................................. 69

10.2 Accident reporting.......................................................................................................... 70

10.3 Other registration and reporting..................................................................................... 70

11 Financial security 73 11.1 Guarantees...................................................................................................................... 73

11.2 Insurance conditions ...................................................................................................... 73

12 Approval in pursuance of section 15 for licences no. 2002/15, 2005/06, 2008/11 and 2011/16 74

Annex 1 - Map of licence area and drilling locations ............................................................... 76

Annex 2 – Guarantee and collateralisation ............................................................................... 76

Annex 2 – Guarantee and collateralisation ............................................................................... 77

Annex 3 – List of chemicals used ............................................................................................. 78

Annex 4 – Map of bird colonies................................................................................................ 79

Annex 6 - Environmental monitoring form .............................................................................. 82

Annex 7 – Template for Activity Report / 3 Day Forward Planning Report............................ 82

Annex 7 – Template for Activity Report / 3 Day Forward Planning Report............................ 83

Annex 8 – In-situ Burning Application Form for Greenland Waters ...................... 86

Annex 9 – Dispersant Application for Greenland Waters ......................................... 87

Annex 10 - Greenland Bureau of Minerals and Petroleum, Exploration Drilling Guidelines .............................................................................................................................. 88

Annex 11 - NORSOK D-001................................................................................................ 89

Annex 12 - NORSOK D-010................................................................................................ 90

Annex 13 - NORSOK D-SR-007 ......................................................................................... 91

Annex 14 - NORSOK R-003................................................................................................ 92

Annex 15 - NORSOK S-001 ................................................................................................ 93

Annex 16 - NORSOK S-003 ................................................................................................ 94

Annex 17 - NORSOK Z-013 ................................................................................................ 95

6

Capricorn Greenland Exploration 1 Ltd.

50 Lothian Road

Edinburgh, Scotland

EH3 9BY

UK

1 The Application

1.1 Application documents

On 4 March 2011, the BMP received an application submitted by Capricorn Greenland

Exploration 1 Ltd. concerning the approval of drilling of up to 7 (seven) exploration wells in

accordance with section 15 of the licences 2002/15, 2005/06, 2008/11 and 2011/16.

For this letter of approval, issued by the BMP, the Danish version shall apply. If there are any

inconsistencies between the Danish and the English/Greenlandic versions, it is the Danish

version that prevails.

Where there are inconsistencies between the English and the Danish/Greenlandic version of the

application documents, the English version prevails.

1.2 Operator and Licensees

The Licensees and operators of the licences to which the application for exploration drillings

pertains are listed below. The operator for the individual licences is marked with * in the tables.

Exclusive Licence no. 2002/15 for exploration for and exploitation of hydrocarbons in an

offshore area north-west of Nuuk, West Greenland is divided between the following companies

as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 47.5

Capricorn Atammik Limited 40.0

2002/15

(Atammik)

NUNAOIL A/S 12.5

Exclusive Licence no. 2005/06 for exploration for and exploitation of hydrocarbons in an

offshore area in West Greenland is divided between the following companies as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 47.5

Capricorn Lady Franklin Limited 40.0

2005/06

(Lady Franklin)

NUNAOIL A/S 12.5

7

Exclusive Licence no. 2008/11 for exploration for and exploitation of hydrocarbons in an

offshore area in West Greenland is divided between the following companies as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 30.00

Capricorn Greenland Exploration 3 Ltd. 18.75

Capricorn Greenland Exploration 4 Ltd. 28.75

PETRONAS International Corporation Ltd. 10.00

2008/11

(Eqqua)

NUNAOIL A/S 12.50

Exclusive Licence no. 2011/16 for exploration for and exploitation of hydrocarbons in an

offshore area in North-West Greenland is divided between the following companies as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 87.50 2011/16

(Napariaq) NUNAOIL A/S 12.50

Capricorn Greenland Exploration 1 Limited, Capricorn Atammik Limited, Capricorn Lady

Franklin Limited, Capricorn Greenland Exploration 3 Limited, Capricorn Greenland Exploration

4 Limited are all fully owned subsidiaries of Cairn Energy Plc.

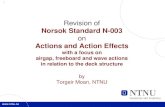

The company structure of the Cairn Energy Group is illustrated below in figure 1.2.A:

Cairn Energy Plc.Listed on London Stock Exchange

Capricorn Oil Ltd.Not listed subsidiary company

Cairn IndiaListed on Bombay

and National Stock Exchange

Other share-

holders

37,66 %

Capricorn

Greenland

Exploration

1 Ltd.

Capricorn

Greenland

Exploration

3 Ltd.

Capricorn

Greenland

Exploration

4 Ltd.

Capricorn

Atammik

Ltd.

Capricorn

Lady Franklin

Ltd.

100% ownership62,34 % ownership

Cairn Energy Plc.Listed on London Stock Exchange

Capricorn Oil Ltd.Not listed subsidiary company

Cairn IndiaListed on Bombay

and National Stock Exchange

Other share-

holders

37,66 %

Capricorn

Greenland

Exploration

1 Ltd.

Capricorn

Greenland

Exploration

3 Ltd.

Capricorn

Greenland

Exploration

4 Ltd.

Capricorn

Atammik

Ltd.

Capricorn

Lady Franklin

Ltd.

100% ownership62,34 % ownership

Figure 1.2.A: Company structure, the Cairn Energy Group

Capricorn Greenland Exploration 1 Limited is operator of licences 2002/15, 2005/06, 2008/11

and 2011/16. Capricorn Greenland Exploration 1 Limited is also the operator of exploration

licence 2008/10 in an offshore area in West Greenland and exploration licences 2008/13,

2008/14, 2009/10, and 2009/11 in offshore areas in South Greenland and exploration licences

2011/13 and 2011/17 in offshore areas in North-West Greenland.

8

NUNAOIL A/S

NUNAOIL A/S is fully owned by the Greenland Self Government.

Figure 1.2.C: Company structure, NUNAOIL A/S

It has been stipulated in concession terms for all exclusive licences for hydrocarbons, that

NUNAOIL A/S shall be included as a licensee in the licences. In the exploration phase

NUNAOIL A/S shall be a ”carried partner”, i.e. the remaining Licensees shall pay all expenses

associated with exploration activities.

