APPLICATIONS AND PROCESSING OF METAL...

Transcript of APPLICATIONS AND PROCESSING OF METAL...

APPLICATIONS AND PROCESSINGOF METAL ALLOYS

Chapter 5

1

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

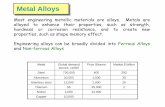

Introduction Alloy is a mixture of two or more elements where at

least one of them is metal. Most engineering metallic materials are alloys. Metals are alloyed to enhance their properties, such as

strength, hardness or corrosion resistance, and tocreate new properties, such as superconductivity andshape memory effect.

2

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Introduction Materials selection decisions may be influenced by the

ease with which metal alloys may be formed ormanufactured into useful components.

Alloy properties are altered by fabrication processes,and, in addition, further property alterations may beinduced by the employment of appropriate heattreatments including annealing procedures, the heattreating of steels, and precipitation hardening.

3

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

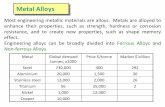

Types of Metal Alloys Metal alloys, by virtue of composition, are often

grouped into two classes to ferrous and nonferrous. Ferrous alloys those in which iron is the prime

constituent are produced in larger quantities than anyother metal type, such as iron, steel and cast iron.

Non-ferrous alloys are those which has a metal otherthan iron as their main constituent. Such asaluminum, copper, tin, zinc, etc.

4

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Ferrous Alloys Ferrous Alloys are important as engineering

construction materials since: Iron-containing compounds exist in abundant quantities

within the earths crust, Metallic iron and steel alloys may be produced using

relatively economical manufacturing techniques, Extremely versatile.

5

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Classification of Metal Alloys

6

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Steels Steels are iron–carbon alloys that may contain

appreciable concentrations of other alloying elements. The mechanical properties of steel are sensitive to the

content of carbon, which is normally less than 1.4 wt%. Steels are classified according to carbon concentration

Low carbon steel (<0.25wt%C), Medium carbon steel (0.25-0.6wt%C), High carbon steel (0.6-1.4wt%C). Ultrahigh carbon steel (up to 1.5wt%C).

7

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Steels Subclasses also exist within each group according to

the concentration of other alloying elements. Plain carbon steels contain only residual

concentrations of impurities other than carbon and alittle manganese.

Alloy steels more alloying elements are intentionallyadded in specific concentrations.

Hardness and strength varies with carbon content.

8

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering 9

EL: Percent elongation or percent reduction in areaHardenability: is the ability of a steel to partially or completely transform from austenite to some fraction of martensite at a given depth below the surface, when cooled under a given condition.

HSLA: High-strength low alloy.TS: Tensile strength of a material is the maximum amount of tensile stress that it can take before failure.

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

High-Alloy Steels :Stainless Steels (SS) The primarily-alloying element is Cr (≥11 wt.%) Highly resistance to corrosion; – Nickel and

molybdenum additions INCREASE corrosionresistance

A property of great importance is the ability of alloyingelements to promote the formation of a certain phaseor to stabilize it.

Stainless steels are divided into three classes on thebasis of the predominant phase constituent of themicrostructure—martensitic, ferritic, or austenitic.

10

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Cast Irons Cast irons are a class of ferrous alloys with carbon

contents above 2.14 wt%. The most cast irons contain between 3.0 and 4.5 wt%. They are easily melted and amenable to casting. The some of cast irons are very brittle, and casting is

the most convenient fabrication technique.

11

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Cast Irons For most cast irons, the carbon exists as graphite, and

both microstructure and mechanical behavior dependon composition and heat treatment.

Cementite decomposes to ferrite + graphiteFe3C 3 Fe (α) + C (graphite)

generally a slow process The most common cast iron types are gray, nodular,

white, malleable, and compacted graphite.

12

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Types of Cast Iron Gray iron

The graphite exists in the form of flakes. It is weak and brittle in tension

and strong in compression. It has excellent vibrational dampening

and wear resistant. It has high fluidity in the molten

state. It is the least expensive of all metallic material.

13

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Types of Cast Iron Ductile (Nodular) iron

It is formed after adding Mg and/orCe on gray iron.