1.3 Project description

Timetable

Capricorn Greenland Exploration 1 Ltd., a subsidiary of Cairn Energy Plc., has submitted an

application for approval of up to 7 (seven) exploration drillings. Activities may be carried out

from the date a licence is granted;

o for location Atammik AT1-A: until 1 December 2011

o for location Atammik AT2-B: until 1 December 2011

o for location Atammik AT7-A: until 1 December 2011

o for location Napariaq 13 Delta A: until 1 October 2011

o for location Eqqua Gamma-B: until 1 October 2011

o for location Lady Franklin LF6-B: until 1 December 2011

o for location Lady Franklin LF7-C: until 1 December 2011.

Any changes to the timetable are to be regulated by the provision in section 1.4.

The drilling operations are part of a 3-year drilling programme which commenced in 2010 and is

expected to be completed in 2012.

Drilling programme

The Licensee has planned to use the drill ship Corcovado for the upper part of the wells to drill

pilot holes and install the casing. The drilling rig Leiv Eiriksson will then be included in the

operation to drill the actual drilling programme with Corcovado.

List of drilling units and ships which the Licensee has applied to use in this project:

Name of

vessel

Shipping

company

Helideck Primary task Secondary task Other tasks

Corcovado, Ocean Rig Yes Drilling Drilling of relief

NUNAOIL A/S

Government of Greenland

100 % ownership

NUNAOIL A/S

Greenland Self Government

100 % ownership

9

Drilling ship well

Leiv

Eiriksson,

Semi-

submersible

Drilling Rig

Ocean Rig Yes Drilling Drilling of relief

well

Balder Viking Trans Atlantic

No Ice

management

Be part of

emergency services

Olympic

Poseidon

Olympic

Shipping

No Ice

management

and oil spill

response

services

ERRV/OSR Fire fighting

Jim Kilabuk Northern

Transportation

Company Ltd.

(NTCL)

No Ice

management

Be part of

emergency services

Alex Gordon Northern

Transportation

Company Ltd.

(NTCL)

No Ice

management

Be part of

emergency services

Siem Ruby Siem Offshore No Ice

management

and oil spill

emergency

services

ERRV/OSR/Transit

accommodation 60

persons

Back-up fire

fighting

Siem

Aquamarine

Siem Offshore No Ice

management

ROV/ERRV Relief guard

vessel, back-up

fire fighting

Siem Danis Siem Offshore No Supply vessel

in Greenland

Be part of

emergency services

Siem Louisa Siem Offshore No Supply vessel

in Greenland

Be part of

emergency services

Sophie Siem Siem Offshore No Supply vessel

in Greenland

Be part of

emergency services

Toisa Vigilant Sealion

Shipping

Limited

Yes Supply vessel

in Greenland

Transit

accommodation 60

persons

Esvagt Don Esvagt No Stand-by

vessel for rig -

oil spill

emergency

response

Be part of

emergency services

Fire fighting

Esvagt

Capella

Esvagt No Stand-by

vessel for rig -

oil spill

Be part of

emergency services

10

emergency

response

Genius Star Well Ship

management

and Maritime

Consultant

Co. Ltd.

No Cargo vessel Be part of

emergency services

Other vessels may be used in connection with the project after approval by the BMP.

Drilling rigs

Ocean Rig is the technical operator on both the drilling units which will be carrying out the

drilling programme in 2011. The drilling ship Corcovado is a new build, which will enter

Greenlandic waters in early May. Leiv Eiriksson is a semi-submersible drilling rig and will sail

to Greenland end of May to commence drilling of the first well.

Support vessels

Vessels to manage ice

There are a total of six vessels to manage ice and at least one is to be allocated to each rig. The

purpose of these vessels is to manage any situations involving ice which may arise. The

functions expected to be carried out are to monitor and manage icebergs on collision course with

the drilling rigs. Monitoring will be with radar equipment on the ships, supplemented by data

from aircraft, helicopters and satellites. Furthermore, two of the vessels managing the ice can

also act as an Emergency Response and Rescue Vessel (ERRV), while the crew is being replaced

on one of the two dedicated ERRVs.

Other vessels

A number of support ships are linked to the drilling programme for various purposes.

Two storage and accommodation ships: The ships will lie off Aasiaat and Nuuk and will be used

as sleeping quarters if the crew is delayed in Aasiaat or Nuuk in transit to and from the drilling

units. The ships will primarily be used as storage facilities for equipment to be used in the

drilling operation.

Two Emergency Response and Rescue Vessels (ERRVs) (standby vessels): The purpose of these

ships is to be ready in the event of an accident. There is equipment on the ships to respond to oil

spills, and the ships also have personnel rescue capability.

Leiv Eiriksson Corcovado

11

Four supply ships: Three of these ships will operate in Greenlandic waters as Platform Supply

Vessels; the fourth will sail between the United Kingdom and Greenland.

Helicopter chartering

The Canadian company, Cougar Helicopters, will supply air transport between Aasiaat and

Nuuk and out to the drilling units. Cougar Helicopters operates under and in accordance with

licences from Air Greenland. There are four helicopters; three are S92’s and one S61. Two of

these are dedicated to SAR tasks. There will be workshops for the helicopters in Ilulissat and

Nuuk, which will also be the helicopter base.

List of aircraft and helicopters which the Licensee has applied to use in this project:

Aircraft

type

Owner/operator Base Primary task Secondary task

Helicopter

S92

Cougar

Helicopters

Ilulissat Crew change for

drilling units

Helicopter

S92

Cougar

Helicopters

Nuuk Crew change for

drilling units

Helicopter

S61 (when

the 3 to 1

model is

chosen)

Cougar

Helicopters

Ilulissat/Nuuk Search and rescue

Helicopter

S92

Cougar

Helicopters

Ilulissat/Nuuk Search and rescue

(SAR)

Aeroplane

Boeing

737

Titan Airways Edinburgh, Scotland Flying crews

Edinburgh –

Kangerlussuaq

(return)

Limited carriage of

freight

Aeroplane

Dash 7

Air Greenland Kangerlussuaq/Nuuk Flying crews

Kangerlussuaq –

Aasiaat - Nuuk

(return)

Limited carriage of

freight

Logistics

Crew

Crew coming from outside Greenland will be flown from Edinburgh to Kangerlussuaq. This will

be three-five times a week. The journey from Kangerlussuaq to Aasiaat or Nuuk will be by

fixed-wing aeroplane and in exceptional cases by helicopter. If necessary, Air Greenland will

also have extra capacity for freight on these routes.

For drilling in the Eqqua and Napariaq licence blocks, the helicopters will transport the crew

from Aasiaat to the two drilling units and back. The helicopters will start the trips in Ilulissat

(where the pilots will stop overnight), and fly empty to Aasiaat, collect the crew and fly

onwards. For drilling in the Atammik and Lady Franklin licence blocks, hangar and workshop

facilities will be in Nuuk, and the crew will also be flown out from here.

12

Cougar Helicopters has signed an agreement with Air Greenland on use of Air Greenland’s

hangar and workshop facilities in Ilulissat and Nuuk.

The figure below shows the logistics in summary form.

Figure 1.3.A: Summary of logistics

Equipment

The port from which most of the equipment and material for the project will come is Peterhead

in the UK. In Greenland the primary supply base will be in Aasiaat for the northern drilling

operations (Eqqua and Napariaq). For drilling in the Atammik and Lady Franklin licence blocks,

the primary supply base will be in Nuuk. When time permits it, supplies will come directly from

Peterhead.

Royal Arctic Line will be the port agent for the Licensee in Greenland.

Waste

All types of solid waste shall be separated at source on the units and then transported to Aasiaat

or Nuuk, where it will be treated locally or transported for treatment outside Greenland.

Wastewater will be discharged into the sea if it complies with the approved threshold limits.

Representation and staff in Greenland

The actual programme will be managed from the Capricorn Greenland Exploration 1 Ltd.’s

office in Edinburgh. Capricorn Greenland Exploration 1 Ltd. will also be represented in Nuuk.

Contingency plans

There are contingency plans for how the Licensee will deal with emergency situations.

Furthermore, a contingency committee has been set up in Greenland to coordinate the

authorities’ emergency response, see chapter 6.

13

In the event of oil spills during drilling operations, equipment to respond to the spills is placed

on the drilling units themselves and the standby vessels around the drilling units (Tier 1), in

Kangerlussuaq (Tier 2), and in the United Kingdom, ready to be flown to Greenland (Tier 3),

see section 6.9.

In the event of oil spills during bunkering, the fire stations in Nuuk, Sisimiut, Aasiaat and

Ilulissat have equipment to respond to oil spills in addition to the equipment available to the

Licensee.

Furthermore a number of emergency response plans exist, including ice management; see

section 6.8.

1.4 The legal foundation for approval

The Exclusive Licences for exploration for and exploitation of hydrocarbons under which

exploration drillings have been applied for are listed below. The operator for the individual

licences is marked with * in the tables.

Exclusive Licence no. 2002/15 for exploration for and exploitation of hydrocarbons in an

offshore area north-west of Nuuk, West Greenland is divided between the following companies

as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 47.5

Capricorn Atammik Limited 40.0

2002/15

(Atammik)

NUNAOIL A/S 12.5

Exclusive Licence no. 2005/06 for exploration for and exploitation of hydrocarbons in an

offshore area in West Greenland is divided between the following companies as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 47.5

Capricorn Lady Franklin Limited 40.0

2005/06

(Lady Franklin)

NUNAOIL A/S 12.5

Exclusive Licence no. 2008/11 for exploration for and exploitation of hydrocarbons in an

offshore area in West Greenland is divided between the following companies as below:

Licence Licensee Share (%)

Capricorn Greenland Exploration 1 Ltd.* 30.00

Capricorn Greenland Exploration 3 Limited 18.75

Capricorn Greenland Exploration 4 Limited 28.75

PETRONAS International Corporation Limited 10.00

2008/11

(Eqqua)

NUNAOIL A/S 12.50

14

Exclusive Licence no. 2011/16 for exploration for and exploitation of hydrocarbons in an

offshore area in West Greenland is divided between the following companies as below:

Licence

Sole-risk party Share (%)

Capricorn Greenland Exploration 1 Ltd.* 87.5 2011/16

(Napariaq) NUNAOIL A/S 12.50

Approval of the drilling programme applied for will be in accordance with Act no 7 of 7

December 2009 on mineral resources and activities of significance for these. Section 98(4) of

this Act states that licences for exploration and exploitation notified before 1 January 2010

pursuant to the previous Mineral Resources Act shall remain valid but they shall be regulated in

accordance with the new Act.

NUNAOIL A/S is a participant in the licence pursuant to the provision of section 8(2) of the

previously applying Mineral Resources Act. NUNAOIL A/S is participating in the licence with

a share of 12.5% and has rights and obligations with regard to its share. In accordance with the

cooperation agreement, NUNAOIL A/S is a carried partner in the exploration phase. This means

costs, expenditures, obligations and liability for damages pertaining to the activities covered by

the licence shall be paid by the other parties.

The activities covered by licences pursuant to the Mineral Resources Act shall not be carried out

unless Naalakkersuisut has previously approved the activities and the associated activities, see

section 86 of the Mineral Resources Act. The provision of section 86(1) states specifically that

complex work which may be associated with a special risk, such as drilling, shaft sinking,

installation of galleries etc. shall be approved by Naalakkersuisut in each case before

implementation.

Therefore, according to the Mineral Resources Act, the drilling programme under application

requires a section 86 approval from Naalakkersuisut before the activities are implemented.

Approval pursuant to section 86 shall also be in accordance with the terms stipulated in the

licences. The licences were notified on standard terms. A term is stipulated in section 15 of the

licence that the licence holder shall submit plans for the activity for approval by the BMP,

including exploration plans; health, safety and environment plans; and plans for socio-economic

studies, including plans for local employment and companies etc.

The foundation for preparation of the drilling programme for work under application includes

Drilling Guidelines, BMP April 2011, which state a number of requirements for documentation

and reporting to be followed during implementation of the drilling programme. The Drilling

Guidelines state that NORSOK standards shall be observed during the preparation and

completion of the drilling programme.

15

Section 79 of the Mineral Resources Act states that safety and health work should be organised

and carried out according to the ALARP principle, which is the internationally recognised and

applied principle for the offshore sector.

Operationally, the requirement to reduce the risks in accordance with the ALARP principle

primarily means that all specific requirements and instructions, as well as threshold values in

legislation and regulations, shall be unconditionally complied with. Next, the enterprises should

assess whether it is possible to eliminate completely or further reduce the safety and health risks.

The ALARP principle means that the enterprises must endeavour to reduce the safety and health

risks as much as is reasonably practicable at any time in accordance with technical and social

developments.

According to the Mineral Resources Act, the Licensee, and Capricorn Greenland Exploration 1

Limited as operator, are obligated to ensure that the safety and health risks associated with the

construction, design and equipment of the mobile offshore facilities are reduced as much as

practically possible, see section 79(1) of the Mineral Resources Act.