Its graphite as nodules not flakes. The matrix often pearlite , it is stronger

but less ductile. Its applications in valves, pump bodies,

gears, and other automotive andmachine components.

14

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Types of Cast Iron White iron

It contains low-silicon cast irons (<1 wt% Si).

Its microstructure is pearlite + cementite.

It is very hard and brittle. limited to applications that necessitate

a very hard and wear resistant surface-for example, as rollers in rolling mills.

15

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Types of Cast Iron Malleable iron

It is formed after making heattreat for white iron at 800-900ºC.

Its graphite in rosettes. It is reasonably strong and ductile. Its applications include connecting

rods, transmission gears, anddifferential cases for the automotiveindustry.

16

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Types of Cast Iron Compacted graphite iron

It is formed after adding small amount ofMg and/or Ce to gray cast iron.

It has wormlike graphite particles. It has desirable characteristics include:

Higher thermal conductivity. Better resistance to thermal shock . Lower oxidation at elevated temperatures.

It is used in diesel engine blocks, gearbox housings andflywheels.

17

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Limitations of Ferrous Alloys:

Forming Relatively high densities. Relatively low electrical conductivities. Generally poor corrosion resistance.

18

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Nonferrous Alloys

19

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Fabrication of Metals

20

Metal fabrication techniques are normally precededby refining, alloying and often heat treating processesthat produce alloys with the desired characteristics.

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Metal Fabrication Methods

Forming:Forming operations are those in which the shape of ametal piece is changed by plastic deformation. Thedeformation must be induced by an external force or stress,the magnitude of which must exceed the yield strength ofthe material.

21

MISCELLANEOUSFORMING CASTING

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Forming OperationsForging: is mechanically working or deforming a singlepiece of a usually hot metal Working.Rolling: The process consists of passing a piece of metalbetween two roll. A reduction in thickness results fromcompressive stresses exerted by the rolls.Extrusion: A bar of metal is forced through a die orificeby a compressive force that is applied to a ram; theextruded piece that emerges has the desired shape and areduced cross-sectional area.Drawing: Drawing is the pulling of a metal piece througha die having a tapered bore by means of a tensile force thatis applied on the exit side.

22

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Forming Operations

23

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Deformation process according to the temperature

Hot working: when deformation is achieved at a temperature above

recrystallization temperature. Large deformations are possible, which may be successively

repeated because the metal remains soft and ductile. Deformation energy requirements are less than for cold

working. Most metals experience some surface oxidation, which

results in material loss and a poor surface finish.

24

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Deformation process according to the temperature

Cold working: when deformation is achieved at a temperature below

recrystallization temperature. Cold working produces an increase in strength and

hardness with decrease in ductility because the metal strainhardens.

Advantages: a high-quality surface finish, good mechanicalproperties, close dimensional tolerance.

Stresses get induced in metal which are removed byannealing.

25

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Deformation process according to the temperature

26

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Metal Fabrication Methods

Casting: Casting is a fabrication process in which a completely

molten metal is poured into a mold cavity having the desired shape; upon solidification, the metal assumes the shape of the mold but experiences some shrinkage.

27

MISCELLANEOUSFORMING CASTING

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Metal Fabrication Methods

Powder Metallurgy Technique involves the compaction of

powdered metal followed by a heattreatment to produce a denser piece.

suitable for metals having lowductilities.

Welding Two or more metal parts are joined to form a single piece

when one-part fabrication is expensive.

28

FORMING MISCELLANEOUSCASTING

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

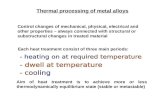

Thermal Processing of Metals

29

Annealing: Heat to Tanneal, the cool slowly.

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

Precipitation Hardening Hardening, strengthening due to formation of precipitate

particles. Particles impede dislocation motion. Procedure:

Solution heat treat (get a solid solution). Quench to room temperature (retain a solid solution). Reheat to nucleate small particles within a phase.

Alloys that precipitation harden: Cu-Be Cu-Sn Mg-Al

30

Dr. Anwar Abu-Zarifa . Islamic University Gaza . Department of Industrial Engineering

References Materials science and engineering (9th Edition)by William

D. Callister and David G. Rethwisch. https://en.wikipedia.org/wiki/Nickel_titanium.

31