According to section 73(1) of the Mineral Resources Act, approval of a number of activities

listed in the Act cannot be granted before an assessment has been made of the impact on the

environment and a report thereon has been approved by Naalakkersuisut. The drilling

programme under application is assumed to be covered by section 73(1), no. v:

“Establishment or location and use of large facilities used for activities subject to this

Greenland Parliament Act, including fixed offshore units, mobile offshore units, accommodation

vessels, mining facilities, subsoil facilities, related energy installations and related pipeline

facilities.”

The drilling programme in itself, both with regard to its intensity and geographical spread, in

relation to the other activities in the area and its vulnerability, mean that the activity could have

significant impacts on the environment.

Approval of the drilling programme under application therefore requires that an environmental

assessment is undertaken and an EIA report is approved by Naalakkersuisut, see section 73(2) of

the Mineral Resources Act.

Furthermore, the parts of the Marine Environment Act which have been brought into force for

Greenland by Royal Decree no. 1035 of 22 October 2004 apply for the ships and drilling rigs

taking part in the drilling programme. The Marine Environment Act implements a number of

global conventions, primarily the MARPOL Convention (International Convention for the

Prevention of Pollution from Ships), and the LONDON Dumping Convention. According to

section 2 of Decree no.1035 of 22 October 2004 on entry into force for Greenland of the

Protection of the Marine Environment Act, authority and administration pursuant to the Marine

Environment Act is the responsibility of Naalakkersuisut, with respect to activities on the

Greenland continental shelf covered by licences notified pursuant to the Mineral Resources Act.

According to section 76(1) of the Mineral Resources Act, approval of an activity assumed to

have significant impact on social conditions cannot be granted before an assessment has been

16

made of the social sustainability (SSA) of performance of the activity and a report thereon (SSA

report) has been approved by Naalakkersuisut.

The provision of section 76(1) should be considered in the context of the objects provision in

section 1(2) of the Mineral Resources Act, which aims to ensure social sustainability in

connection with mineral resource activities. The requirement for social sustainability is to ensure

that activities are organised so that social development can take place on a sustainable basis and

that the necessary measures are taken to counter adverse effects for society while identifying and

exploiting positive development opportunities.

The scope of the drilling programme under application in financial terms as well as in terms of

both the intensity of material used such as drilling rigs, ships, aircraft, and the geographical

spread of activities should be assumed to have a significant impact on social conditions.

Approval of the drilling programme therefore requires that a social impact assessment (SIA) is

carried out as stipulated in section 76(1) of the Mineral Resources Act, and that a report (SIA

report) is approved by Naalakkersuisut.

The company shall keep itself informed and updated on any amendments to acts, regulations,

etc., which may occur in the period of implementation of the activities dealt with in this

approval.

BMP requires well-operations in connection with the drilling programme in 2011 to be planned

and executed in accordance with the Offshore North Sea Standards for similar activities. Ice

management shall be completed in accordance with the best Arctic standard.

BMP may, at any time and on the basis of ice conditions or other relevant conditions, adjust the

length of the drilling season.

2 Drilling programme

The Licensee’s drilling programme can be divided into a number of sub elements:

• Offshore activities

• Ports and onshore activities

• Other activities (fixed-wing aircraft)

• Personnel conditions and working hours

2.1 Offshore activities Examples of offshore activities include:

• Drilling wells

• Ice management

• Standby and safety services

• Supply services

• Crew changes without air transport (require exemption)

17

Drilling wells

Drilling will be carried out by the drill ship ”Corcovado” and the semi-submersible rig ”Leiv

Eiriksson” respectively. Both vessels have been designed and equipped to suit the purpose of the

planned drilling operations, with regard to overall health and safety, the environment and the

geology.

The general plan is to end the wells at a depth which covers the most interesting geological

prospects for possible hydrocarbon discoveries. If occurrences of hydrocarbons are found, if

possible, further exploration and evaluation of the wells will be carried out in the form of limited

test production (well testing) after drilling has ceased. The extra equipment required to perform

well testing shall be mobilised and installed onboard before well testing is carried out. This

requires separate approval from the BMP.

The Licensee has decided to use the same size and type of material and equipment to develop all

wells. This means that the Licensee has equipment to drill a relief well in the event of an

incident while drilling a well, such as a blow-out.

The Licensee will temporarily shut down the wellbore, if the Licensee discovers geological

formations that contain hydrocarbons of interest to the Licensee and which require further

investigation, and if the Licensee is unable to complete the well during this drilling season. The

Licensee plans to shut down all wellbores (permanently), if they show no signs of hydrocarbons.

Permanent and temporary shutdowns shall be approved by the BMP.

The Licensee’s plan is to carry out wireline logging and logging while drilling after reaching the

TD. Geologists will evaluate the geological layers in the well and identify possible hydrocarbon

formations. On the basis of these geological evaluations the Licensee will apply to shut down

the wellbore either temporarily or permanently.

Standby and safety services.

In order to ensure the safety of the crew members onboard the drilling unit, it is a requirement

that there is an Emergency Response and Rescue Vessel (ERRV) at each drilling unit. This means

presence at the drilling unit 24 hours a day. When the crew on one of the two ships is to be

replaced, one of the vessels designated for ice management will act as an ERRV. There is

equipment on the ERRV’s to respond to oil spills, and the ships also have personnel rescue

capability for the entire crew on the drilling unit, if necessary.

Supply services.

The Licensee has permanent vessels which will be in transit between the base ports in Greenland

and the drilling units as well as between international and Greenland ports / drilling units.

Additionally, spot-hire vessels will be hired.

Requirements for spot-hire vessels

2.1.1. The BMP shall be informed before the planned use of spot-hire vessels. The use of spot-

hired vessels must be included in the monthly onhire vessel report.

2.1.2. The Licensee shall submit navigation plans to the BMP before the vessel enters

Greenland waters. The navigation plan must include the name of the vessel, shipping

18

company, when the vessel is expected to enter Greenland waters and when it is expected

to leave Greenland waters.

2.1.3. Spot-hire carriage trade vessels which are subject to this approval may not carry material

directly to the drilling units. They may only be used to carry material between

international and Greenlandic ports.

2.1.4. When establishing the charter parties, the Licensee shall only choose shipping companies

which meet the requirements for recognised good international practice for maritime

shipping and drilling operations under conditions similar to those in the offshore area

west of Greenland.

2.1.5. Ships shall register with KYSTKONTROL before entering Greenland waters and be

equipped with LRIT (Long Range Identification and Tracking System). Ships must also

comply with regulations for ordinary navigation in Greenland waters (GREENPOS).

2.1.6. The BMP may, at any time, demand submission of the certificates/safety plans of all

cargo vessels for inspection.

2.1.7. The Licensee shall register and submit reports on the consumption of fuel, oil etc., as

well as on emissions and discharges to the air and sea, see section 9.7.

Exemption requirements for crew changes without air transport

In situations where helicopters cannot be used for crew changes, e.g. because of fog, the crew

may be sailed to the drilling unit by the flotel and lifted on board using a basket lift; provided

that a separate BMP approval has been obtained in advance, except the cases listed in section

2.1.9 below.

Requirements for basket lifts

2.1.8. Transfer of personnel using a basket shall be in accordance with the terms and

requirements of NORSOK R-003, section 5: Additional requirements for the lifting of

personnel and in accordance with the requirements below

2.1.9. Basket lifting of crew shall be approved in each individual case. The Licensee need not,

however, apply in advance, provided basket lifting of crew is necessary in order to

counter a kick, a blow-out or similar circumstances. In such cases the Licensee can

initiate the basket lift required and subsequently document the basket lift and the

necessity of the lift to the BMP.

2.1.10. Transfer of personnel may only be after careful analysis and assessment of the danger

and risk involved in transferring personnel using a basket. An assessment of the danger

and risk shall be submitted to the BMP as part of the application.

2.1.11. Being lifted onboard a drilling unit by a basket lift must be voluntary.

19

Two-rigs policy

The two-rigs policy entails that there must be at least two drilling units equipped for drilling a

relief well in the same area at the same time. This means that the drilling unit with the least

capability will set the limit for the project activities.

The following activities are not covered by the two-rigs policy:

• Pilot hole

• Drilling and installing the two first casings and the well head

• Drilling relief wells

Requirements for drilling units and operations in connection with the two-rigs policy

2.1.12 Both drilling units shall be fully functional and comparable with regard to being able to

drill a relief well.

2.1.13 There shall be equipment and material on board the drilling units to enable immediate

commencement of a relief well and without unnecessary delay to the relief well.

The Licensee has submitted documents which relate to the two-rig policy.

The Licensee shall adhere to these documents throughout the whole drilling season.

Furthermore, the documents shall be updated on a weekly basis and be submitted to the

BMP. The weekly updated schedule shall reflect last week’s operational progress.

2.2 Ports and onshore activities For the drilling project under application, it will be necessary for the Licensee to carry out

activities both onshore and in port. Examples of these activities and facilities are listed below:

• Port and storage facilities

• Diving services

• Offices

• Accommodation for shore-based employees

• Waiting facilities for drilling personnel in transit

• Personnel transport between the flotel and the port

• Workshop facilities for helicopters

• Depot for contingency equipment

• Facilities to change into survival suits

All onshore facilities are covered by the relevant regulations and requirements applicable in

Greenland. The BMP may, however, stipulate further requirements for activities onshore.

Ports and storage facilities

When dealing with a project of this extent, it will be necessary to store materials and equipment

onshore before onward transportation. Materials and equipment may be stored outside ordinary

port facilities.

20

Requirements for ports and storage facilities

2.2.1 If areas outside the port are used for storage, the Licensee shall ensure that the area

in question is suitable for storing the relevant material and equipment, and the

Licensee shall apply for permission to use the area in question for storage purposes

(area allocation).

2.2.2 The Licensee shall ensure that all storage facilities are guarded day and night, so

that no trespassers can get to the stored materials and equipment.

2.2.3 The Licensee shall ensure that dangerous goods are stored in a manner which is

appropriate in terms of the environment, as well as human health and safety.

2.2.4 Furthermore, the Licensee is responsible for cleaning up and remediating the area

when storing goods. This also applies to transport between the port and any storage

facility outside the port.

2.2.5 In the event that materials or equipment fall into the port basin in connection with

loading or pilotage, the Licensee shall report this to the BMP immediately, and

commence work to recover the lost materials and equipment.

2.2.6 Recovery of materials or equipment may only take place following careful analysis

and assessment of the danger and risk involved in the work.

Diving services

During ice management activities there is a risk that a hawser or similar gets caught in the

propeller of an ice management vessel when the vessel couples on or off an iceberg. In such

cases diving services may be applied.

Requirements for diving services 2.2.7. Use of diving services shall be approved by the BMP.

2.2.8 Diving services may only be utilised if the work can be performed in a manner

which is responsible in terms of human health and safety.

2.2.9 Diving may only occur in port basins or in sheltered waters.

2.2.10 Divers must be trained and have the proper experience to be able to perform the

work in question.

Passenger transport between the flotel and the port

In order to transport employees between the port and the flotel, the Licensee may use locally

chartered boats, if these are in compliance with current Greenlandic and Danish legislation.

Such vessels do not require pre-approval from the BMP.

21

Requirements for the transport of passengers and freight to and from the flotel inside the

port

2.2.11 Only vessels approved according to “Tekniske forskrift om mindre fartøjer, der

medtager maksimalt 12 passagerer” (technical regulations for small vessels

carrying a maximum of 12 passengers) may be used.

2.2.12 The vessels shall be suitable for the purpose for which the Licensee intends to use

them.

2.2.13 The Licensee shall register and submit reports on consumption of fuel, oil etc., as

well as on emissions to air and sea, see section 10.3.

2.2.14 The use of chartered boats shall be included in the monthly onhire vessel report.

2.3 Other activities

Aircraft activity

The Licensee is responsible for ensuring that all activities carried out with reference to this

approval letter are in compliance with Greenlandic, Danish as well as international legislation

for this type of operation.

Requirements for other activities 2.3.1 The Licensee is responsible for transport of all personnel between Scotland and

Greenland.

Medical care and medical treatment

At the drilling units it is necessary to have competent medical personnel to treat possible injuries

and illness among the crew and e.g. to provide the necessary medical treatment before a crew

member is transported to a hospital onshore. The Licensee has entered into an agreement with

the health services in Greenland that the health services will provide medical treatment to the

extent possible at the relevant time and place.

Requirements for medical care and medical treatment

2.3.2 The Licensee shall make sure that at least one physician and one nurse is present on

each of the drilling units.

2.3.3 There shall be sufficient medical care and medical treatment available on board all

of the vessels at all times.

2.3.4 Reporting of industrial injuries shall be in accordance with section 10.2.

2.4 Personnel conditions and working hours Determination of working hours varies from one group of employees to the other. When

planning work hours on offshore facilities this shall be in accordance with Directive 2003/88/EC

22

of the European Parliament and of the Council of 4 November 2003 concerning certain aspects

of the organisation of working time.

Requirements for personnel conditions and working hours

2.4.1 Working hours shall as a general rule, be arranged so that employees get a resting

period of at least 11 consecutive hours per 24 hour period.

2.4.2 Working hours on board the drilling units and the support vessels may be no more

than 12 hours per shift. Exceptionally overtime of fours hours per day is permitted.

After this, personnel who have worked for 16 hours shall have a rest period of no less

than eight hours.

2.4.3 In the event that a person has worked for 16 successive hours on a shift, and no

replacement is available on board for this position, operations shall be stopped until

the person has had the required rest period of eight hours.

2.4.4 The Licensee shall record the working hours of individual persons on the vessels.

2.4.5 Normal rotation of work shall be 14 days offshore followed by 14 days off ashore.

For personnel resident outside Greenland, work periods of up to 28 days on the

vessel are permitted, followed by a subsequent period off of equal length.

2.4.6 Normal rotation of work shall be 28 days on support vessels followed by 28 days off

ashore. For personnel resident in Greenland, the following work rotation is

recommended: 14 days offshore followed by 14 days off ashore, providing this is

possible within the normal rotation schedule.

2.4.7 All personnel are entitled to be paid during waiting periods due to unpredictable

events which cause delays in connection with transportation between place of

residence and place of work.

2.4.8 Through audit and inspection, the Licensee shall ensure that personnel receive the

free time to which they are entitled when they have time off outside the vessel and in

the operation.

2.4.9 Each drilling unit must have an adequate number of cabins. Each cabin must provide

accommodation for no more than two persons. Sleeping hours must be regulated so

that only one person at a time sleeps in the relevant cabin. This means that each

person is entitled to their own cabin/bed in their rest period between shifts and that

the other person with whom they share a cabin must be on shift while the other is

resting.

2.4.10 “Hot bedding” is not permitted. This means that a person may not take over another’s

bed immediately after this person has gone on shift.

2.4.11 Only persons of the same sex are allowed to be allocated the same cabin.

23

3 Authorisation terms for mobile drilling units, vessels and aircraft

Drilling units, ships and aircraft included in the drilling programme under application should, on

the basis of the acceptance criteria chosen, meet the requirements necessary to ensure that the

safety, health and environment risks associated with the drilling programme under application

are reduced as much as possible in the context of an overall project assessment in accordance

with ALARP.

The following documentation on drilling units, ships and vessels has been received:

• Acknowledgement of Compliance (11.07.2008) from Norwegian authorities and a

Safety Case from the British authorities for Leiv Eiriksson.

• Safety Case from the British authorities for Corcovado.

• Certificate of Fitness from Lloyd’s Register for Alex Gordon, LR no. 7420730.

• Certificate of Fitness from the Norwegian Veritas (DNV) for Balder Viking, DNV

no. 21804 (14.05.2010).

• Certificate of Fitness from Lloyd’s Register for Jim Kilabuk, LR no. 7420754.

• Certificate of Fitness from the Norwegian Veritas (DNV) for Olympic Poseidon,

DNV no. 20115 (21.08.2008).

• Certificate of Fitness from the Norwegian Veritas (DNV) for Siem Aquamarine,

DNV no. 27783 (30.07.2010).

• Certificate of Fitness from the Norwegian Veritas (DNV) for Siem Danis, DNV no.

26397 (06.11.2007).

• Certificate of Fitness from the Norwegian Veritas (DNV) for Siem Louisa, DNV

no. 26398 (12.12.2007).

• Certificate of Fitness from the Norwegian Veritas (DNV) for Siem Ruby, DNV no.

27926 (07.10.2010).

• Certificate of Fitness from the Norwegian Veritas (DNV) for Sophie Siem, DNV

no. 26148 (21.01.2011).

• Certificate of Fitness from the Norwegian Veritas (DNV) for Toisa Vigilant, DNV

no. 24572 (24.03.2011).

• Certificate of Fitness from Bureau Veritas for Esvagt Don, no. GLS1000791

• Certificate of Fitness from Bureau Veritas for Esvagt Capella, no.

Oslo/BHO/20091214202548.

• Certificate of Fitness from xxx for MV Dollard.

• Certificate of Fitness from Germanischer Lloyd for Genius Star, GL. no. 107389

Third party certificate examinations and approvals on ships and drilling units provided by the

Licensee have been reviewed by the BMP.

24

3.1 Vessels in general

Requirements

3.1.1 General requirements for the vessels, aircraft and helicopters referred to above

include suitability for their purposes in question and compliance with international

requirements.

3.1.2 Before the drilling units are put into operation on the Greenland continental shelf, the

Licensee shall submit documentation prepared by an independent third party. It shall

be documented that all relevant requirements have been complied with in full and as

a minimum cover;

• vessel certificates from a recognised classification society;

• documentation of independent verification of the equipment on drilling rigs

and vessels, see section 83 of the Mineral Resources Act on performance of

activities covered by a licence in accordance with acknowledged best

international practices in the area under similar conditions;

• documentation that vessels and drilling installations are completely safe, and;

• a bridging document which describes duties and responsibilities in connection

with emergency response plans for cohesion between drilling units, ships,

aircraft, helicopter operations and the safety and management control systems

of the Licensee.

All documents on which the independent third party has based its approval shall

also be enclosed and submitted to the BMP.

The Licensee is obligated to update the bridging document, in the event of changes

to the emergency response plans of the drilling units.

3.2 Drilling units and vessels

Prior to any drilling actions, the Licensee shall forward documentation that the health, safety,

environment and management systems of all parties/technical operators comply to best

international standards and have been updated to fit Greenlandic conditions regarding the

activities or services required and that each participating party is familiar with their respective

area of responsibility (i.e. a bridging document). The bridging document shall be updated at all

times, covering all conditions of the operation and filling any gap between the systems and plans

of the parties/technical operators, thereby ensuring the entire project functions as one system and

one plan.

The systems and contingency plans of parties/technical operators which must be coordinated

through Licensee’s bridging document are those established by:

• Cairn

• Ocean Rig

25

• Mobile drilling units

• Trans Viking

• Olympic Shipping

• Northern Transportation Company Ltd. (NTCL)

• Siem Offshore

• Dealion Shipping Limited

• Esvagt

• Bremer Rederi

• Air Greenland

• Cougar Helicopters

The BMP has received bridging documents from the Licensee describing relations between the

individual companies’ health, safety, environment and management systems, see section 6. The

BMP has reviewed the bridging documents from the Licensee and the parties/technical operators

and finds them suitable for the drilling project activities.

Requirements

3.2.1 The certificates of drilling units and vessels shall be without comments or remarks.

3.2.2 Drilling units and vessels shall register with KYSTKONTROL and they shall have

equipment fitted to link to the VMS (Vessel Monitoring System). Furthermore,

vessels shall be equipped with LRIT (Long Range Identification and Tracking

System). The BMP will stipulate detailed procedures on the issuance and content

of the notifications to be submitted to KYSTKONTROL. The Licensee shall

ensure that this happens before the vessels are in Greenlandic waters.

3.3 Mobile drilling units The Licensee has applied for approval to use the following 2 drilling units:

The drill ship Corcovado, owned by Ocean Rig.

The drilling rig Leiv Eiriksson, owned by Ocean Rig.

According to the Mineral Resources Act, the Licensee is obligated to ensure that the safety and

health risks associated with the construction, design and equipment of the mobile drilling units

are reduced as much as is practically possible, see section 79(1) of the Mineral Resources Act.

The BMP has received a health and safety report for Leiv Eiriksson, both as a Safety Case dated

20 August 2004, and an AoC dated 11 July 2008. The drilling ship, Corcovado, holds an

approval from the American Bureau of Shipping (ABS) dated January 3rd

2011, however, before

approval of the drilling ship, a Safety Case, certified by an independent third party (DNV) shall

be presented.

Requirements for mobile drilling units

3.3.1 An up-to-date and approved health and safety report (“Acknowledgement of

Compliance” (AoC) from Norway or a “Safety Case” from the United Kingdom)

26

or a similar health and safety report for the drilling units before the activities may

commence.

3.3.2 As supervisory authority, the BMP can conduct an inspection of the drilling units

in order to assess whether it is necessary to require that changes be made to reduce

safety and health risks according to the ALARP principle.

3.3.3 After approval of an AoC or a Safety Case, application for further approval of any

physical and operational changes is required before implementation of the

changes, if such changes are of significance to health and safety or if such changes

are significant in scope. The application for approval of changes shall be

accompanied by an updated safety and health report.

3.4 Ships

The application covers approval of the vessels mentioned in section 2 to be deployed for the

implementation of the drilling programme.

Requirements for vessels

3.4.1 IMO guidelines 2010: ”GUIDELINES FOR SHIPS OPERATING IN POLAR

WATERS” Resolution A.1024 (26) shall be complied with. In the event of deviations

from the Guidelines, the reason for these shall be reported as well as the

compensatory initiatives that will be taken to ensure at least the same level of safety

as would exist, if the guidelines had been followed precisely.

3.4.2 The provisions of Danish Maritime Authority Executive Order no. 417 of 28 May

2009 on technical regulation for the safety of navigation in Greenland territorial

waters shall be complied with to the extent relevant for navigation carried out as part

of the drilling programme under application.

3.4.3 Each of the vessels shall at all times have at least one Fishing Liaison Officer on

board who can communicate in both Greenlandic and English.

3.5 Aircraft and helicopter operations

Application has been made to the Danish Transport Authority for approval of the four

helicopters and for the helidecks on the two mobile drilling units Leiv Eiriksson and Corcovado,

for take-offs and landings with the helicopter types mentioned in this chapter.

Documentation for approval of the four helicopters as well as the helideck on Leiv Eiriksson and

Corcovado from the Danish Transport Authority has been submitted to the BMP.

Requirements for aircraft and helicopter operations

3.5.1 All aircraft and helicopter operations shall at all times comply with current

international and national regulations.

27

3.5.2 Necessary approvals and licences shall be obtained from the Danish Transport

Authority, including the Authority’s technical and operative approvals of the four

helicopters and the Authority’s approval of helidecks for the helicopter types to be

used on the drilling units.

3.5.3 All passengers who are transported by helicopter offshore shall have a personal

survival suit in a size that fits them as well as access to a lifejacket. The survival suit

shall be of North Sea offshore standard and approved for use in Arctic waters.

3.5.4 All offshore helicopter passengers must be equipped with Personal Locator Beacons

(PLBs).

4 Drilling locations

The Operator has applied for permission to drill the following wells:

Licence block Well name UTM coordinates (UTM

zone 21, WGS 84)

Water depth (m)

Atammik AT1-A 558 903m E; 7 168 309m N 948

Atammik AT2-B 575 984m E; 7 137 731m N 1020

Atammik AT7-A 561 482m E; 7 180 386m N 905

Napariaq Delta A 440 494m E; 7 912 435m N 288

Eqqua Gamma-B 383 745m E; 7 706 791m N 1520

Lady Franklin LF6-B 467 957m E; 7 077 899m N 1160

Lady Franklin LF7-C 467 610m E; 7 097 284m N 989

4.1 Site survey evaluation regarding geohazards

The BMP requires that an evaluation of any hazards be carried out. In addition the BMP has the

following requirement to drilling of the top hole section:

4.1.1 Prior to commencing the actual drilling programme, pilot holes with a maximum

diameter of 9 7/8 inches must be drilled to the planned setting depth of the 20” casing.

The maximum depth of the pilot holes is the setting depth of the 20” casing shoe + 10 m.

4.1.2 The pilot holes shall be drilled in accordance with NORSOK Standard D-010, part 5.7.2.

4.1.3 The drilling activity shall take place so that sudden geohazards, such as unexpected gas

and abnormal pressure, can be managed. If unexpected geohazards occur or are

identified, the necessary precautions shall be taken, so that the drilling operation is

always being performed in accordance with the best international standards.

28

4.1.4 The actual drilling programme cannot commence before site surveys covering the relief

well locations have been finally approved by the BMP. This will be done after inspection

of the drilling units.

4.2 Requirements to data acquisition

Requirements

Besides the requirements set out in the Greenland BMP - Exploration Drilling Guidelines (See

Appendix 10) and § 18 of the exclusive licences 2002/15, 2005/06, 2008/11 and 2011/16

regarding reporting, acquisition, submission and storing of samples and data, the following shall

apply.

4.2.1 The BMP or a consultant appointed by the BMP shall be able to monitor all real time

data (including LWD and MWD) online during the entire drilling operation unless

otherwise is approved by the BMP.

4.2.2 The BMP shall be notified if any changes are made to the original logging programme

forwarded by the Licensee as part of the drilling application.

4.2.3 Samples of wet cuttings shall be forwarded to the BMP as stated in the Greenland BMP -

Exploration Drilling Guideline. However, sample sizes of at least 500g will be accepted

regardless of the 1000g stated in the Greenland BMP - Exploration Drilling Guidelines.

4.2.4 The BMP shall have the opportunity to carry out at least one geological inspection per

well. If the BMP finds it necessary further inspections can be required.

5 Drilling and well operations

Drilling operations in this chapter refer to all work conducted onboard the drilling units, directly

related to the construction of wells.

Part of Licensee’s application contains phase 6 documentation according to BMP Drilling

Guidelines. Phase 6 documentation contains a preliminary and brief description on structure and

planned operations constructing the wells. The Licensee shall forward a detailed drilling

programme and well design for BMP approval before commencing any drilling activities.

Before any drilling operation into hydrocarbon-carrying layers, the principle of having two

independent and at all times tested and verifiable safety barriers in place for all systems,

equipment and designs, shall be complied with. This principle is also known as the primary and

secondary barriers. According to this principle, should one safety barrier fail, there will always

be a secondary barrier in place to control the situation during the time it takes to re-establish the

primary barrier. This principle shall be in place for all installation systems and equipment, as

well as for the well design. The BMP requires the Licensee to include the two-barrier principle

for well designs as well as for the selection of drilling facilities.

29

The well designs are such that they can only be used for exploration use. There are no plans for

further use of the wells in addition to carrying out exploration drilling and collecting data.

In the period up to commencement of drilling, the Licensee and their technical operators will

review the well design and the operation plans. This review could lead to changes that will be

incorporated into the final drilling programme.

5.1 Requirements for drilling and well operations

5.1.1. Planning and execution of drilling operations shall be in accordance with the terms

and requirements under NORSOK D-010 and in accordance with the following

requirements.

5.1.2. A drilling operation may not be commenced until the BMP has inspected the drilling

unit as well as the planned drilling operation (pre-spud inspection at each drilling

location). This also applies for permanent well shutdown operations.

5.1.3. For all planned operations, the plan shall include the time it will take to install an

extra barrier in the wellbore, in the event the well will potentially have to be shut

down temporarily.

5.1.4. Before a drilling operation can be commenced, the Licensee shall present a final,

detailed drilling programme that describes all the changes made by the Licensee and

their technical operators and the final result. The drilling programme shall be verified

by an independent third party. Documentation of this review as well as a copy of the

final drilling programme shall be submitted to the BMP before drilling commences.

5.1.5. A detailed programme, descriptions of procedures and risk assessments for each

section to be drilled shall be prepared and verified by an independent third party.

Documentation of this verification as well as copies of the detailed drilling

programme and the procedures shall be submitted to the BMP. The programmes and

procedures shall be verified by use of HAZID/HAZOP methodology and log

systems, and shall involve the technical operators selected for the specific areas of

work tasks. The BMP shall be invited to participate in the planned HAZID/HAZOP’s

for the project.

5.1.6. The BMP requires meticulous planning and description of the drilling operations in

the form of detailed procedures. The procedures shall be reviewed and verified by the

executing drilling companies together with the Licensee, before drilling work can be

commenced.

5.1.7. The Licensee shall comply with the procedures and standards of the technical

operators. The technical operators may suspend work if they deem the planned

activity may pose an unacceptable risk for safety, health and the environment.

5.1.8. During the operations on board the drilling units, activity plans shall be prepared

daily for the following 24-hours. These plans shall identify necessary resources, and

30

verify the availability of these resources to carry out the operations. The plans shall

also take into account the current emergency response status, the contingency plans

and the weather forecast.

5.1.9. The Licensee shall have a final plan including a detailed timetable for drilling a relief

well.

5.1.10. When a drilling rig is moved between two locations; the BOP and marine riser shall

be placed on the rig.

5.1.11. The Licensee shall conduct inspections, supervision and verifications of the activity,

at the premises of the Licensee and those of their technical operators, and on

installations offshore and onshore.

5.1.12. The drilling operations shall at all times adhere to the relevant health, safety and

contingency plans approved by the BMP.

5.1.13. The most recent and most detailed programmes for the operations shall be presented

to and approved by the BMP before drilling can be commenced.

5.1.14. A general plan for limited well testing and for well appraisal shall be submitted to the

BMP prior to start up of a drilling operation.

5.1.15. Limited well testing shall be approved by the BMP before commencement.

5.1.16. The BMP can furthermore require the Licensee to carry out additional studies with

regards to improving drilling in progress and to meeting the targets set up for the

drilling operations, including further studies for use in well appraisal.

5.1.17. The BMP may at all times impose further requirements to the drilling operations, if

the BMP finds this necessary. The Licensee shall execute the requirements imposed

within a reasonable time frame.

5.2 Primary and secondary well barriers

It is a requirement for all drilling operations in Greenland waters that at least two independent

safety barriers are in place for all systems, equipment and designs. These are called the primary

and secondary barriers. These barriers shall be independent of each other and shall be tested and

verifiable at all times.

Primary Barrier:

Drilling mud is the primary barrier to maintain the well pressure equiliberium between

formation pressure and hydraulic pressure. Therefore drilling mud is monitored continuously in

order to ensure that there is enough weight to prevent any influx or outflow.

Secondary Barrier:

31

The Secondary Barrier is the BOP (Blow Out Preventer). The BOP is placed on the seabed and

is connected to the well and the marine riser which connects to the drilling unit. The BOP has

several valve systems which can be used to ensure safe execution of operations. The valve

systems have several independent means of activation for closure. The BOP provides the

possibility to cut the drill pipe situated in the well and thereafter seal the well.

Release mechanism if connection is lost to the BOP

It shall be possible to activate the BOP by means of electric and hydraulic connections. The

BOP system shall be constructed in such a way that it ensures safe conditions by shutting down

in the event of a failure in the system (fail to safety). If connection to the BOP is lost due to the

loss of one or both the electrical and hydraulic connection, a “deadman’ system shall be installed

which will automatically be activated prompting the BOP to seal off the well. If this system is

not activated, an acoustic trigger that can be controlled remotely shall be installed, which can

activate the BOP from another location than the drilling unit. This remotely operated system

shall be independent of the hydraulic and electric triggers. This additional safety feature shall be

used in those situations where contact to the drilling unit is lost and the ‘deadman’ system fails

to activate. In addition it must be possible to use a Remote Operated Vehicle (ROV) to

hydraulically activate the valve system manually; allowing the BOP to seal off the well.

Highly advanced measuring and logging instruments will be used during the drilling operations.

These will constantly provide information e.g. about pressure conditions in the well, so that the

crew can respond without delay to any abnormal conditions.

Requirements for barriers

5.2.1 Identification, testing and verification of barriers and barrier elements throughout the

whole drilling operation shall be in accordance with NORSOK D-010 and in

accordance with the requirements listed below.

5.2.2 The Licensee shall construct the barrier systems so that there are at least two